Installation device for auto door seal strip of automobile

A technology for installing equipment and car doors. It is used in motor vehicles, transportation and packaging. It can solve problems such as the inability to guarantee the pressing force of the sealing strip, the uneven bonding surface of 3M glue, and the distortion of the sealing strip. Improve assembly quality and avoid stretching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

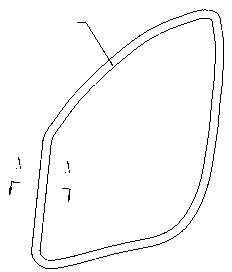

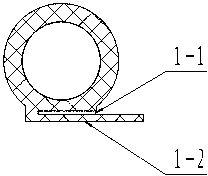

[0021] See Figure 1, figure 2 , the integral 3M adhesive sealing strip 1 is consistent with the profile of the door frame, and the sealing strip 1 is provided with a notch card groove 1-1 and an adhesive surface 1-2.

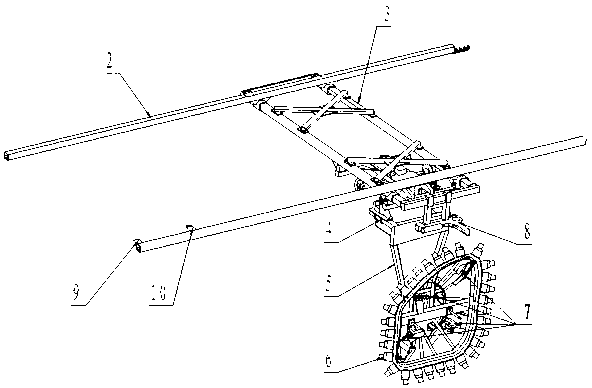

[0022] see image 3 , Figure 4 , the present invention includes a fixed slide rail 2, a translation slide rail 3, a sliding trolley 4 and a profiling frame 5, the fixed slide rail 2 is composed of two longitudinal rails, the translation slide rail 3 is arranged transversely, and it is connected with the fixed slide rail The rail 2 is equipped, the sliding trolley 4 is equipped with the translation slide rail 3, and the outline shape of the profiled frame 5 matches the door frame. It is hoisted under the sliding trolley 4, and a A group (not less than two) of positioning pins 5-1, which match the positioning holes on the door sheet metal structure 11, and a group of clamping units 7 are also arranged on the profiling frame 5, the clamping units 7 The quantit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com