Shaft rod for heald shafts

A technology of heald frame rods and heald frames, applied in the direction of healds, textiles, textiles and papermaking, etc., to achieve the effects of reducing dynamic downward bending, large weaving width, and high machine speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

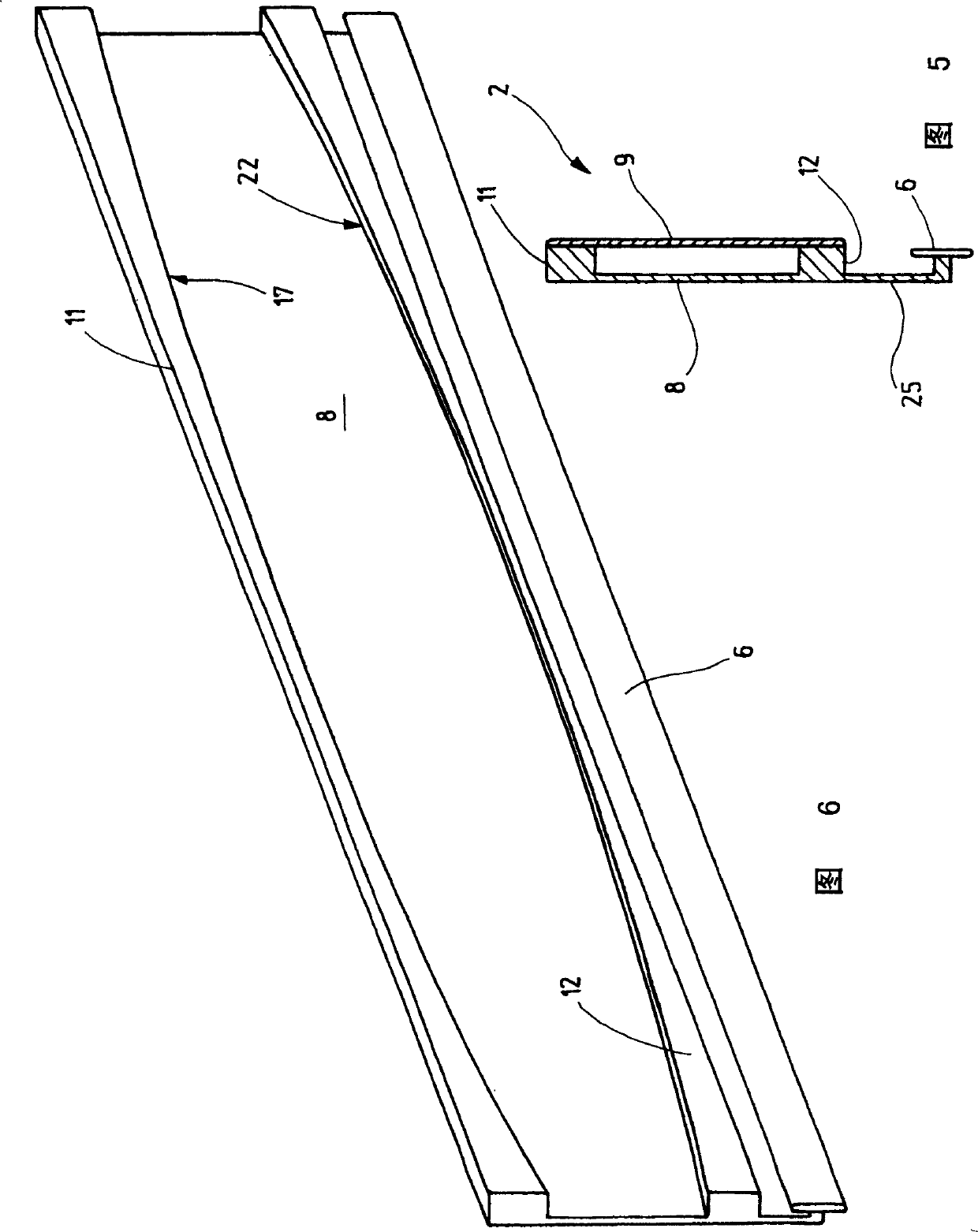

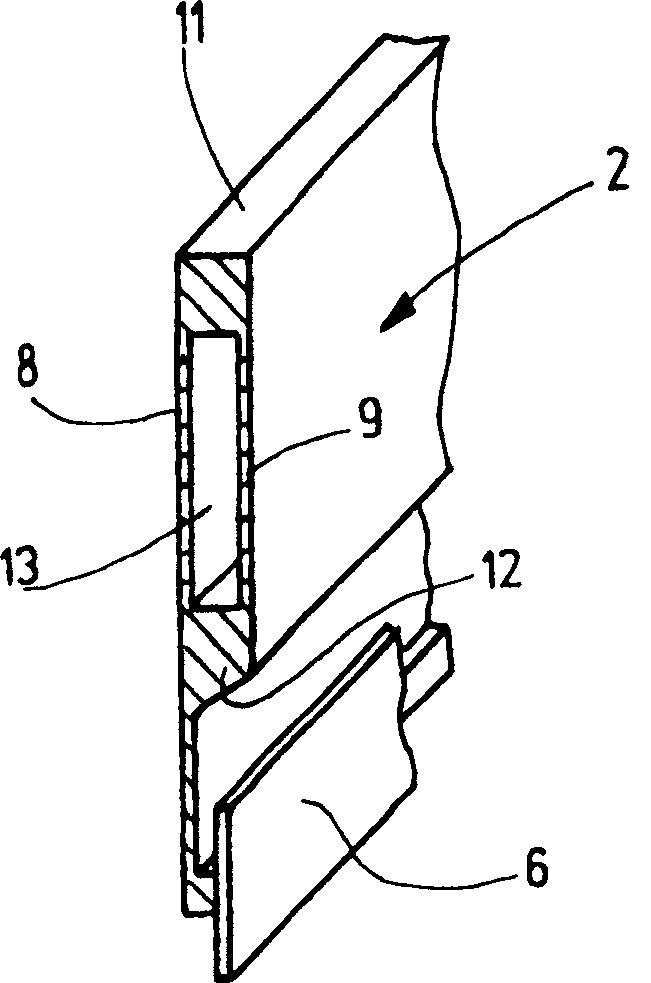

[0029] figure 1 A heald frame 1 is shown, which has an upper heald frame bar 2 , a lower heald frame bar 3 and two side supports 4 , 5 . On the heald frame bar 2,3 fixed heald guide rail bar 6,7, they are as by figure 2 As can be seen, it can be made from flat profiled steel.

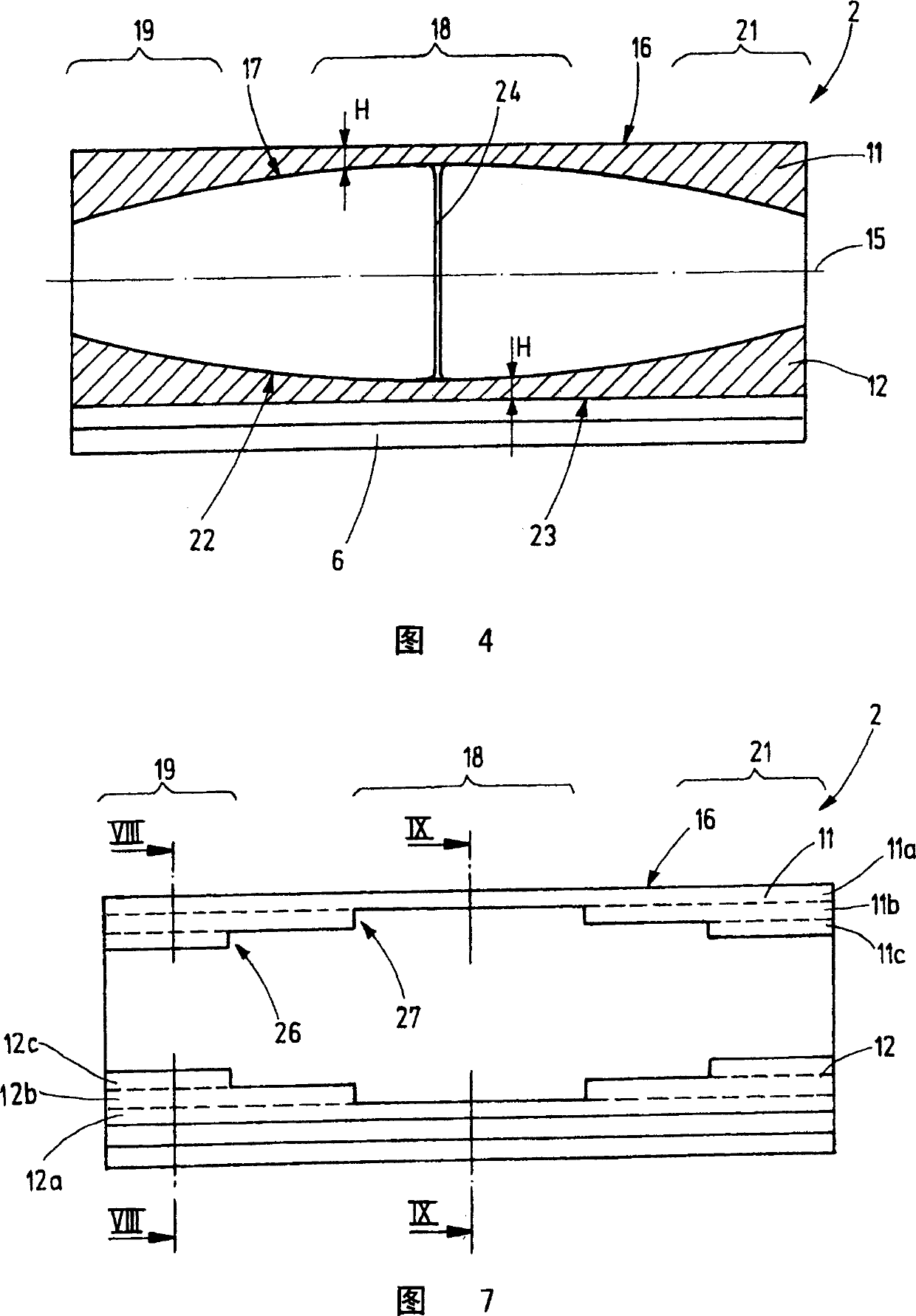

[0030] Usually, the heald frame rod 2 is made of figure 2 Visible, made from an aluminum continuous extrusion profile designed as a box-shaped hollow section. It has two side walls 8, 9 forming a flat surface. Bands 11 , 12 are provided at the top and bottom, which are integral with the side walls 8 , 9 and enclose an interior space 13 . The cross section of the heald rod 2 is constant over its length.

[0031] image 3 A variant of such a conventional heald rod is shown, which is designed as a double-chamber section with a longitudinally extending intermediate strip 10 . The heald rod has two inner chambers 13 , 14 . A part of the heald rod can be milled, in particular at its upper corner, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com