Patents

Literature

30results about How to "Solve technical problems with deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

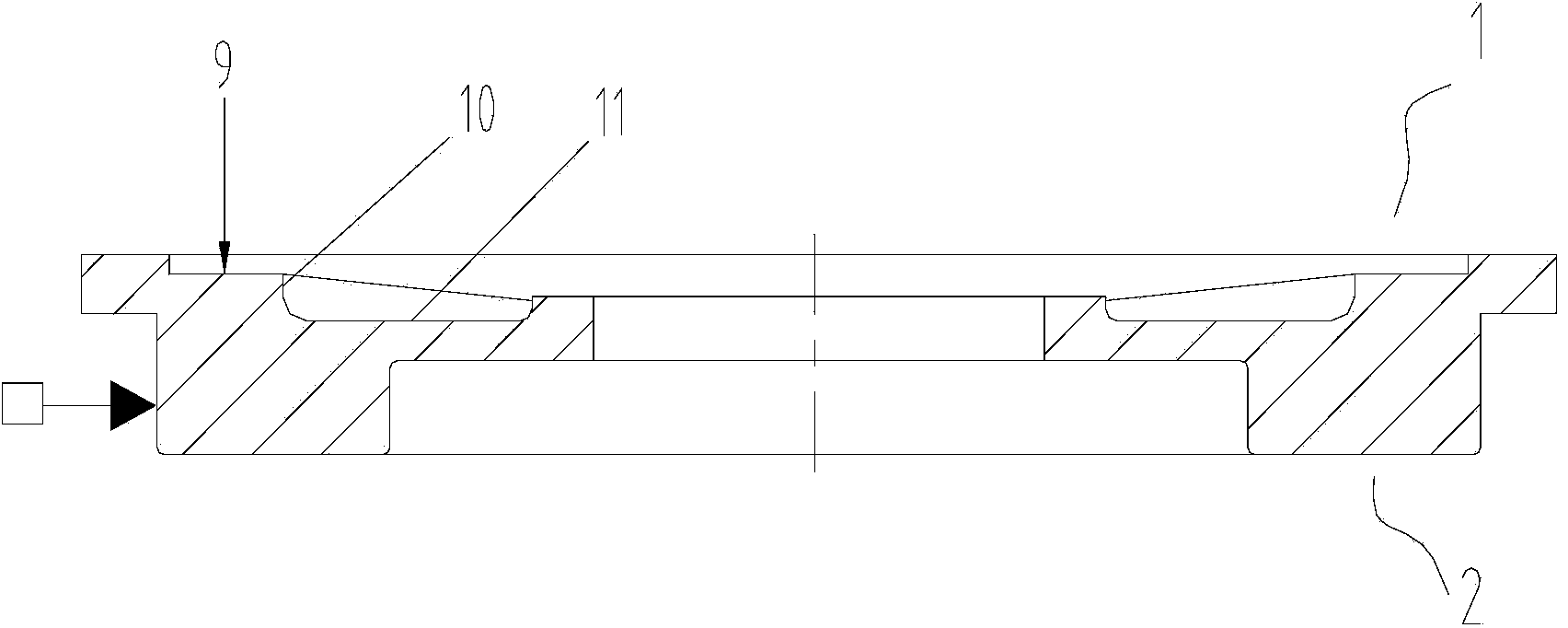

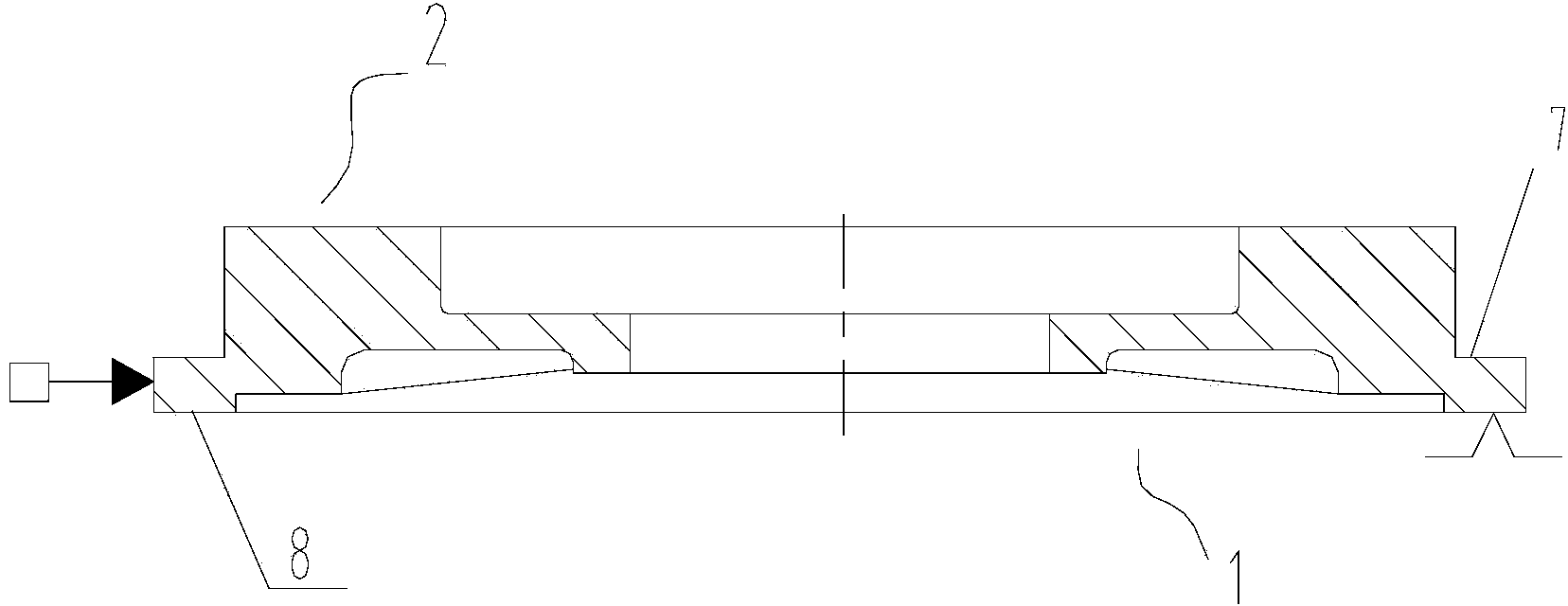

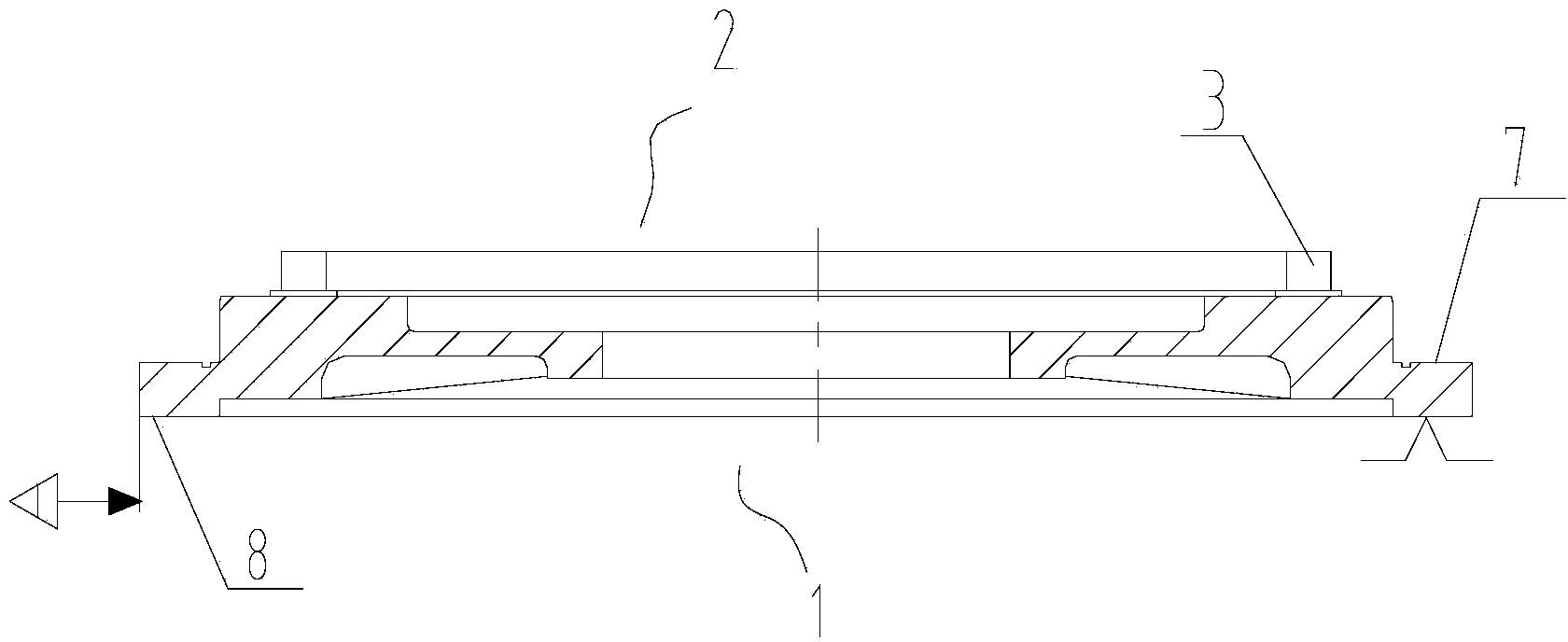

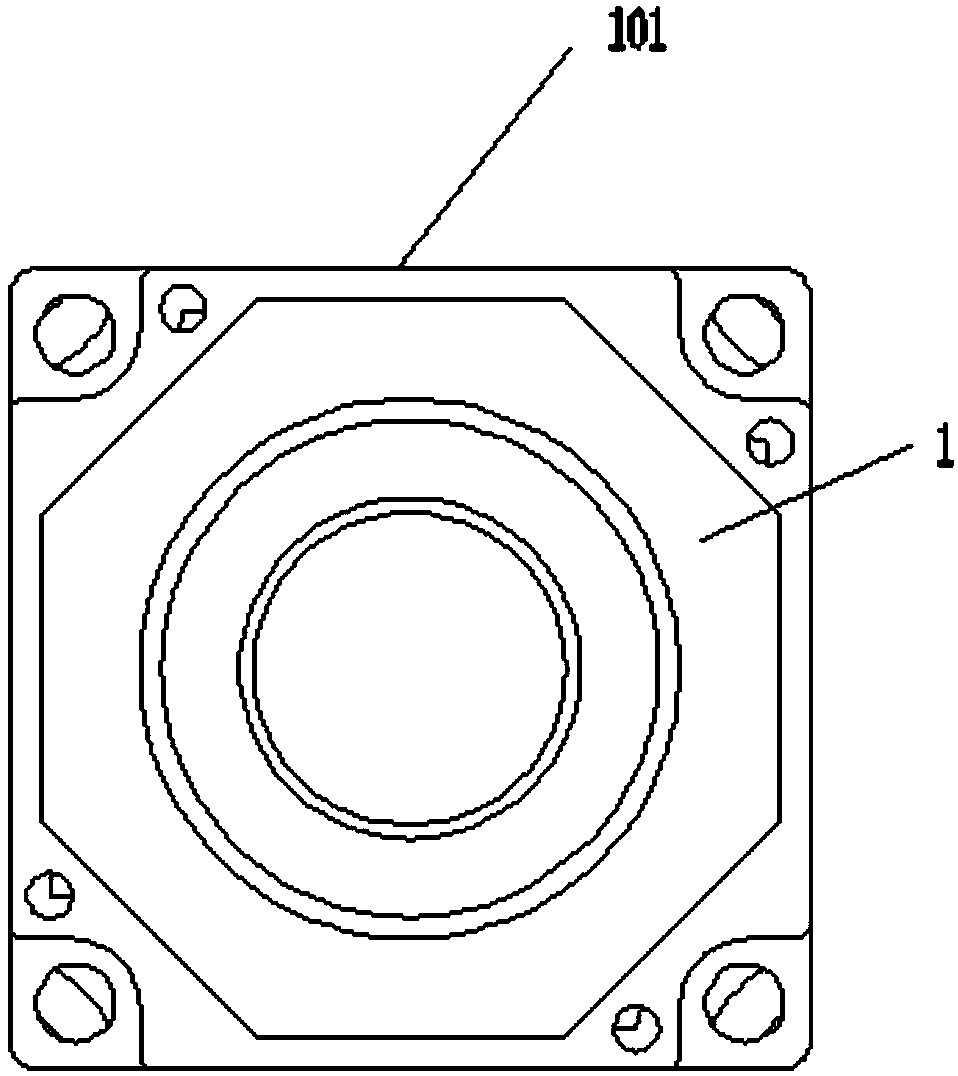

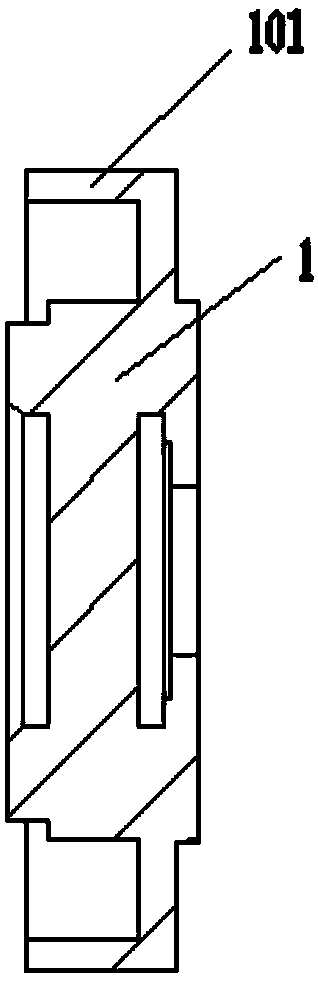

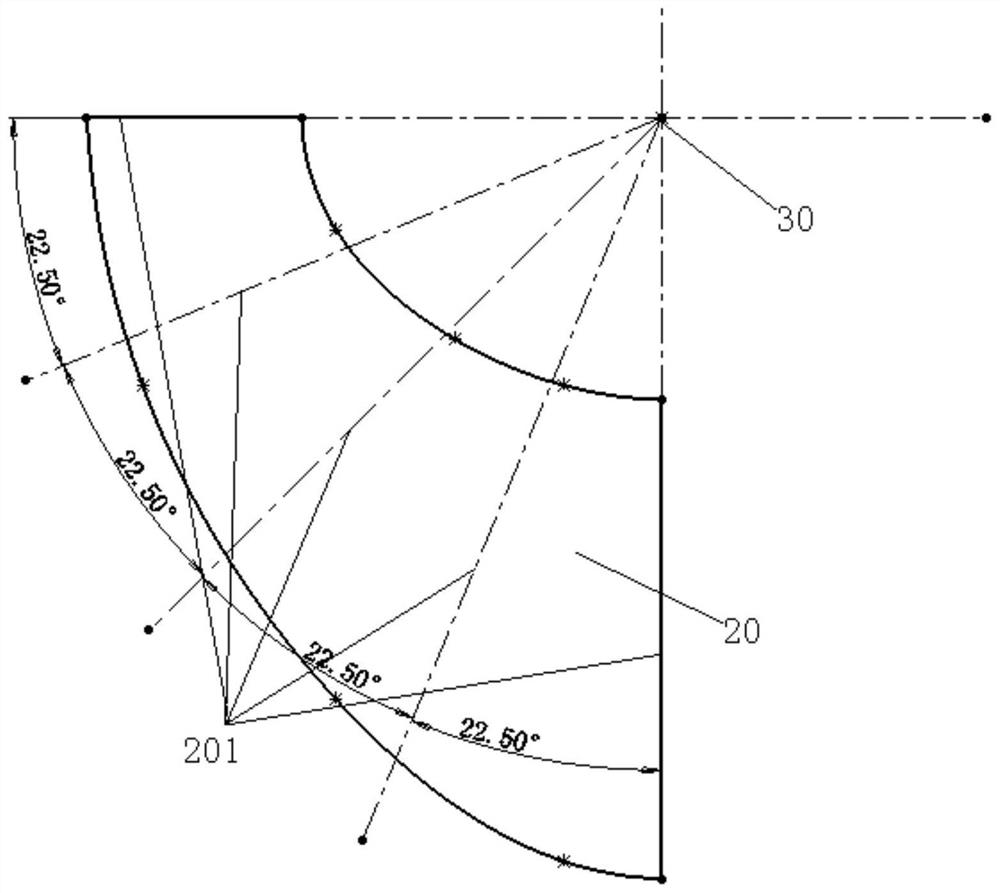

Manufacturing method of centrifugal vapor compressor diffuser

ActiveCN104227359ASolve technical problems with deformationImprove profileCoordinate-measuring machineEngineering

The invention provides a manufacturing method of a centrifugal vapor compressor diffuser. The method comprises the following steps: performing heat treatment on a blank; roughly turning the end surface, excircle, inner bore and second step end surface of a large end of a diffuser; roughly turning the end surface, excircle, inner bore and first step end surface of a small end of the diffuser; drilling and milling a locating hole in the edge of the end surface of the large end, mounting a milling tool, locating by virtue of the locating hole, and roughly milling a blade on the small end; performing half finish turning on the end surface, excircle, inner bore and first step end surface of the small end of the diffuser; performing half finish turning on the end surface, excircle, inner bore and second step end surface of the large end of the diffuser; mounting a milling tool, locating by virtue of the locating hole, performing fine milling on the blade, and delivering the product into a coordinate measuring machine for inspection after fine milling is finished; if the product is qualified, marking center lines for drilling on the end surfaces of the large and small ends and the first step end surface; aligning the center liens; drilling and threading; finely turning the end surface and inner bore of the large end of the diffuser; performing draw filing on the bottom of a blade passage; performing penetrant inspection on the blade.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

