Separated bandwidth

A technology of isolation belt and surface layer, which is applied in the direction of insulation layer, floor, covering/lining, etc., can solve the problems of material consumption and complex multi-layer structure of isolation belt, and achieve the effect of saving materials and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

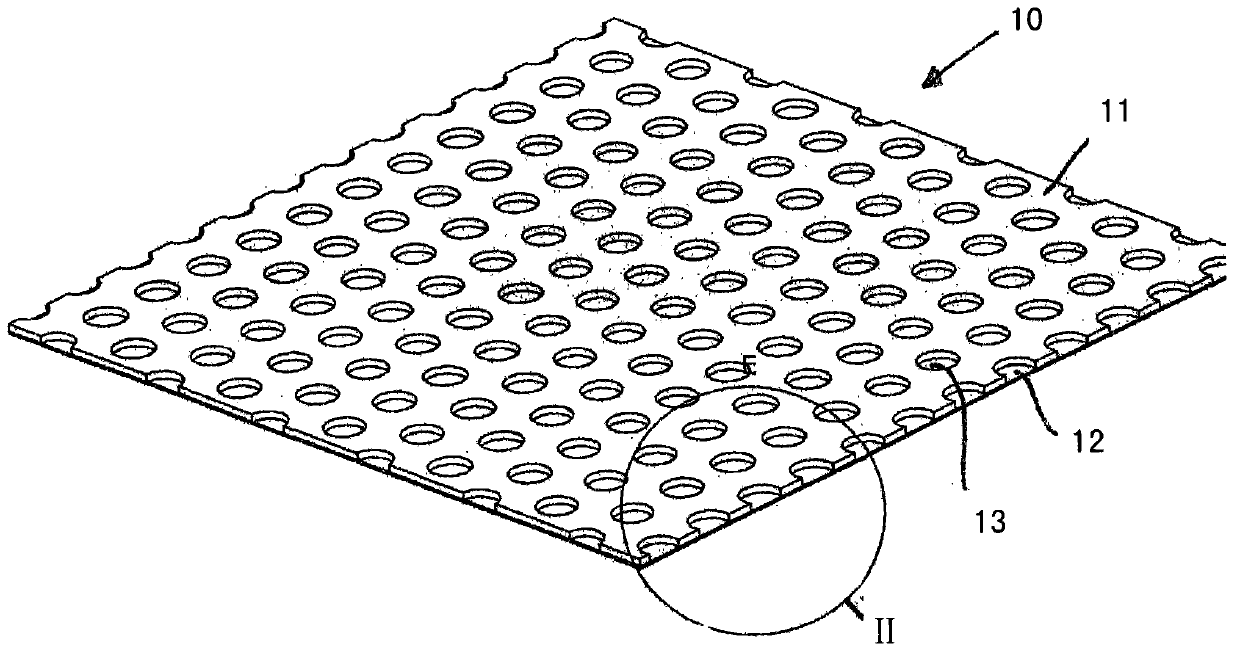

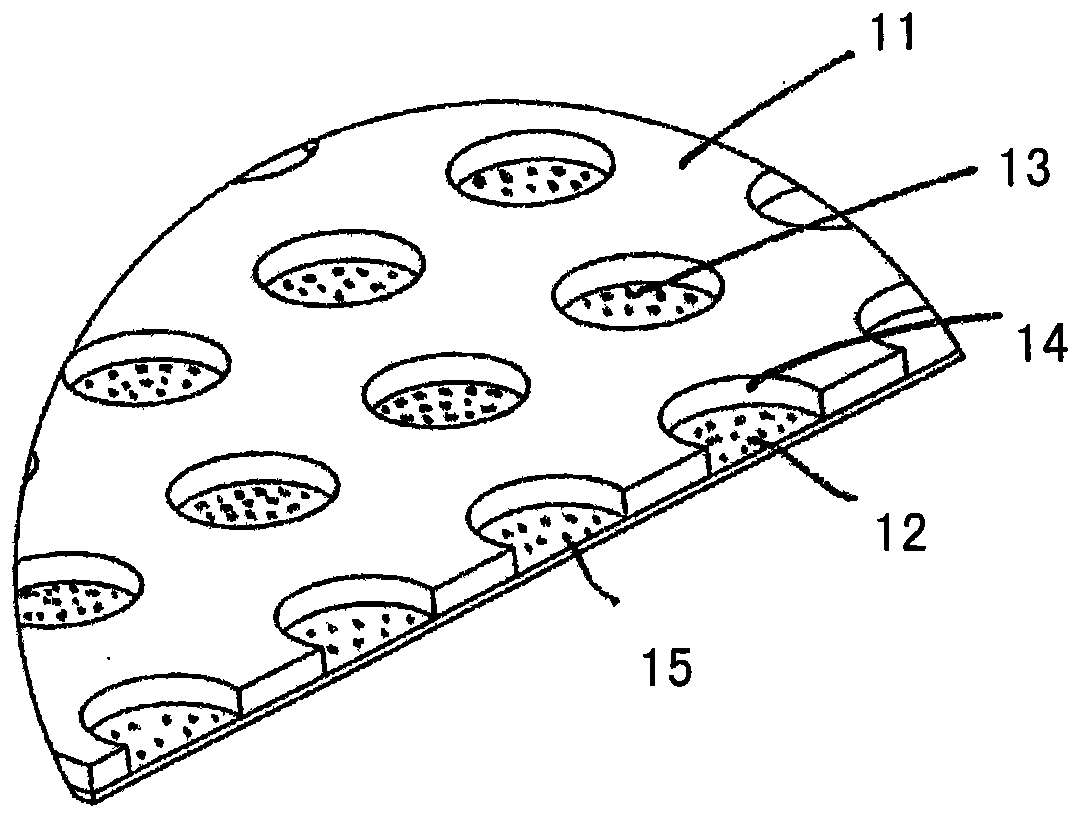

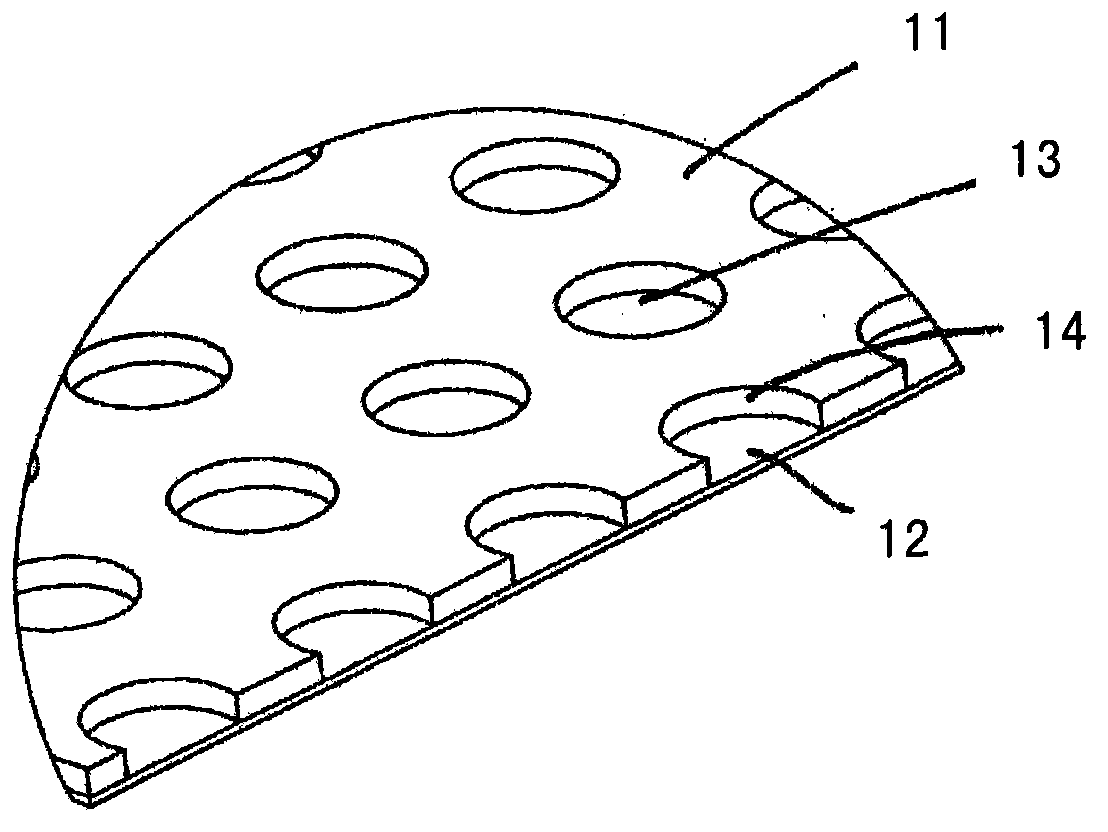

[0019] The insulating strip 10 shown in the drawings consists of two interconnected layers, to be precise, a foam layer 11 formed by foaming a waterproof and dimensionally stable foam material with small openings and a foam layer 11 according to the shown attachment. Figure laying the bottom layer 12 on its bottom surface. After the foam layer 11 has been produced, the base layer 12 can then be connected, preferably glued, to the foam layer 11 .

[0020] In the exemplary embodiment shown, perforations 13 are distributed evenly along the surface of the foam layer 11 and extend from the exposed surface of the foam layer 11 as far as the base layer 12 lying thereon. Each individual perforation 12 thus forms a surrounding wall 14 which consists of the foam material of the foam material layer 11 with small openings.

[0021] To produce the foam layer 11 it is expedient to extrude the respectively used foam. In this case, the perforations 13 can be formed directly during the extru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com