Side surface support lifting device on yarn winding machine

A lifting device and winding machine technology, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material processing, can solve the problems of inflexible lifting, unstable contact pressure, and large vibration, and achieve smooth operation and contact Stable pressure and little vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

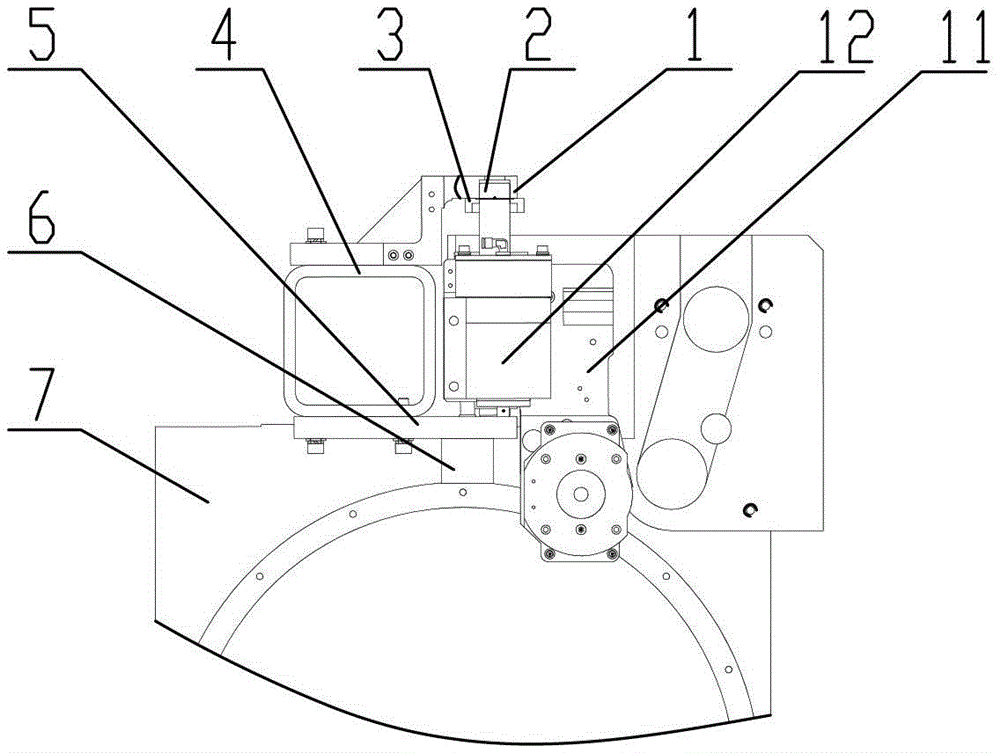

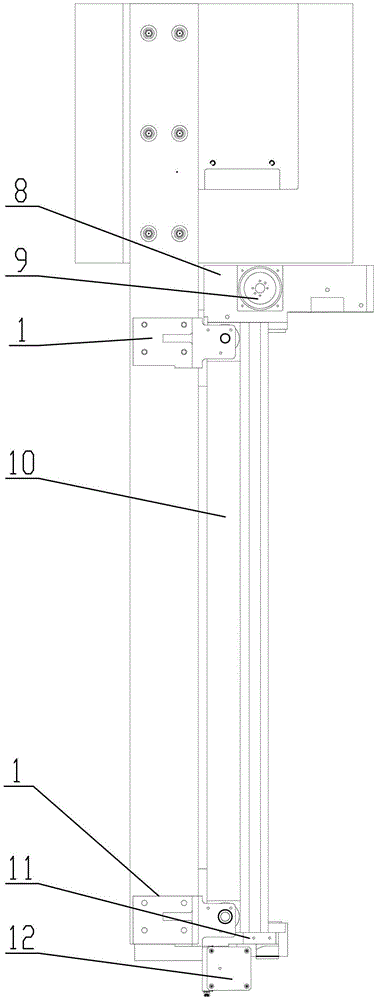

[0023] see figure 1 and figure 2 In this embodiment, a side support lifting device on a yarn winding machine is provided. The main components involved in this embodiment include an upper positioning plate 1, a steel ball guide post 2, a rubber ring 3, a supporting square tube 4, a lower Positioning plate 5, jacking cylinder 6, machine base 7, lifting seat 8, rear lifting cylinder 9, friction roller casing 10, friction roller front box plate 11, front lifting cylinder 12.

[0024] The support square tube 4 is installed on the support 7, and the weight of the lifting device all bears on the support square tube 4.

[0025] Above the supporting square tube 4, one upper positioning plate 1 is provided at the front and rear, and one lower positioning plate 5 is respectively provided at the front and rear of the supporting square tube 4, and each pair of upper positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com