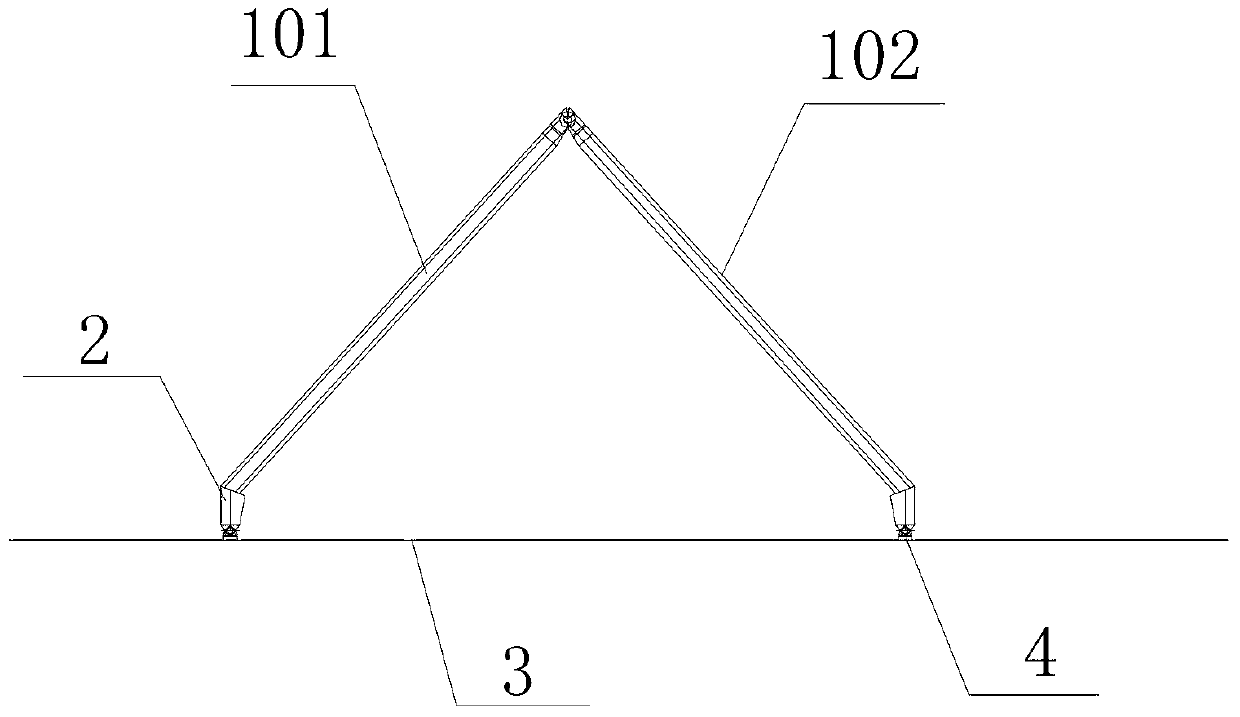

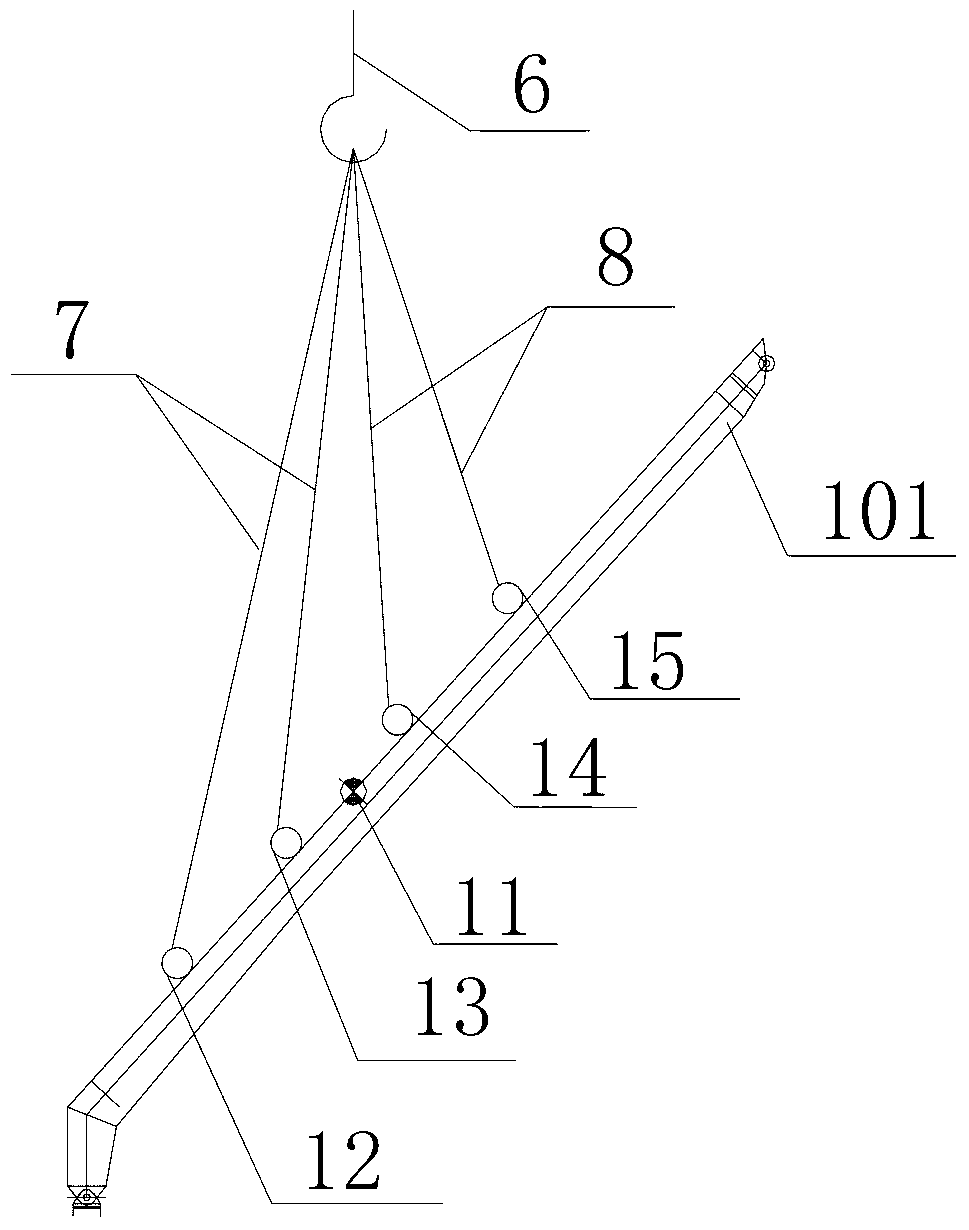

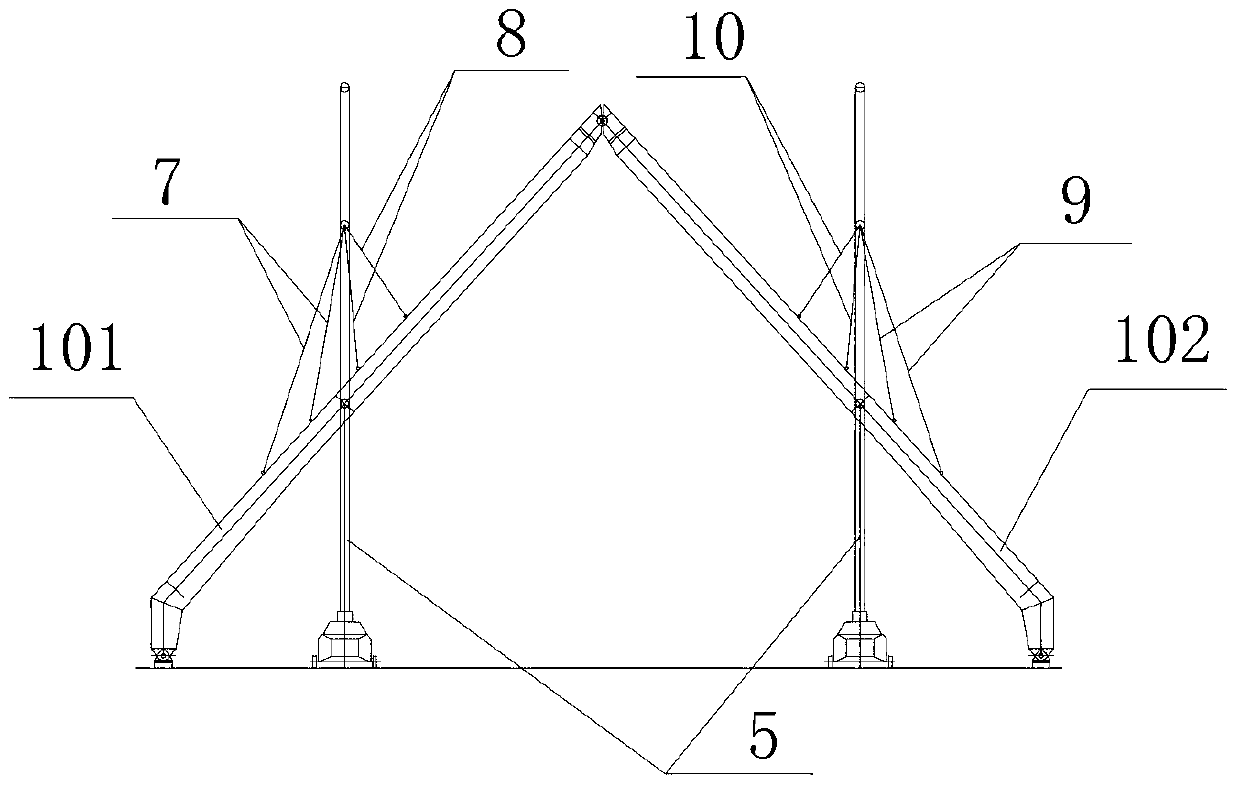

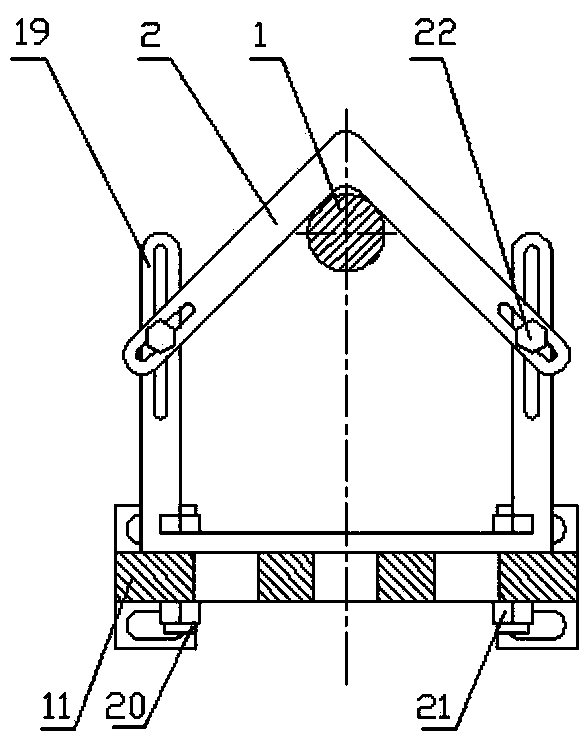

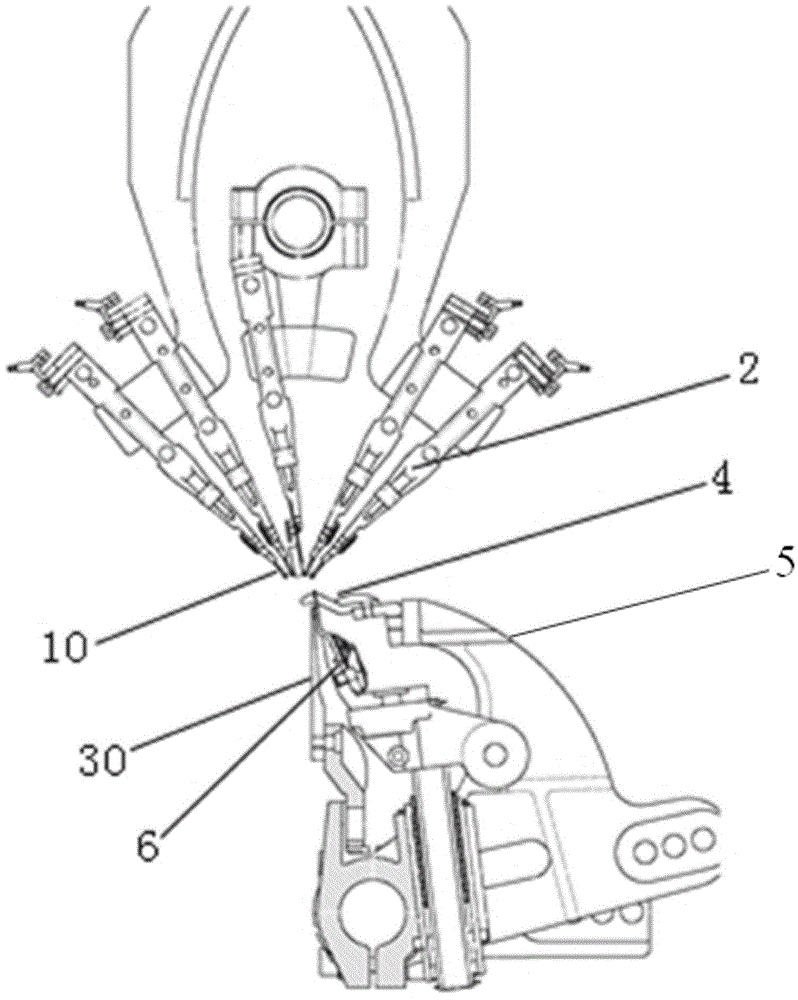

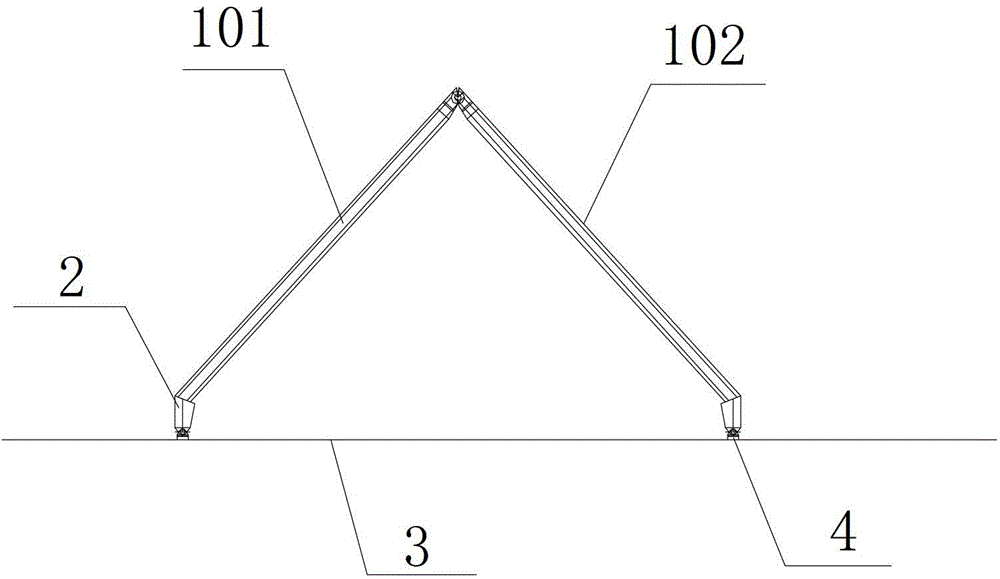

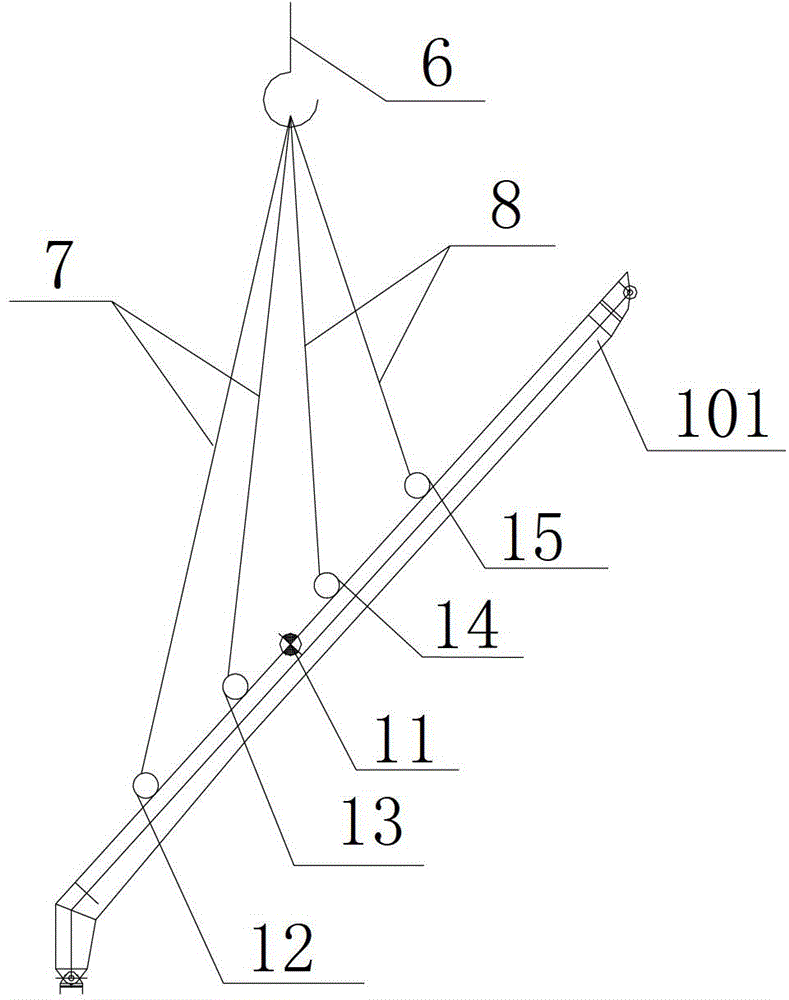

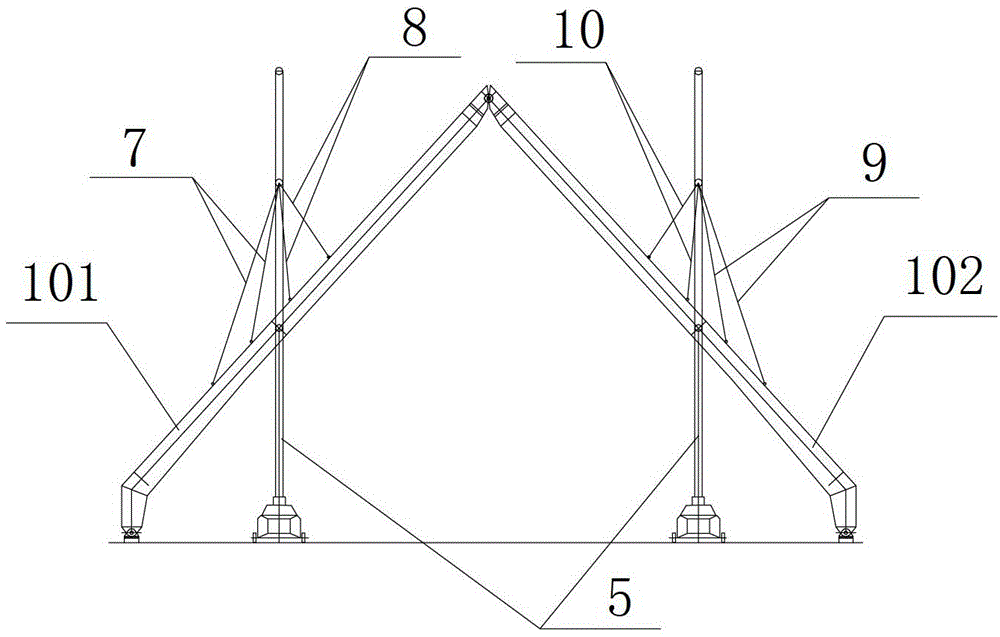

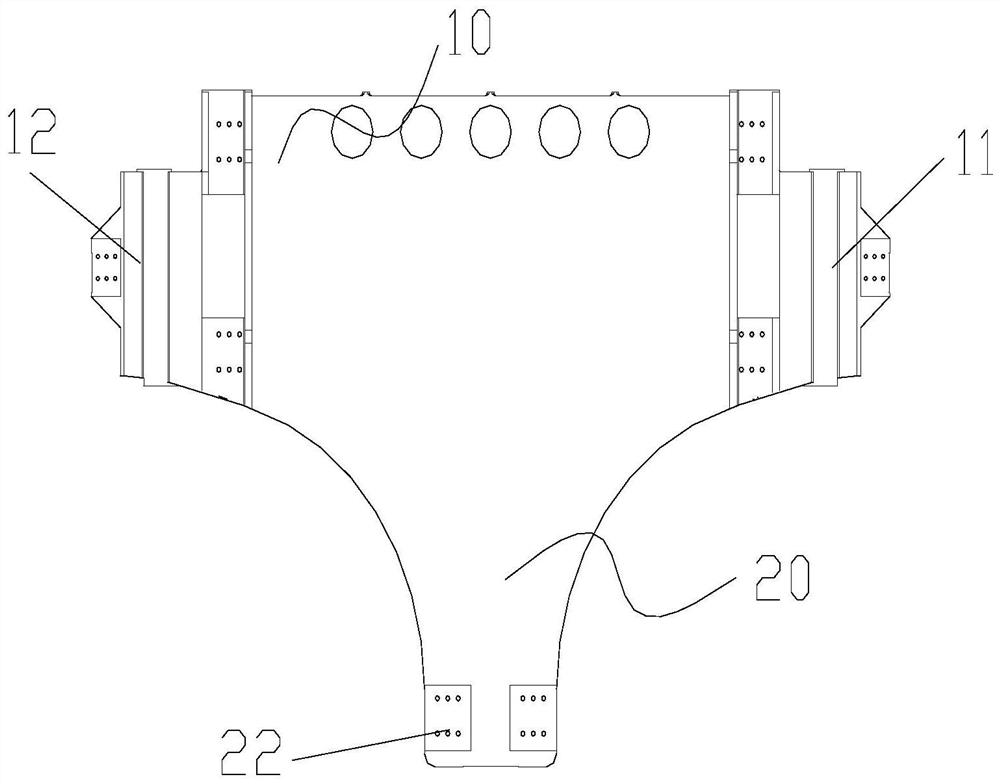

Hoisting method for large-span hinged type herringbone steel arch

ActiveCN103276907ASolve the stiffness problemSolve technical problems that produce deformationBuilding material handlingSpandrelWire rope

The invention provides a hoisting method for a large-span hinged type herringbone steel arch. The hoisting method comprises the steps of conducting hinge joint connection, setting hoisting points, installing hoisting rings, determining the lengths of hoisting steel wire ropes, hoisting and the like. According to the hoisting method for the large-span hinged type herringbone steel arch, due to integral and multipoint hoisting, the technical problems that hinge pin installation in high attitude is difficult, high in construction cost, low in working efficiency and the like are effectively solved. In addition, due to the facts that two hoists are used for hoisting, multipoint hoisting is adopted, and the hoisting points are set reasonably, the situation that the herringbone steel arch deforms due to lack of rigidity in the hoisting process is avoided. Due to the fact that the hoisting steel wire ropes with suitable lengths are selected, the installation angle of the herringbone steel arch is effectively controlled, and two column feet is made to be positioned on bases easily.

