Framed plate for electronic equipment and plastic forming method

An electronic equipment, plastic molding technology, applied in the direction of electrical equipment shell/cabinet/drawer, electrical components, chassis/cabinet/drawer parts, etc., can solve the problems of large shrinkage, sheet deformation, etc. The effect of plastic usage, enhancement of mechanical strength, and reduction of sheet deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

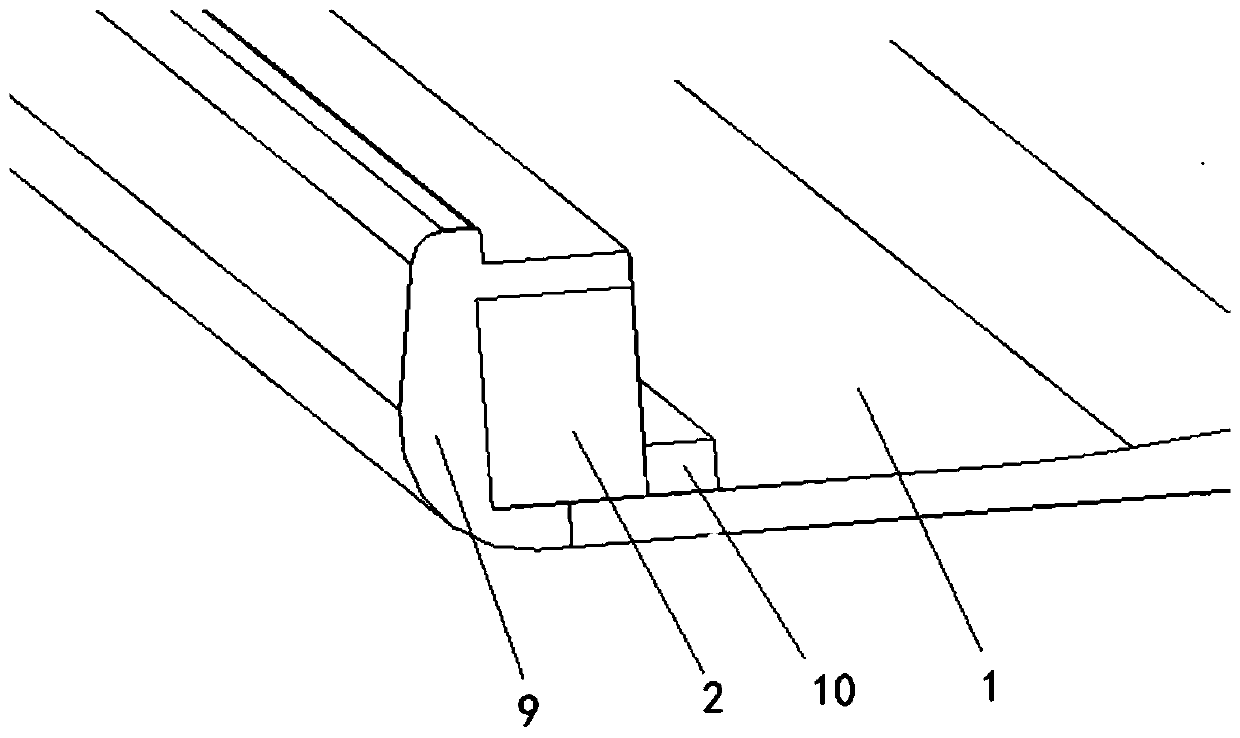

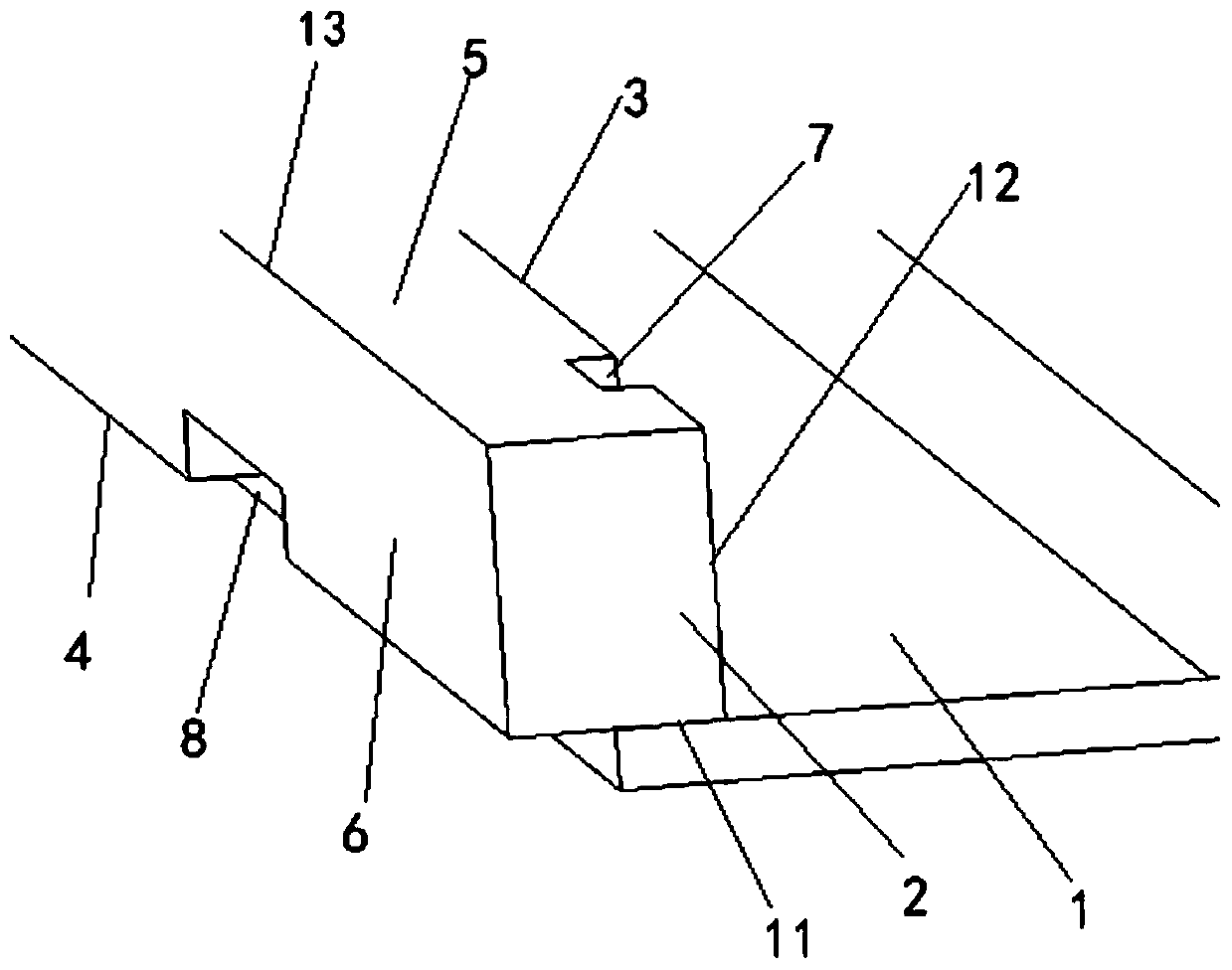

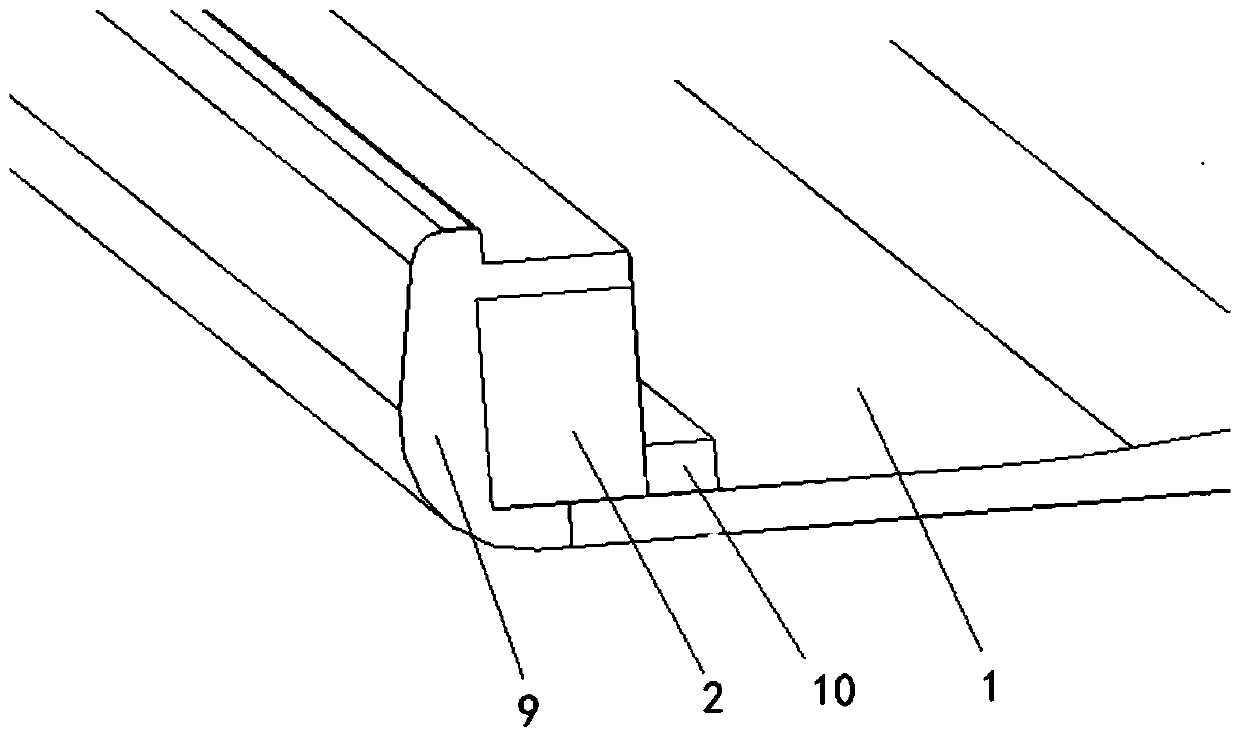

[0031] The embodiment of the present invention provides a framed board for electronic equipment, please refer to the attached Figure 1-2 , used to make housings for electronic devices, the framed sheet includes:

[0032] board body 1;

