A driving assembly in a processing box and a processing box including the driving assembly

A technology for driving components and processing boxes, which is applied to the equipment of electric recording technology using charge patterns, electric recording technology using charge patterns, and electric recording techniques, etc. It can solve the problems such as easy shaking of power transmission mechanisms and flanges, etc. Achieve the effect of smooth force transmission, smooth driving force transmission, and reduced shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The structure of the drive assembly in a process cartridge is as follows:

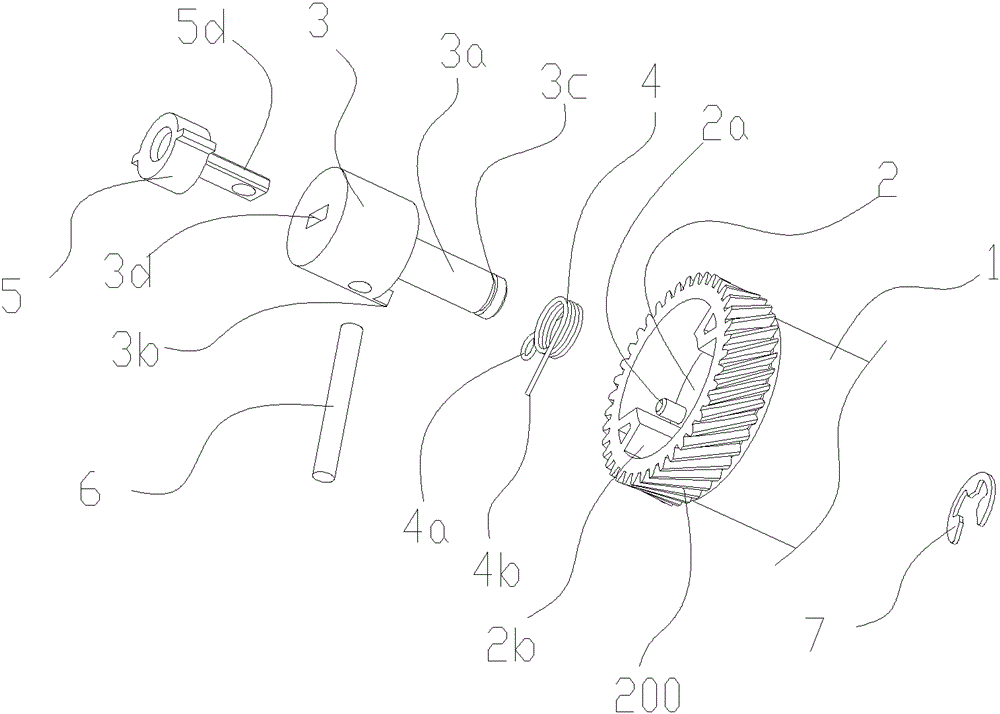

[0041] Figure 6 It is an exploded schematic view of the drive assembly in the process box used in the embodiment. As known from the figure, the drive assembly in the process box includes: a flange 20 that is arranged at the end of the rotating part and transmits power to the rotating part; The power transmission mechanism for the driving force of the image forming device, the elastic element 40 that acts as a buffer, and the connecting piece 7 that connects the flange 20 with the power transmission mechanism.

