A water pipe carrying device of an automobile radiator core assembly machine

A technology for automobile radiators and bearing devices, which is applied in vehicle parts, transportation and packaging, metal processing, etc., can solve problems such as deformation, and achieve the effects of reducing pressure, solving deformation, and reducing impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

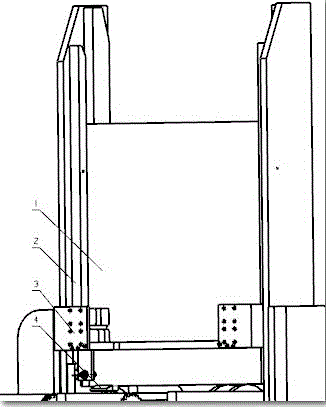

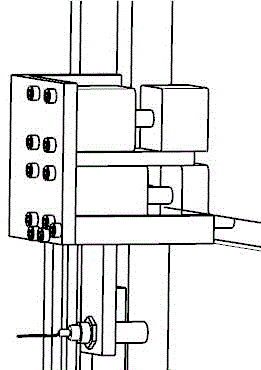

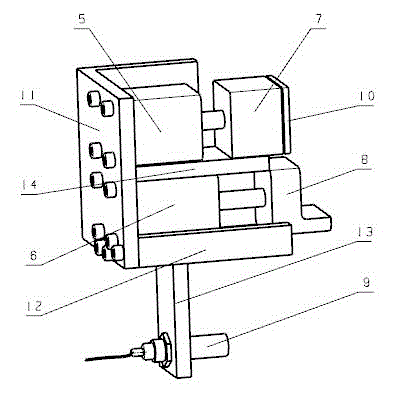

[0015] refer to figure 1 Also refer to the working status of the water pipe bearing device of the automobile radiator core assembly machine figure 2 The structural diagram of the water pipe bearing device of the automobile radiator core assembly machine, in figure 1 Both the middle pressing block and the water pipe bearing block move forward to the limit position. The water pipe bearing block bears most of the radiator water pipes in the pipe silo, and reserves a small amount of water pipes required for operation at the lower end of the bearing block. When pressing the water pipe above the block does not fall. Some water pipes are arranged between the pressing block and the water pipe bearing block.

[0016] Its entire workflow is as follows:

[0017] 1) As the work progresses, the water pipes below the water pipe bearing block 8 gradually decrease, and its overall height continues to decrease;

[0018] 2) When the height drops below the installation position of the phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com