Special-shaped steel low-temperature correcting device

A special-shaped steel, low-temperature technology, applied in the field of deep processing of steel, can solve the problems of secondary damage and low correction accuracy of special-shaped steel, and achieve the effects of no secondary damage, small footprint and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

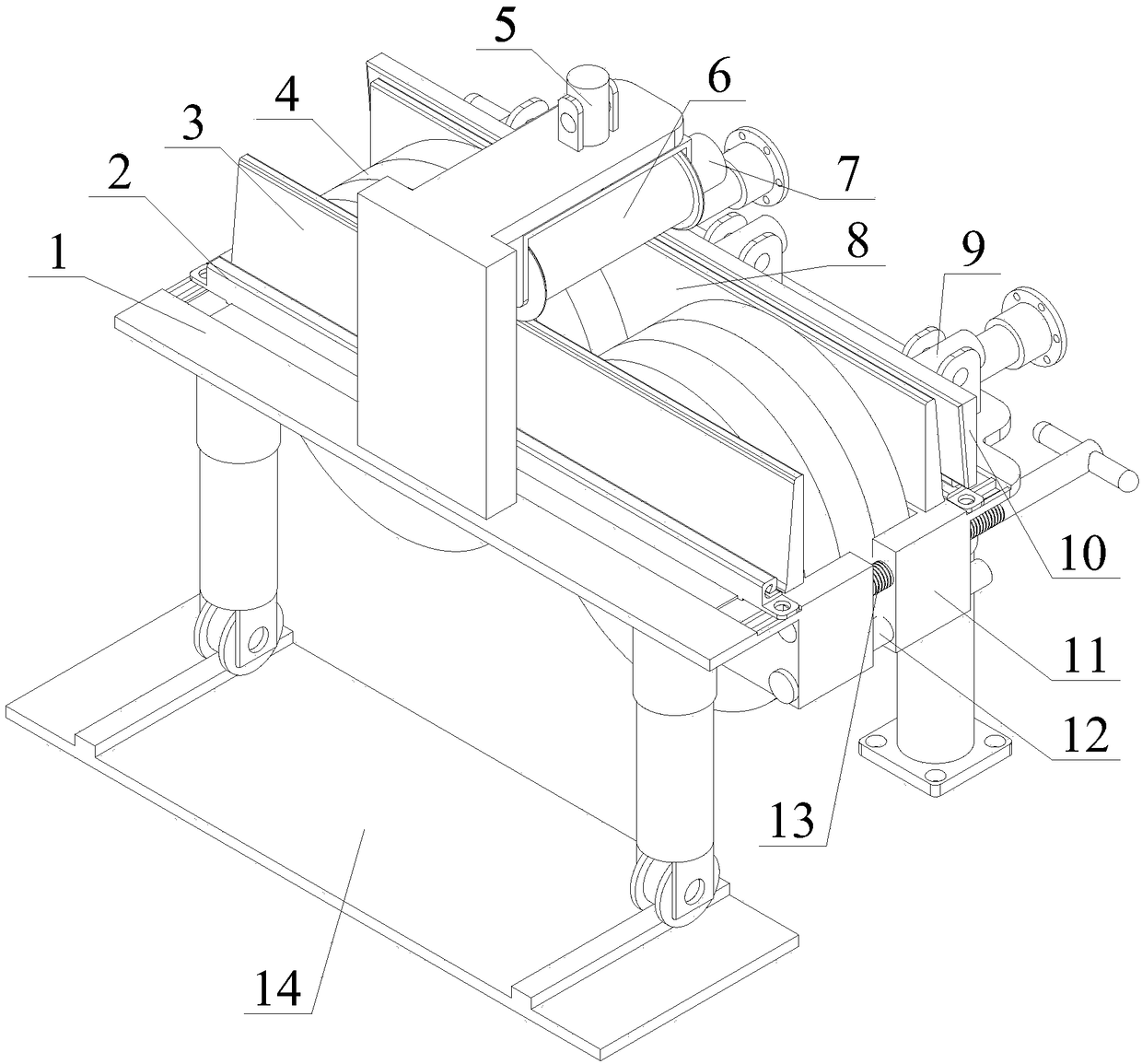

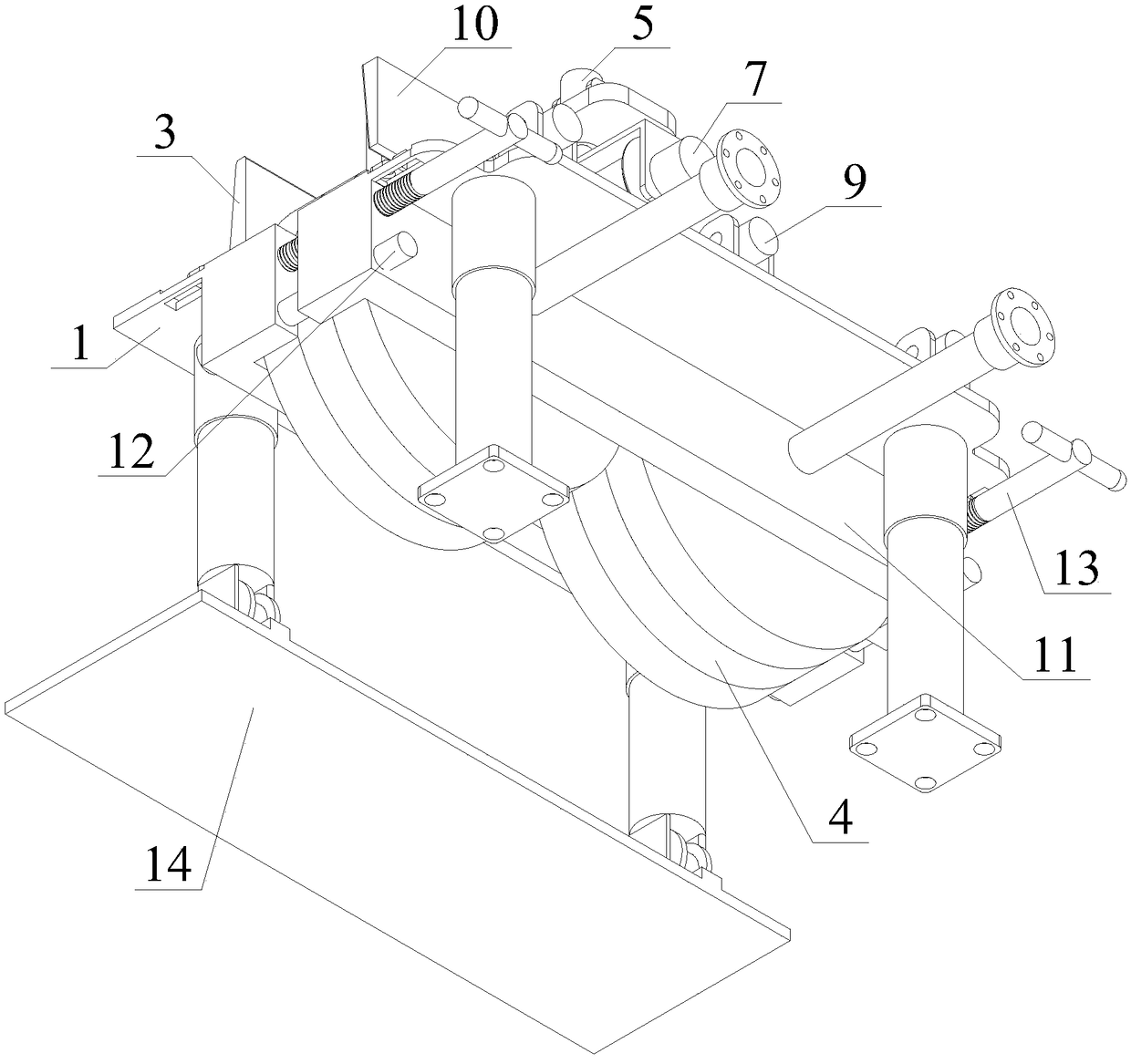

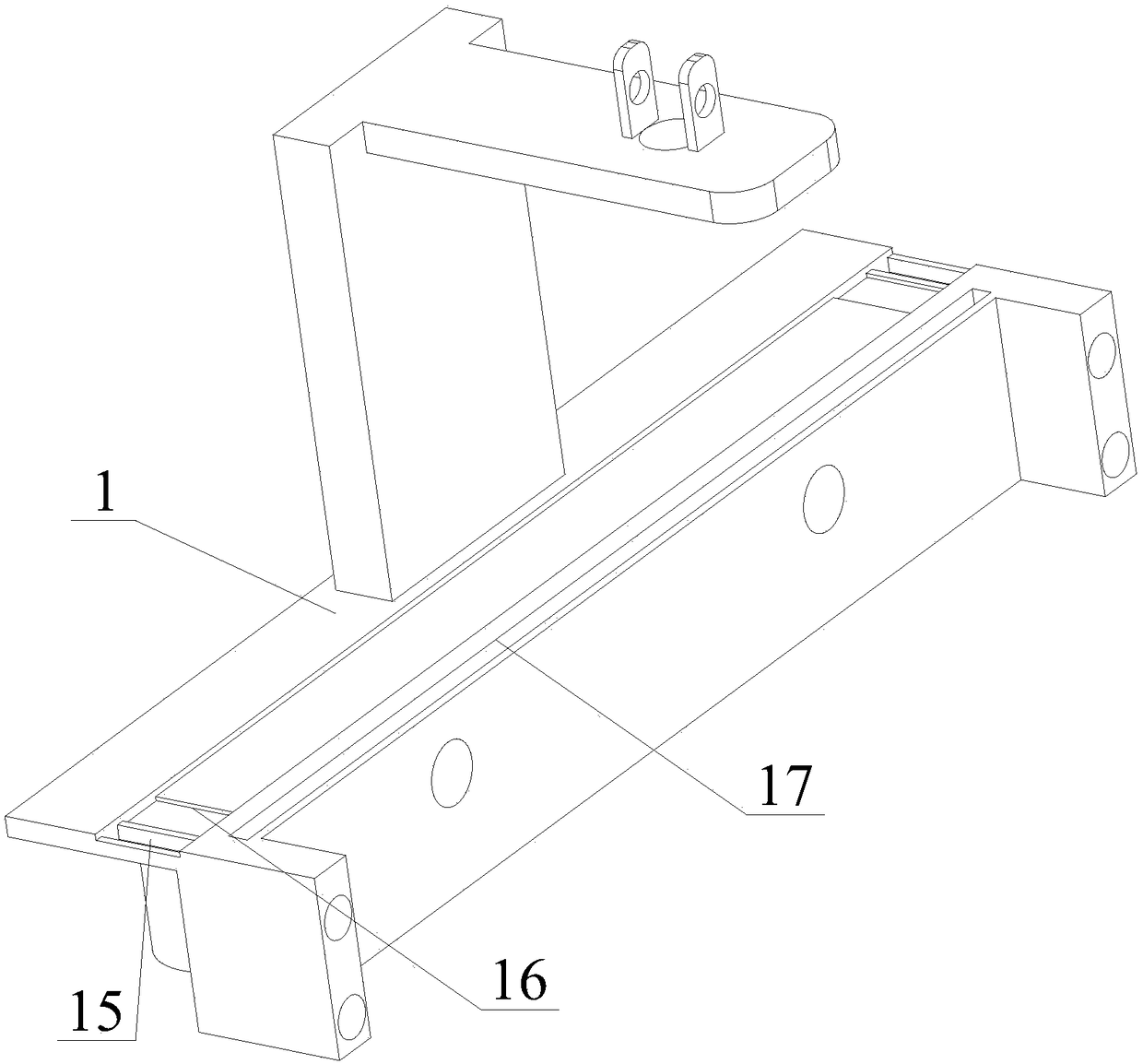

[0047] Such as Figure 1 to Figure 6 As shown, the present embodiment has two first medial correcting devices 4 devices, four first driving devices 9; Third inner orthotic device 8, first outer orthotic device 6, second outer orthotic device 2, third outer orthotic device, fourth outer orthotic device 10, second drive device 5, third drive device 7, fourth drive device 1. The number of conveying rollers is one; the first workbench and the second workbench 11 are connected by two guide rods 12 and two screw rods 13 . The first driving device 9 and the second driving device 5 are hydraulic cylinders; the third driving device 7 and the fourth driving device are motors.

[0048] When correcting and shaping, the distance between the sliding seat 1 and the mounting seat is regulated by rotating the screw mandrel 13; the number of correcting rings 18 on the transmission shaft 19 is determined (for example three) according to the workpiece (special-shaped steel to be corrected) size....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com