Knit slide fastener

A technology for zippers and zipper tapes, applied in the field of woven zippers, can solve problems such as difficult locking, and achieve smooth sliding and reliable locking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

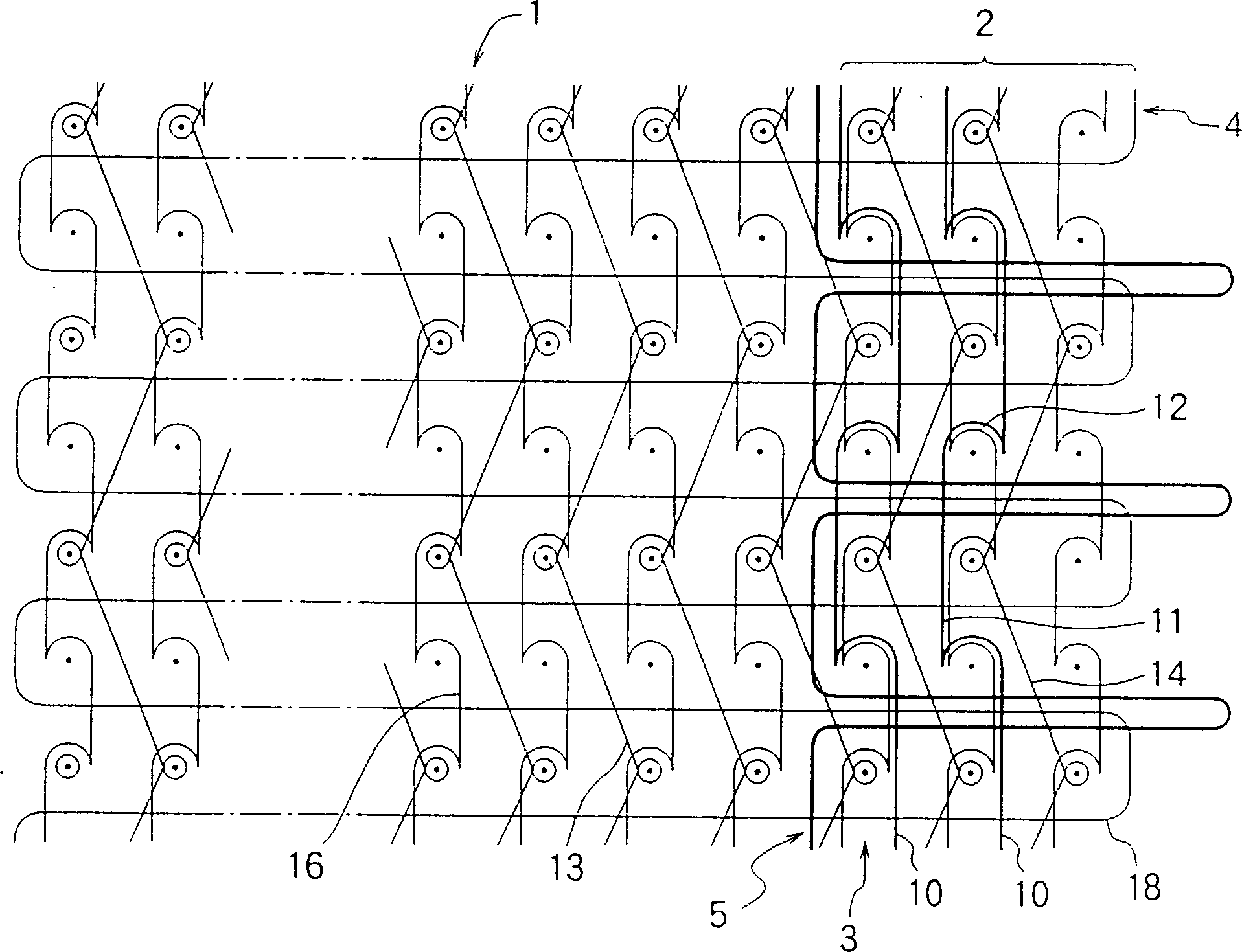

[0025] Some preferred embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. See attached figure 1 , which shows a point diagram of a braided zipper according to a first embodiment of the present invention.

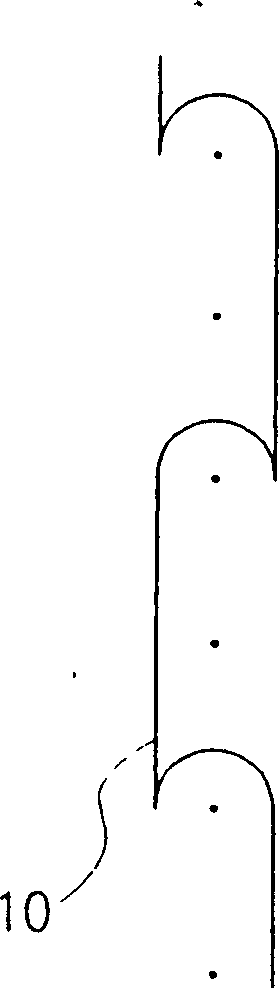

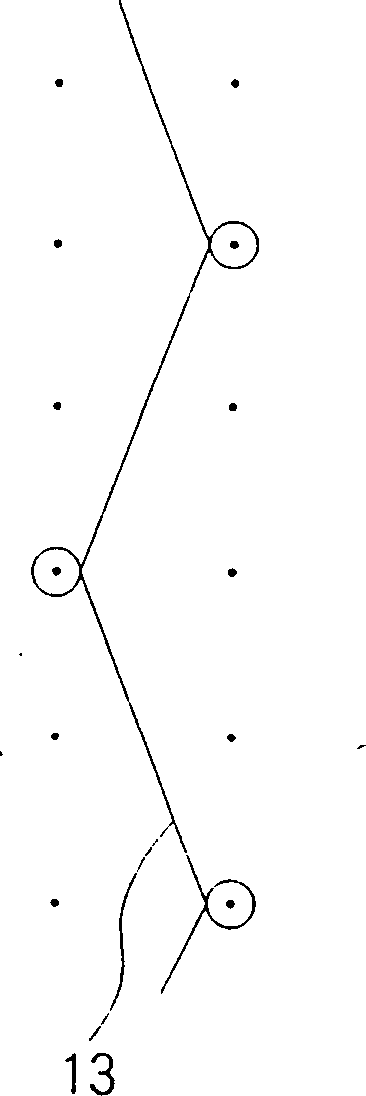

[0026] Woven zippers are knitted on a universal warp knitting machine with a single needle board. This zipper comprises warp-knitted zipper tape 1, and its base structure adopts (1-0 / 1-1 / 1-2 / 1-1 (attached Figure 2B )) type crochet stitches 13, (1-0 / 0-1 (attached Figure 2C )) type chain stitches 16, and zigzag or zigzag padding wefts that pass through the width direction of the zipper tape 1 on each course. The fastener tape 1 has three adjacent warp threads extending along one longitudinal edge portion thereof to form a fastener support area 2 to which a row of continuous helical loop fastener elements 5 are secured. A single synthetic resin monofilament reciprocates transversely across the above-ment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com