Semi-continuous spinning machine and spinning cake production process thereof

A spinning machine and semi-continuous technology, which is applied in the field of semi-continuous spinning machine and its silk cake production process, can solve the problems affecting fiber strength, elongation, fineness and dyeing performance, decrease of physical properties of inner and outer layers of raw silk, and refining effect. and drying effect, etc., to achieve the effect of increasing height, stable lifting movement, and stable lifting operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

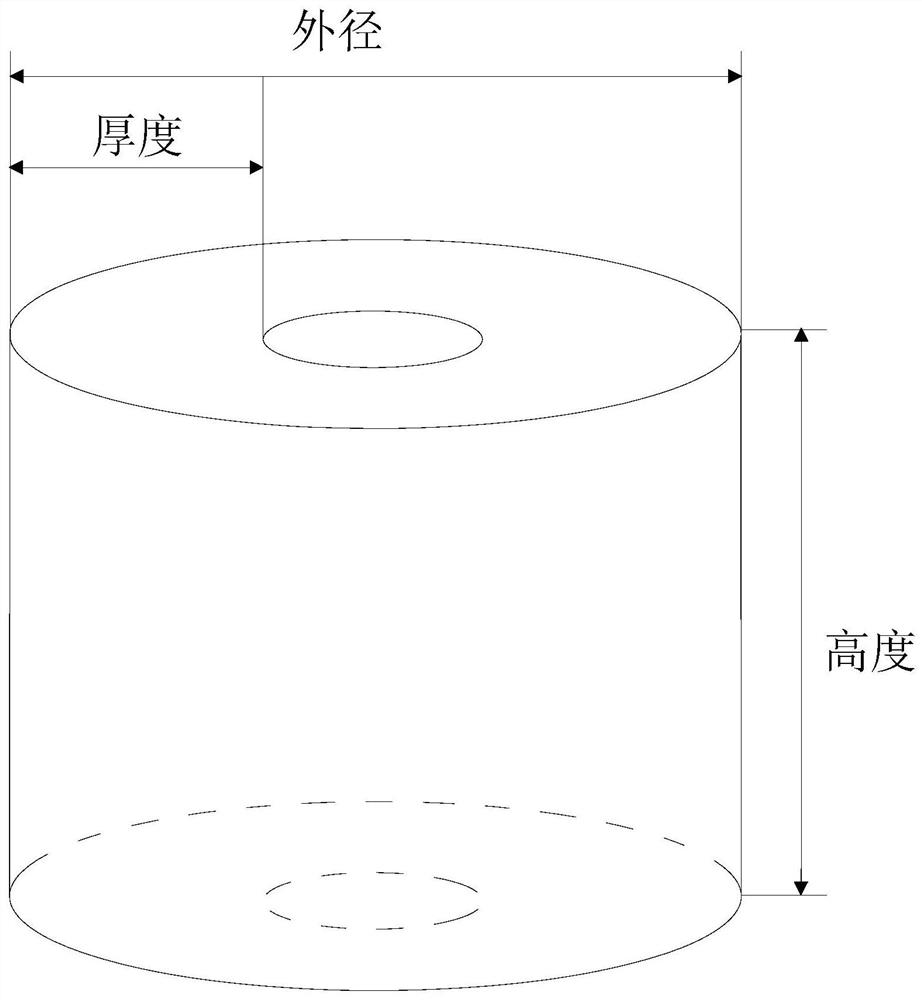

[0039] see figure 1 As shown, the semi-continuous spinning machine of this embodiment needs to produce a kind of big silk cake, and the dry weight of described silk cake is 0.9kg~1.5kg, and described silk cake is hollow cylinder structure, and the outer diameter of silk cake is The ratio to the thickness of the silk cake is (5-9):1.

[0040] In the above scheme, the ratio of the outer diameter of the silk cake to the thickness of the silk cake is (5-9): 1, thus ensuring the refining effect and drying effect of the subsequent processing of the silk cake while increasing the weight of the silk cake. It will not reduce the physical properties of the inner and outer layers of the original silk by simply increasing the thickness of the silk cake like the existing ones, and will also lead to poorer refining and drying effects in the follow-up, affecting the strength, elongation, fineness and dyeing performance of the fibers.

[0041] Preferably, the ratio of the outer diameter of t...

