Steering shaft for electric boosting steering system

A technology of electric power steering and steering shaft, which is applied in the direction of electric steering mechanism, automatic steering control components, steering mechanism, etc., and can solve problems such as small matching surface, torque fluctuation of torsion bar, complex processing of input shaft and output shaft, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

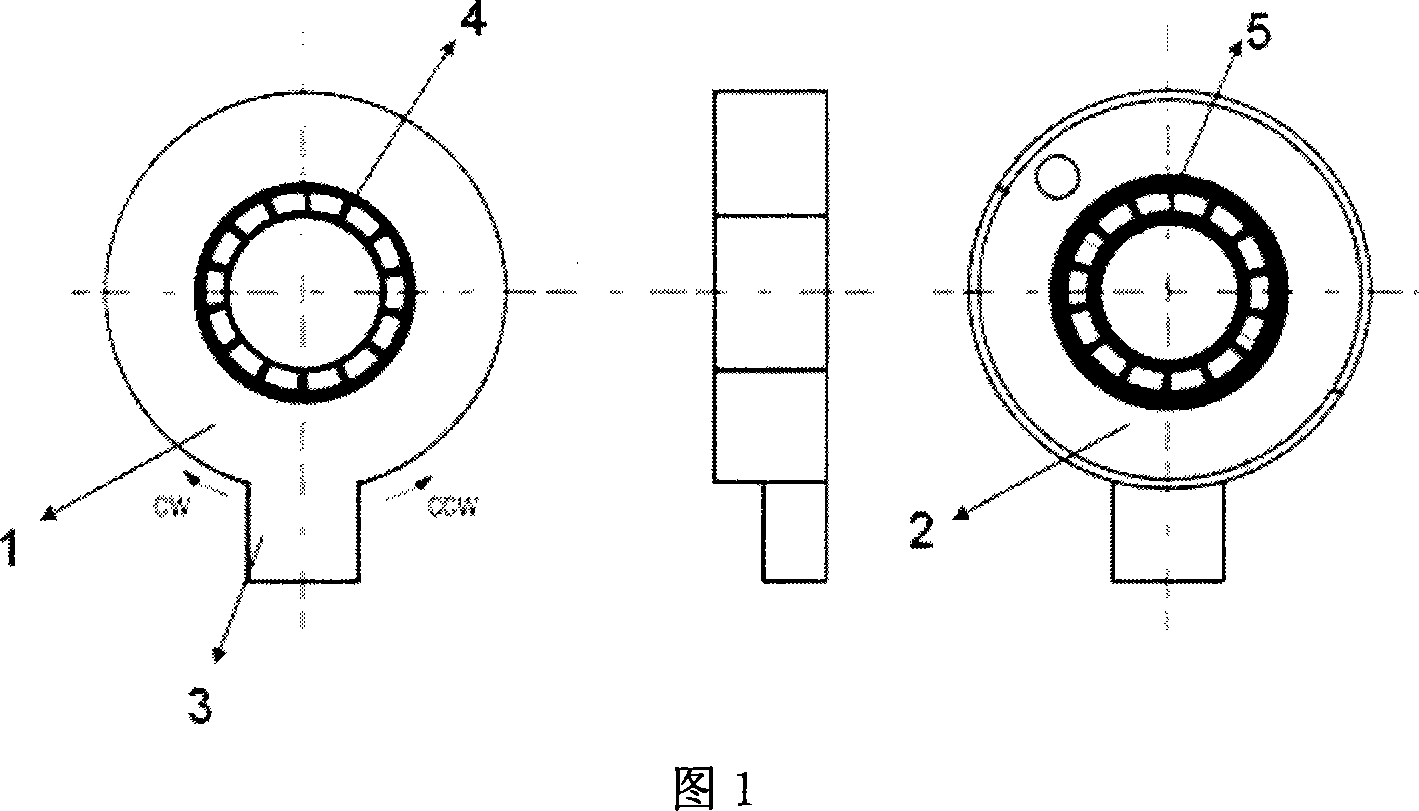

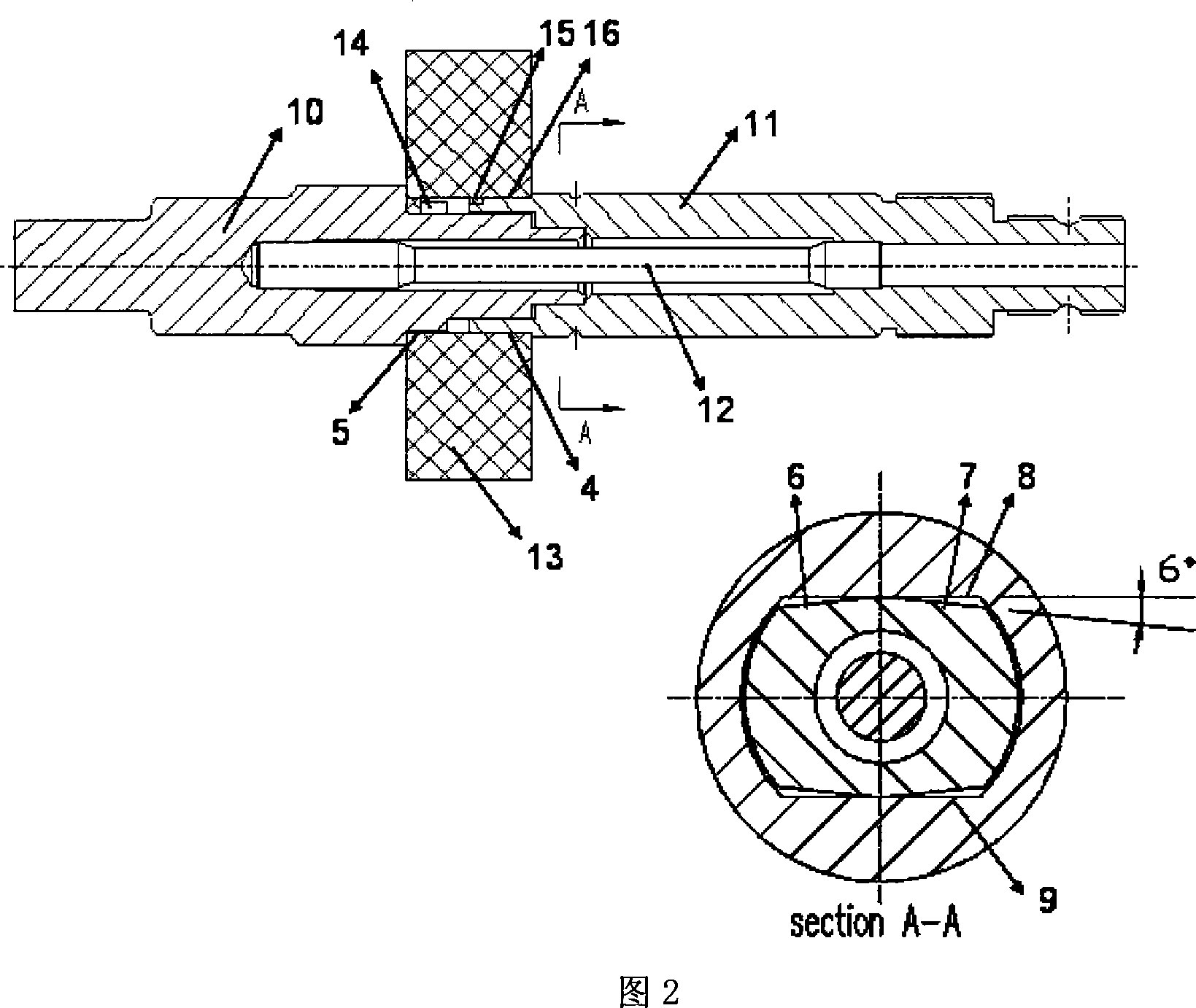

[0011] As shown in FIGS. 1 and 2 , the present invention mainly includes: an input shaft 10 , an output shaft 11 , and a torsion bar 12 . The connection method is as follows: in Fig. 1, 1 and 2 are the shell of the torque-angle composite sensor, 3 is the output end of the data line, and 4 and 5 are the inner rings that can rotate relative to the shell. 4 is called the position rotor, which is connected with the output shaft 11, and 5 is called the torque rotor, which is connected with the input shaft 10.

[0012] FIG. 2 is an assembly diagram of the installation device of the torque-rotation-angle composite sensor 13 designed in the present invention. The upper end of the input shaft 10 is fixedly connected to the steering wheel, and the lower end is connected to the output shaft 11 through the torsion bar 12 to transmit the driver's torque on the steering wheel; the output shaft 11 is connected to the wheel to be steered through the universal transmission and the rack steerin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com