Manufacturing method of special-shaped metal air duct

A technology of special-shaped metals and production methods, which is applied in metal processing equipment, manufacturing tools, design optimization/simulation, etc., can solve the problems of heavy stakeout workload, low air duct aesthetics, and low accuracy of results, and achieve stakeout workload Small size, low technical level requirements for workers, and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

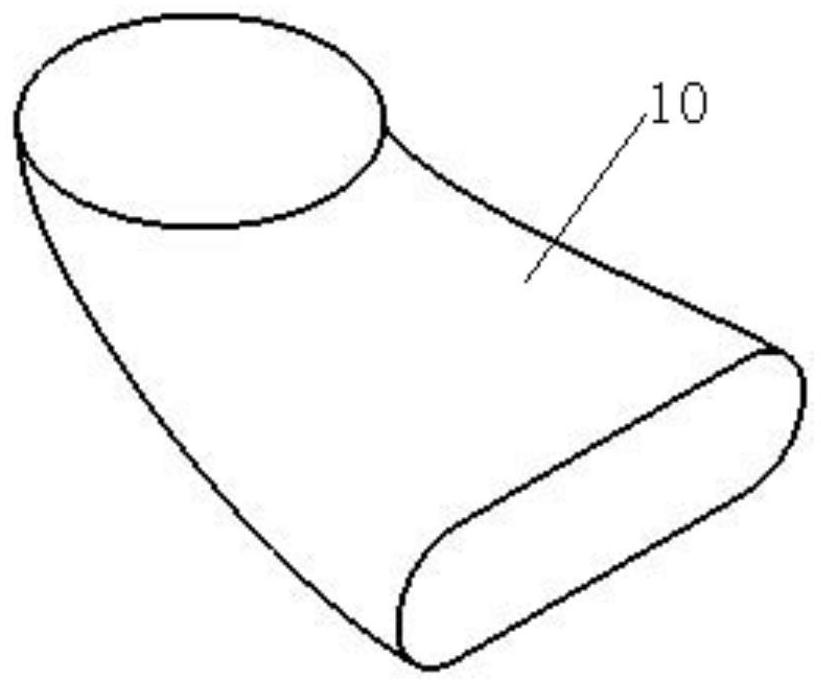

[0032] refer to figure 1 , a preferred embodiment of the present invention provides a method for manufacturing a special-shaped metal air duct, comprising the following steps:

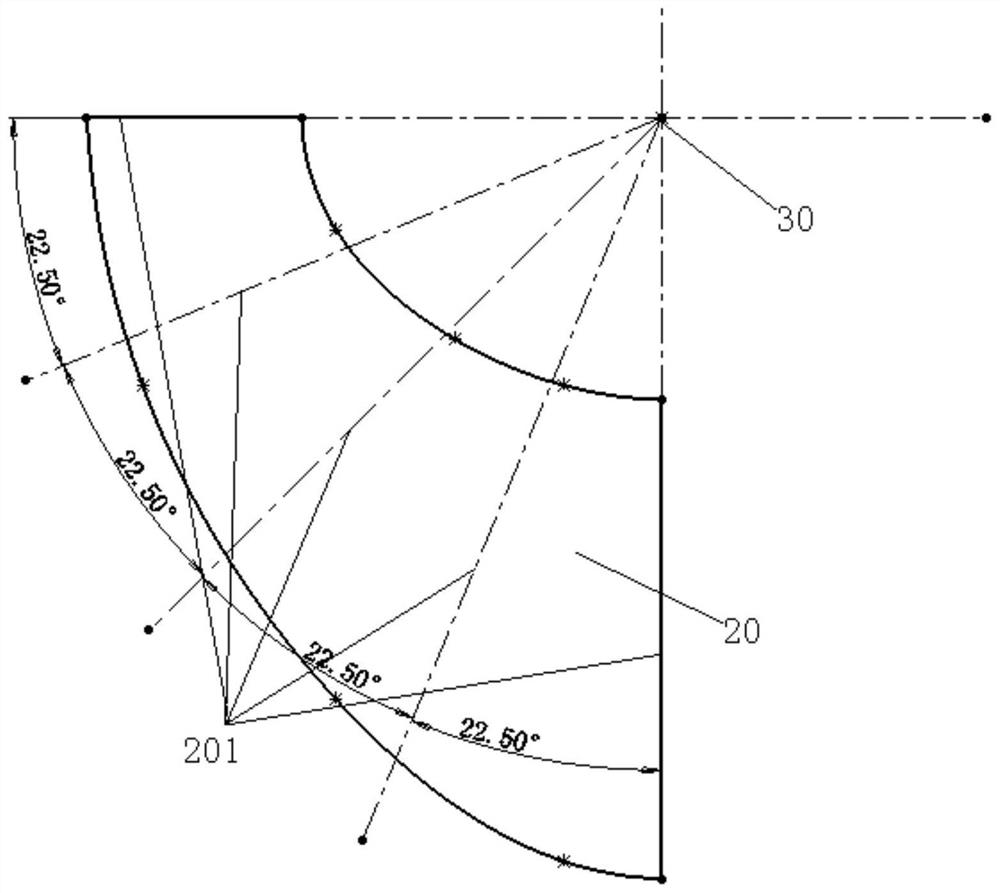

[0033] S10: Establish an air duct model 20 of the air duct 10 to be produced in a three-dimensional software according to the design drawing, and segment the air duct model 20 .

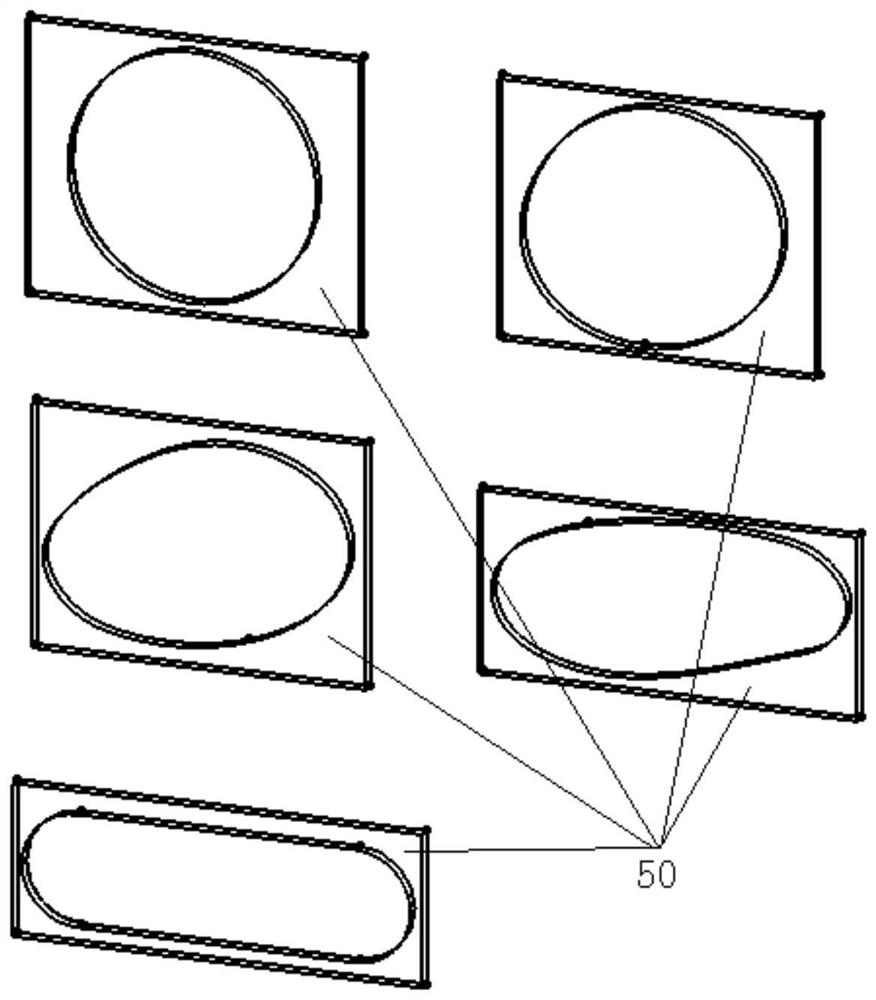

[0034] S20: Establish the coordinate system 30 in the three-dimensional software to obtain the coordinates of each segmented section 201, and make the inner flange and outer flange 50 of each segmented section 201 according to the coordinates of each segmented section 201.

[0035] S30 : Simulating the established coordinate system 30 to make a coordinate frame 60 , and positioning and fixing the outer flange 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com