Electric lifting mechanism

An electric lifting mechanism and electric push rod technology, which is applied to lifting devices, connecting components, mechanical equipment, etc., can solve the problems of inability to adjust the height of the LED screen light box, lack of lifting adjustment devices, and the lifting operation is not stable enough. The overall structure is compact and the appearance is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

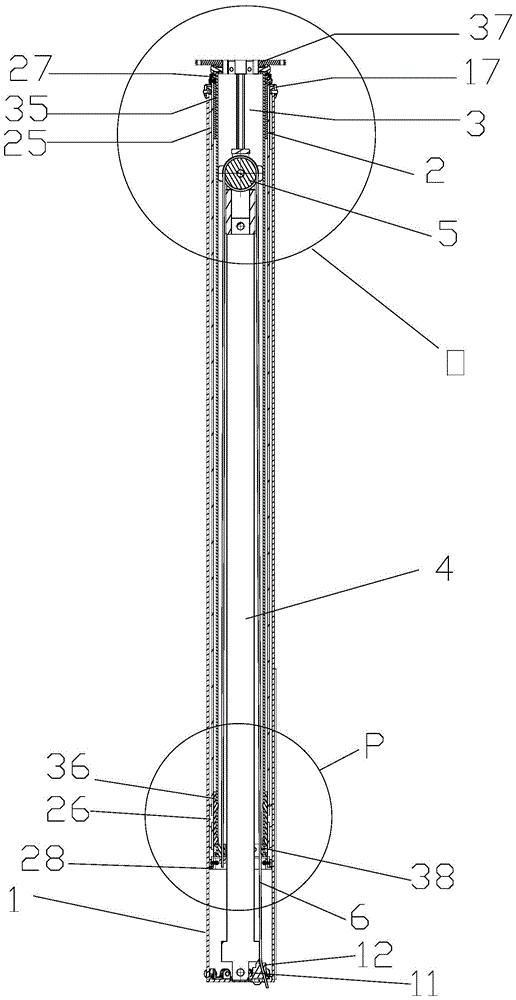

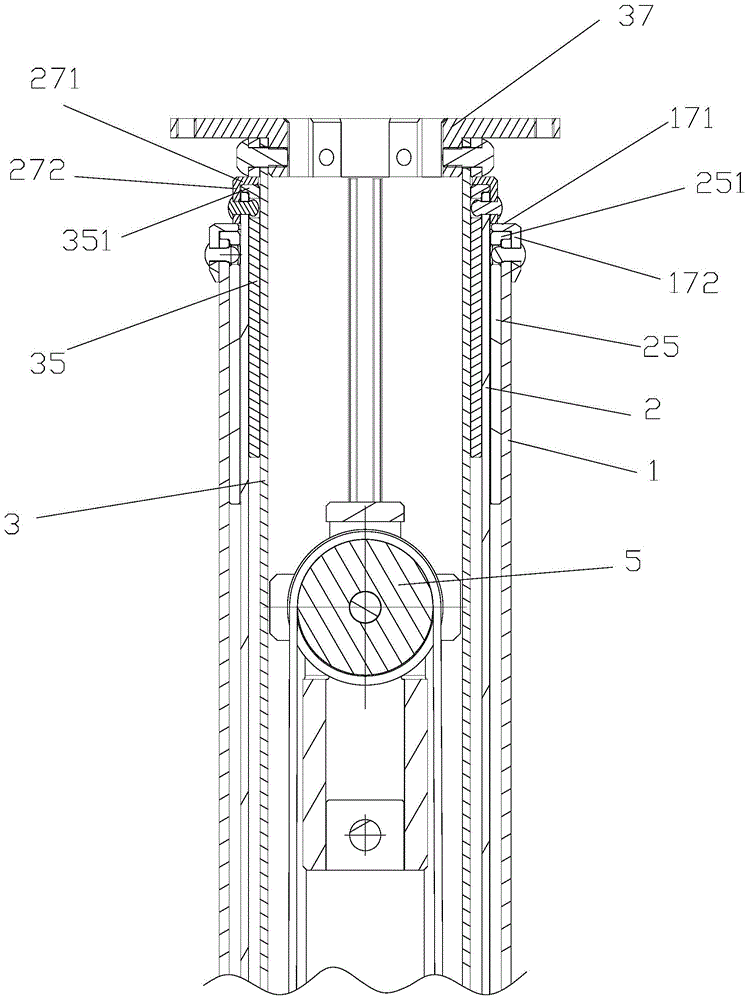

[0017] Please refer to Figure 1 to Figure 6 . An electric lifting mechanism according to an embodiment of the present invention includes a bushing, an electric push rod 4 , a pulley 5 and a wire rope 6 wound on the pulley 5 . The sleeve includes an outer tube 1 , a middle tube 2 and an inner tube 3 from outside to inside.

[0018] The bottom of the lumen of the outer tube 1 is provided with an electric push rod fixing part 11 and a wire rope fixing part 12 . The top of the lumen of the outer tube 1 is fixedly provided with an upper bushing 25 of the middle tube. A circle of flanging 251 is provided on the top of the upper bushing 25 of the middle pipe, and the bottom surface of the circle of flanging 251 of the middle pipe upper bush is pressed against the upper end surface of the outer pipe. The upper end of the outer pipe is fixedly provided with an outer pipe u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com