Plastic edge covering plate for electronic equipment and secondary plastic forming method

A technology of electronic equipment and plastic molding, applied in the direction of electrical equipment shell/cabinet/drawer, application, electrical components, etc., can solve the problems of reducing sheet deformation, large shrinkage, sheet deformation, etc., and achieve the effect of reducing sheet deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

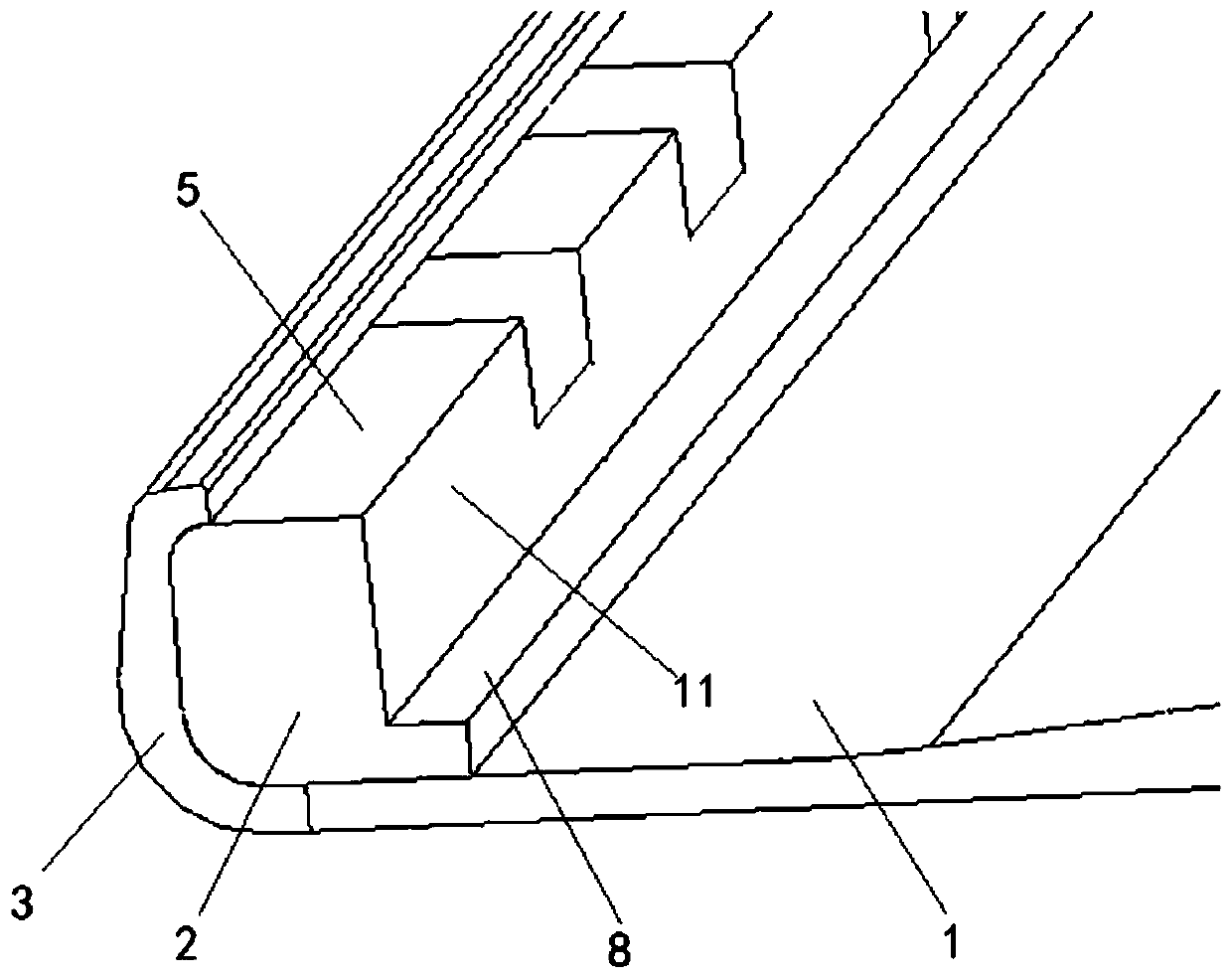

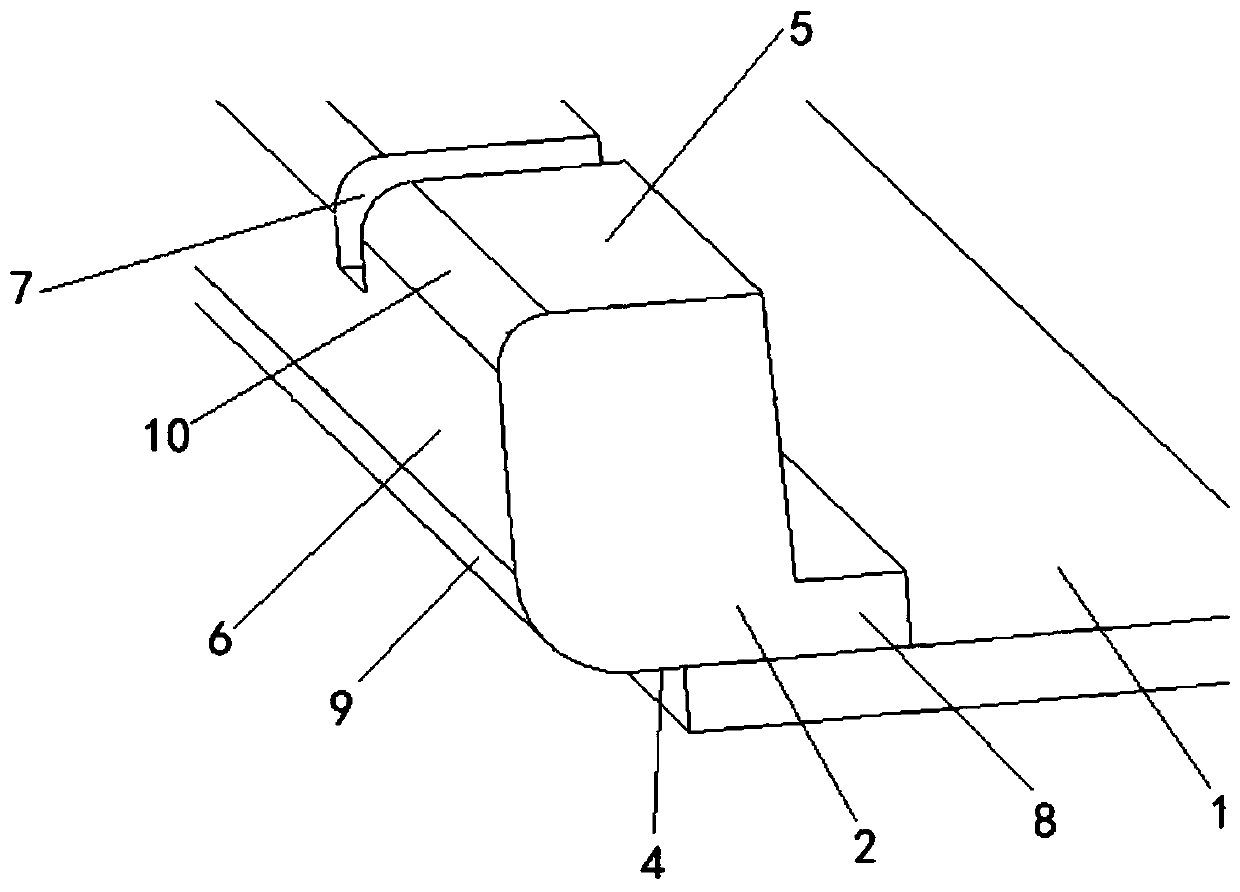

[0034] The embodiment of the present invention provides a plastic edge-wrapped sheet for electronic equipment, please refer to the attached Figure 1-2 , used to make housings for electronic devices, the plate includes:

[0035] board body 1;

[0036] Specifically, the board body 1 is a board with a certain shape and a certain shape, and a plurality of the board bodies 1 are assembled together to form a casing, and electronic equipment is arranged in the casing.

[0037] M first plastic bodies 2, the M first plastic bodies 2 are arranged on the edge of the upper surface of the board body 1;

[0038] Further, when M≧2, a first space is provided between two adjacent first plastic bodies 2 , and the second plastic body 3 fills a plurality of the first spaces.

[0039] Specifically, the M first plastic bodies 2 are arranged on the edge of the upper surface of the board body 1 through injection molding process, and the M first plastic bodies 2 are combined with the board body 1, ...

Embodiment 2

[0069] This application also provides a secondary plastic molding method for making the plastic edge-wrapped board, please refer to the attached Figure 1-2 , the secondary plastic molding method includes:

[0070] Step 1: placing the plate body 1 in a first mold;

[0071] Step 2: pouring the first plastic material into the first mold to form the first plastic body 2;

[0072] Step 3: After the first plastic material is solidified, remove the first mold;

[0073] Step 4: placing the board body 1 including the first plastic body 2 in a second mold;

[0074] Step 5: pouring a second plastic material into the second mold to form the second plastic body 3;

[0075] Step 6: After the second plastic material is solidified, remove the second mold.

[0076] Specifically, the first plastic material and the second plastic material can be PC+ABS, PC+10%-60% glass fiber, PA+10%-60% glass fiber, PPS+10%-60% One of the glass fibers, but not limited to the above several materials. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com