Owner:CHINA HUAYE GROUP

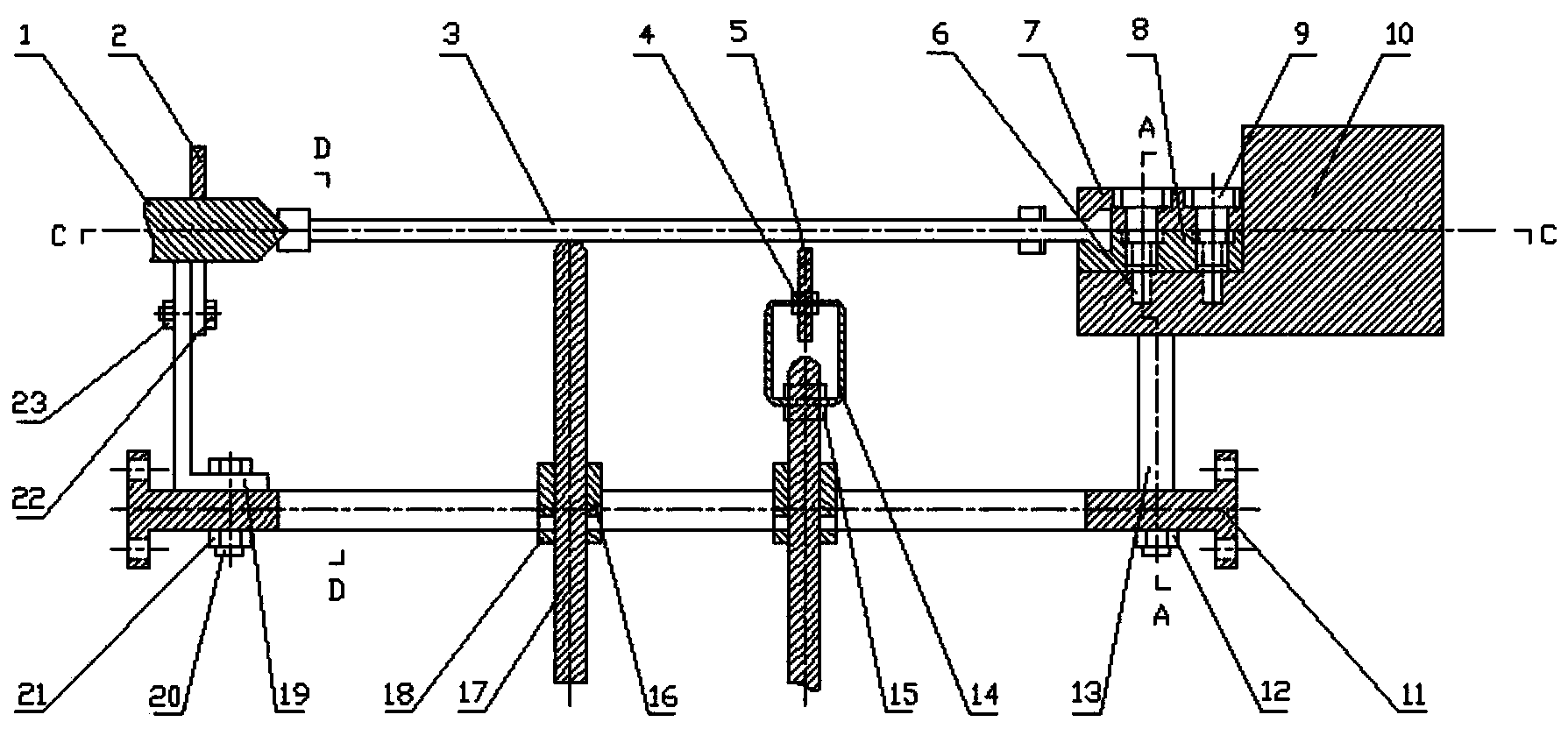

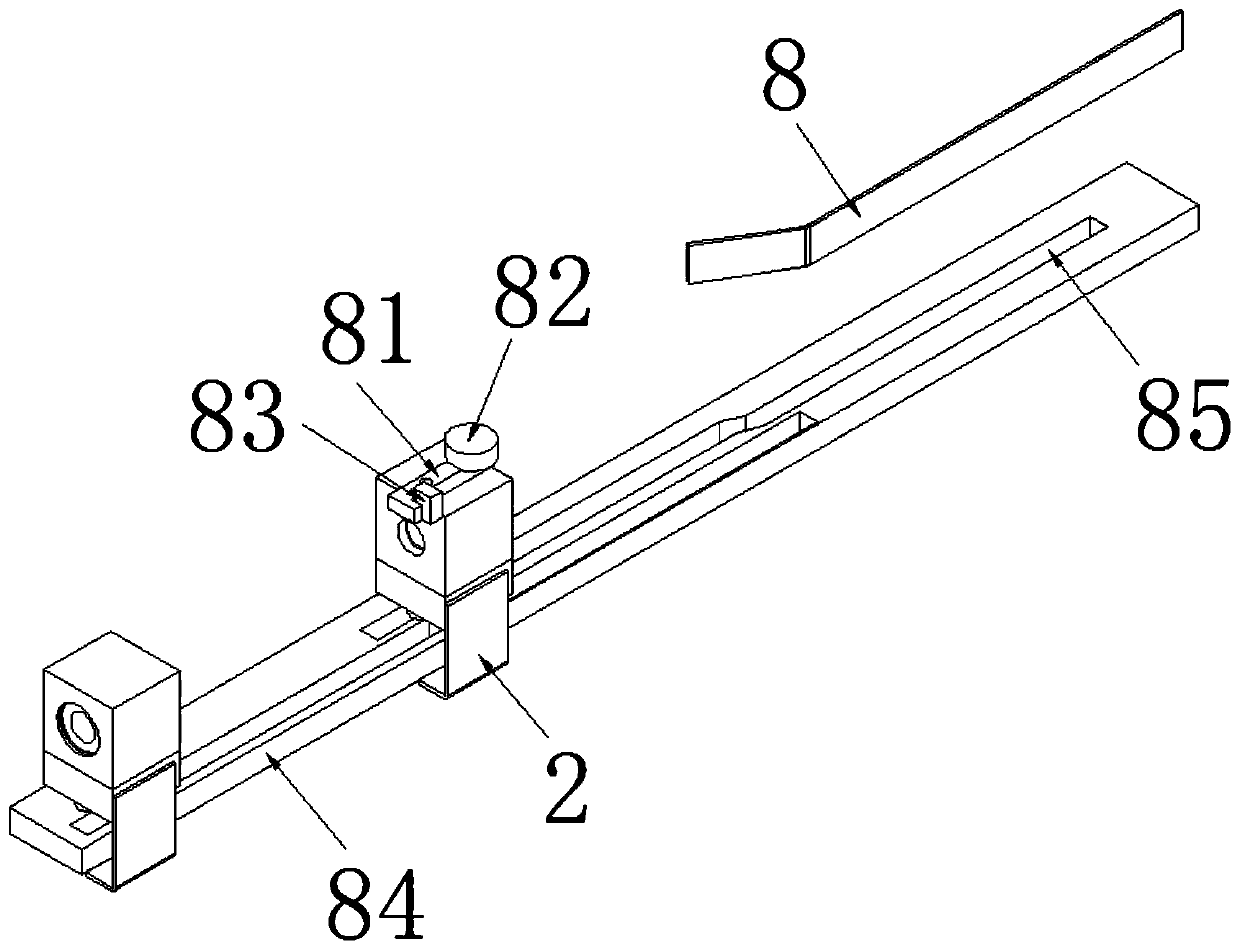

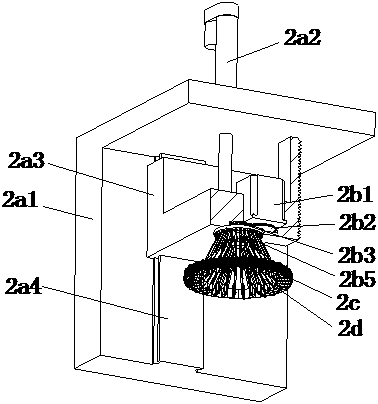

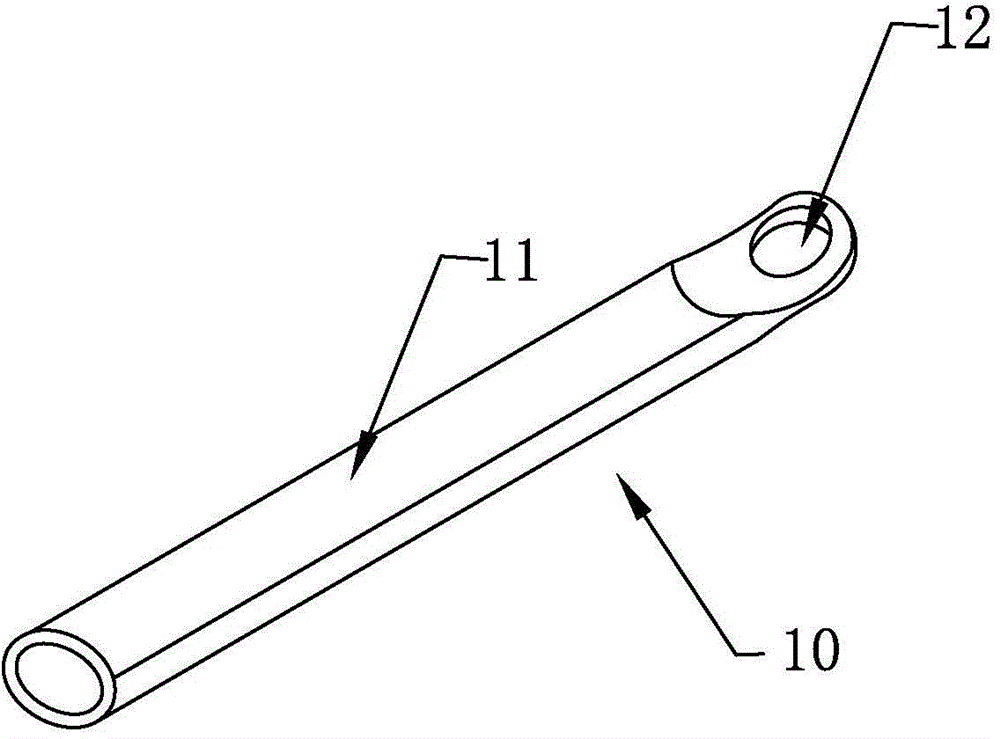

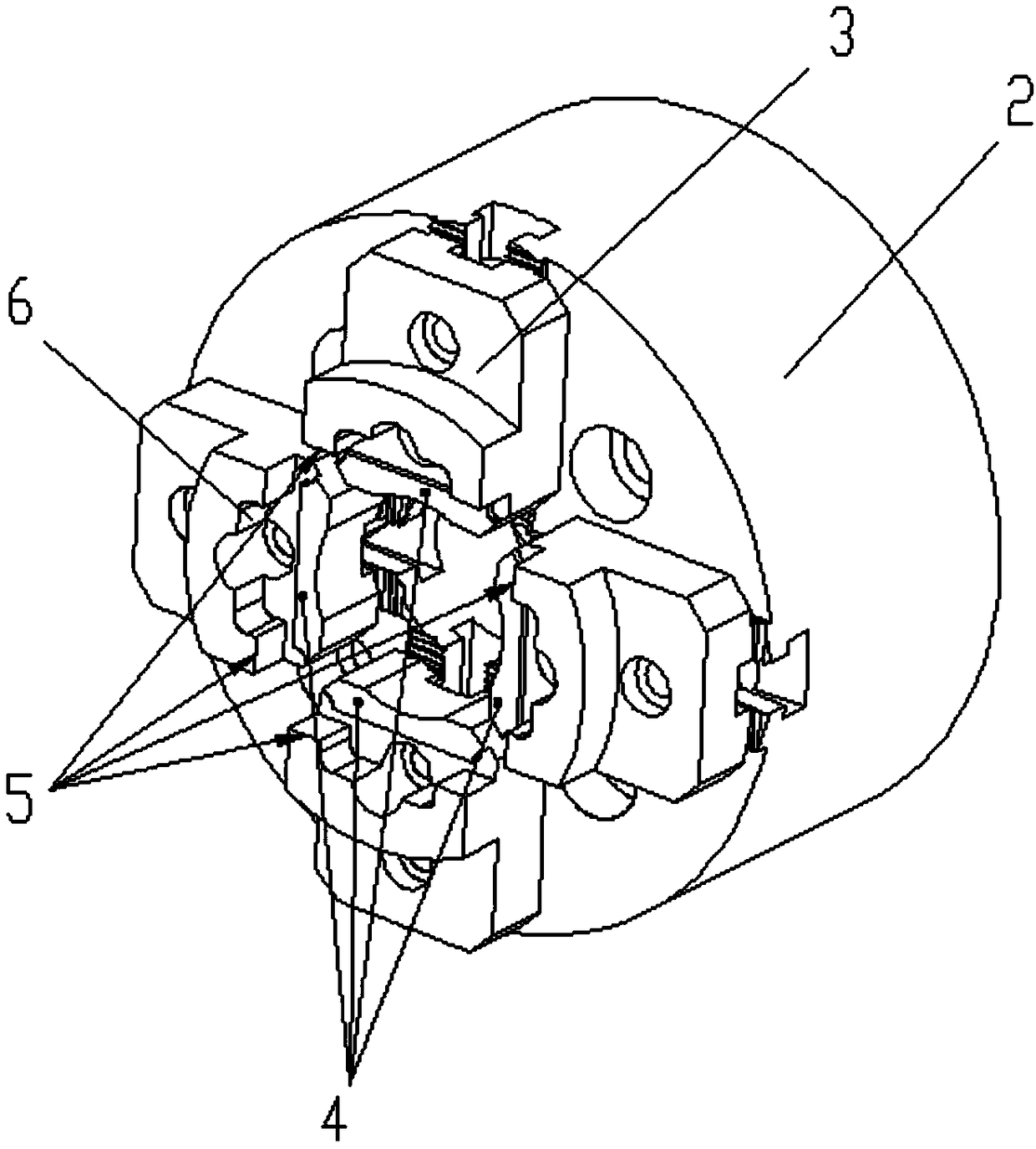

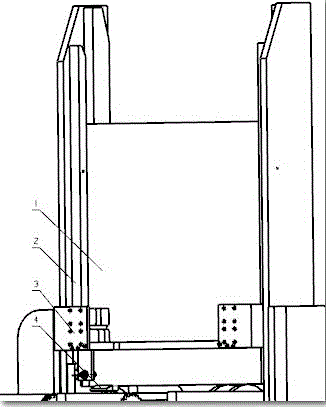

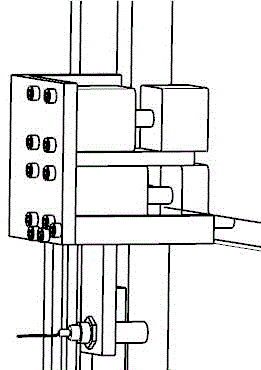

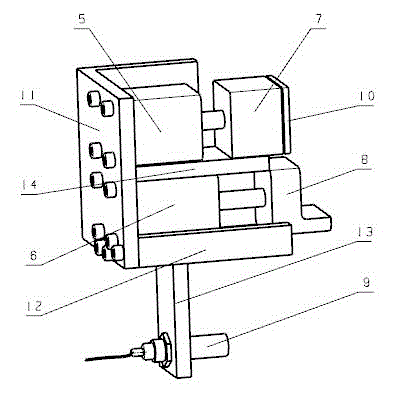

Combined clamp for online measuring of aero-engine blade processing

ActiveCN103909432AReduce manufacturing costIncrease productivityWork clamping meansMeasurement/indication equipmentsEngineeringAviation

The invention discloses a combined clamp for online measuring of aero-engine blade processing and is used for solving the technical problem that existing blade numerical-control-processing precise positioning clamps are poor in practicability. The technical scheme includes that the combined clamp comprises displacement sensors, a guide rail base, a sensor switching module, a slider and supporting screws, the guide rail base is composed of four guide rails with rectangular sections, the slider is mounted on the guide rail base and matched with the same, and can freely slide on the same, the supporting screws are mounted on the slider and are freely adjustable in height, and the displacement sensors are fixed on the supporting screws through the sensor switching module. Support is provided by the supporting screws, so that the technical problem of deformation of a knife due to poor rigidity of a blade body in the process of cutting is solved; due to use of the displacement sensors, online monitoring during blade processing is realized; a tenon clamping module is replaceable, so that troublesomeness in replacing the whole clamp during processing of blades different in type is avoided.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

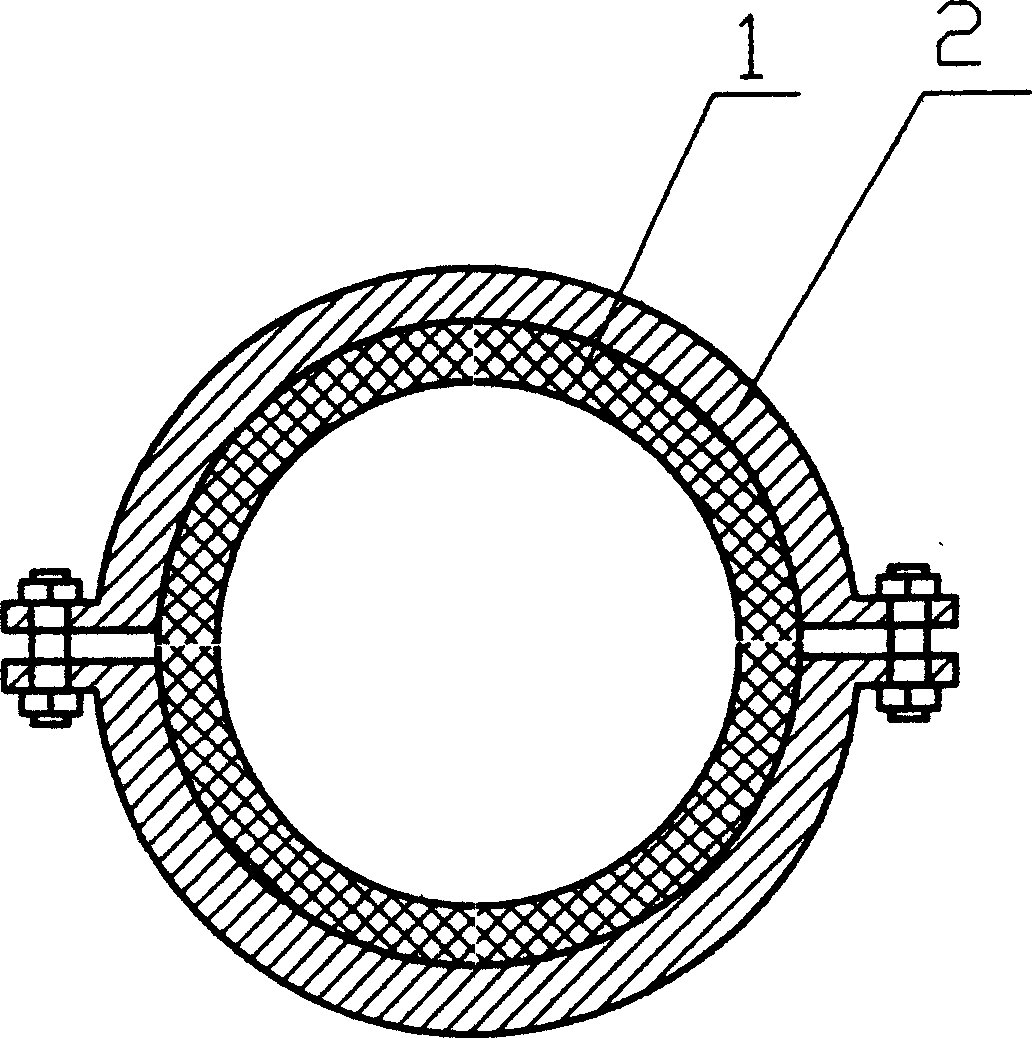

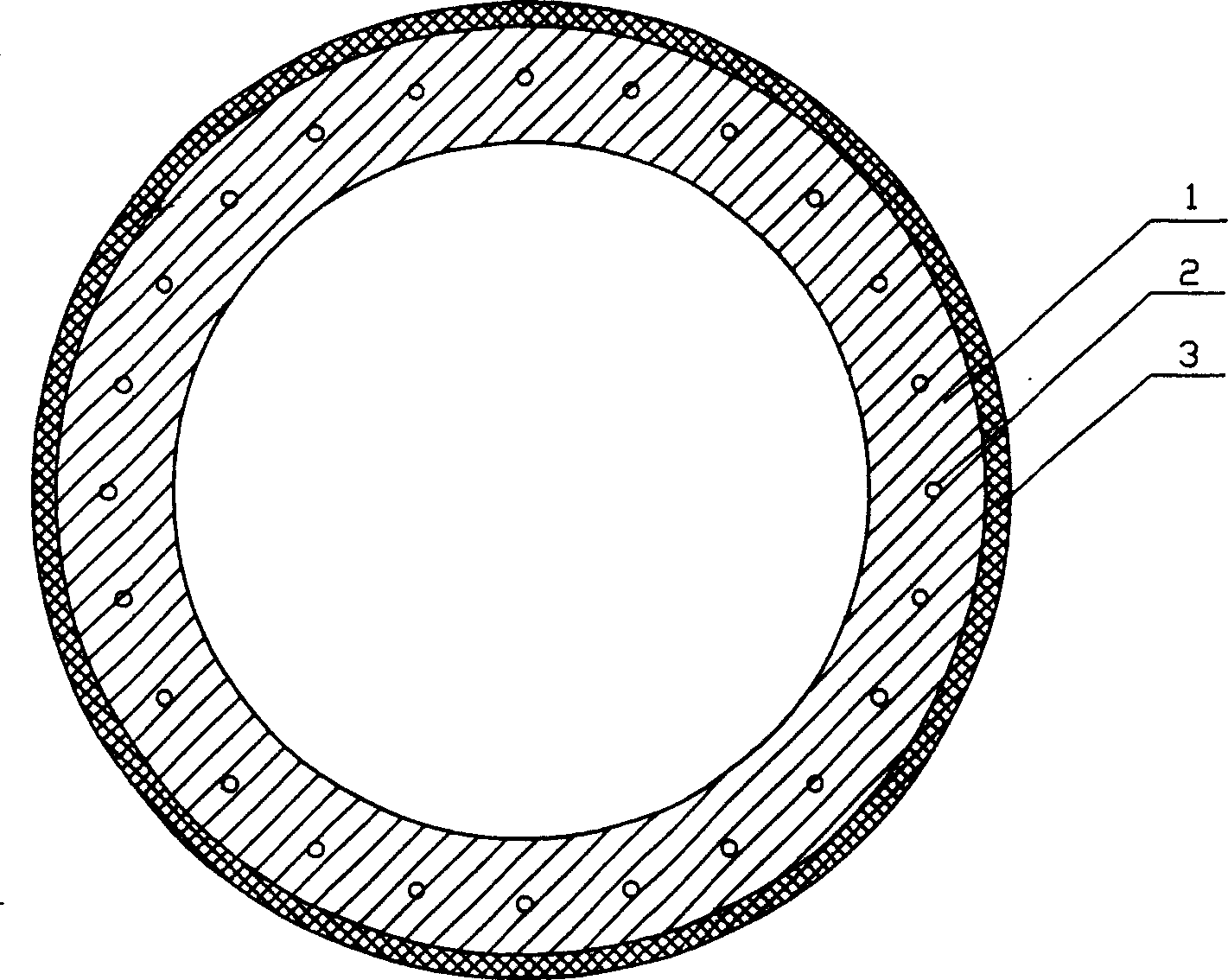

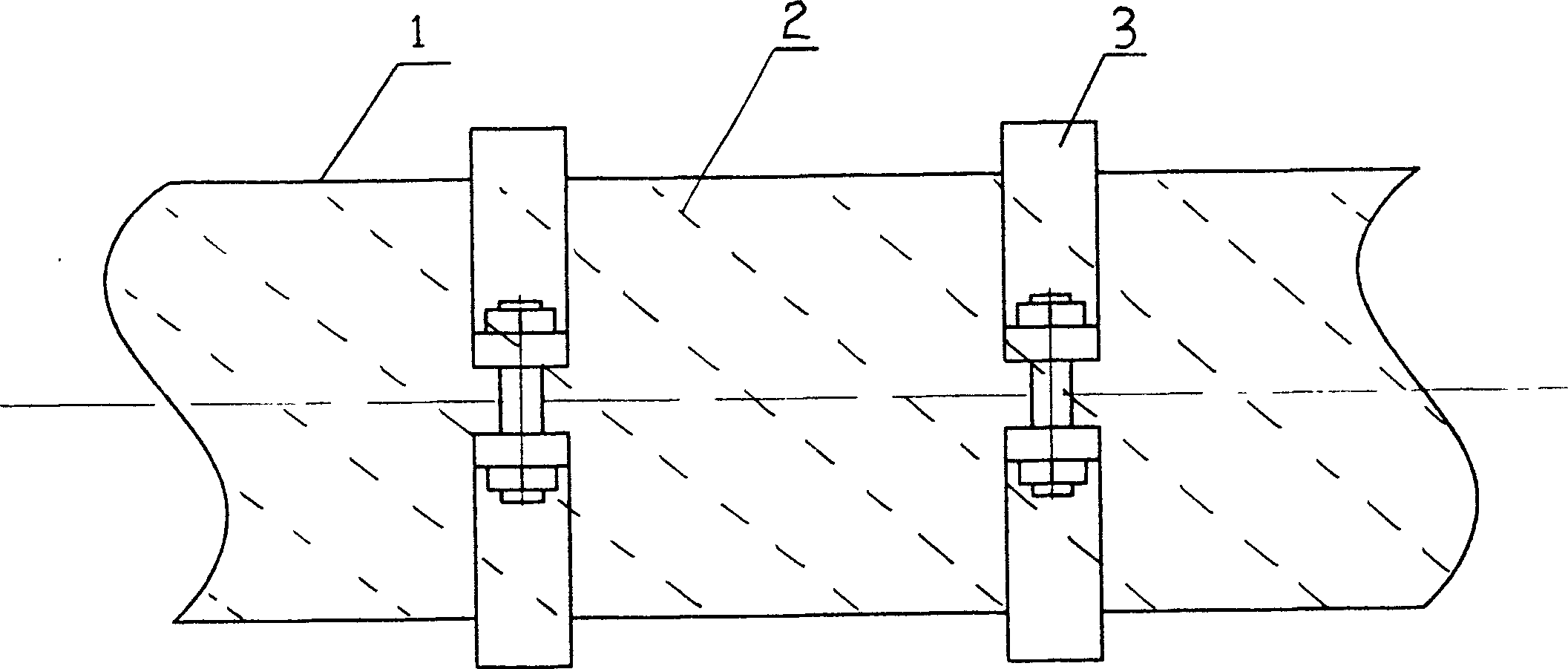

Pipe with reinforced device

InactiveCN1865751ASolve technical problems with deformationReasonable designRigid pipesBiomedical engineeringDeformation Problem

The invention discloses a tube with solidifier, belonging to the improvement of tube. It is formed by a tube and a solidifier. The invention has the advantages that it can improve the support ability of tube an solve the deformation problem by combining the tube and the solidifier to increase the safety factor of production and reduce the producing cost.

Owner:李研

Pressure resistant pipe material

InactiveCN1904447AAvoid negative pressure flatteningAvoid phenomena such as positive pressure ruptureRigid pipesEngineeringDeformation Problem

A pressure tube consists of a pipe and internal and external reinforced units. Because the tube adopts several kinds of reinforcing ways, the deformation problem of the plastic tube has solved and the service life of the tube has increased.

Owner:李寿山

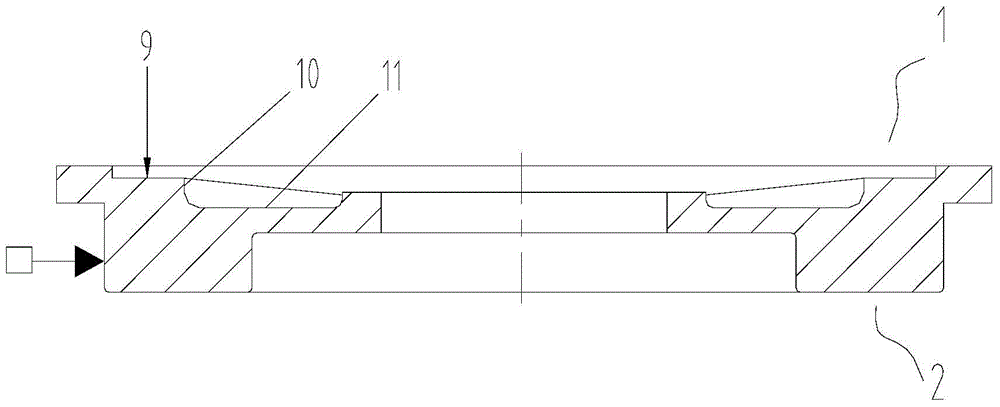

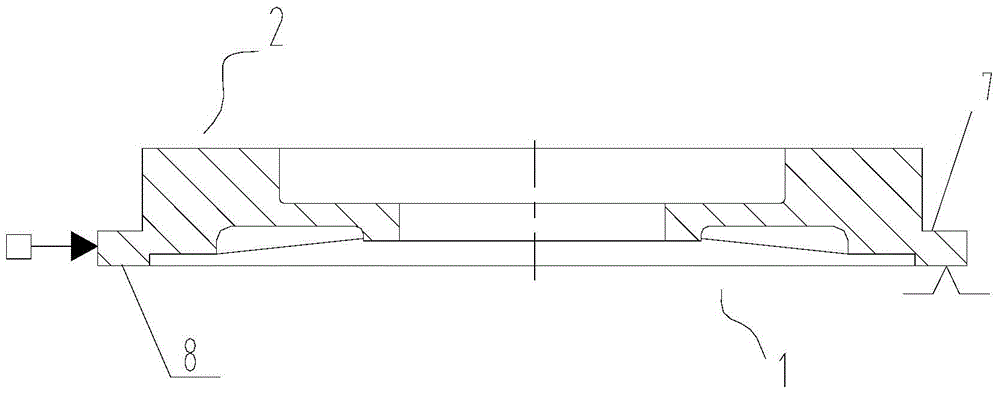

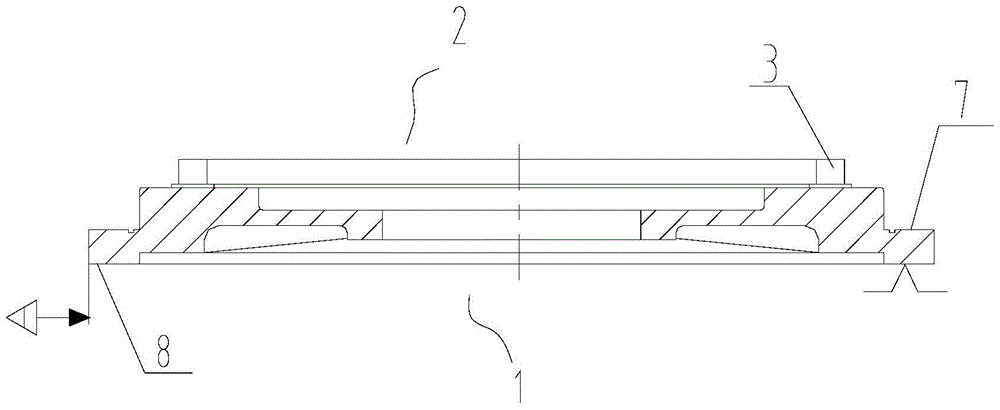

Integrated opening and closing guiding elevator door system

ActiveCN111204645ASolve the vulnerability to external forcesSolve technical problems with deformationBuilding liftsStructural engineeringMechanical engineering

The invention belongs to the technical field of elevators, and particularly relates to an integrated opening and closing guiding elevator door system, which comprises a general mounting shell. The general mounting shell is internally provided with a driving device, a guiding device and connecting pieces, and the bottom of the general mounting shell is horizontally provided with an elevator door along the inner bottom wall of the general mounting shell; the driving device controls the elevator door fixedly connected to the bottoms of the connecting pieces to be opened and closed after converting power through the guiding device; and the elevator door comprises an inner door and an outer door, and a gap is formed between the opposite side faces of the inner door and the outer door. Accordingto the integrated opening and closing guiding elevator door system, by arranging the guiding device, the effect of automatically offsetting the inner door and the outer door through a mechanical structure is realized.

Owner:杭州宝宸科技有限公司

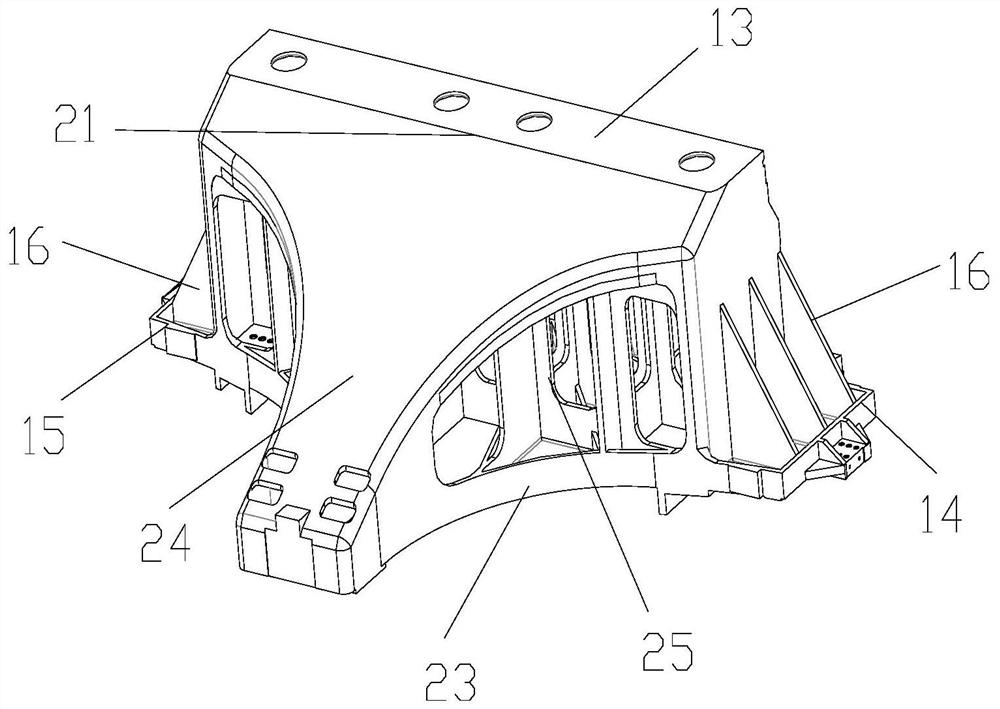

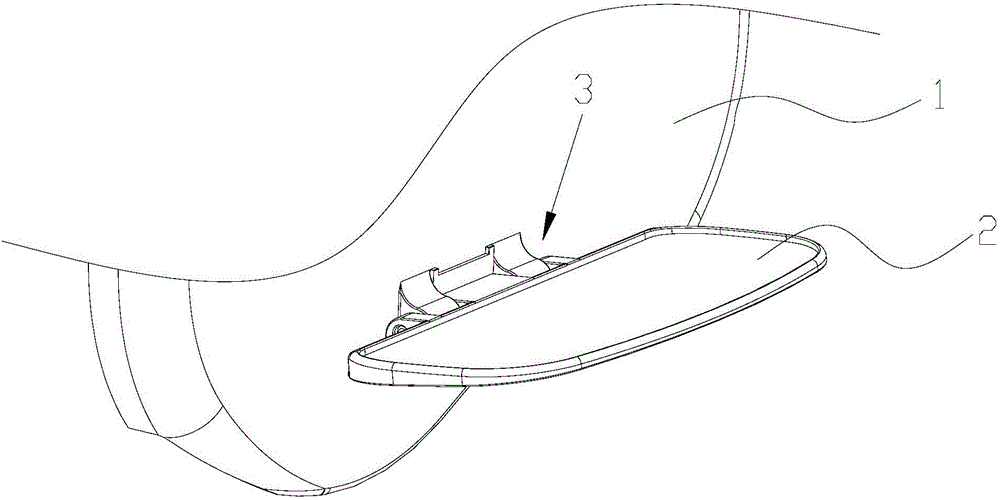

Motorcycle fairing structure assembly

InactiveCN104149887AImprove structural strengthGuaranteed installation position accuracyWeather guardsSteering columnEngineering

The invention discloses a motorcycle fairing structure assembly comprising a fairing back plate and a connecting plate on a motorcycle steering column. The motorcycle fairing structure assembly is characterized in that a mounting base and mounting columns are arranged on the fairing back plate, and the mounting columns are fixed on the motorcycle steering column correspondingly to the mounting base; mounting holes allowing the mounting columns to be inserted in and fixed are formed in the mounting seat, fixing holes are further arranged in the fairing back plate, and the fairing back plate is fixed on the steering column connecting plate through the fixing holes. A motorcycle applies the fairing back plate mounting assembly, structural strength of the mounting columns on the connecting plate on the motorcycle steering column is far higher than that of fairing back plate lugs in the prior art, the technical problems of breakage and deformation of the fairing back plate lugs in the prior art are solved, strength of the fairing back plate is improved, mounting position accuracy of the fairing guide plate and safety performance of motorcycle running are guaranteed, probability of occurrence of labor waste and material waste is reduced, and cost is saved.

