Aero-engine blisk-blade welding repair clamping device

An aero-engine and blisk technology, applied in the field of aviation maintenance, can solve the problems of poor quality, lack of stability of the aero-engine blisk-blade welding repair process, lack of flexible adjustment of clamping tooling and cooling and heat dissipation capabilities, etc., to achieve Strong stability, diverse adjustments, and effective heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

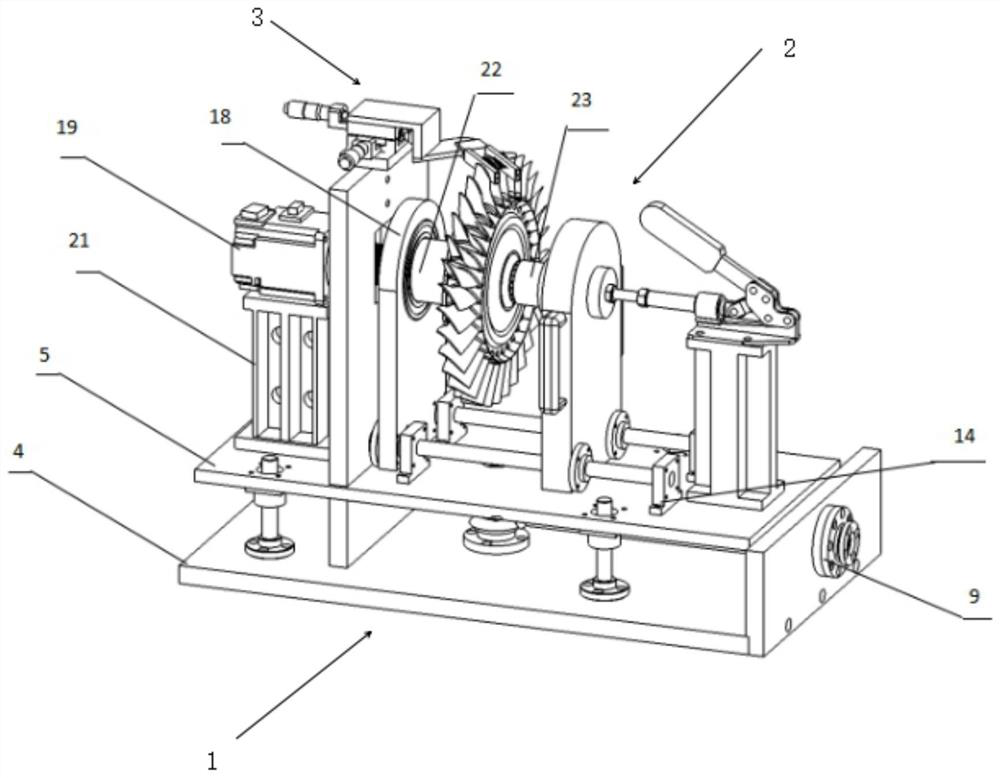

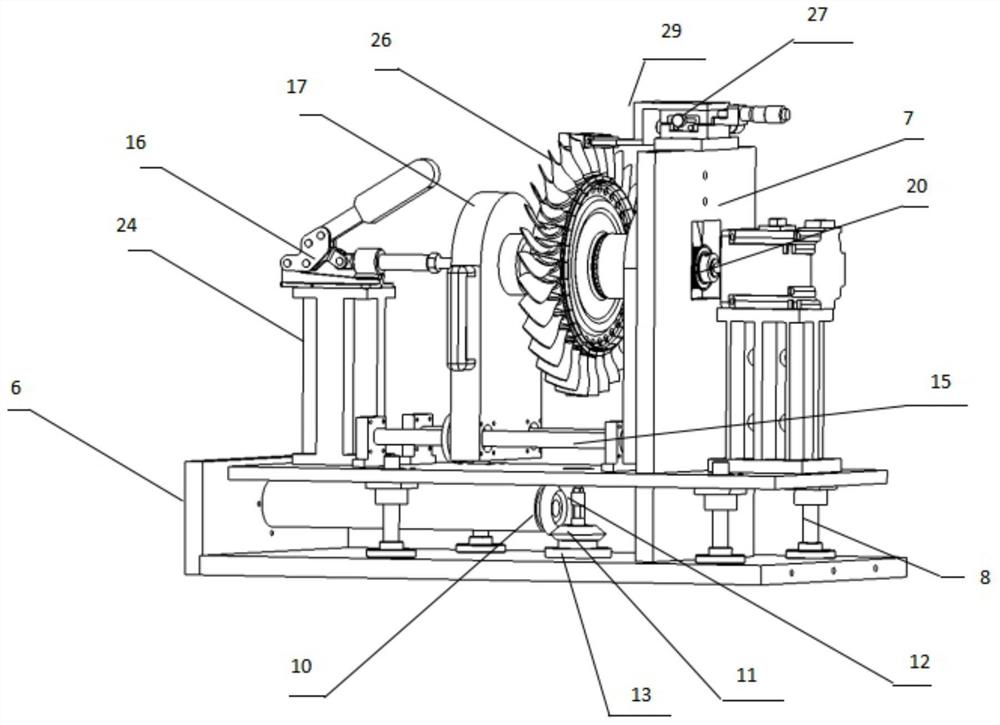

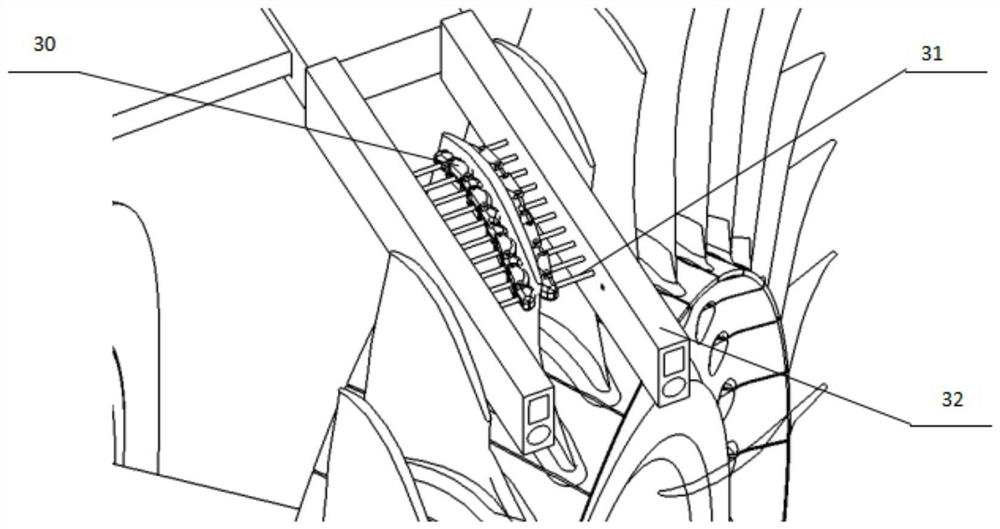

[0021] Such as Figure 1 to Figure 3 As shown, the aero-engine integral blisk-blade welding repair clamping device provided by the present invention is innovative in that it includes a platform linear lifting system 1, an integral blisk clamping rotation system 2 and a blade flexible clamping system 3; The leaf disc assembly and clamping system 2 is installed on the platform linear lifting system 1, and can be lifted together with the platform linear lifting system 1; the blade flexible clamping system 3 is located on the top of the vertical plate on the right side of the platform linear lifting system 1, and can be moved along the XY direction Hold the blades.

[0022] The platform linear lifting system 1 includes a base plate 4, a lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com