Embodiment 2

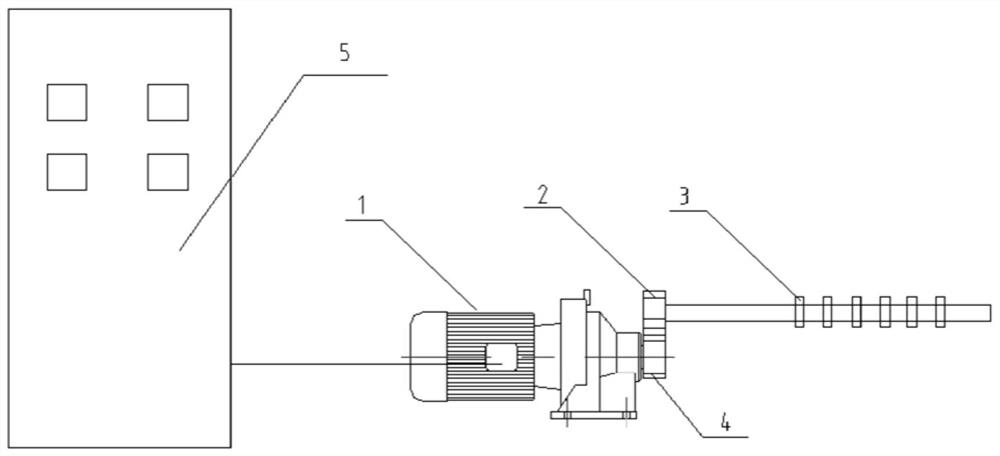

[0051] The second embodiment provides a semi-continuous spinning machine for producing the silk cake in the first implementation, including a winding device, the winding device includes a centrifuge tank, and the centrifuge tank has a cylindrical chamber, and the inner diameter of the chamber is the same as The height ratio is (0.7~1.2):1. Preferably, the ratio of the height of the chamber to the height of the silk cake is (1.0-1.5):1. Further preferably, the height of the chamber is greater than the height of the silk cake by 3-5 cm.

[0052] In the above solution, in order to produce the large silk cake, the present invention performs adaptive design on the structural size of the centrifuge tank, so as to realize the production of the silk cake.

[0053] Preferably, the inner diameter of the cylindrical chamber is 165-325 mm, and the height is 165-200 mm; more preferably, the inner diameter of the cylindrical chamber is 204-206 mm, and the height is 190-199 mm; Most prefer...

Embodiment 3

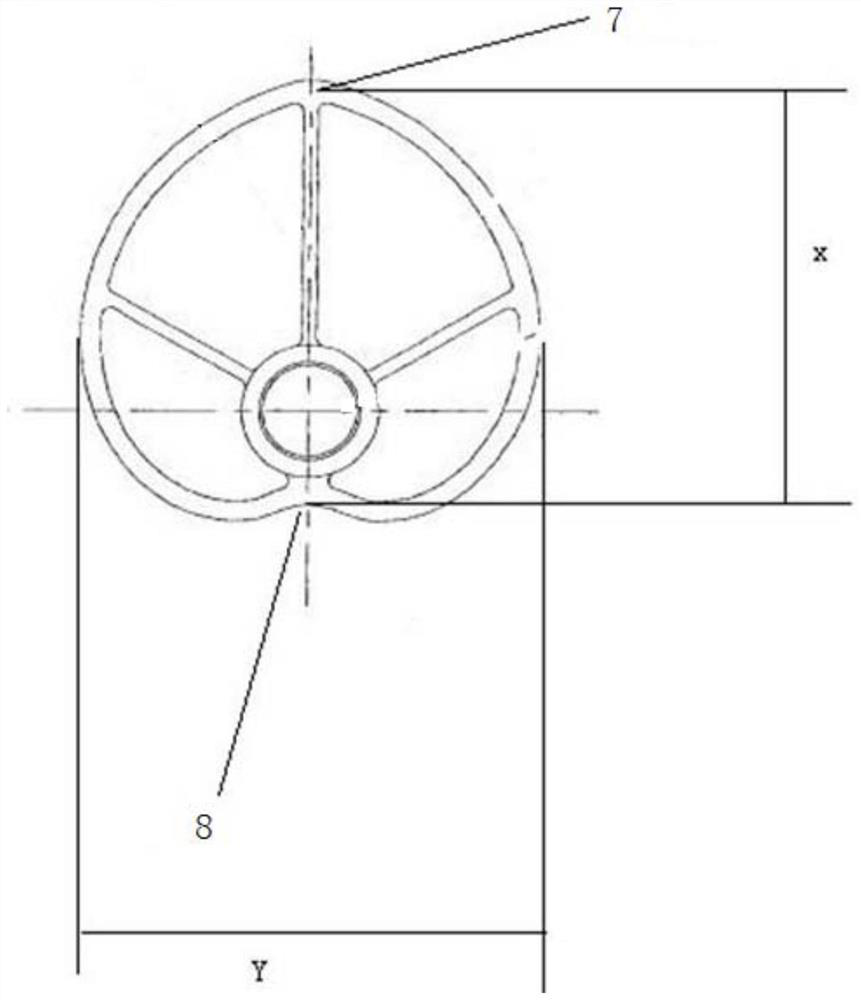

[0065] The present embodiment further provides the structure of a semi-continuous spinning machine. The semi-continuous spinning machine includes a centrifugal tank, a lifting rod, a funnel bracket installed on the lifting rod and a cam that drives the lifting rod to move up and down. The inside of the centrifugal tank has a chamber. The ratio of the stroke of the cam to the height of the chamber of the centrifuge tank is (130~170):(165~200). Cam structure see image 3 and Figure 4 .

[0066] In the above scheme, the lifting stroke of the original cam is increased, and part of the structural modification of the whole machine is carried out to increase the height of the manufactured silk cake, expand the adjustment range of the winding angle of the silk cake, and ensure the high-speed spinning speed. The movement is stable, and large silk cakes can be produced, saving a lot of labor.

[0067] Preferably, in the present invention, the stroke of the cam is 130-170 mm. More p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com