Looping mechanism of artificial lawn warp knitting machine

A loop forming mechanism and artificial turf technology, applied in the field of warp knitting machines, can solve the problems of loose fabric structure, low strength, low production efficiency, etc., and achieve the effect of tight structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

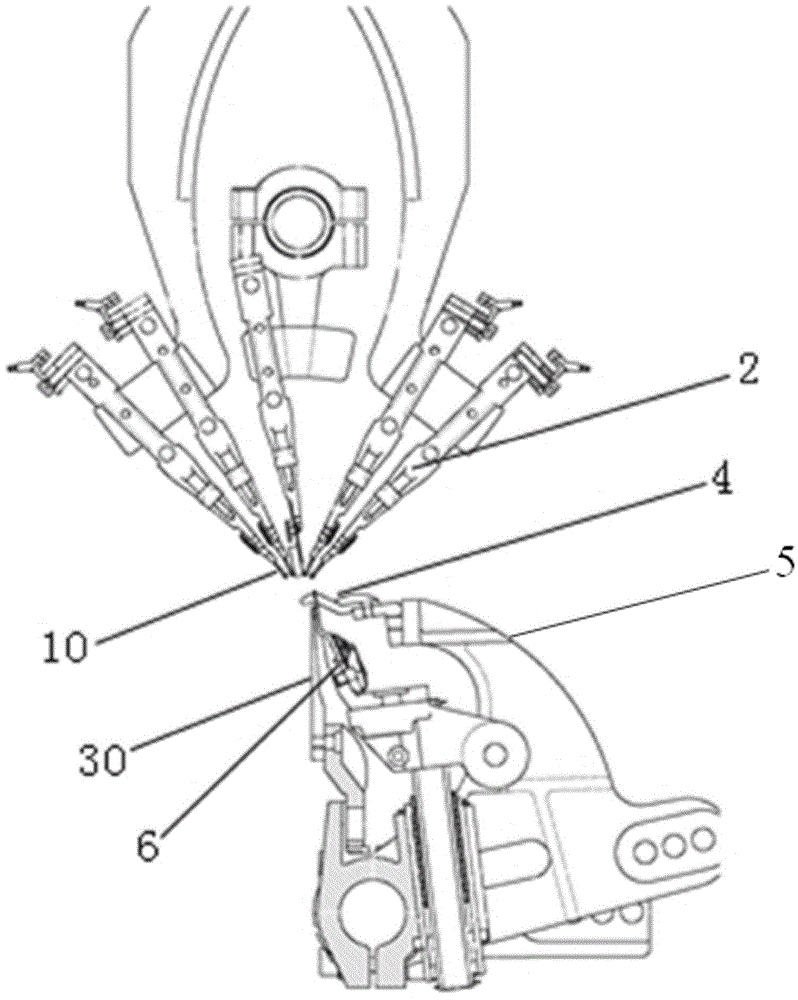

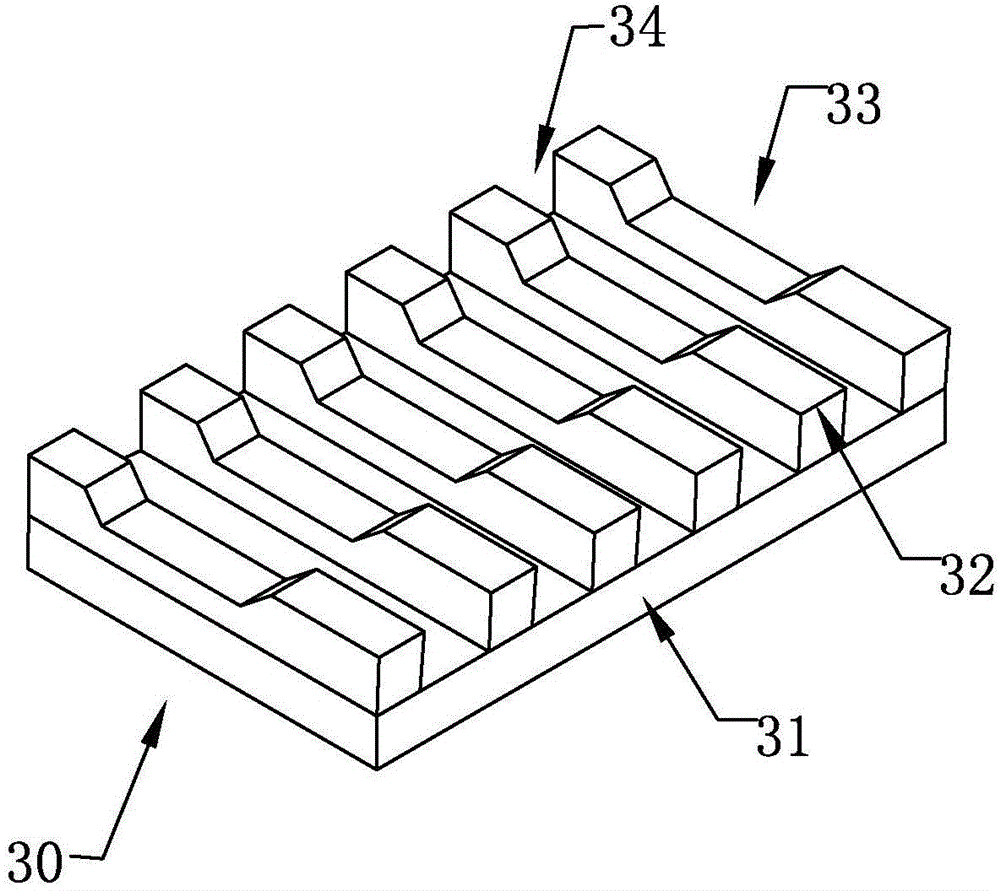

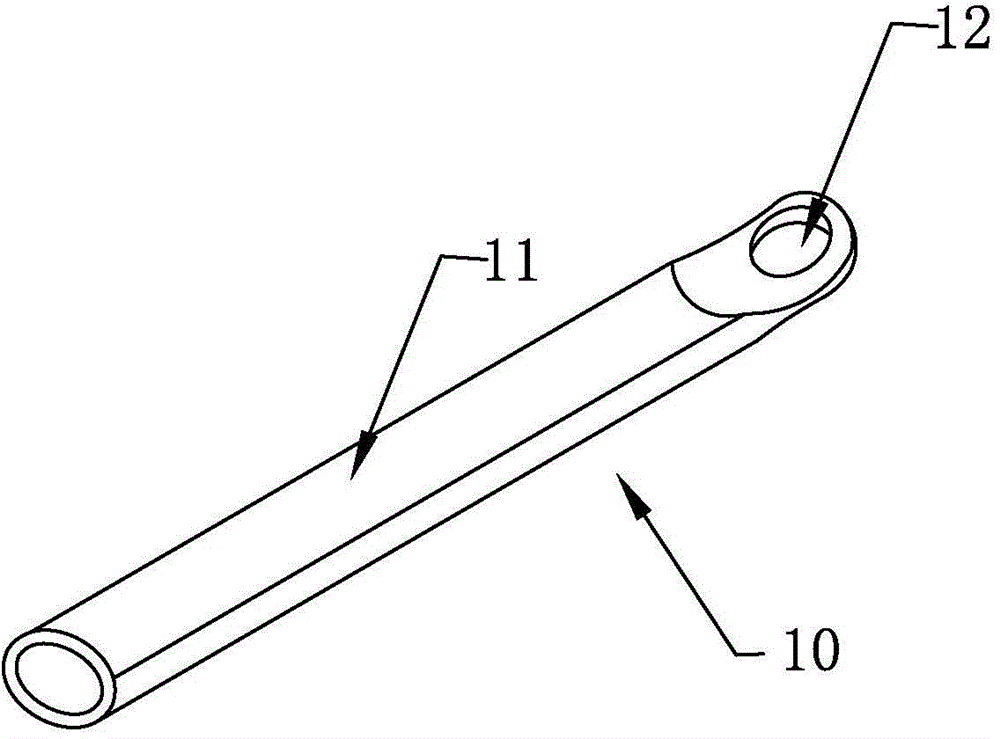

[0017] Such as Figure 1 to Figure 3 As shown, a knitting mechanism of an artificial turf warp knitting machine includes a guide needle 10, a sinker 4, and a knock-off plate 30; the guide needle 10 is fixed on the wool yarn bar 2, and the sinker 4 is fixed on the sinker bed 5, stripping plate 30 is connected with a main shaft by connecting rod. Wherein, in order to increase the strength of the yarn guide needle 10, the needle body 11 of the yarn guide needle 10 is set as a stainless steel tube; one end of the needle body 11 is provided with an annular pinhole 12, and the other end is welded on the wool yarn bar 2, the inner diameter of the pinhole 12 is 3-6 mm. The stripping plate 30 has a plate body 31, on which at least two block blocks 32 arranged side by side are arranged, a groove 33 is provided in the middle of the block block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com