Owner:CHONGQING LONCIN MOTOR

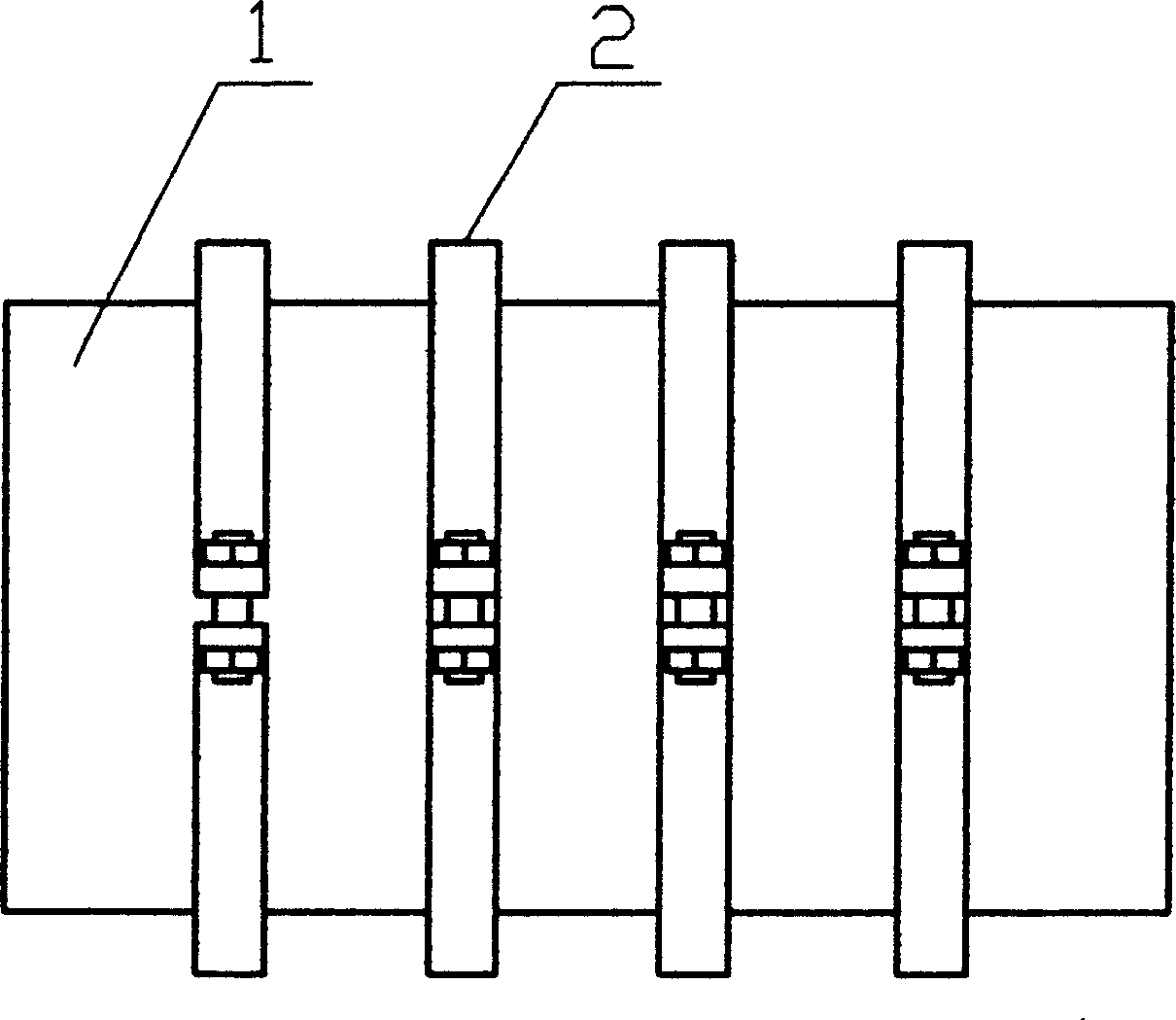

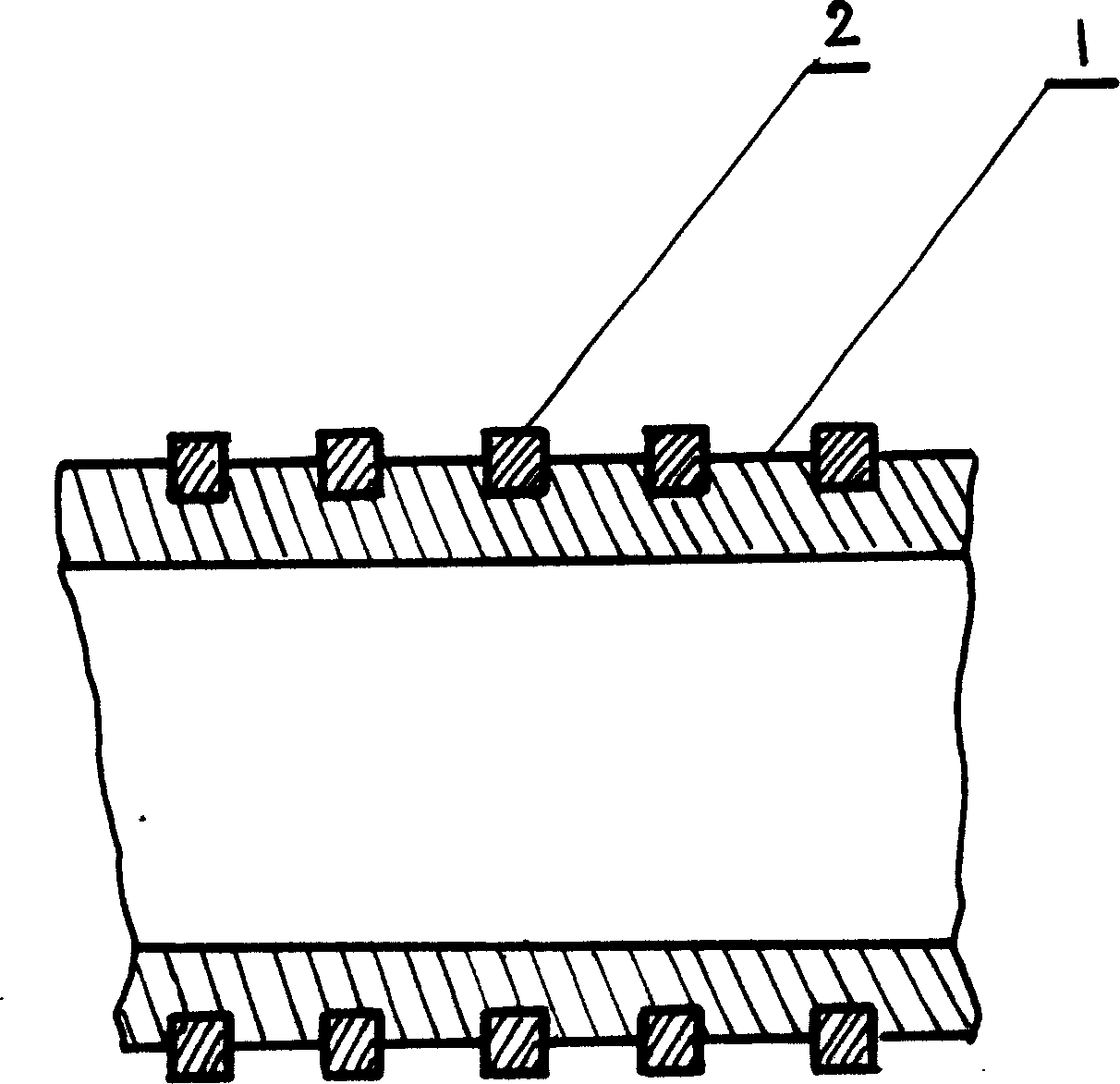

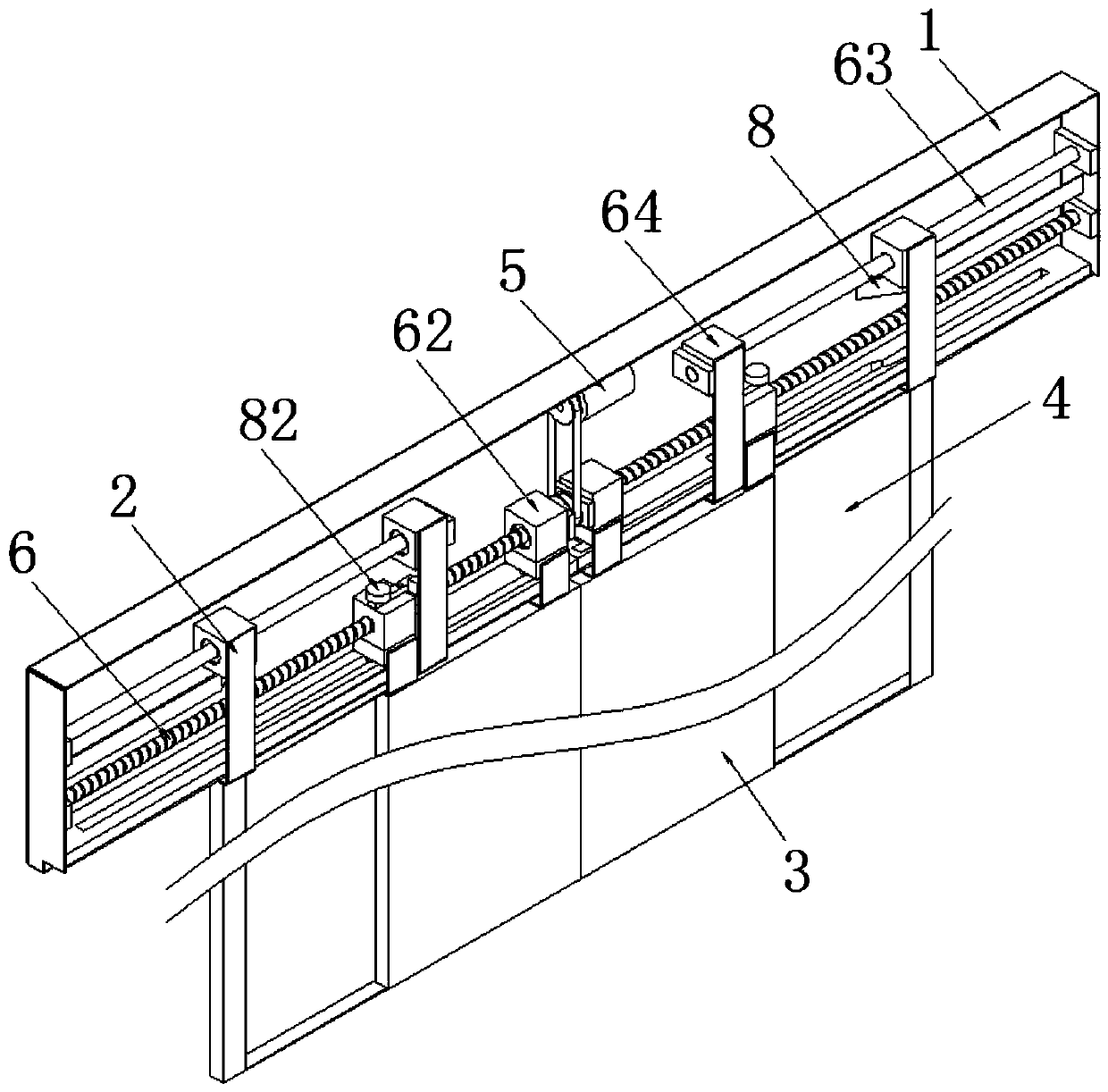

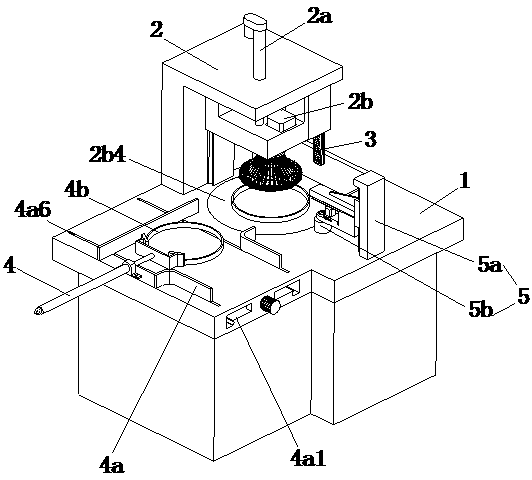

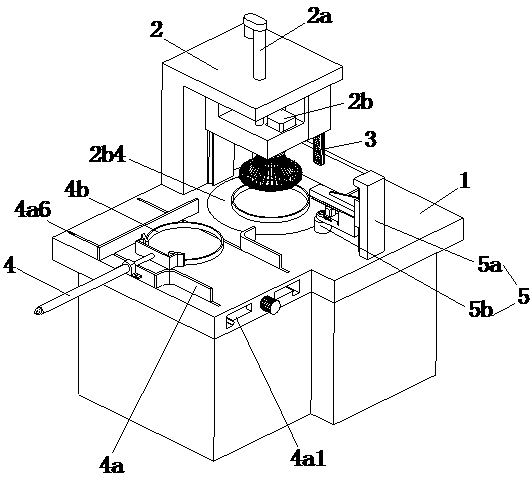

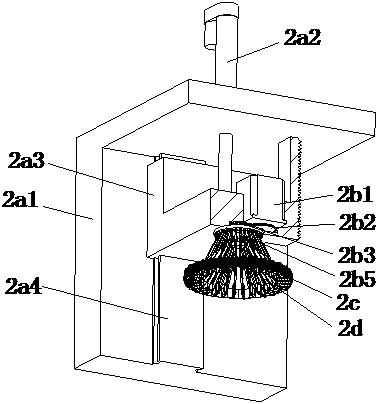

Working method of machining device for annular metal parts

ActiveCN111360623AReceived expansion forceAvoid deformationEdge grinding machinesPolishing machinesPolishingEngineering

The invention discloses a working method of a machining device for annular metal parts, and belongs to the technical field of machining equipment. The machining device comprises a workbench, a positioning mechanism, a limiting mechanism, a feeding mechanism and a polishing mechanism. The positioning mechanism comprises a lifting assembly, a connecting assembly, a plurality of positioning assemblies and a plurality of reset assemblies. The connecting assembly is installed at the lower end of the lifting assembly. The plurality of positioning assemblies are circumferentially distributed beside the connecting assembly. The plurality of reset assemblies correspond to the plurality of positioning assemblies one to one. Each reset assembly is installed above the corresponding positioning assembly. The feeding mechanism comprises an adjusting assembly and a feeding assembly, and the polishing mechanism comprises a moving assembly and a polishing assembly. According to the working method, annular workpieces with small inner and outer diameter difference values can be fixed and machined, workpiece deformation cannot be caused during fixing, and the same equipment can machine the annular workpieces of different sizes. The machining device further has the advantage of low positioning precision, and the cost can be reduced.

Owner:唐山特迪机械设备制造有限公司

Fragrance product formula and preparation method thereof

PendingCN108822961ASolve crackingSolve technical problems with deformationEssential-oils/perfumesFlavorLarge size

The invention discloses a fragrance product formula and a preparation method thereof. The formula comprises fragrance components and adhesive powder, wherein the fragrance components and the adhesivepowder comprise the following components in parts by weight: 1-3 parts of agilawood, 1 part of benzoin, 2-8.7 parts of sandalwood, 0.4-0.7 part of ambergris and 1.6-2.7 parts of adhesive powder. The preparation method comprises the following steps: preparing fragrances, performing compatibility of the fragrances, binding the fragrances, and carrying out condensation molding. The technical problemthat in the process of drying the condensation fragrance product in shade, moulds in the condensation fragrance product breed and the moulding shrinkage ratio is large, so that cracking and deformingare caused is solved, the technical problems caused when fragrances are processed as artworks, artware, large-size sculptures and practical living articles can be solved, processing and manufacturingof fragrance beads, fragrance wares, fragrance sculptures, fragrance prints, practical living articles, innovative tea fragrance sculpture series and health fragrance sculpture series can be achieved, a condensation fragrance product has the metal and gold textures, has the irises and orchid characters, has fragrance lasting for hundreds of years, is solid as iron, has the texture as jade and haslong-lasting fragrance smell of hundreds of years, standardization levels of fragrance product manufacturing processes are increased, and the processes can be widened to other materials.

Owner:柴龙国

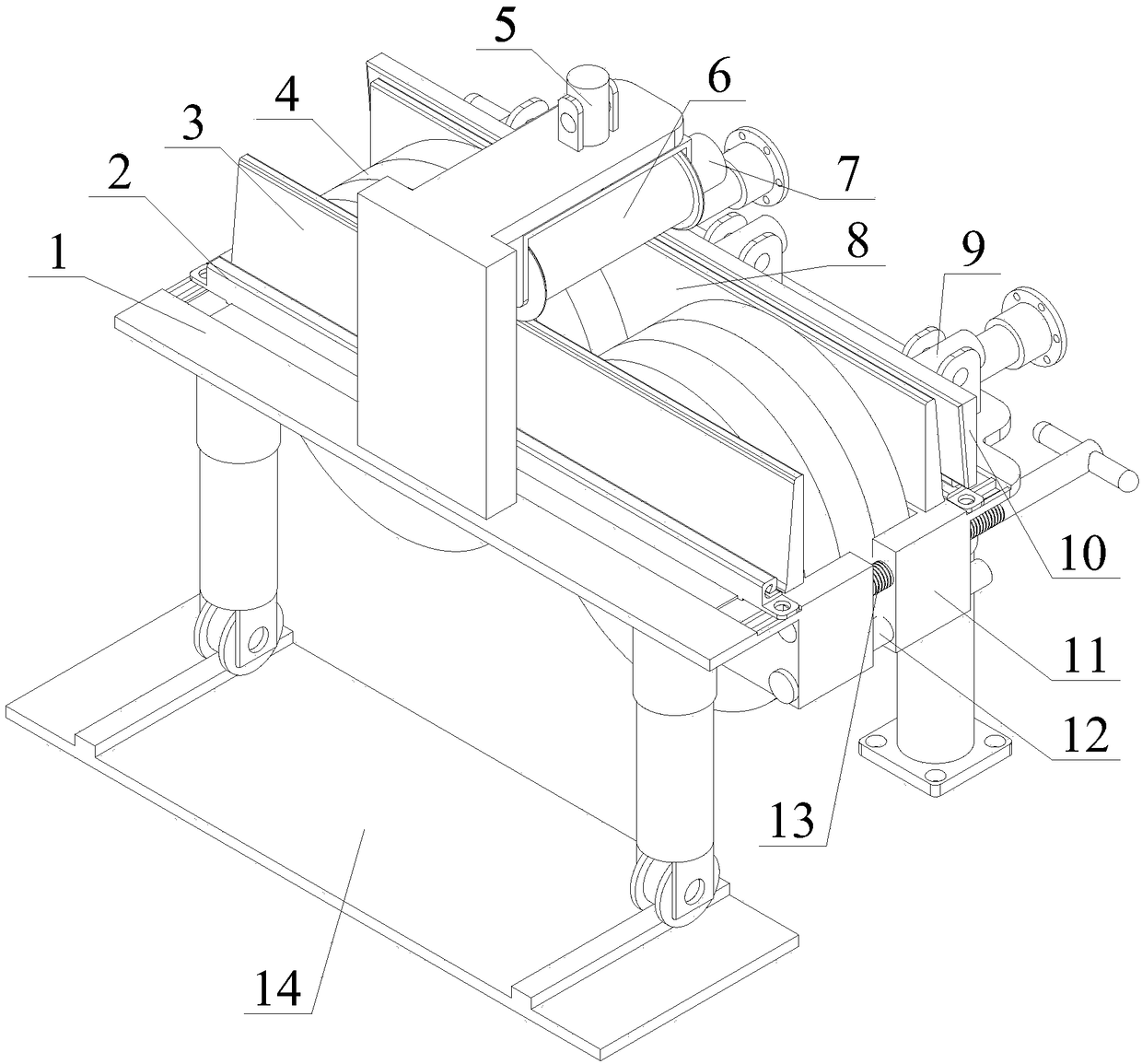

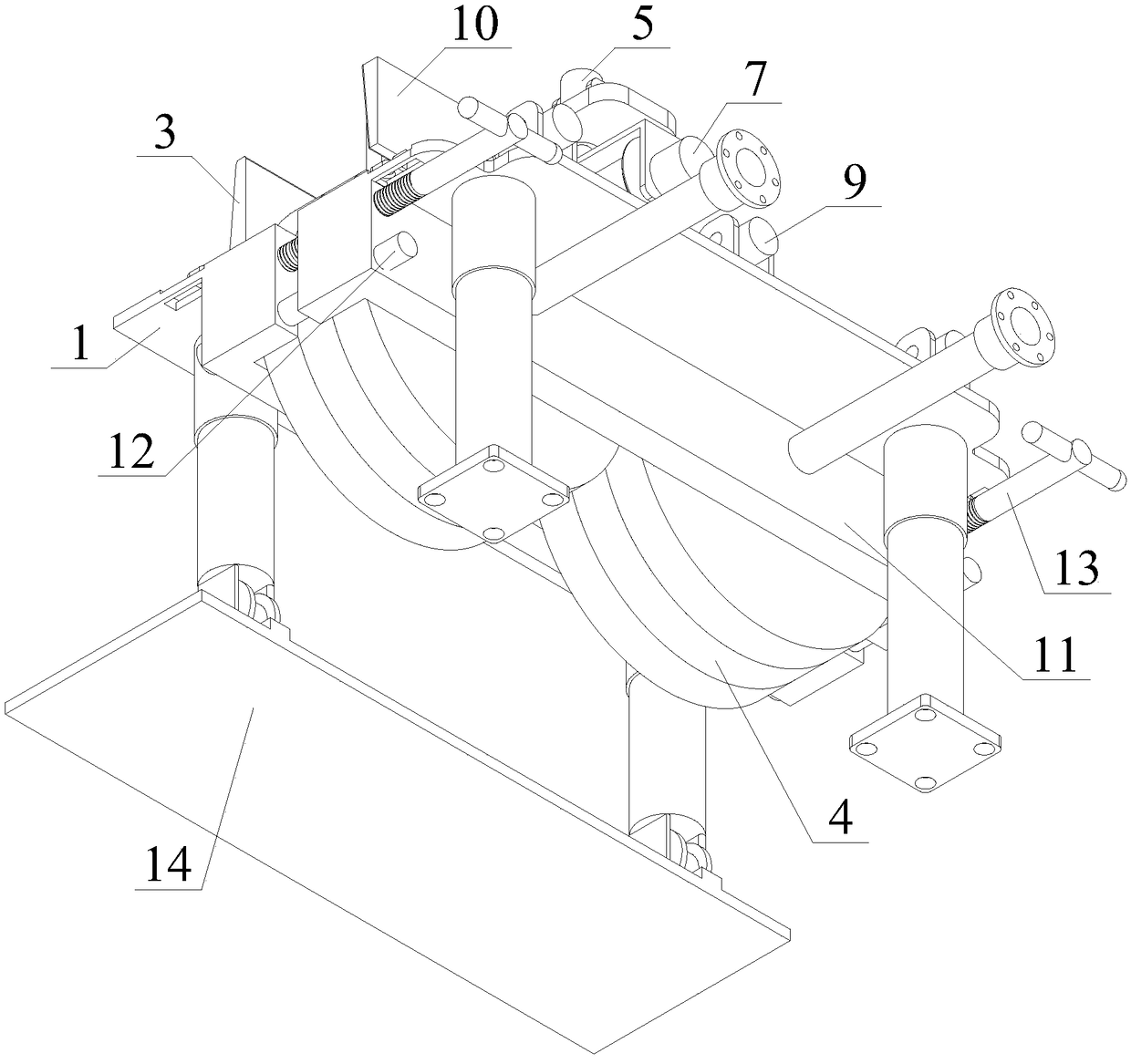

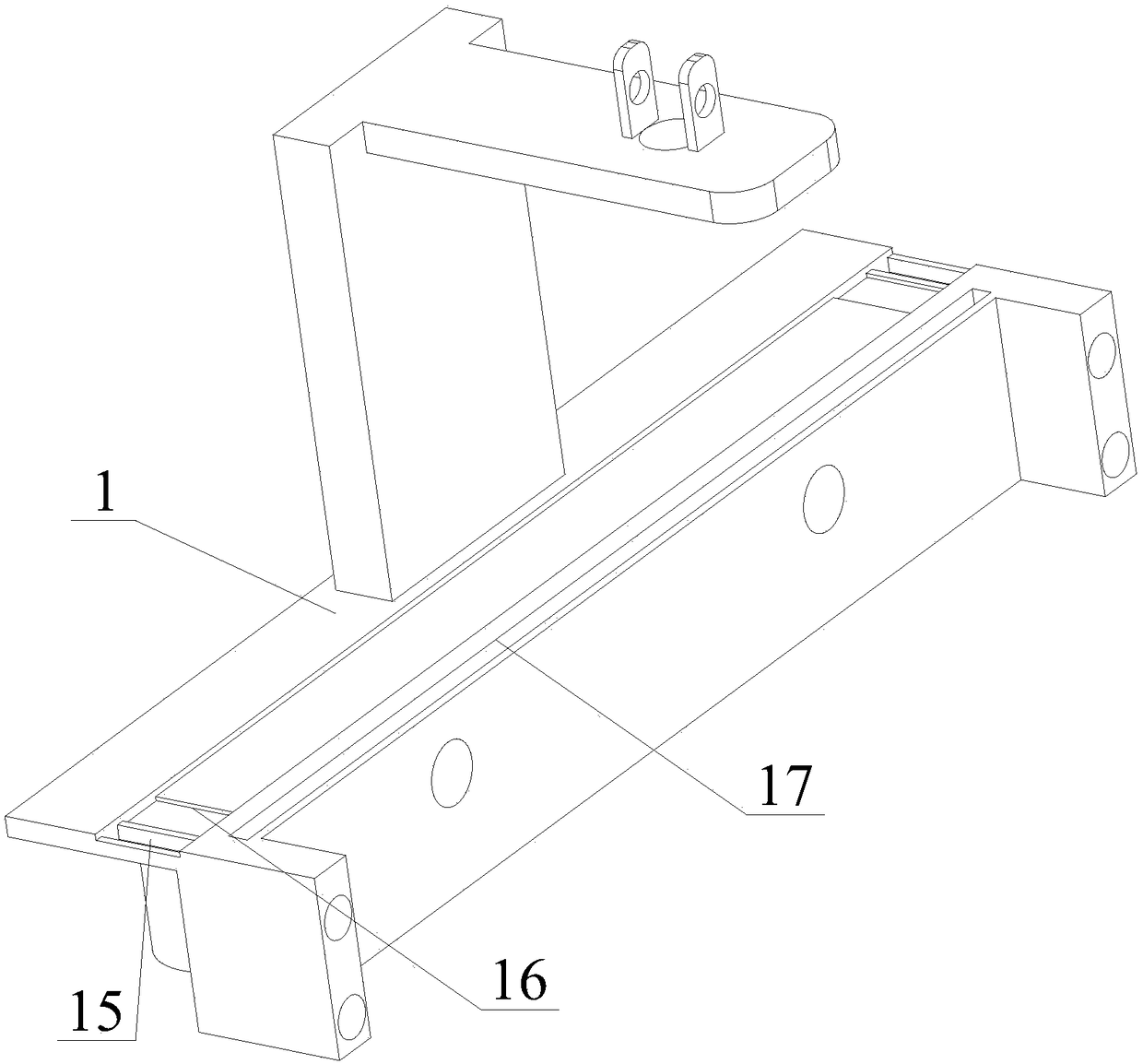

Special-shaped steel low-temperature correcting device

The invention belongs to the technical field of deep processing of steel, in particularly relates to a special-shaped steel low-temperature correcting device. The device comprises a first workbench, asecond workbench, first inner side correcting devices, a second inner side correcting device, a third inner side correcting device, a first outer side correcting device, a second outer side correcting device and a third outer side correcting device; the first outer side correcting device is used for correcting the outer surface of the upper side of the special-shaped steel; the second outer sidecorrecting device and the second inner side correcting device are used for correcting the left side surface of the special-shaped steel; and the first inner side correcting devices are used for correcting the inner surface of the upper side of the special-shaped steel, and the third outer side correcting device and the third inner side correcting device are used for correcting the right side surface of the special-shaped steel. According to the device, the occupied area is small, the installation is convenient and flexible, the special-shaped steel can be accurately corrected, secondary damageto the special-shaped steel is avoided, and the device has the characteristics of being high in correcting precision, high in working efficiency and free of the secondary damage.

