A remote control self-propelled lifting cylinder type walnut manual auxiliary picking machine

A lifting cylinder and artificial assistance technology, which is applied in the direction of picking machines, harvesters, agricultural machinery and tools, etc., can solve the problems of manual walnut picking difficulty, high picking cost, personal injury, etc., and achieve the reduction of manual operation cost and mature technology Reliable, low-cost-to-manufacture results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

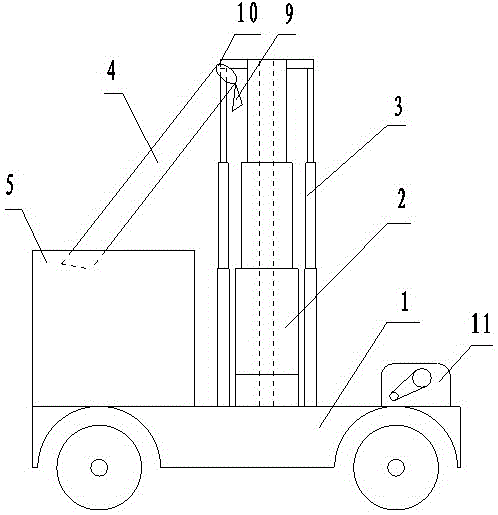

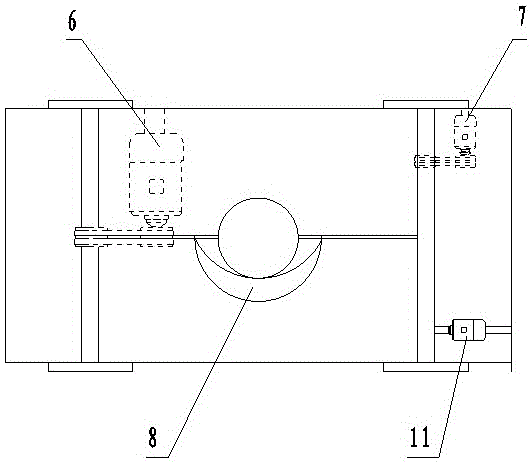

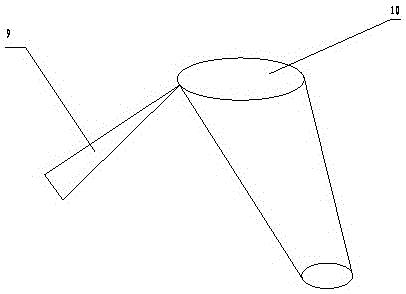

[0024] In the embodiment shown in 1~3, a kind of remote control self-propelled lifting oil cylinder type walnut manual auxiliary picking machine is made up of trolley 1, motor 11, double acting force lifting oil cylinder 2, telescopic frame 3, telescopic harvesting bag 3 and The collection box is composed of 5. Check the condition of the control system and the transmission system before operation. The drive motor 6 and the steering motor 7 are arranged on the lower surface of the chassis of the trolley 1. The rear drive mode is adopted. The drive motor 6 rotates forward and the trolley 1 moves forward, and the drive motor 6 reverses. Drive the trolley 1 back, turn the steering motor 7 clockwise to drive the trolley 1 to the right, and turn the steering motor 7 counterclockwise to drive the trolley 1 to the left. On the upper surface of the chassis of the trolley 1, a double-acting lifting cylinder 2, a motor 11, and a telescopic frame 3 are arranged. , retractable harvesting ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com