Motorcycle fairing structure assembly

A technology for motorcycles and shrouds, used in bicycle accessories, weather shields, transportation and packaging, etc., can solve the problems of breakage and deformation of the shroud back plate lugs, etc., to improve strength, reduce industrial waste, guarantee The effect of installation position accuracy and vehicle driving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

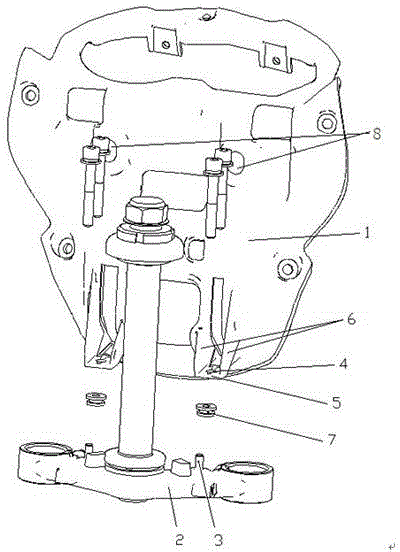

[0016] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure: the installation assembly of the wind deflector back plate of the present embodiment; includes a mounting seat fixed on the wind deflector back plate 1 and correspondingly said mounting seat is fixed on the vehicle steering column and connected The mounting column 3 of the plate 2; the mounting seat is provided with a mounting hole 4 for the mounting column 3 to be inserted and fixed, and the connecting plate 2 and the mounting column 3 on the vehicle direction column are all cast steel parts, and the mounting column 3 is aligned with the vehicle direction The connecting plates 2 on the column can be integrally formed or fixed by existing connection methods such as threaded connection, welding, riveting, etc.; The wind deflector back plate 1 is made of PP material, and the structural strength of the mounting column 3 on the connecting plate 2 on the vehicle steering co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com