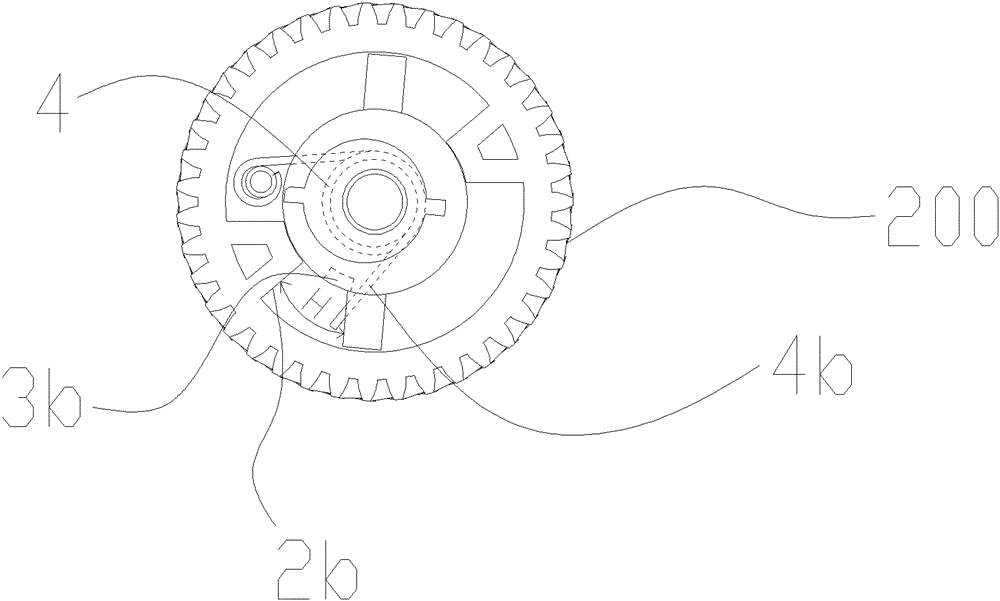

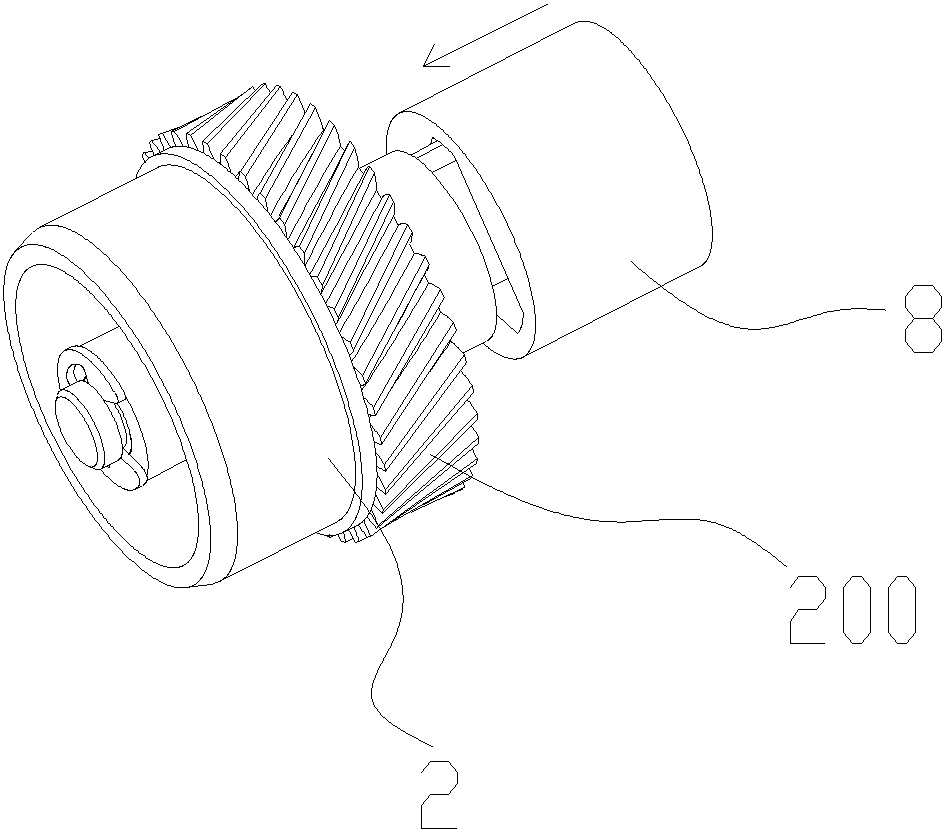

[0042] Figure 7 and Figure 8 They are the three-dimensional schematic diagram and the cross-sectional view of the flange respectively. As can be seen from the figure, the flange 20 includes: a cylindrical groove 20d coaxial with the flange, a central shaft hole 20c set on the axis of the flange, and a central axis hole 20c set in the groove 20d A pair of radially symmetrically distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com