Owner:SHANDONG IRON & STEEL CO LTD

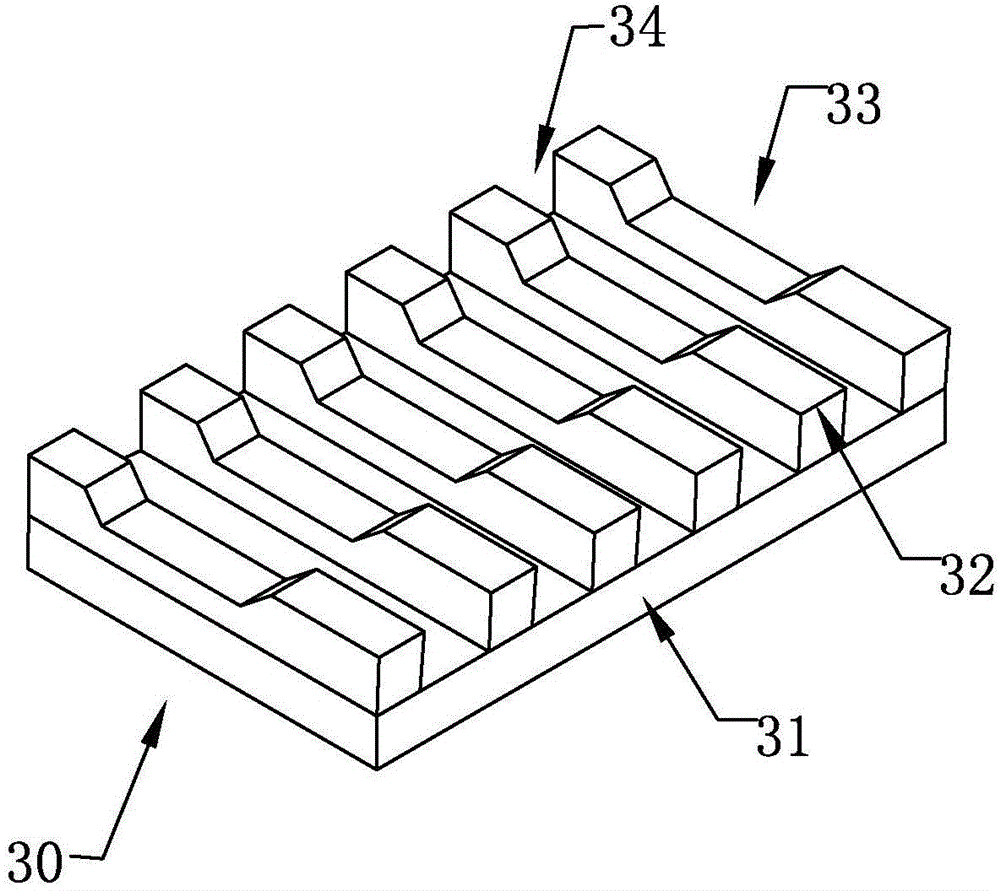

Looping mechanism of artificial lawn warp knitting machine

A looping mechanism of an artificial lawn warp knitting machine comprises a yarn guide needle, a sinker and a knocking-over bar, wherein the yarn guide needle is fixed on each wool yarn guide bar; a sinker is fixed on a sinker bed; and the knocking-over bar is connected with a main shaft via a connection rod. The looping mechanism of the artificial warp knitting machine is characterized in that the knocking-over bar is provided with a plate body; the plate body is equipped with at least two baffle blocks arranged side by side; a groove is formed in the middle of each baffle block; all the grooves are the same; a needle slot is formed by adjacent baffle blocks; and a latch needle elevates in the needle slot. The looping mechanism is mainly applied to knitting artificial lawns; latch needle elevating stroke is added, so knitting product achieved has tight structure and is firm and durable.

Owner:YANTAI DONGXING TEXTILE MACHINERY

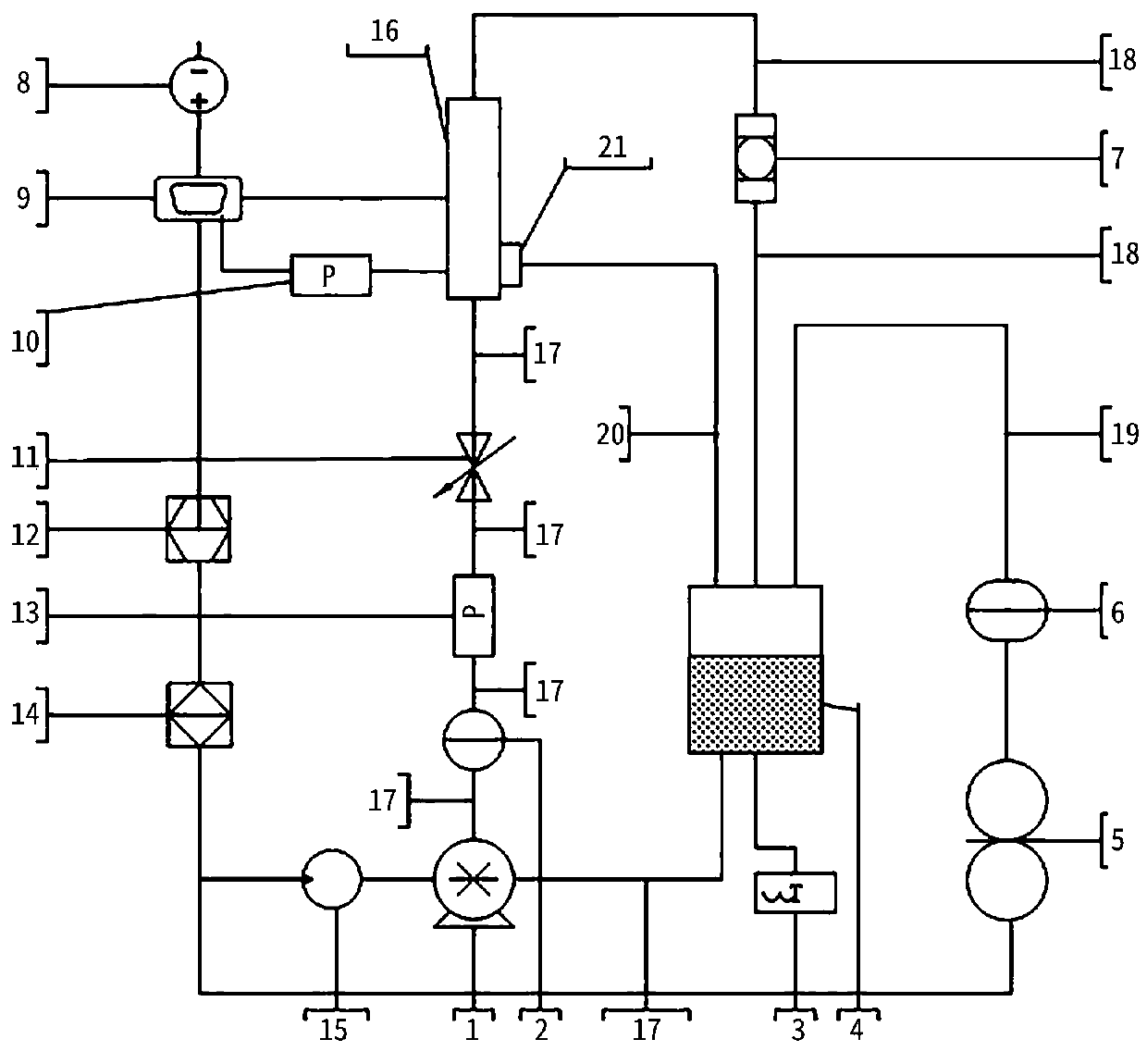

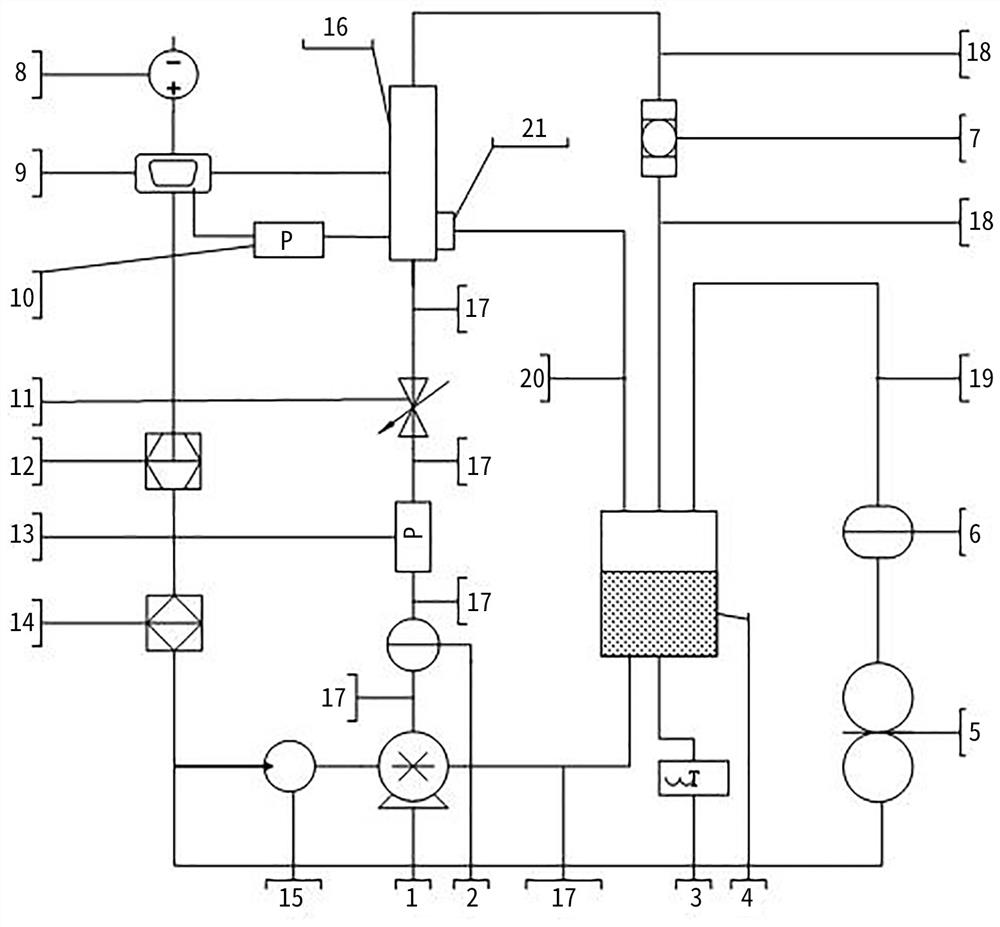

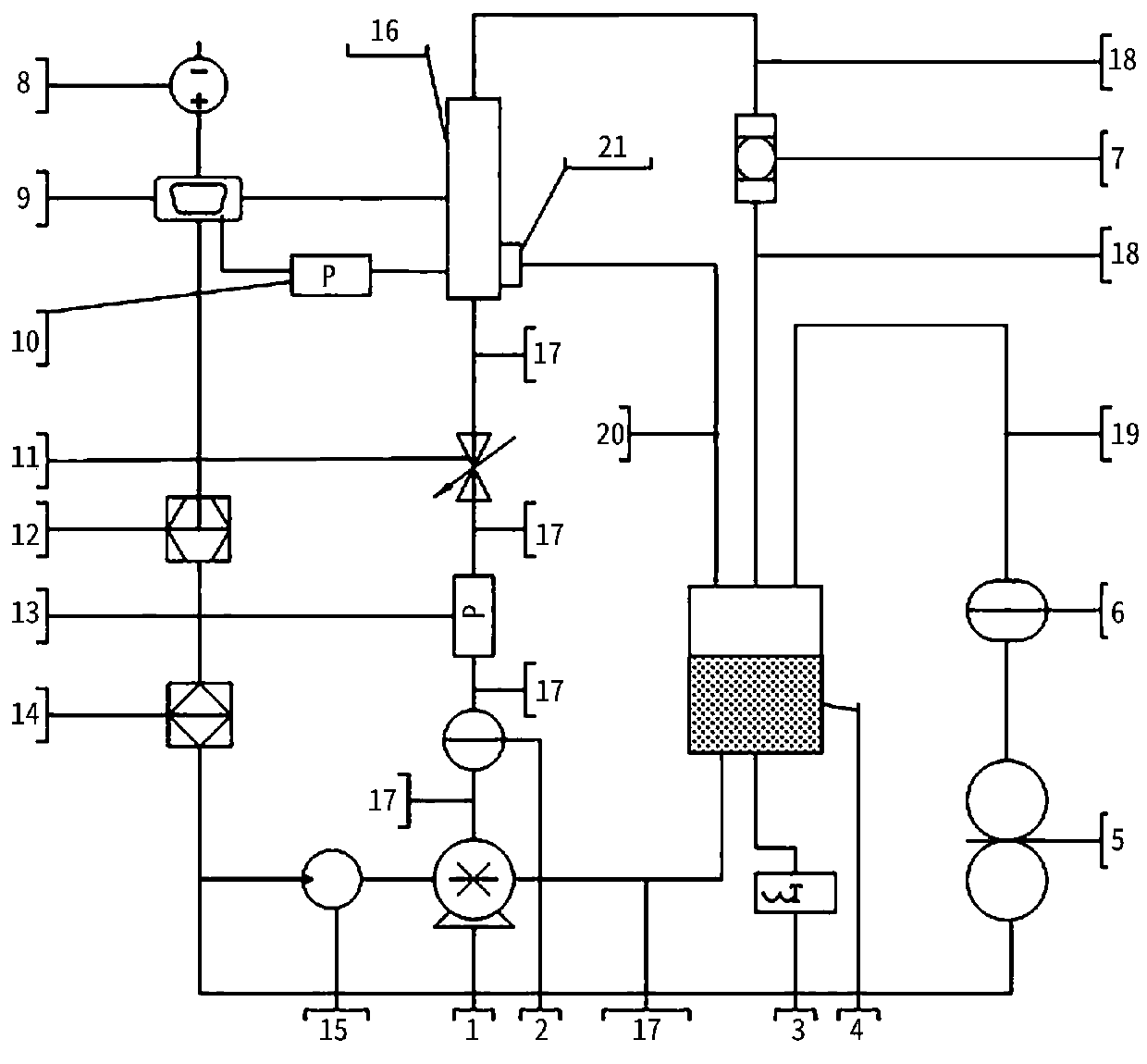

Vacuum oil filling method adopting vacuum oil filling device for petroleum drilling

ActiveCN109812469AMeet the requirements of vacuum oilingTiny air bubblesDirectional drillingFluid-pressure actuator componentsAutomatic controlPressure balance

The invention discloses a vacuum oil filling realization method adopting a vacuum oil filling device for petroleum drilling. A device main body comprises a circulation system, a vacuum system, an automatic control system and a vacuum pressure balance pipeline. The method mainly comprises the following steps: starting a vacuum pump through software, and carrying out adequate circulating vacuumizingon hydraulic oil according to a vacuum degree requirement at first; after a vacuum degree meets the requirement, connecting oil filling pipelines and oil return pipelines of a hydraulic module and the balance pipeline, and carrying out oil filling preparation; closing a stop valve, vacuumizing the hydraulic module through a part of the oil filling pipelines and the oil return pipelines, and the balance pipeline, and enabling the vacuum degree to reach 0.5mBar and below; and opening the stop valve, starting an oil filling pump through computer software, and carrying out oil filling according to automatic control of the computer control software. Firstly, the vacuum oil filling realization method adopting the vacuum oil filling device for petroleum drilling meets the requirement of vacuum oil filling for the rotary-guide hydraulic module; secondly, the method realizes the requirements of pressure balance and automatic control in an oil filling process; and thirdly, the method realizes the vacuum degree requirement of oil filling.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

