Positioning and mounting structure for rear auxiliary frame of electric vehicle

A technology of rear subframe and installation structure, which is applied in the direction of the connection between the upper structure, the lower structure and the sub-assembly of the upper structure, to achieve the effect of enhancing the local rigidity and strength, reducing the difficulty of installation and simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

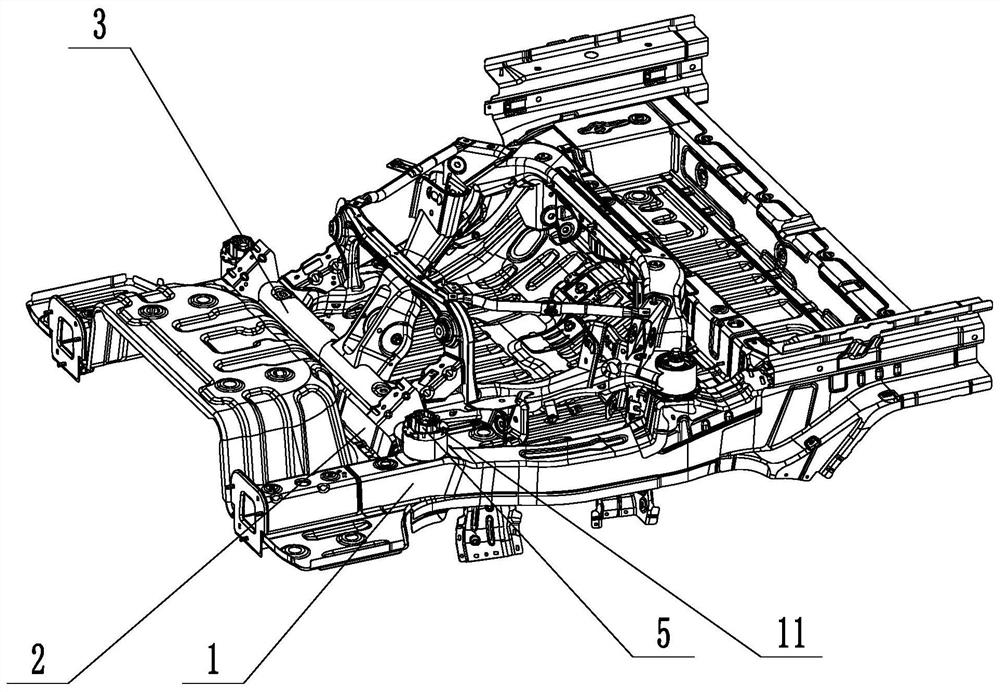

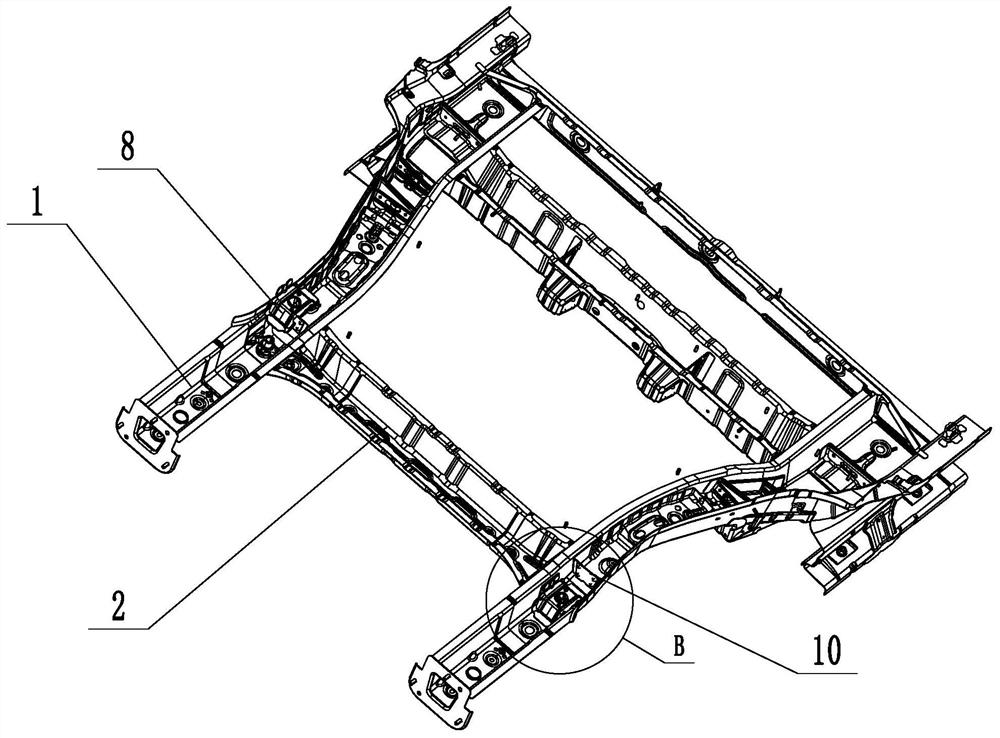

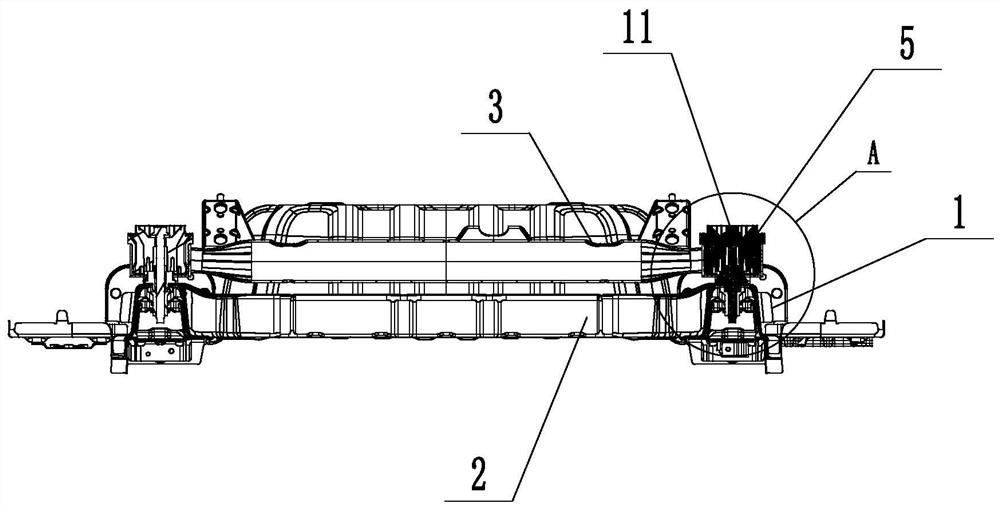

[0025] Such as figure 1 , figure 2 with image 3 As shown, a rear sub-frame positioning and installation structure of an electric vehicle includes a rear longitudinal beam 1, a rear cross beam 2, a rear sub-frame 3, a U-shaped reinforcement 6, a middle support 7, a box-shaped reinforcement plate 8 and a longitudinal The beam reinforcement plate 10, the two ends of the rear cross beam 2 are respectively fixed to the rear longitudinal beam 1 on both sides, and the two joints of the rear cross beam 2 and the rear longitudinal beam 1 are each provided with a positioning connecting pipe 4, such as Figure 4 As shown, the positioning connecting pipe 4 is provided with a positioning counterbore 4.1, and the bottom surface of the positioning counterbore 4.1 is provided with a connecting threaded hole 4.2, and each side of the rear subframe 3 is provided with a positioning bushing 5, and one of the positioning bushings 5 The outer contour of the positioning boss 5.1 on the top is ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com