In-mold forming method and in-mold forming equipment

A technology of in-mold molding and equipment, applied in the field of electronics, can solve problems such as large stress and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] During the production process of the first in-mold molding equipment, a large stress will be generated between plastic parts, carbon fiber sheets or metal parts.

[0052] In order to reduce the stress generated between plastic parts, carbon fiber sheets or metal parts during in-mold molding. An embodiment of the present invention provides an in-mold forming method of an in-mold forming device that can be used to manufacture an electronic device casing.

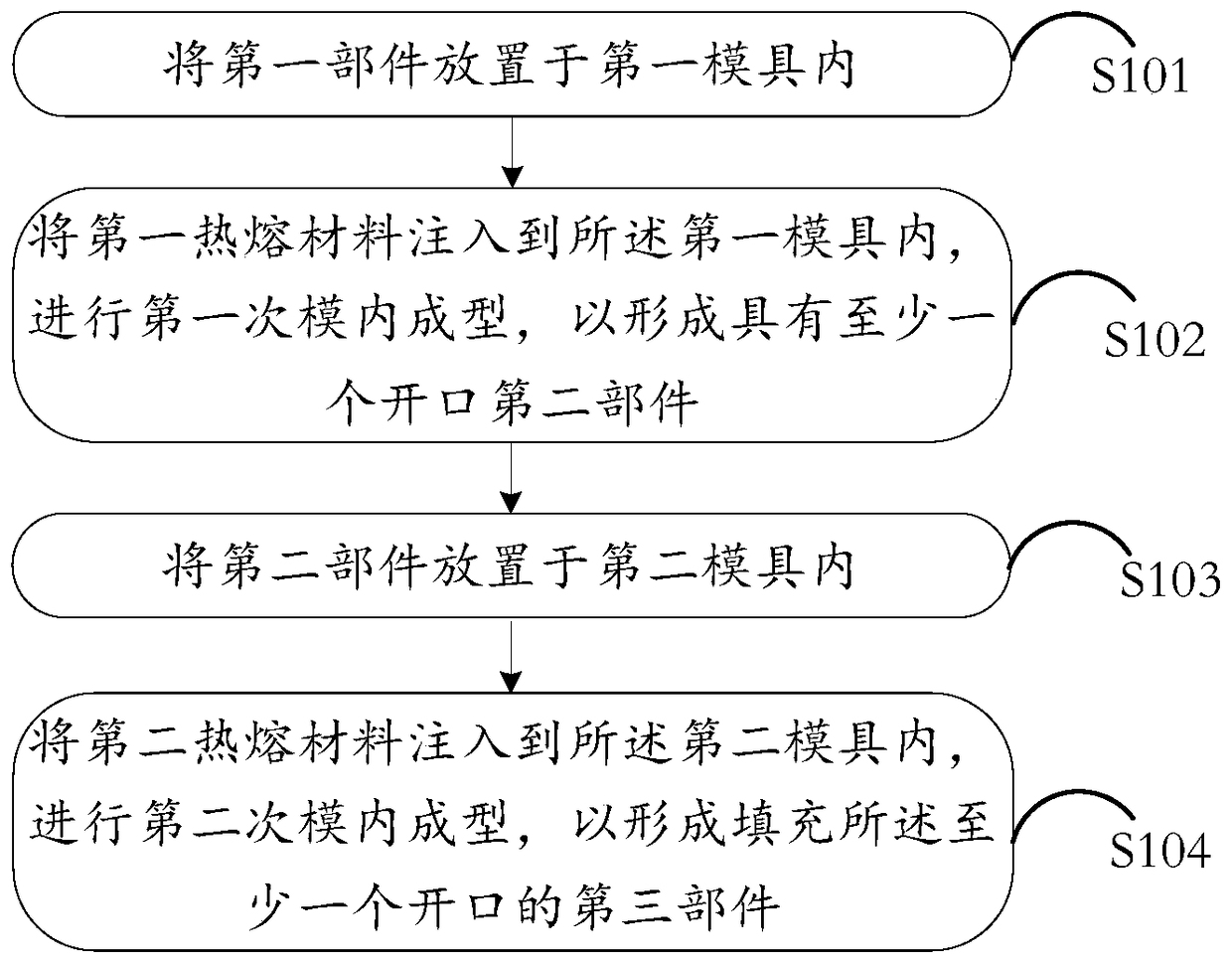

[0053] Please refer to figure 1 , the embodiment of the present application provides an in-mold forming method for forming the first in-mold forming device, the method comprising:

[0054] S101: placing the first part in the first mold;

[0055] S102: inject a first hot melt material into the first mold, and perform a first in-mold molding to form a second part with at least one opening;

[0056] S103: placing the second component in a second mold;

[0057] S104: Inject a second hot melt material into the second mol...

Embodiment 2

[0083]Based on the same inventive concept, an in-mold forming device is also provided in the embodiment of the present invention, please refer to Figure 4 The in-mold forming equipment provided by the embodiment of the present invention includes: a first component 41, a first in-mold forming component 42, and a second in-mold forming component 43, wherein,

[0084] The first in-mold component 42 forms a second part together with the first part 41 by a first in-mold, and the second part includes at least one opening;

[0085] Said second in-molding component 43 forms a third part together with said second part by a second in-molding, said third part comprising a portion filling said at least one opening.

[0086] Specifically, the first component 41 is a component formed by stamping a carbon fiber plate or a metal plate.

[0087] The thickness of the first component 41 is 0.05mm˜2.0mm.

[0088] The first upper surface of the first in-mold forming component 42 and the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| fatigue bending times | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com