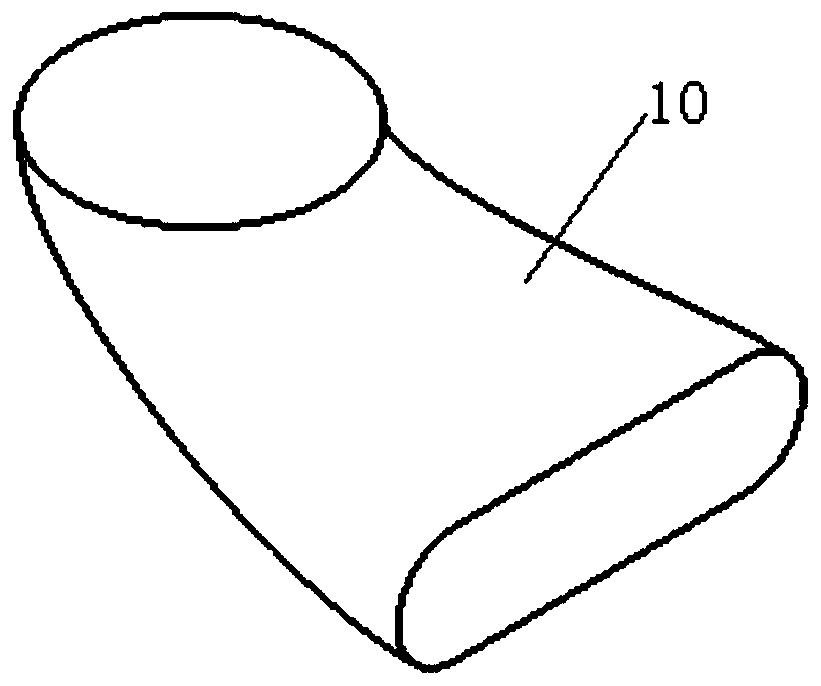

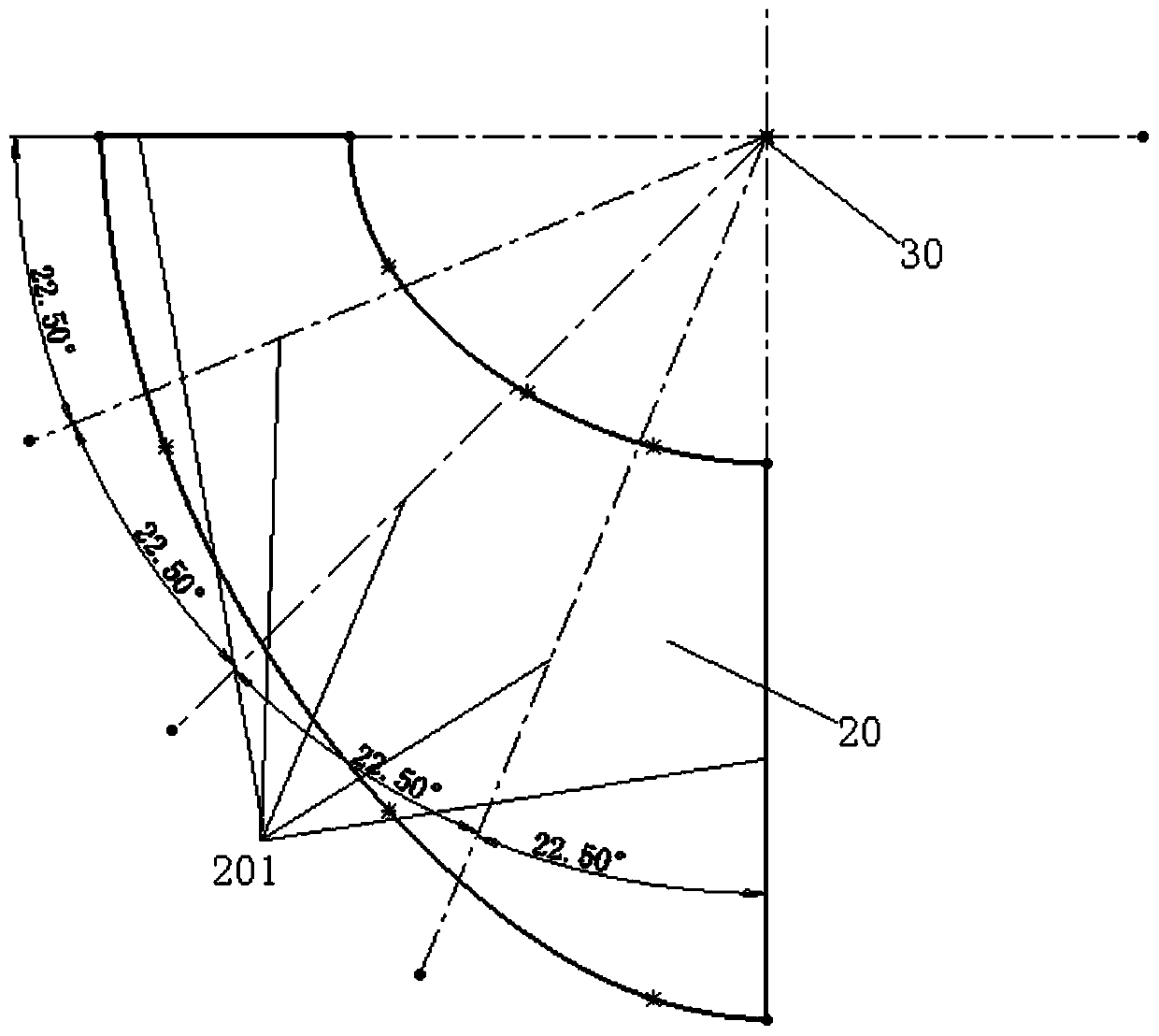

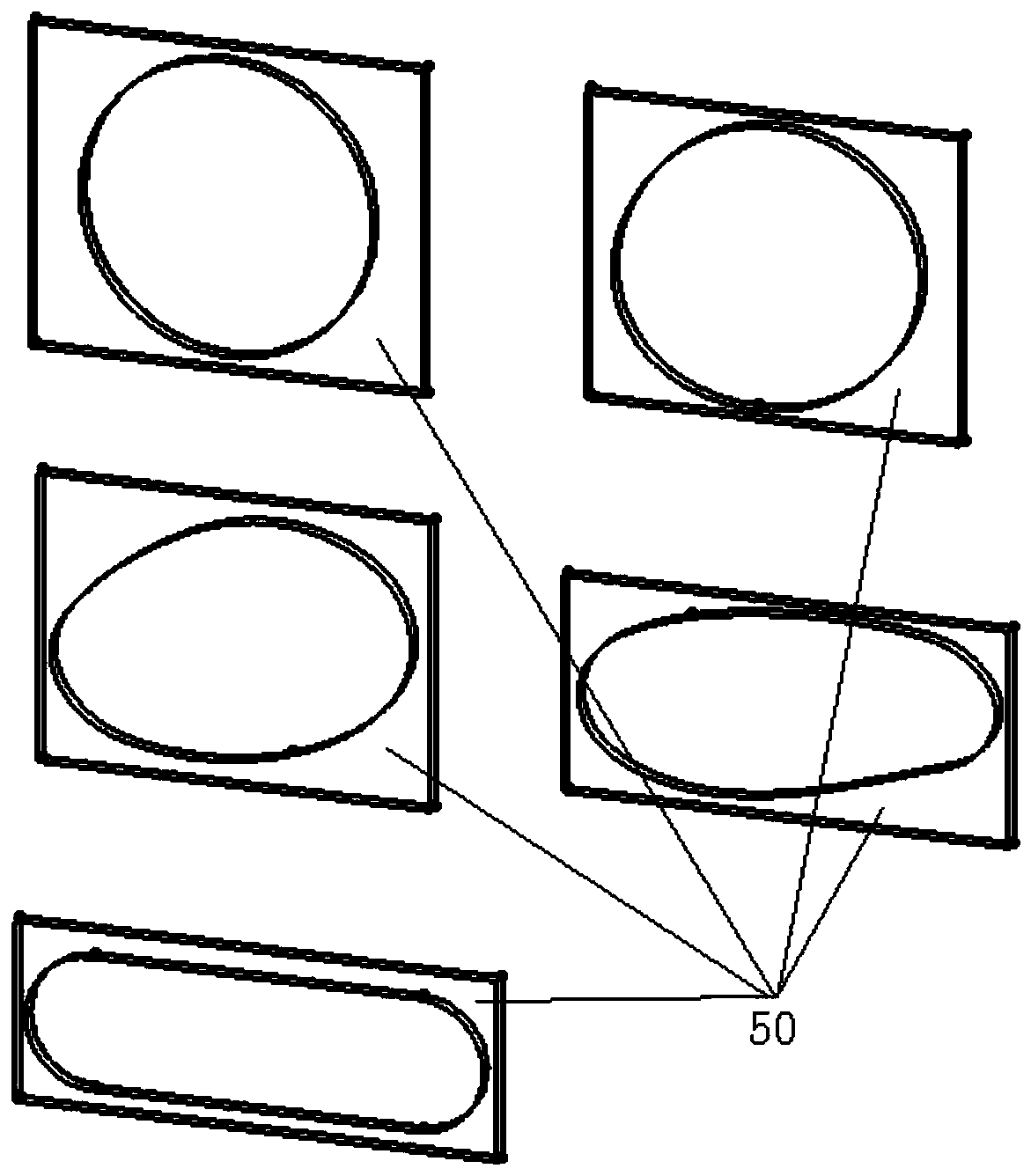

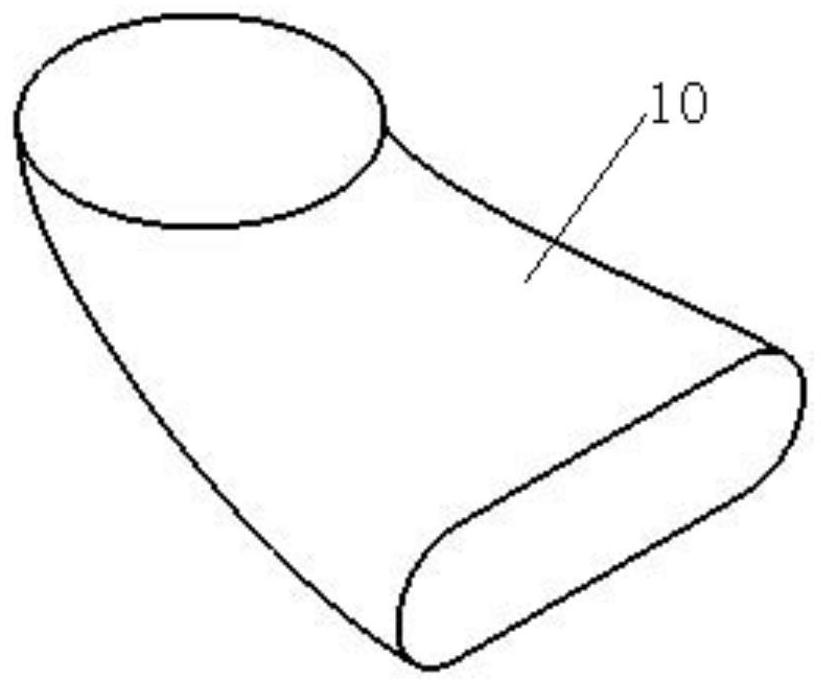

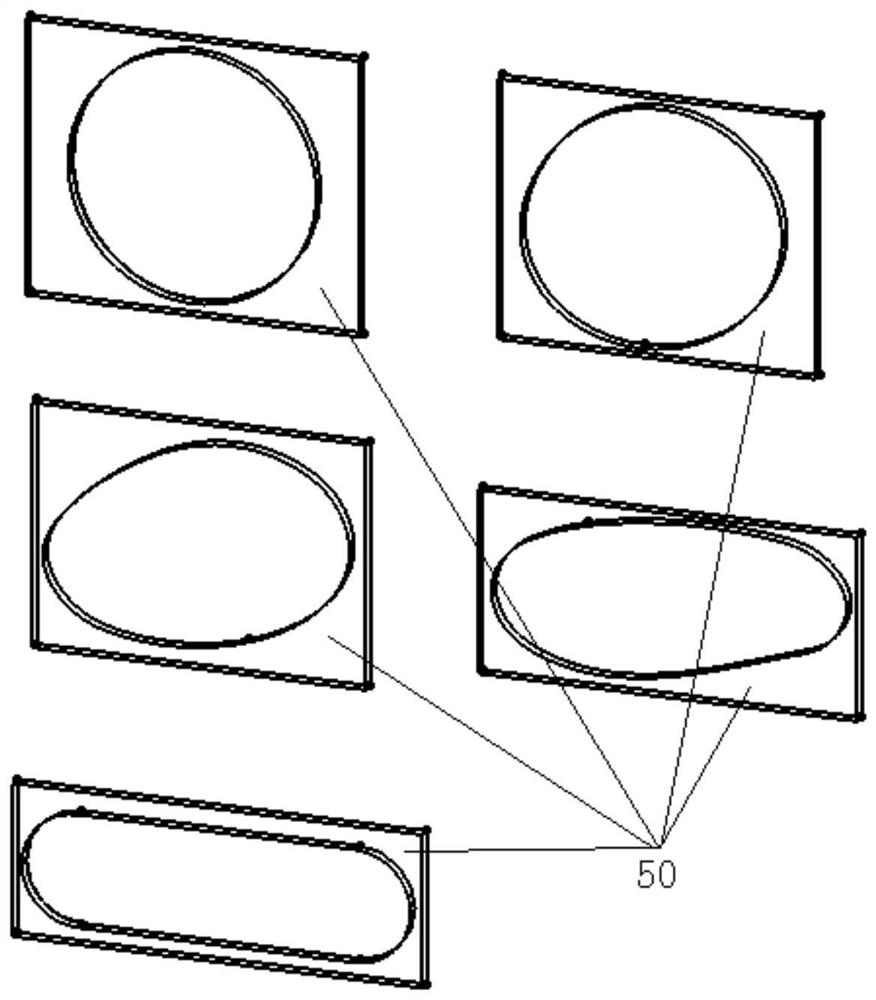

Manufacturing method of special-shaped metal air pipe

ActiveCN110280920ASolve preparation difficultiesLess patchworkGeometric CADDesign optimisation/simulationEngineeringWorkload

The invention discloses a manufacturing method of a special-shaped metal air pipe. The manufacturing method comprises the following steps of establishing an air pipe model of the air pipe to be manufactured in three-dimensional software according to a design drawing, and segmenting the air pipe model; establishing a coordinate system in the three-dimensional software so as to obtain the coordinates of each segmented section, and manufacturing an inner flange and outer flange of each segmented section according to the coordinates of each segmented section; simulating the established coordinate system to manufacture a coordinate frame, and positioning and fixing the outer flanges to the coordinate frame according to the coordinates of the segmented sections corresponding to the outer flanges; adopting a manual positioning and covering method to obtain an expanded pattern of each section of air pipe and then carrying out blanking, or using the three-dimensional software to unfold the model of each section of air pipe and then carrying out discharging; and fixing the inner flanges to the corresponding outer flanges, and then performing forming and group welding on all material plates, and dismounting each inner flange and outer flange and the coordinate frame after welding to obtain the air pipe to be manufactured. According to the manufacturing method, the workload of loading is small, results are accurate, the manufactured air pipe is small in joint seam, and the attractiveness is high.

Owner:CHINA HANGFA SOUTH IND CO LTD

Hoisting method for large-span hinged type herringbone steel arch

ActiveCN103276907BSolve the stiffness problemSolve technical problems with deformationBuilding material handlingWire ropeHinge joint

The invention provides a hoisting method for a large-span hinged type herringbone steel arch. The hoisting method comprises the steps of conducting hinge joint connection, setting hoisting points, installing hoisting rings, determining the lengths of hoisting steel wire ropes, hoisting and the like. According to the hoisting method for the large-span hinged type herringbone steel arch, due to integral and multipoint hoisting, the technical problems that hinge pin installation in high attitude is difficult, high in construction cost, low in working efficiency and the like are effectively solved. In addition, due to the facts that two hoists are used for hoisting, multipoint hoisting is adopted, and the hoisting points are set reasonably, the situation that the herringbone steel arch deforms due to lack of rigidity in the hoisting process is avoided. Due to the fact that the hoisting steel wire ropes with suitable lengths are selected, the installation angle of the herringbone steel arch is effectively controlled, and two column feet is made to be positioned on bases easily.

Owner:CHINA HUAYE GROUP

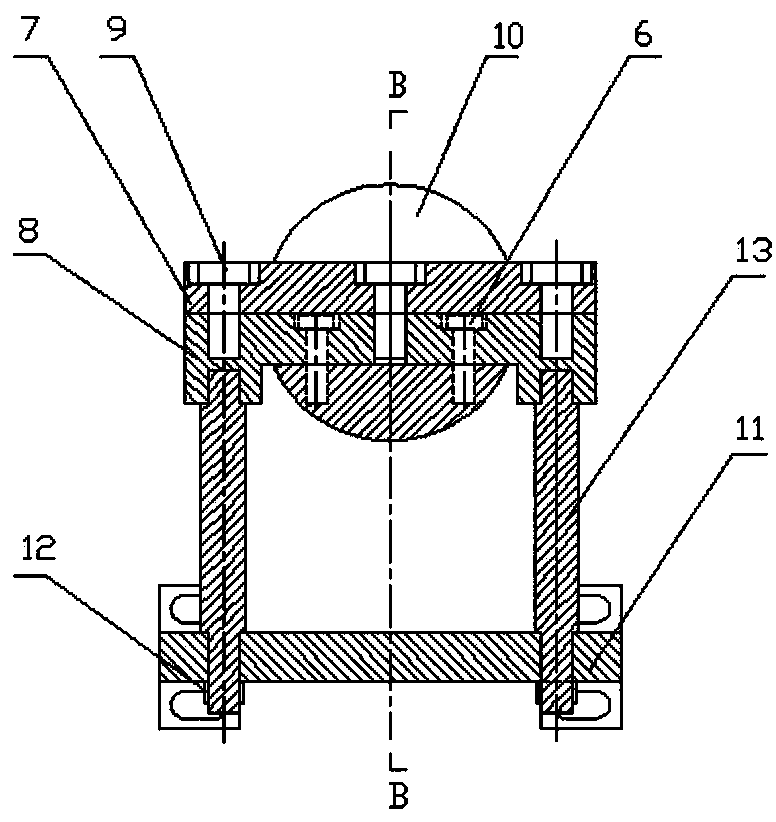

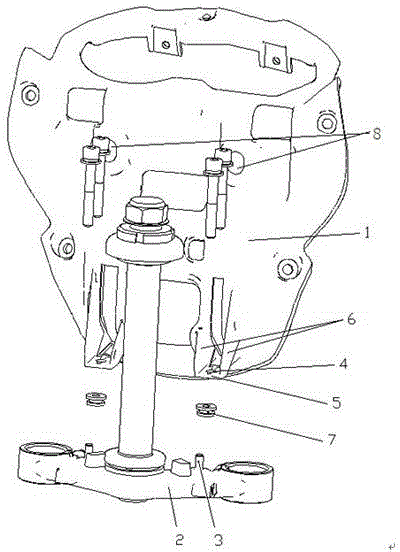

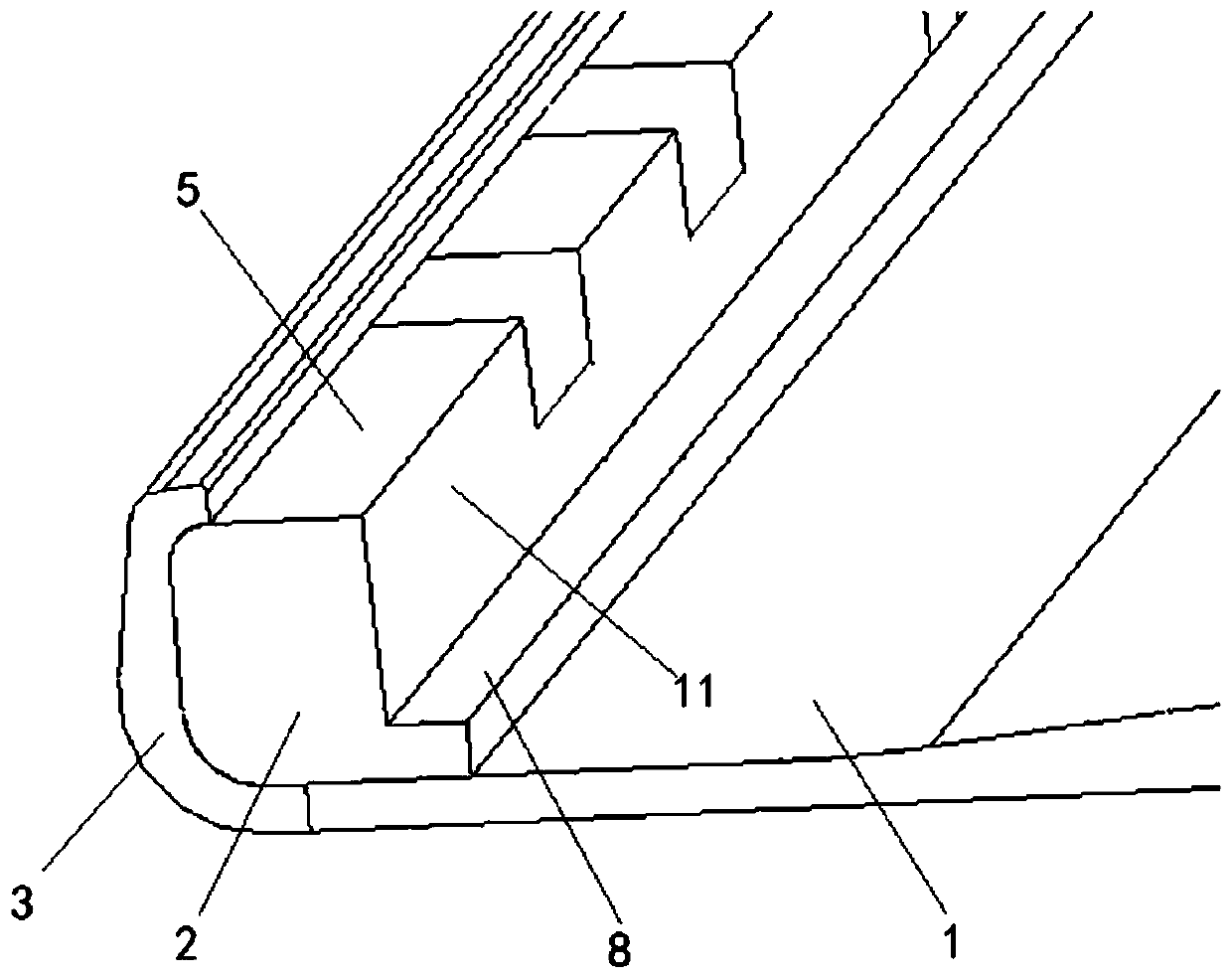

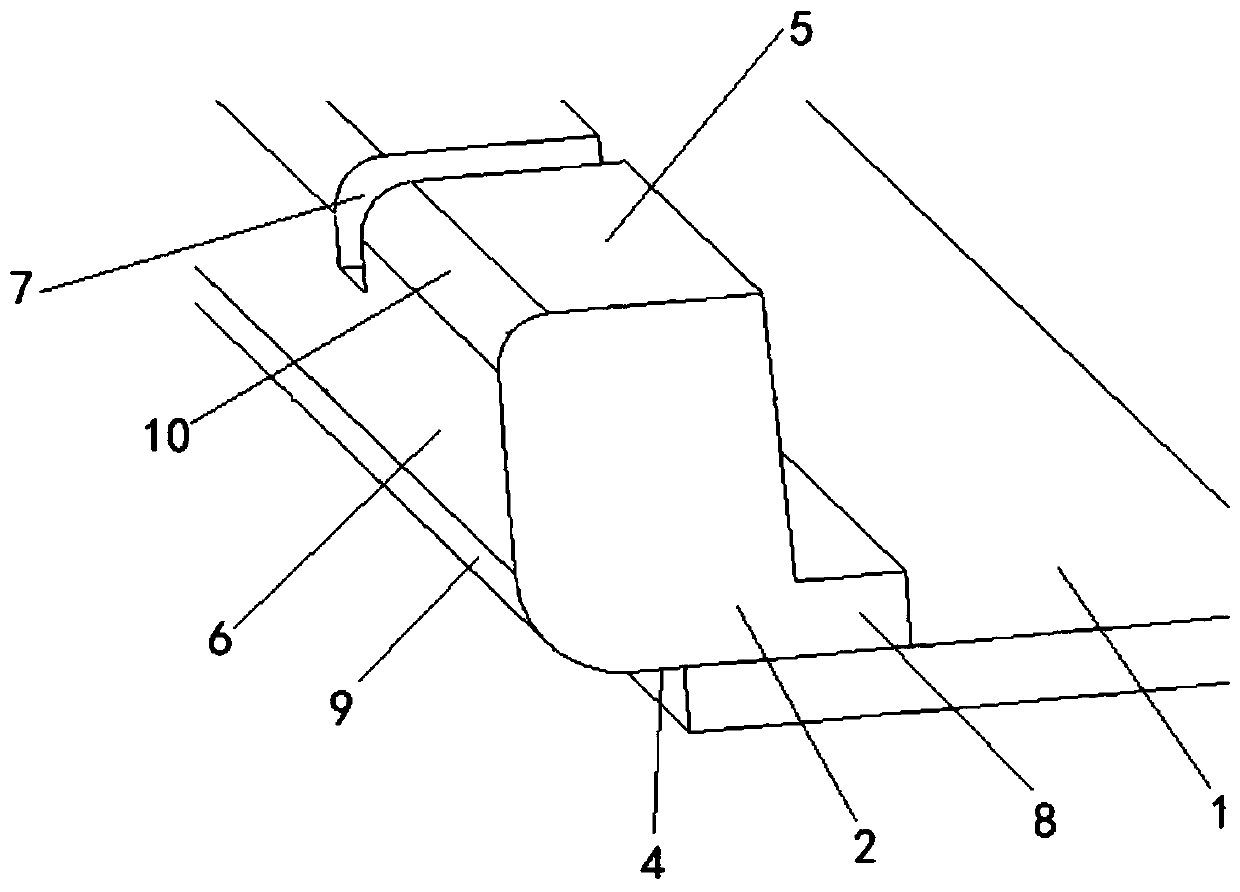

Four-jaw chuck for preventing workpiece deformation

PendingCN109226798APrevent extrusion deformationReduce contact areaChucksThin shellsLinear displacement

The invention provides a four-jaw chuck for preventing workpiece deformation, which comprises a chuck body, claws and a claws equidistant linear displacement mechanism wherein a positioning surface and a clamping surface mutually vertical to each other are respectively arranged at the front end of a claws centripetal displacement mechanism; and the workpiece is contacted with a first-step concavetable formed by the clamping surface and the positioning surface; and the first-stage concave table is matched to the corresponding right-angle part of the periphery of the thin shell side wall of theworkpiece; wherein the positioning surface is tightly attached and supports the bottom of the workpiece; the clamping surface is tightly attached to the side wall of the thin shell at the periphery of the workpiece; and an inner concave avoiding groove for reducing the contact area is arranged at the contact area of the clamping surface and the side wall of the thin shell at the periphery of theworkpiece. The four-jaw chuck for preventing a workpiece deformation is characterized by not only ensuring the stability, the square linearity and the centering parallelism of the four-jaw chuck in the process of clamping the square workpiece, but also more effectively preventing the deformation of the clamped thin shell workpiece, and being particularly suitable for the processing application ofsquare thin shell parts.

Owner:SHAANXI HALET PRECISION MACHINERY

A water pipe carrying device of an automobile radiator core assembly machine

InactiveCN103522032BRelieve pressureSolve the technical problem of deformation caused by excessive hitting forceVehicle componentsMetal working apparatusAssembly machineHeat spreader

A water tube bearing device of a vehicle radiator core assembling machine mainly comprises a pressing cylinder, a pressing block, a bearing cylinder, a water tube bearing block and a photoelectric sensor. By means of the pressing function of the pressing block and the supporting function of the bearing block, most of radiator water tubes in a tube bin of the assembling machine can be controlled to be arranged on the bearing device and above the bearing device, and therefore few water tubes are reserved at the bottom of the tube bin, and the technical problem that the bottommost water tube is prone to being deformed in the striking process due to too large pressure is effectively solved. When the water tubes at the bottom of the tube bin are reduced to a certain number, the photoelectric sensor arranged at the bottom sends out a signal, the water tube bearing block and the pressing block move forward and backward step by step to release a part of the water tubes to the bottom of the tube bin, and meanwhile the water tubes above the bearing block fall onto the bearing block so as to guarantee continuity of work.

Owner:YANCHENG INST OF TECH

A surface vacuum oil injection device for oil drilling rotary steerable tools

ActiveCN109958395BMeet the requirements of vacuum oilingTiny air bubblesPump testingPump assembliesAutomatic controlPressure balance

The invention discloses a ground vacuum oiling device for oil drilling rotary steering tools. A device body comprises a circulation system, a vacuum system, an automatic control system and a vacuum pressure balance pipeline. The circulation system comprises an oiling motor, an oiling pump, a granulometer, an oil pressure gauge, a stop valve, a filter, an oil tank, an oil inlet pipeline, an oil returning pipeline and a quick coupling connected with the pipelines; the vacuum system comprises a vacuum pump, a vacuum gauge, a vacuum degree display unit, a connection pipeline and a connection joint; the control system comprises a computer, a programmable logic controller, and a driving circuit power supply; the vacuum pressure balance pipeline comprises a pressure balance pipeline, a pipeline joint and a balance joint; a rack structure of the circulation system, the vacuum system and the control system is installed; and a temperature display unit and a force display unit are installed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

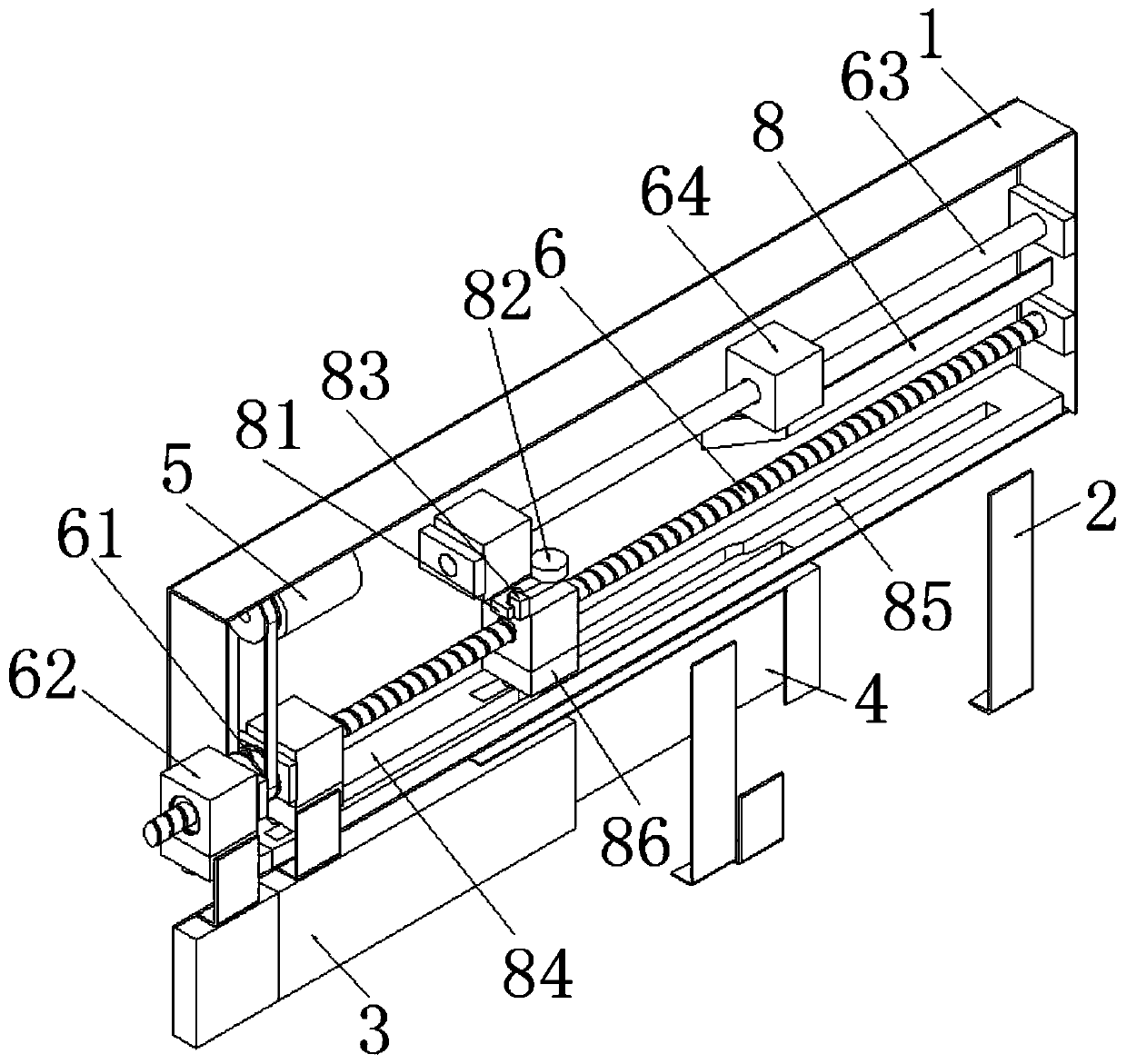

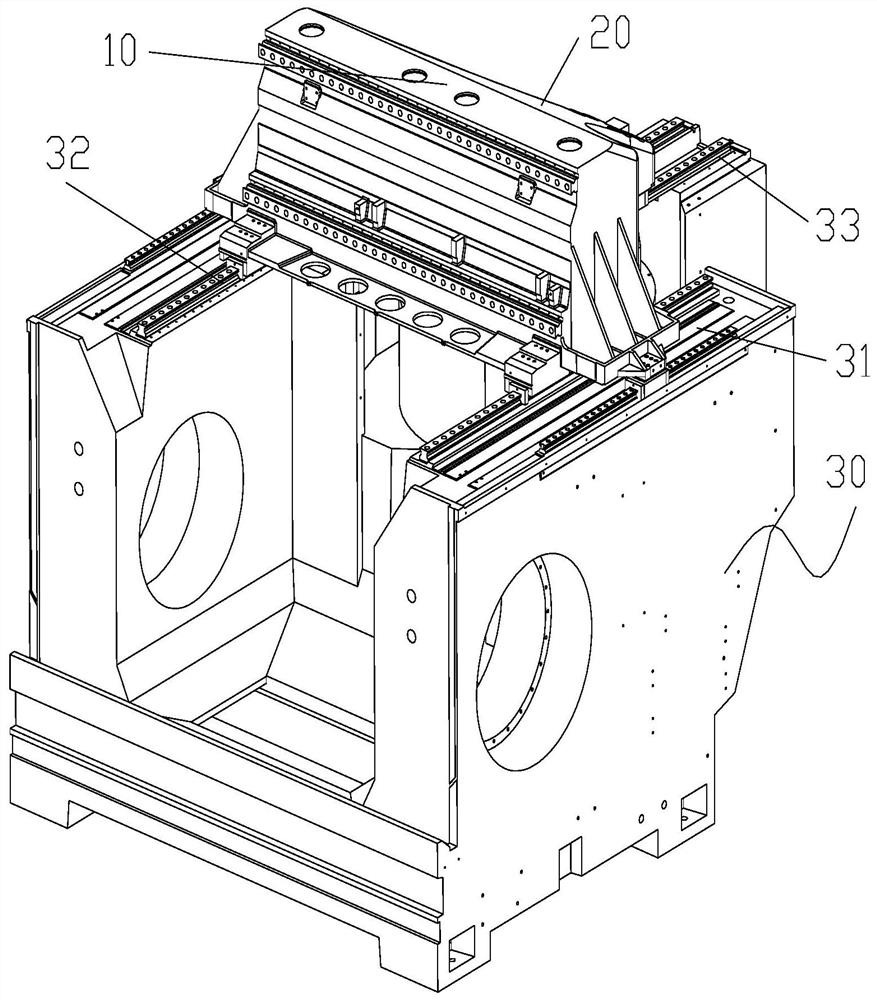

Cross beam structure and machine tool having same

PendingCN111687648ASolve the stiffness problemSolve technical problems with deformationLarge fixed membersEngineeringMachine tool

