Sand mold compacting device for V-process casting

A technology for sand molds and vibrating motors, which is applied to casting molding equipment, casting molds, molding machines, etc. It can solve the problems of difficulty in ensuring the stability of the height of the vibrating table, the lack of seal between the sand box and the sand feeder, and the ineffective sand feeding effect. Ideal and other problems, to achieve good vibration effect, reduce the number, and stabilize the lifting position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

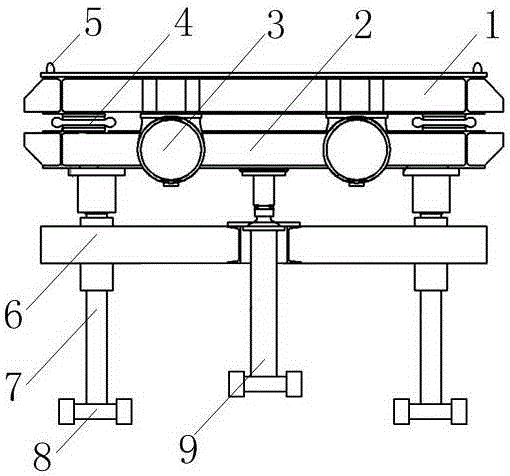

[0015] Such as figure 1 As shown, the sand mold vibration device in the V method casting in the V method casting of the present invention includes a positioning pin 5, a vibration table 1, a vibration base 2, an air spring 4, a guide rod 7, a hydraulic cylinder 9, and a support frame 6. Lateral vibration motor 3 and up and down vibration motor 8.

[0016] The positioning pins are arranged on the upper surface of the vibrating table. The positioning pin is used to fix the sand box or the pumping chamber of the sand box, and is positioned by cooperating with the positioning pin sleeve at the bottom of the sand box or the bottom of the pumping chamber of the sand box, thereby fixing the sand box or the pumping chamber of the sand box.

[0017] The bottom four corners of the vibrating table are respectively connected to the vibrating base through air spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com