[0033] Specifically, the board body 1 is a board with a certain shape and a certain shape, and a plurality of the board bodies 1 are assembled together to form a casing, and electronic equipment is arranged in the casing.

[0034] A frame body 2, the frame body 2 is fixed on the edge of the upper surface of the board body 1;

[0035] Further, the frame body includes: a third surface, the third surface is fixed on the upper surface of the board body 1 by pasting to form an overlapping portion, the width of the overlapping portion is K, and the third surface The width of the surface is P; where, 0.5P≤K≤P.

[0036] Specifically, the panel body 1 has an upper surface, a lower surface and side edges, and the upper surface and the lower surface a...

Embodiment 2

[0068] The present application also provides a plastic molding method for making the framed sheet for electronic equipment, please refer to the attached Figure 1-2 , the plastic molding method includes:

[0069] Step 1: paste the frame body 2 on the edge of the upper surface of the board body 1;

[0070] Step 2: Put the board body 1 with the frame body 2 fixed into the mold;

[0071] Step 3: pouring plastic material into the mold to form the first plastic body 9 and the second plastic body 10;

[0072] Step 4: After the plastic material is solidified, remove the mold.

[0073] Further, the mold has at least two injection ports.

[0074] Specifically, the mold includes at least two injection ports, namely a first injection port and a second injection port, and plastic material is poured into the first injection port to form the first plastic body 9; Plastic material is poured into the second injection port to form the second plastic body 10 .

[0075] Through the plastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com