The invention provides a cross beam structure and a machine tool having same. The cross beam structure comprises a first support portion and a second support portion, wherein the first support portionextends in a first preset direction, and is provided with a first support end and a second support end oppositely arranged; the second support portion is disposed on the first support portion, and extends in a second preset direction; the second preset direction and the first preset direction are arranged by a preset angle; the second support portion is provided with a connection end and a thirdsupport end oppositely arranged; the connection end is connected to the first support portion; and the third support end is positioned between the first support end and the second support end to implement supporting by means of the first support end, the second support end and the third support end, so that the technical problem of deformation caused by insufficient rigidity of a cross beam structure in the prior art is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Framed plate for electronic equipment and plastic forming method

PendingCN111148396ASmall degree of deformationReduce usageCasings/cabinets/drawers detailsHermetically-sealed casingsEngineeringUltimate tensile strength

The embodiment of the invention provides a framed plate for electronic equipment and a plastic molding method. The framed plate is used for manufacturing a shell of an electronic device, and the framed plate comprises a plate body, a frame body and a first plastic body; the frame body is fixed on the edge of the upper surface of the plate body, and the frame body comprises a first edge, a second edge, a first surface, a second surface, M first grooves and N second grooves, wherein the M first grooves are formed in the first edge; the N second grooves are formed in the second edge; the first plastic body wraps the first surface, the second surface and the second edge, fills the first groove and the second groove, and is connected with the side edge of the plate body, wherein M and N are 0 or positive integers. According to the invention, the technical problems that in the prior art, plastic is directly poured into the edge of a plate, the shrinkage amount is large after plastic forming,and plate deformation is likely to be caused are solved, and the technical effects of enhancing the mechanical strength of the edge of the plate, reducing the plastic consumption and reducing the plate deformation degree are achieved.

Owner:合肥山秀碳纤科技有限公司

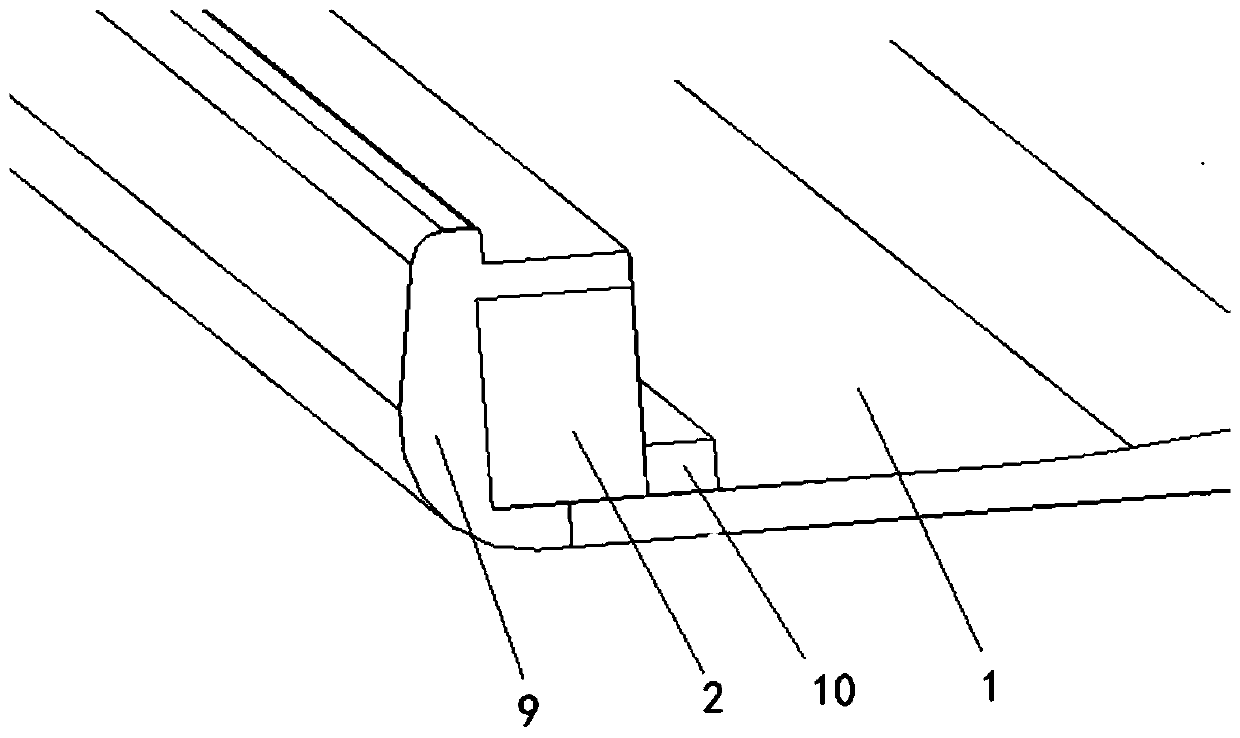

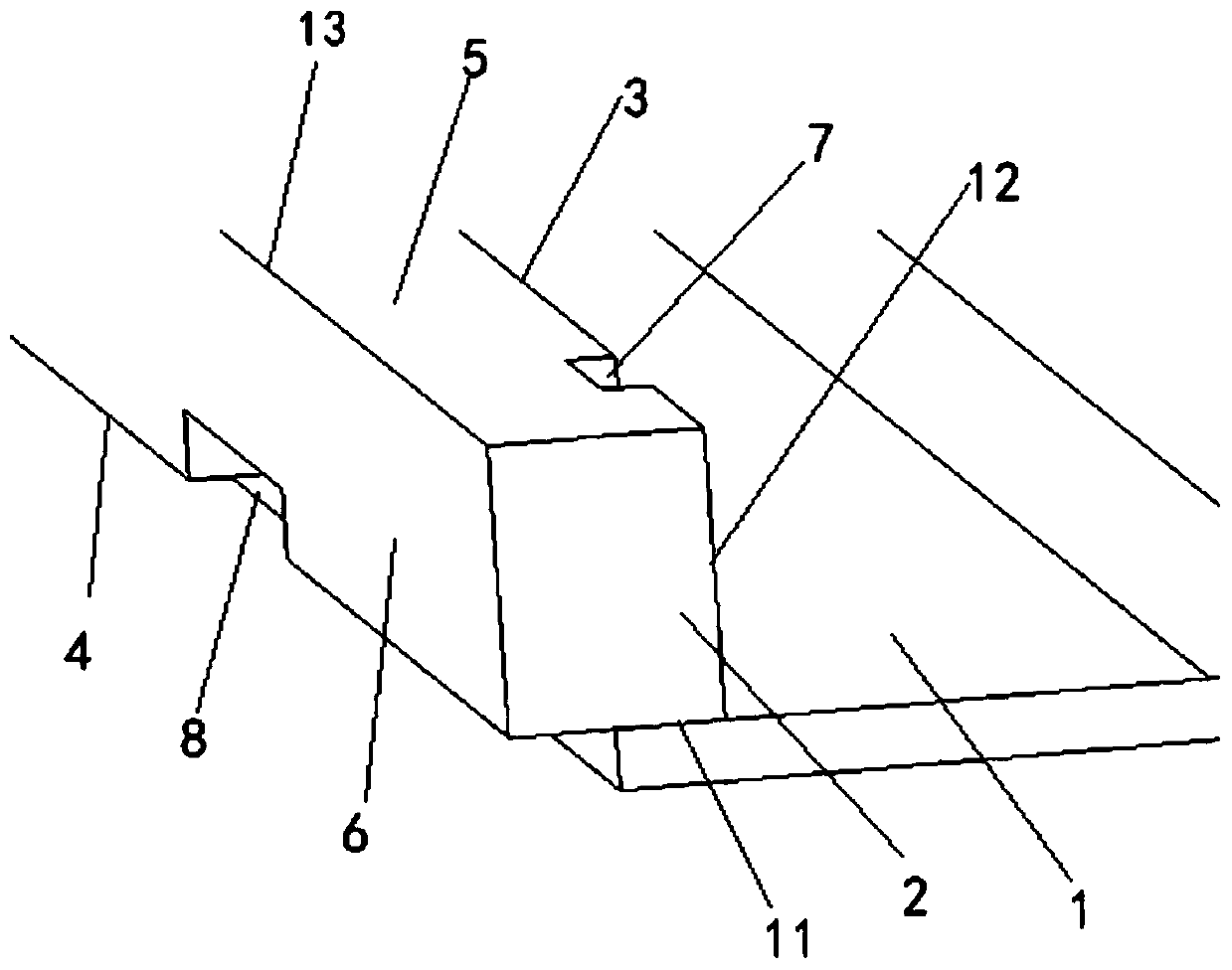

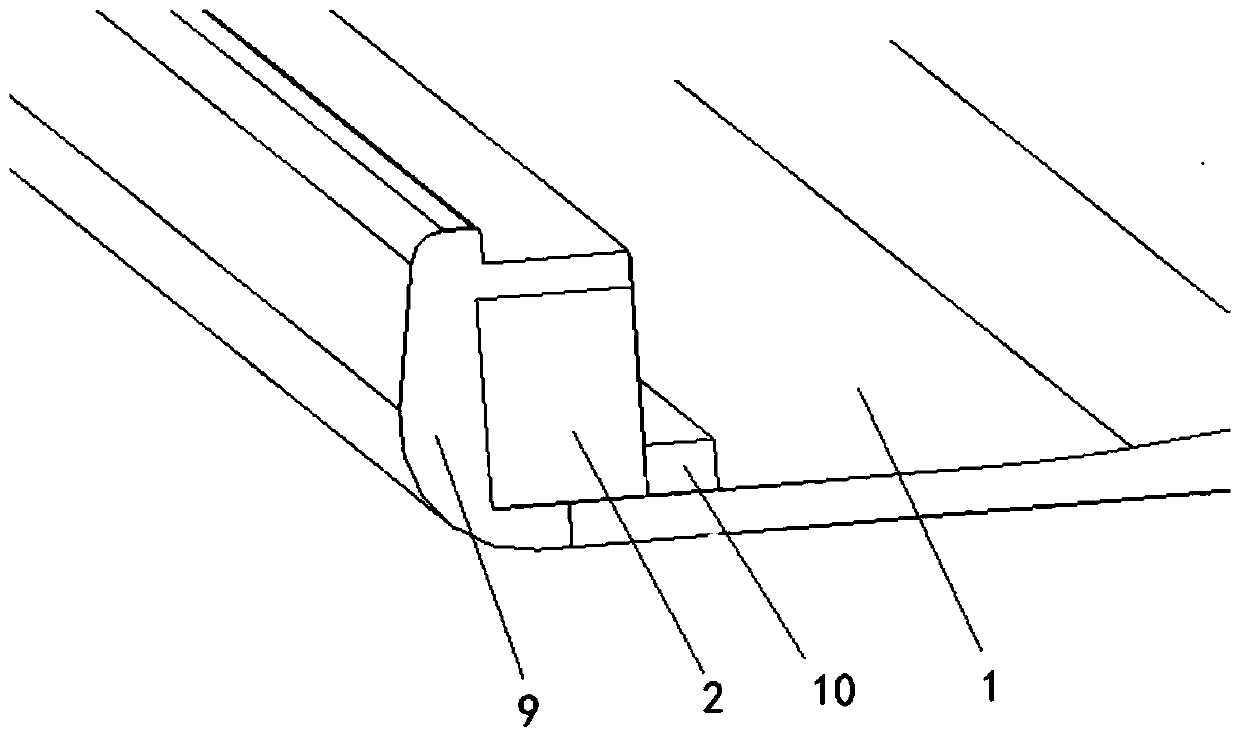

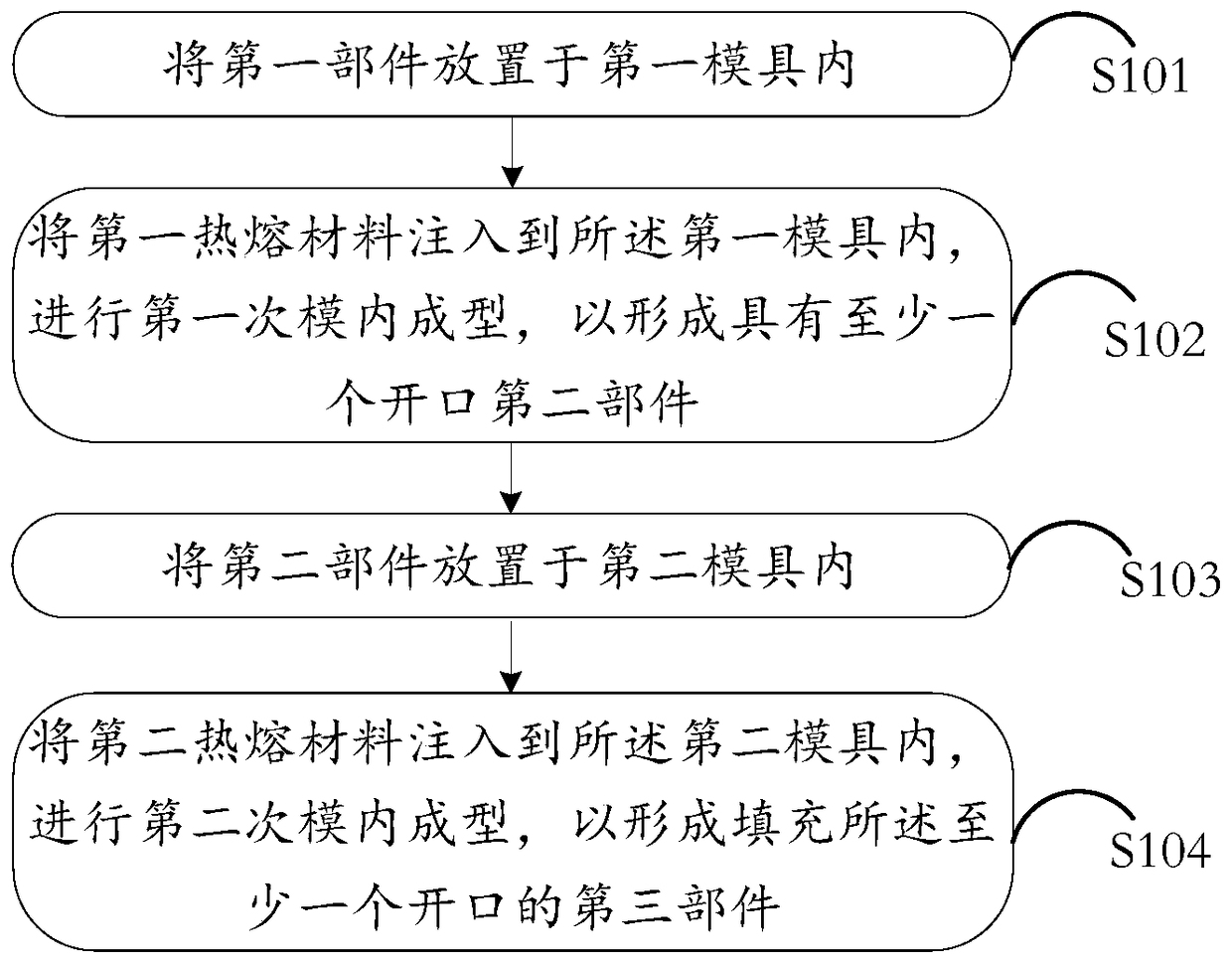

In-mold forming method and in-mold forming equipment

The invention discloses an intra-die forming method and intra-die forming equipment. The method comprises the following steps: putting a first component into a first die; pouring a first hot melting material into the first die to carry out first time of intra-die forming, so as to form a second component with at least one opening; putting the second component into a second die; and pouring a second hot melting material into the second die to carry out second time of intra-die forming, so as to form a third component for filling up the at least one opening, wherein the third component is the first intra-die forming equipment. The method disclosed by the invention is used for solving the technical problem of a one-time intra-die forming technology that relative great stress is generated between plastic components, carbon fiber plates or metal parts in the prior art, thus achieving the technical effect of reducing the stress between the plastic components, the carbon fiber plates or the metal parts during intra-die forming.

