Solderable contact

A technology of contact parts and contact parts, which is applied in the direction of contact parts, welding/welding connections, parts of connection devices, etc., can solve the problems of contact spring deformation, deformation, etc., to reduce the risk of damage, avoid lateral distortion, and low defects The effect of rate and damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

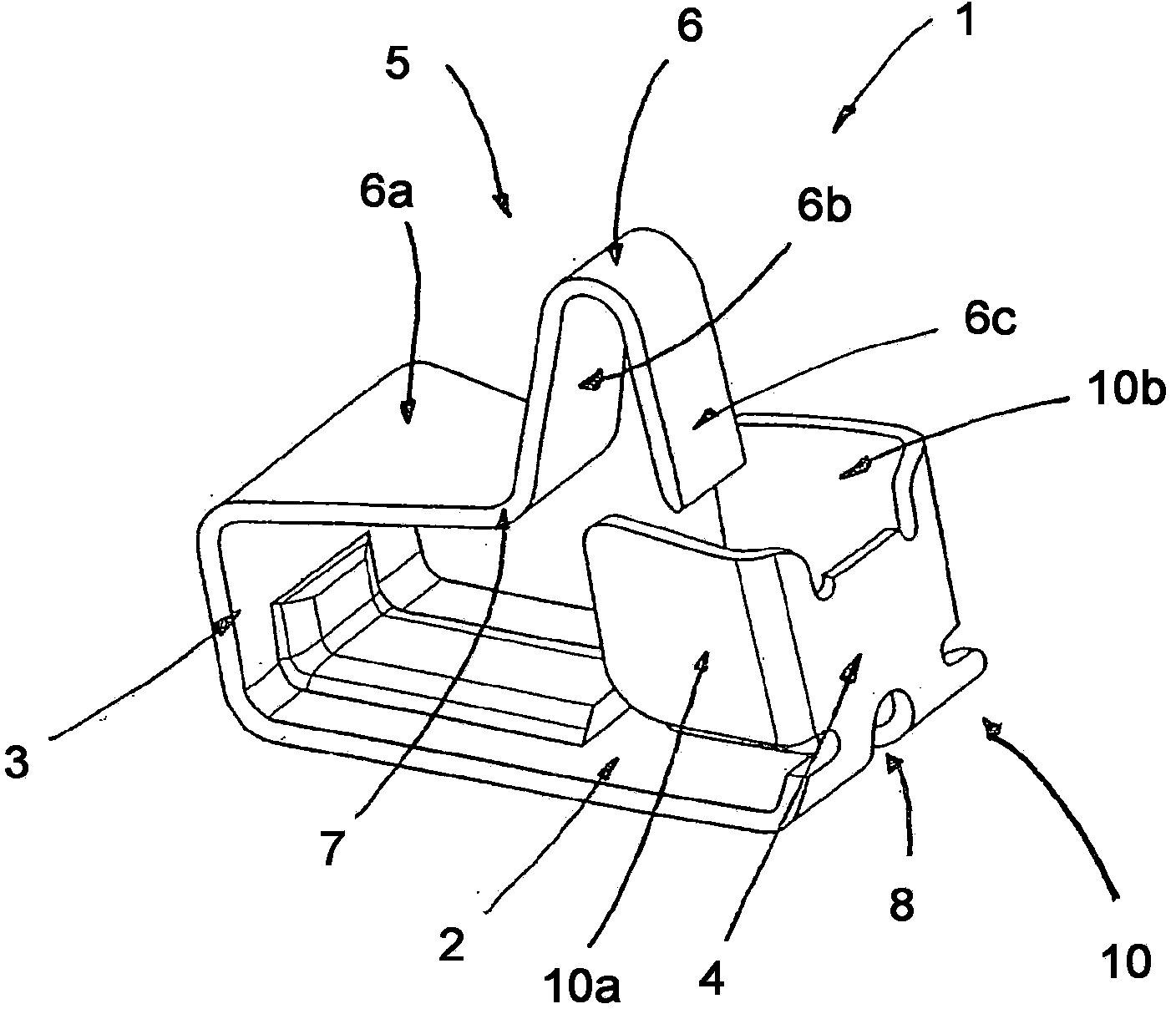

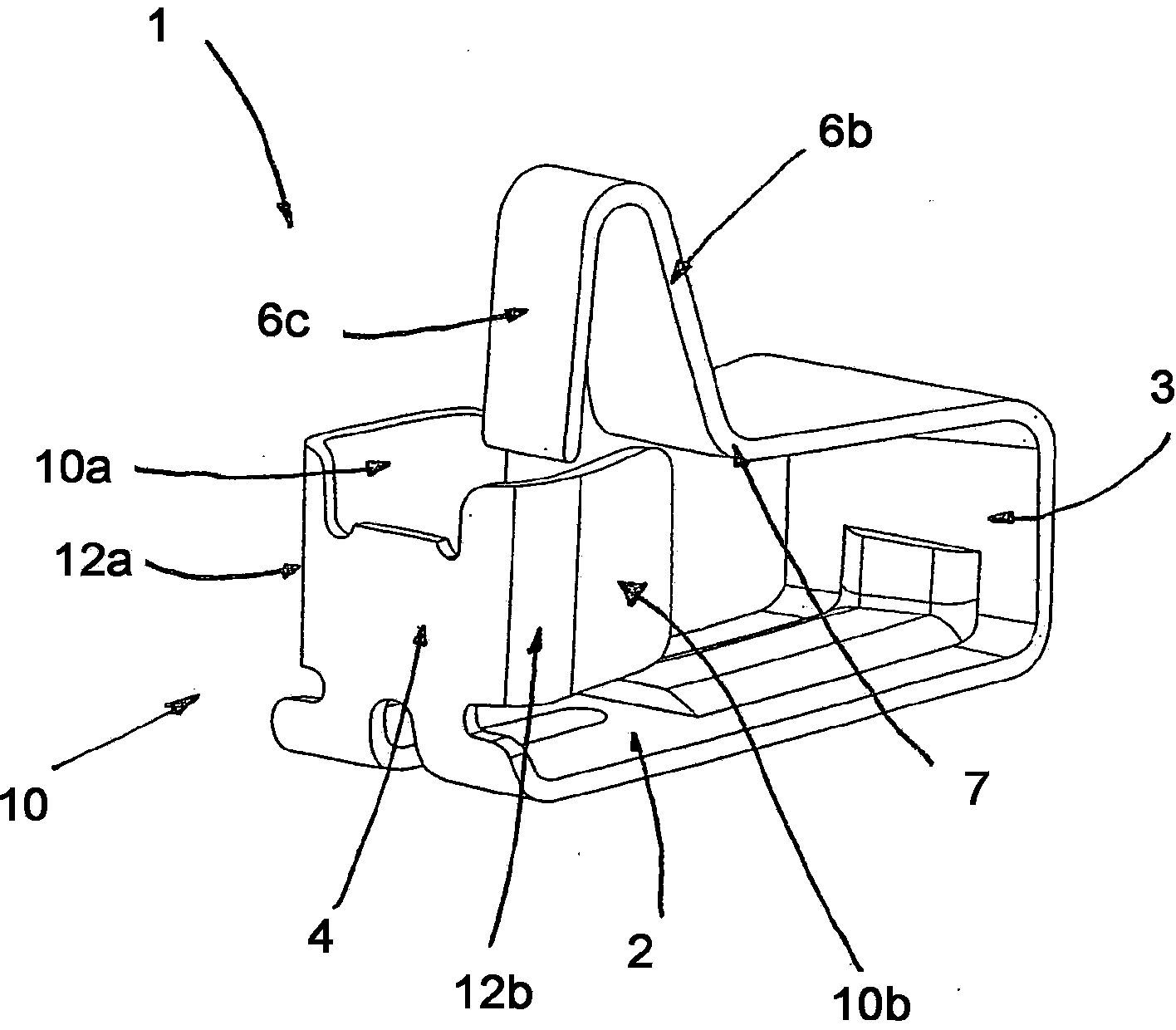

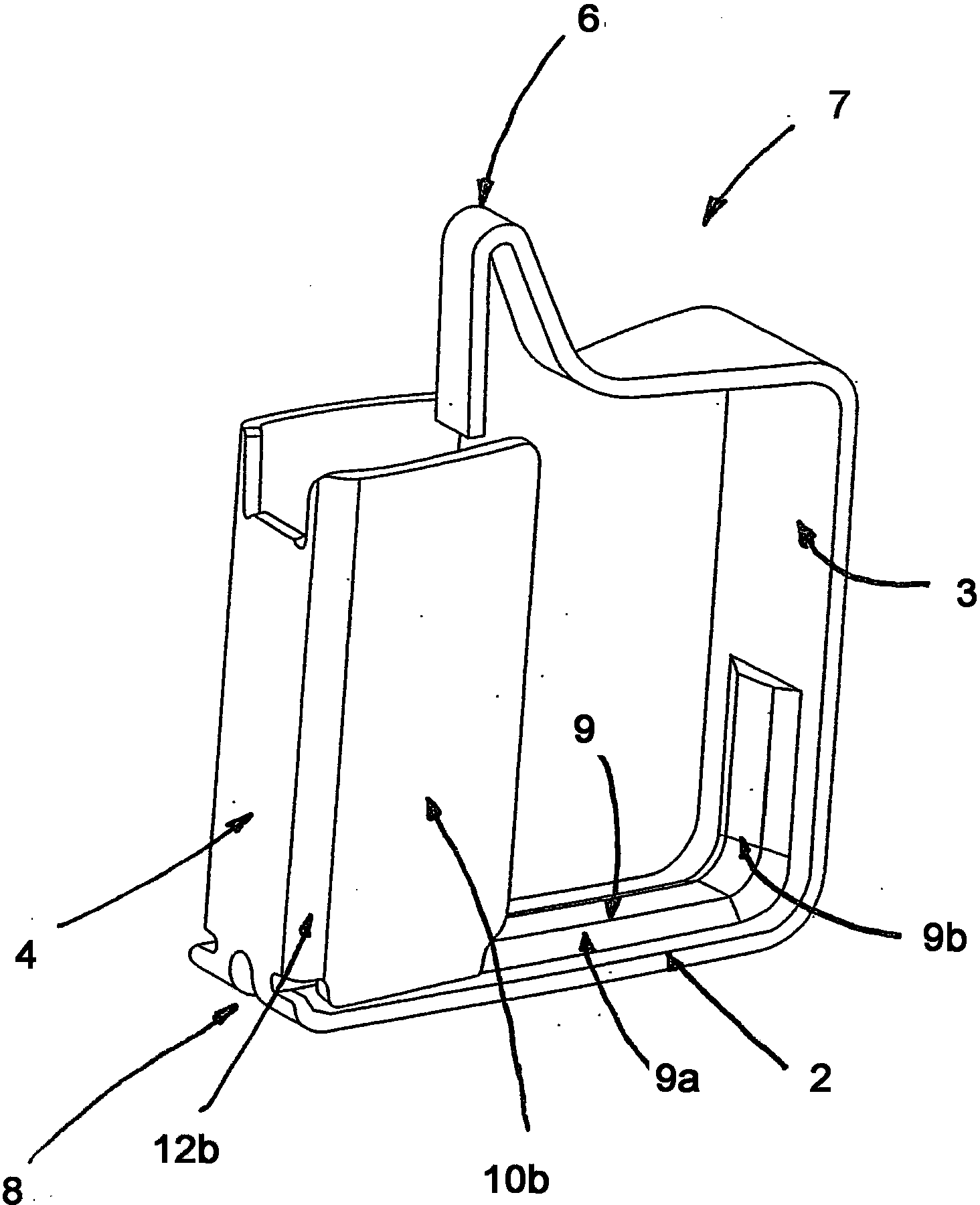

[0030] figure 1 with figure 2 A first exemplary embodiment of the invention is shown, more precisely a solder contact 1 or a spring terminal 1 .

[0031] The solder contact 1 is designed as an essentially U-shaped solder contact 1 which is formed from a base plate 2 with two legs 3 , 4 .

[0032] This U-shape is intended to represent the configuration of the base plate 2 and the two legs 3, 4, which are oriented at an angle of 90° relative to each other and in close proximity to each other.

[0033] Substrate (such as figure 1 shown in ) is designed as a substantially elongated or rectangular base plate 2 , on each longitudinal end of which a leg plate 3 and a leg plate 4 are arranged.

[0034] The leg plates 3 , 4 will hereinafter be referred to simply as legs 3 , 4 .

[0035] On the leg 3 is fixed an elastic arm 5 having a first elastic arm portion 6a extending substantially parallel to the base plate, which is adjacent to a second elastic arm portion 6b via a bend 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com