Hoisting method for large-span hinged type herringbone steel arch

A hoisting method and technology for steel arches, which are applied in the processing of building materials, construction, building structure, etc., can solve the problems of difficult installation, easy deformation of the arch, unable to meet the technical requirements of installation, etc. Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

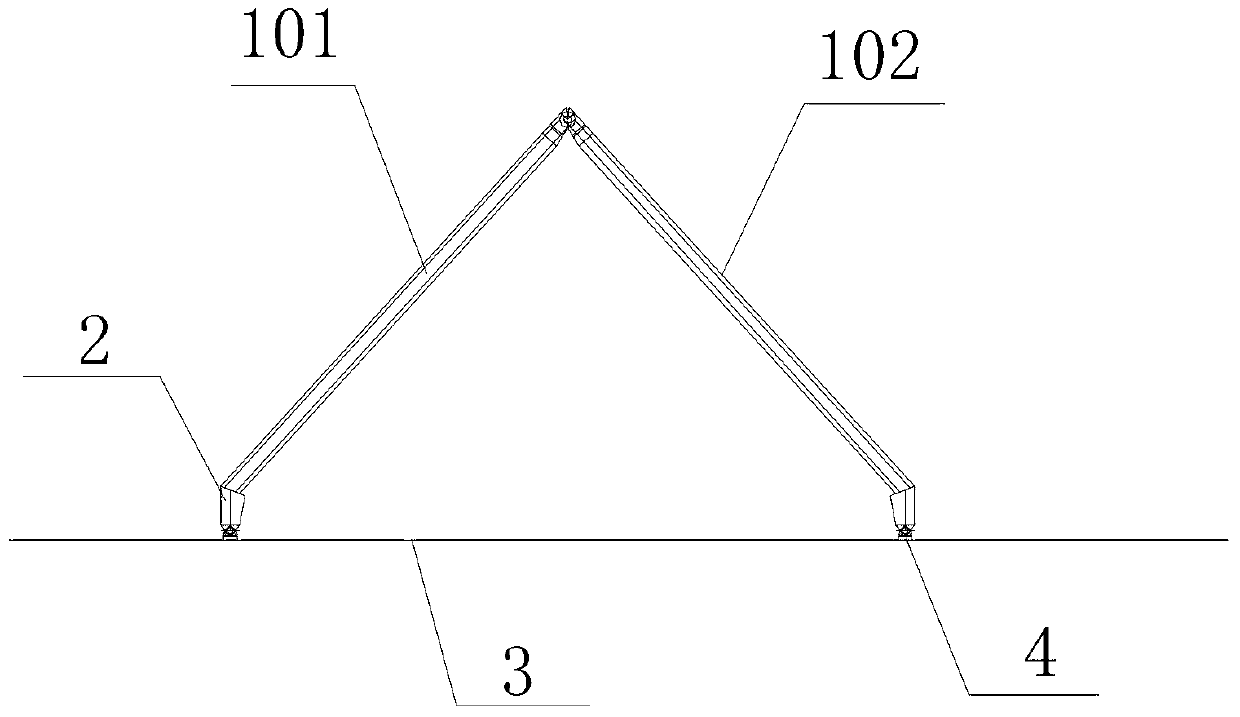

[0028] figure 1 It is a schematic diagram of a herringbone steel arch structure, such as figure 1 As shown, the herringbone steel arch 1 includes symmetrically arranged components I101 and II102. Both components I101 and II102 are welded H-shaped steels, and may also be made of other suitable materials. The tops of the component I101 and the component II102 are hingedly connected by a pin, and the distance between the two columns 2 of the component I101 and the component II102 is the design width; after hoisting, the two columns 2 and the base on the embedded plate 3 4 hinged connections. The herringbone steel arch 1 is hoisted according to the following steps:

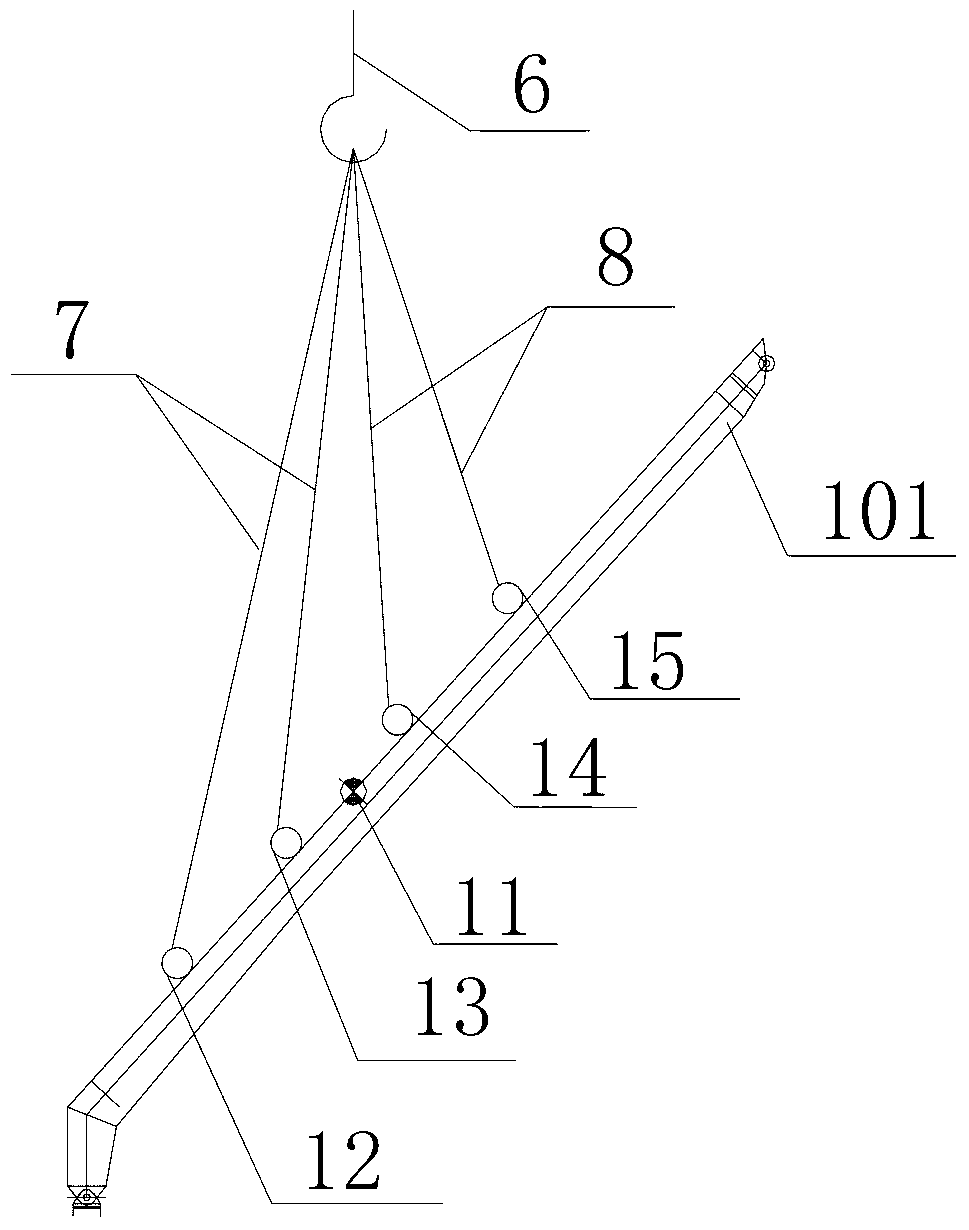

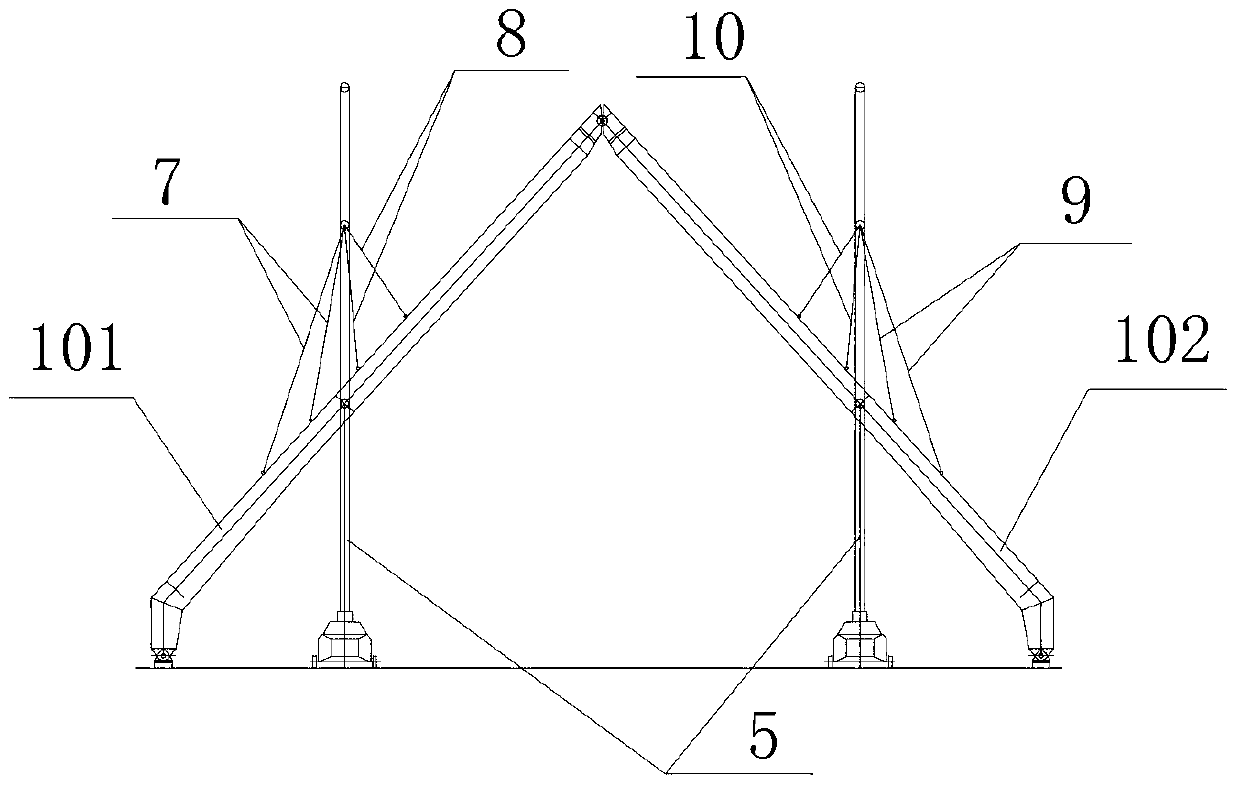

[0029] Step 1. If Figure 4 As shown, on the ground, the tops of member I101 and member II102 of the herringbone steel arch 1 are hinged and connected by pins to assemble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com