Owner:LENOVO (BEIJING) LTD

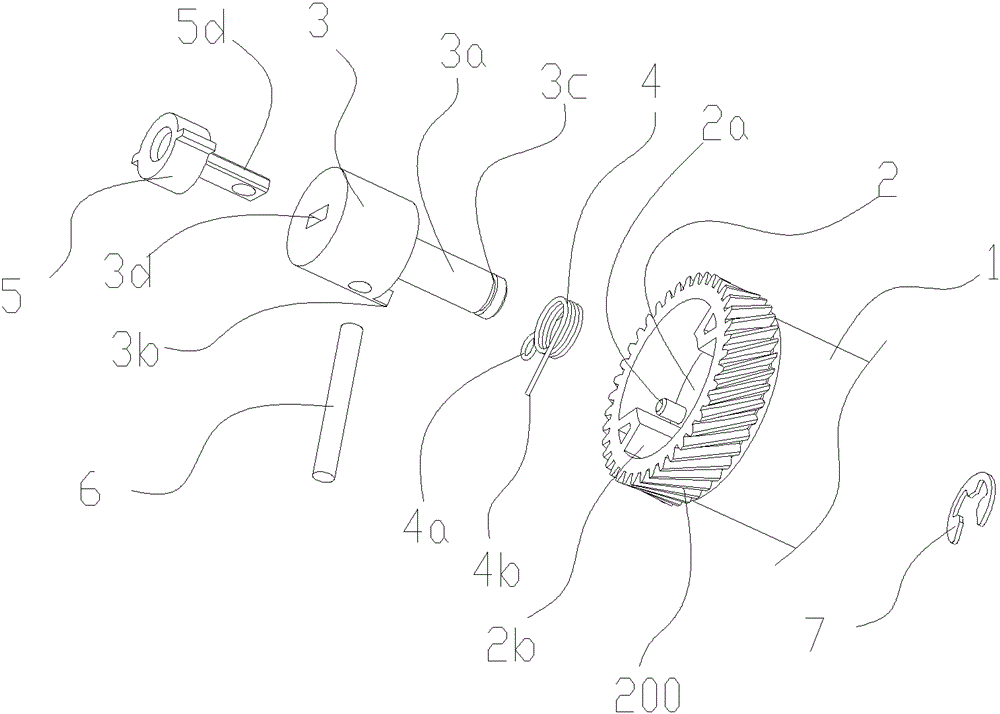

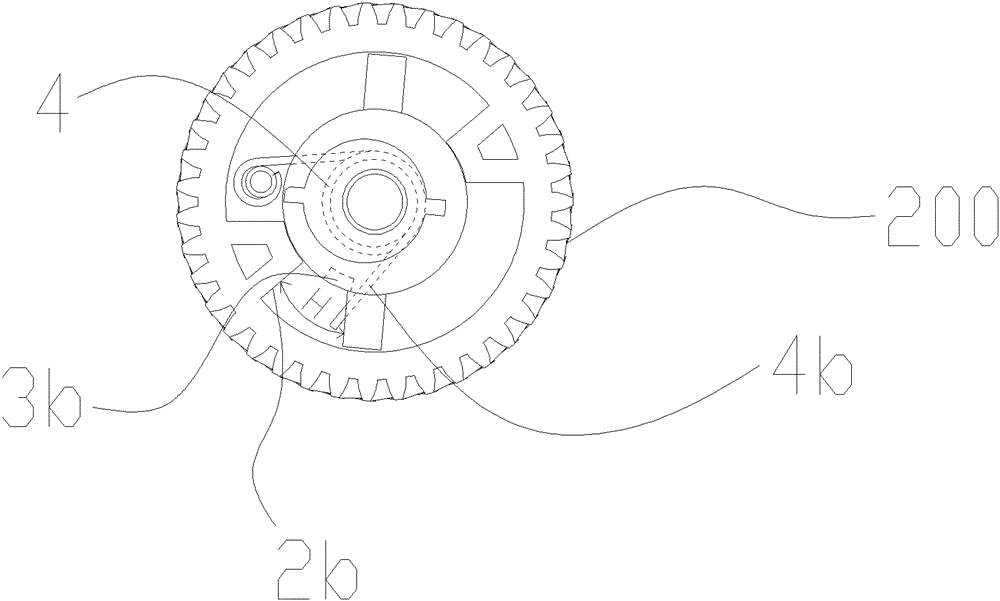

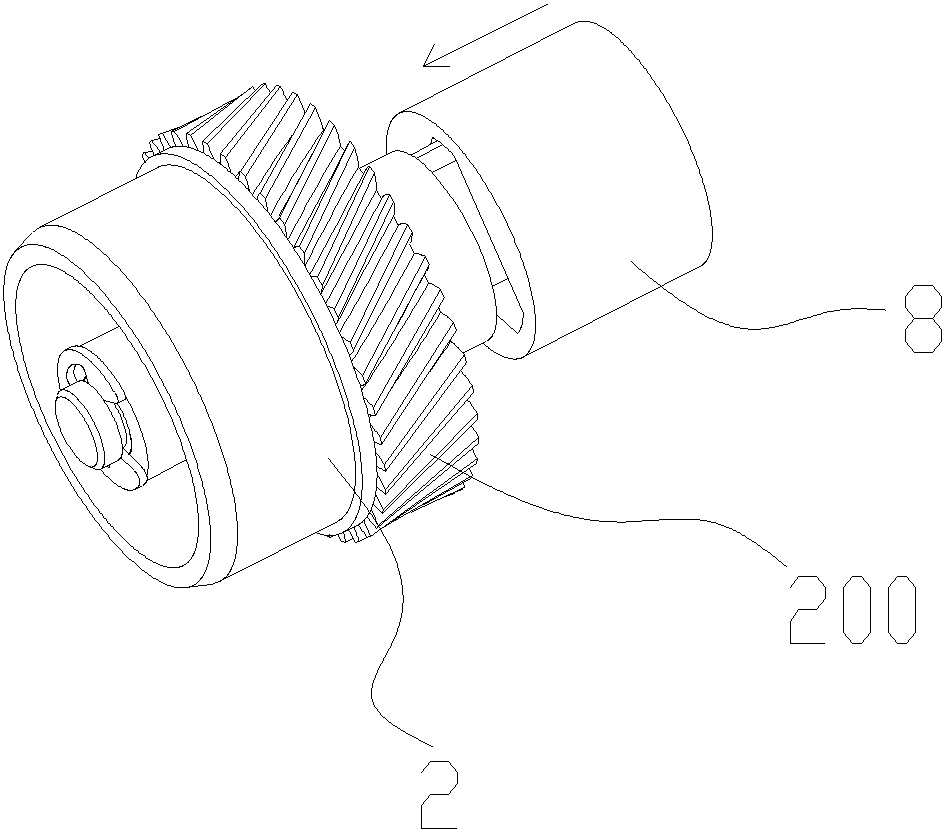

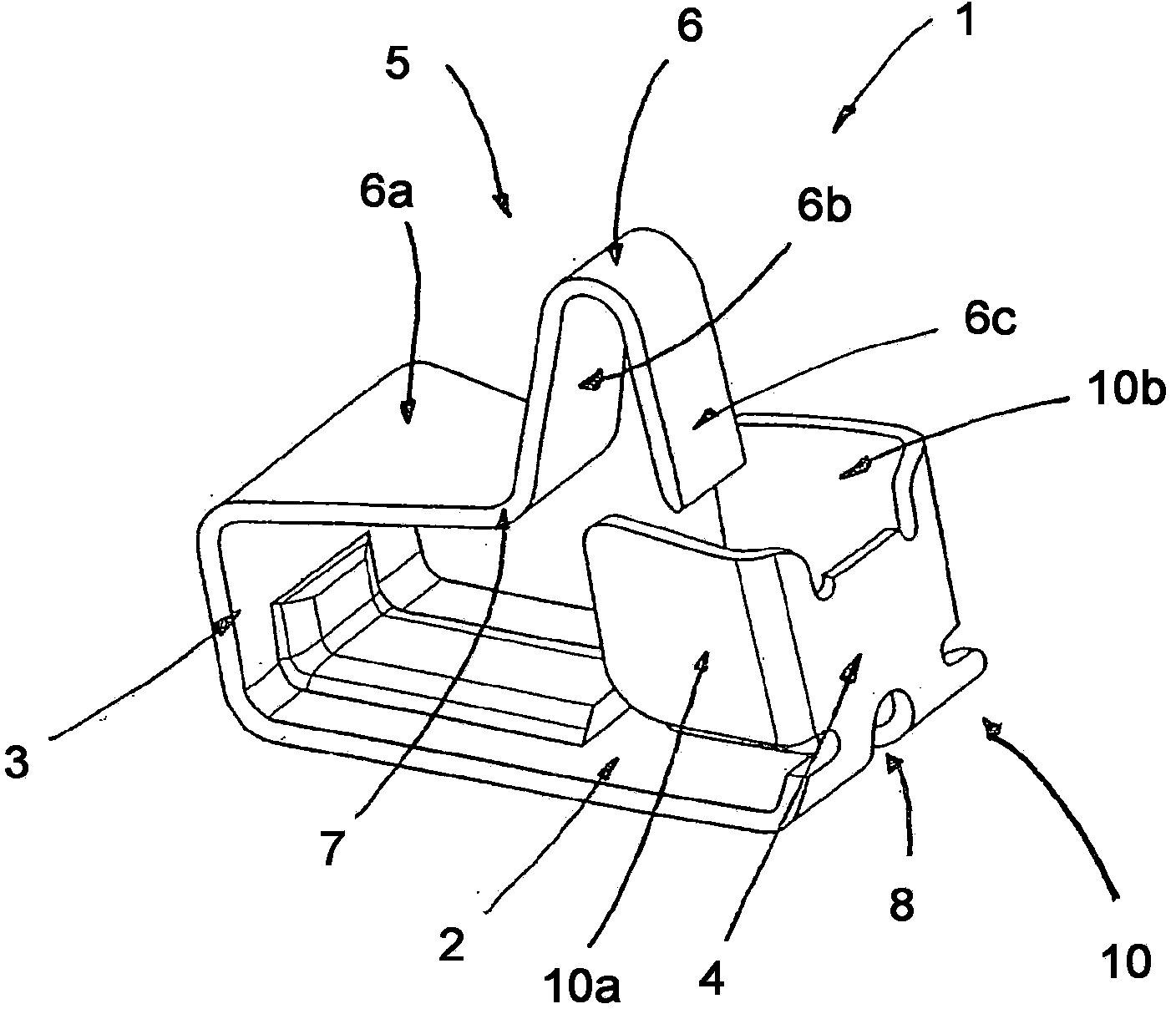

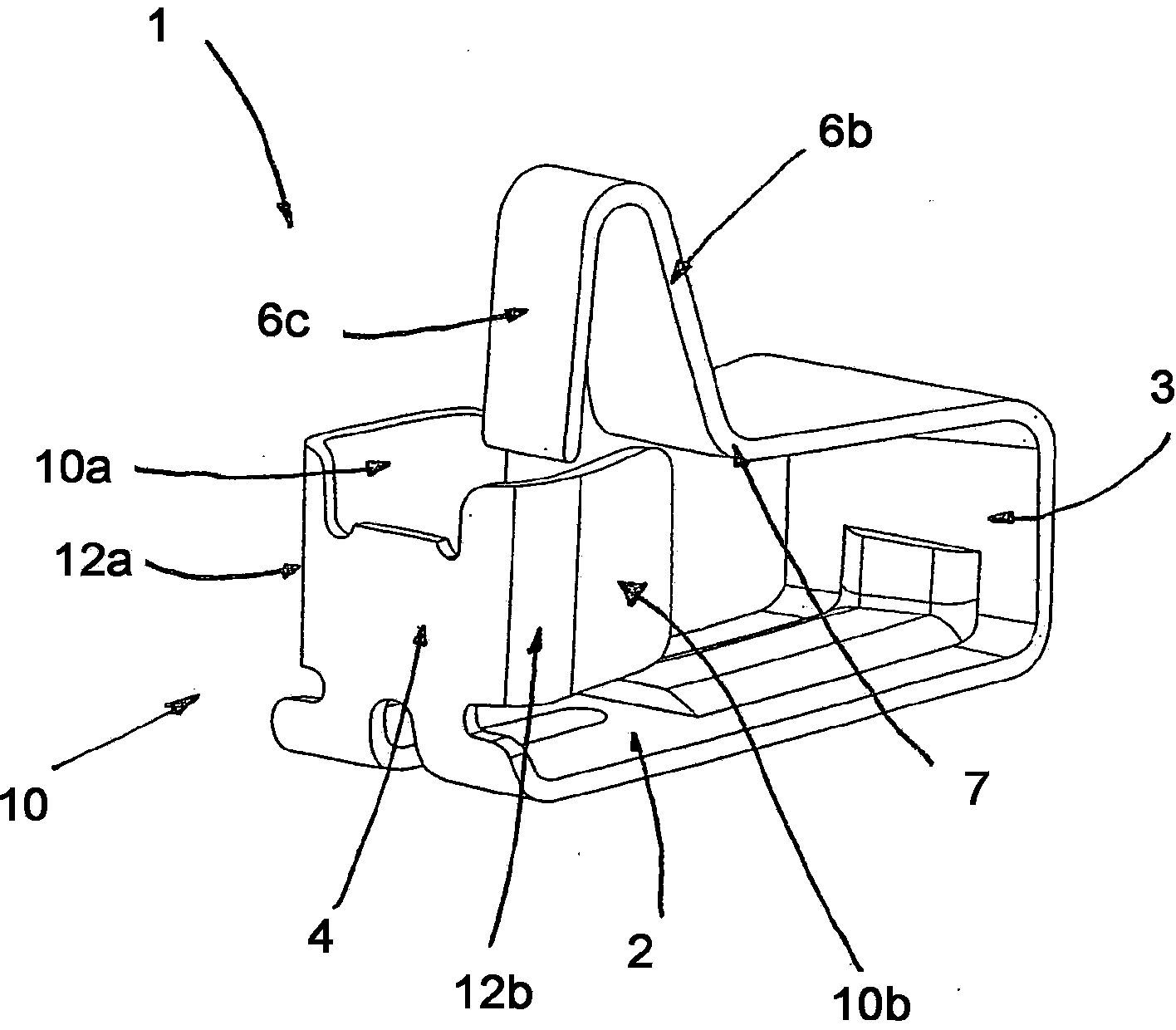

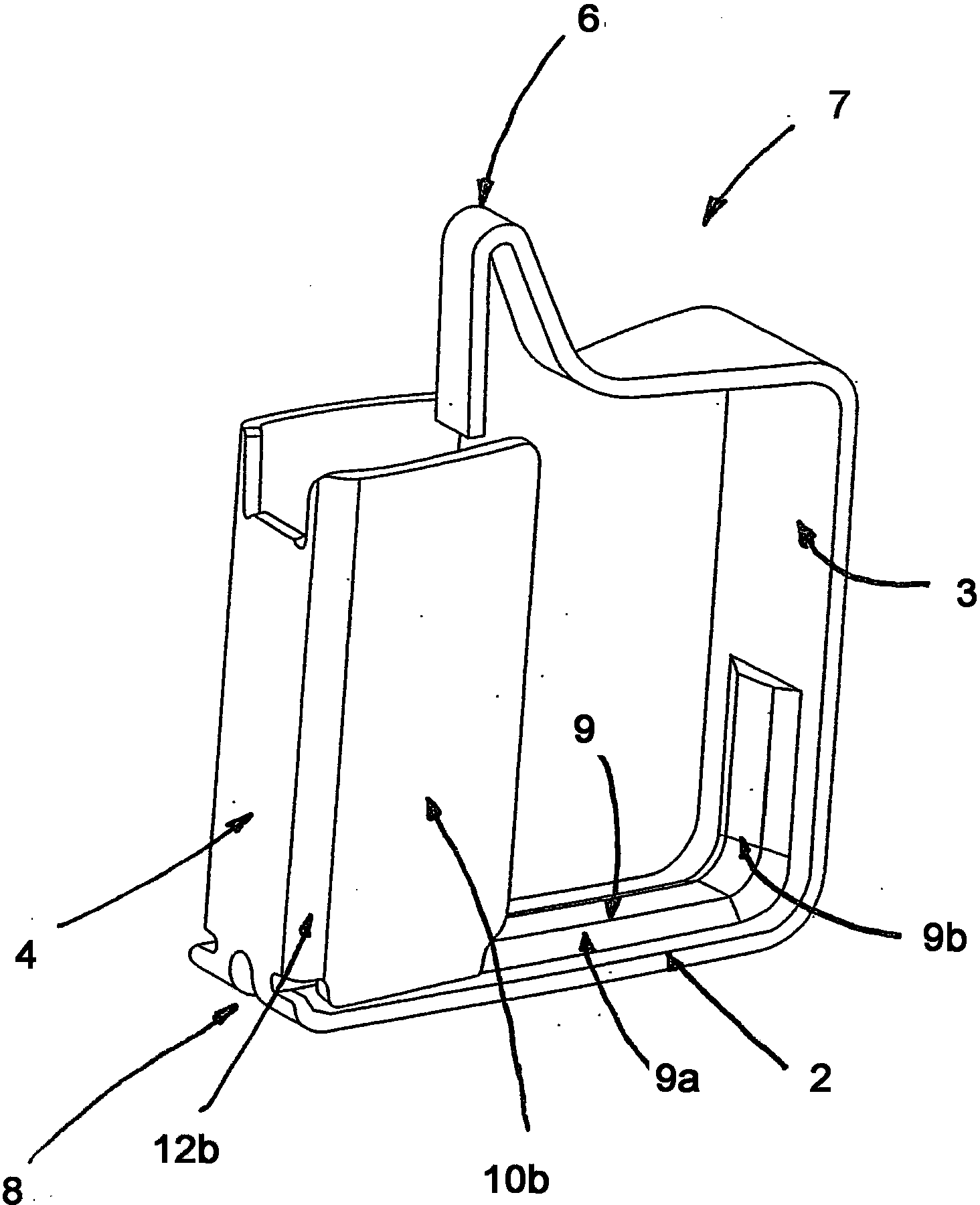

A driving assembly in a processing box and a processing box including the driving assembly

ActiveCN103135385BReduce shakingIncrease contact areaElectrographic process apparatusEngineeringFlange

The invention relates to a driving assembly in a processing box anda processing box with the driving assembly; the driving assembly comprises a flange, a power transmission mechanism located in the flange, and an elastic element disposed between the flange and the power transmission mechanism for resetting; the flange comprises a pair of flange force-bearing parts which are symmetrically distributed radially; the power transmission mechanism comprises a power transmission member, a support column, an elastic element force-bearing part, a power receiving part, a pair of force transmission parts which are symmetrically distributed radially, and a support disc; the power transmission member is sleeved by the support disc. The power transmission member is supported by the support disc and the support column, so sloshing of the power transmission member generated during rotation relative to the flange is reduced.

Owner:NINESTAR CORP

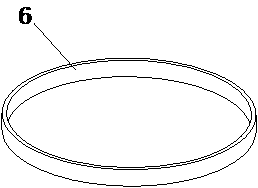

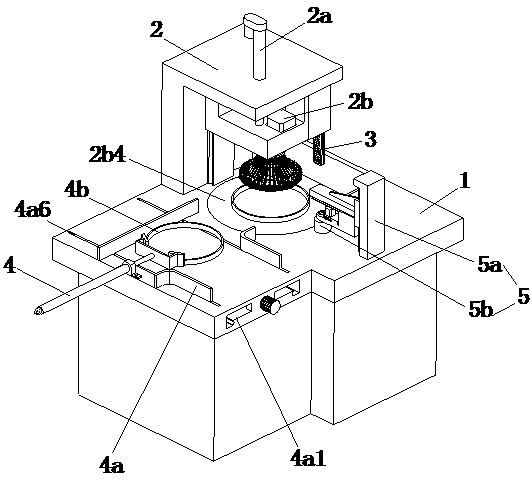

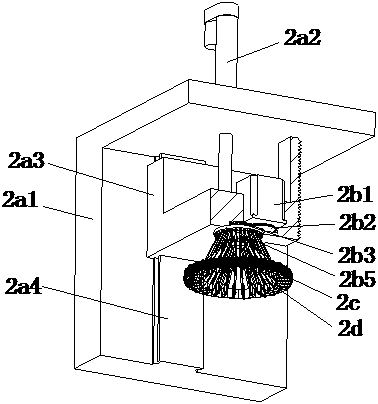

A processing device for ring metal parts

ActiveCN111230643BReceived expansion forceAvoid deformationEdge grinding machinesGrinding drivesPolishingEngineering

The invention discloses a processing device for ring-shaped metal parts, which belongs to the technical field of mechanical processing equipment and includes a workbench, a positioning mechanism, a limit mechanism, a feeding mechanism and a polishing mechanism. The positioning mechanism includes a lifting component, a connecting component, several positioning assembly and several reset assemblies, the connecting assembly is installed at the lower end of the lifting assembly, several positioning assemblies are distributed on the side of the connecting assembly in a circle, several reset assemblies correspond to several positioning assemblies one by one, each reset The components are installed above the corresponding positioning components, the feeding mechanism includes an adjusting component and a feeding component, and the polishing mechanism includes a moving component and a polishing component. The present invention can fix and process ring-shaped workpieces with a small difference between inner and outer diameters without deformation of the workpiece during fixing. The same equipment can process ring-shaped workpieces of different sizes. The present invention also has the characteristics of low positioning accuracy. Can reduce costs.

Owner:廊坊利国机械设备科技有限公司

Manufacturing method of centrifugal vapor compressor diffuser

ActiveCN104227359BSolve technical problems with deformationImprove profileCoordinate-measuring machineEngineering

The invention provides a manufacturing method of a centrifugal vapor compressor diffuser. The method comprises the following steps: performing heat treatment on a blank; roughly turning the end surface, excircle, inner bore and second step end surface of a large end of a diffuser; roughly turning the end surface, excircle, inner bore and first step end surface of a small end of the diffuser; drilling and milling a locating hole in the edge of the end surface of the large end, mounting a milling tool, locating by virtue of the locating hole, and roughly milling a blade on the small end; performing half finish turning on the end surface, excircle, inner bore and first step end surface of the small end of the diffuser; performing half finish turning on the end surface, excircle, inner bore and second step end surface of the large end of the diffuser; mounting a milling tool, locating by virtue of the locating hole, performing fine milling on the blade, and delivering the product into a coordinate measuring machine for inspection after fine milling is finished; if the product is qualified, marking center lines for drilling on the end surfaces of the large and small ends and the first step end surface; aligning the center liens; drilling and threading; finely turning the end surface and inner bore of the large end of the diffuser; performing draw filing on the bottom of a blade passage; performing penetrant inspection on the blade.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

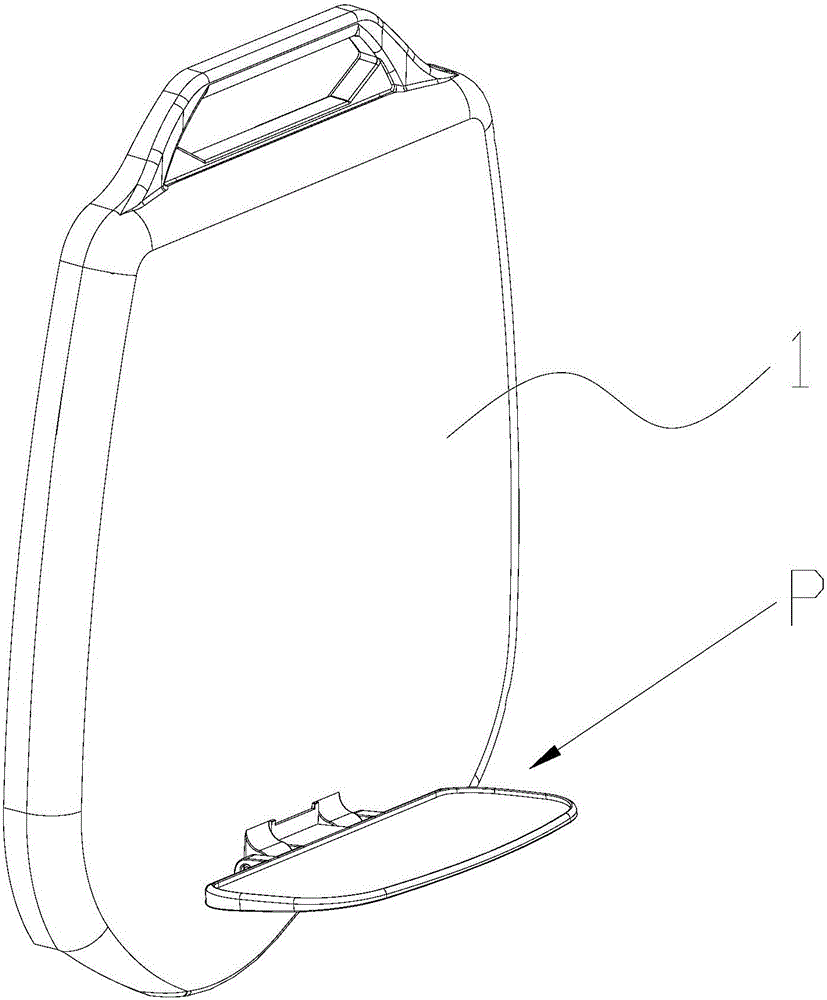

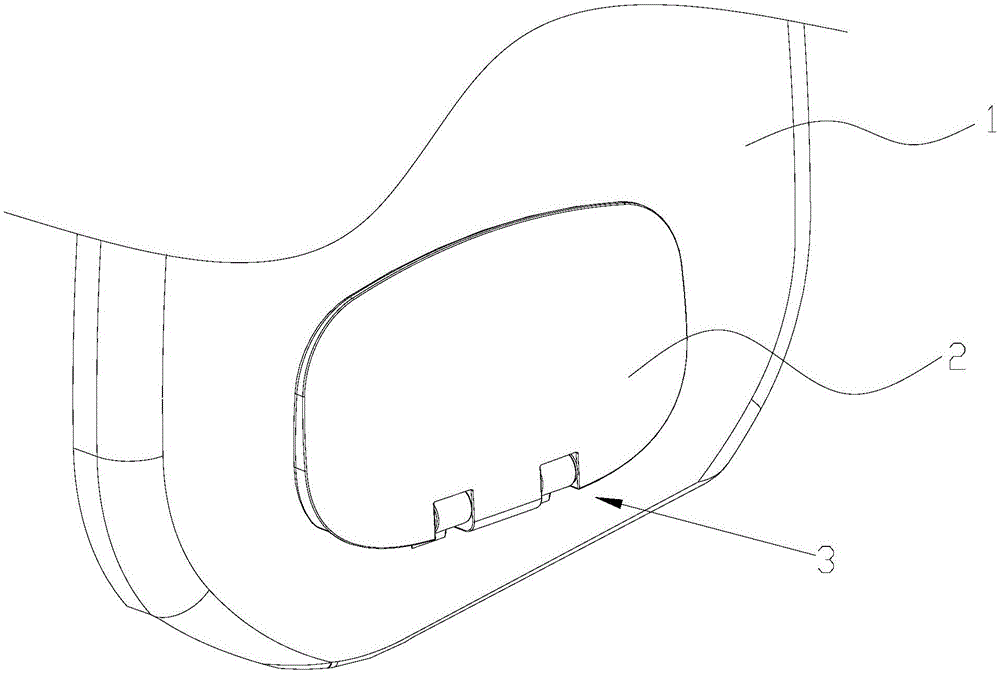

Electric vehicle pedal device and electric vehicle thereof

InactiveCN106005144ASolve technical problems with deformationUnicyclesMotorised scootersEngineeringElectric vehicle

The invention relates to an electric vehicle pedal device and an electric vehicle adopting the same. According to the pedal device, on the basis that pivotal connection between a pedal and a wheel cover part is achieved, the stress direction of the wheel cover part is converted skillfully, so that the wheel cover part can bear stress of the pedal in the unfolded usage state, and the technical problem that in the prior art, deformation occurs to the wheel cover part due to the fact that stress of the pedal is transmitted to the wheel cover part is solved.

Owner:张军凯

Manufacturing method of special-shaped metal air duct

ActiveCN110280920BSolve preparation difficultiesLess patchworkGeometric CADDesign optimisation/simulationGraphicsEngineering

Owner:CHINA HANGFA SOUTH IND CO LTD

A vacuum oil injection method using a vacuum oil injection device for oil drilling

ActiveCN109812469BMeet the requirements of vacuum oilingTiny air bubblesDirectional drillingFluid-pressure actuator componentsAutomatic controlControl system

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Plastic edge covering plate for electronic equipment and secondary plastic forming method

ActiveCN111278248ASolve technical problems with deformationSmall degree of deformationDomestic articlesHermetically-sealed casingsStructural engineeringMechanical engineering

The embodiment of the invention provides a plastic edge covering plate for electronic equipment and a secondary plastic forming method. The plastic edge covering plate is used for manufacturing a shell of an electronic device. The plastic edge covering plate comprises a plate body, M first plastic bodies and a second plastic body, the M first plastic bodies are arranged on the edge of the upper surface of the plate body, each first plastic body comprises a first surface, a second surface, a third surface, a first edge and a second edge, and the N grooves are formed in the second surface. The second plastic body wraps the third surface, the first edge, the second edge and the filling groove and is connected with the side edge of the plate body; wherein M is a positive integer, and N is 0 ora positive integer. The technical problems that in the prior art, the edge of a plate is wrapped with plastic in a one-time forming mode, the shrinkage amount is large after plastic forming, and plate deformation is likely to be caused are solved, and the technical effects that the edge of the plate is wrapped with plastic in a two-time forming mode, and the plate deformation degree is reduced are achieved.

Owner:合肥山秀碳纤科技有限公司

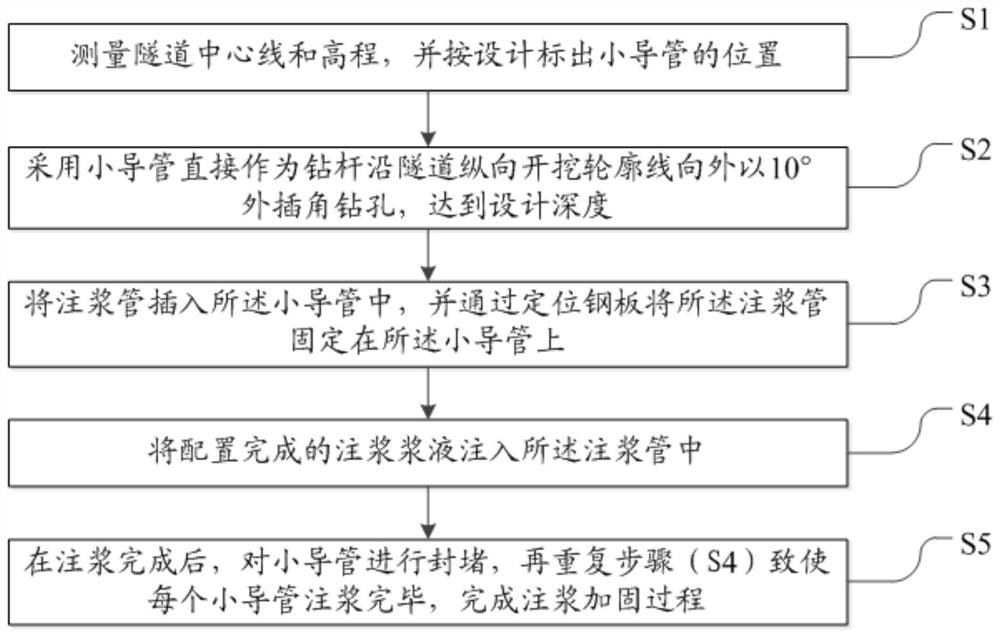

Grouting slurry for reinforcement in tunnel hole and grouting method

ActiveCN113461376AEasy to excavateControlled Diffusion RangeTunnelsSolid waste managementPhysical chemistrySlurry

The invention provides grouting slurry for reinforcement in a tunnel hole and a grouting method. The grouting slurry comprises slurry A and an additive B; the slurry A is prepared by stirring cement and water according to a water-cement ratio of 1: 1 in a grouting process and then stirring according to a water-cement ratio of (0.8-0.9): 1; the additive B is prepared from an accelerator and a high polymer material solution according to the volume ratio of 1: 1 in the grouting process, and the mass of the accelerator and the mass of the high polymer material solution both account for 3%-5% of the mass of the cement. The diffusion range of the slurry is controlled by controlling the gelation time of the slurry, so the purpose of controlling the reinforcement range is achieved; the strength of a slurry stone body in preset time is controlled by adjusting the adding ratio of the accelerator to the high polymer material solution, it is guaranteed that collapse does not occur during excavation of a tunnel face, tunneling of a tunnel is facilitated, and the technical problems that when a tunnel penetrates through a loose accumulation body stratum for construction, line invasion and deformation of a supporting arch frame are prone to occurring are solved.

Owner:核工业华东建设工程集团有限公司

Solderable contact

InactiveCN103765679AAdequate shape stabilitySolve technical problems with deformationSoldered/welded conductive connectionsCoupling contact membersMechanical engineering

Owner:AMPHENOL TUCHEL ELECTRONICS

Working method of a processing device for annular metal parts

ActiveCN111360623BReceived expansion forceAvoid deformationEdge grinding machinesPolishing machinesPolishingMachining

The invention discloses a working method of a processing device for ring-shaped metal parts, which belongs to the technical field of mechanical processing equipment and includes a workbench, a positioning mechanism, a limit mechanism, a feeding mechanism and a polishing mechanism. The positioning mechanism includes a lifting component, a connecting component, Several positioning components and several reset components, the connecting components are installed at the lower end of the lifting component, several positioning components are distributed on the side of the connecting component in a circle, and several reset components correspond to several positioning components one by one, Each reset assembly is installed above the corresponding positioning assembly, the feeding mechanism includes an adjustment assembly and a feeding assembly, and the polishing mechanism includes a moving assembly and a polishing assembly. The present invention can fix and process ring-shaped workpieces with a small difference between inner and outer diameters without deformation of the workpiece during fixing. The same equipment can process ring-shaped workpieces of different sizes. The present invention also has the characteristics of low positioning accuracy. Can reduce costs.

Owner:唐山特迪机械设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com