Method for machining universal robot welding fixture of middle-large size excavator movable arm and supporting base

A technology of robotic welding and processing methods, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of inability to ensure accurate positioning, inability to ensure the beauty of the weld seam and the shape of the welded section, and achieve guaranteed The effect of performance and reliability, reliable performance and high welding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

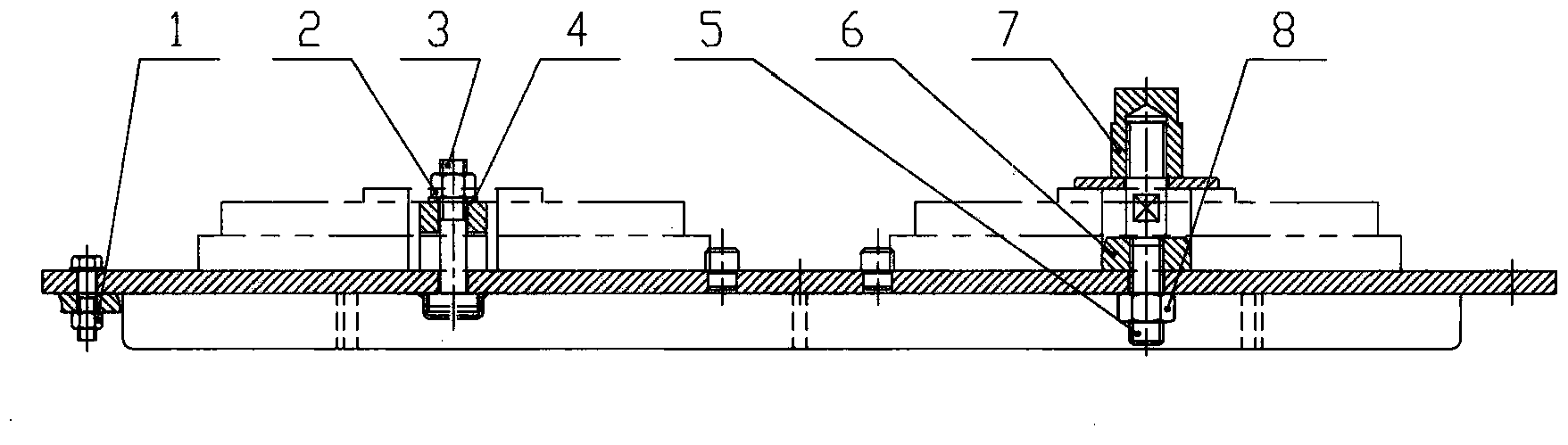

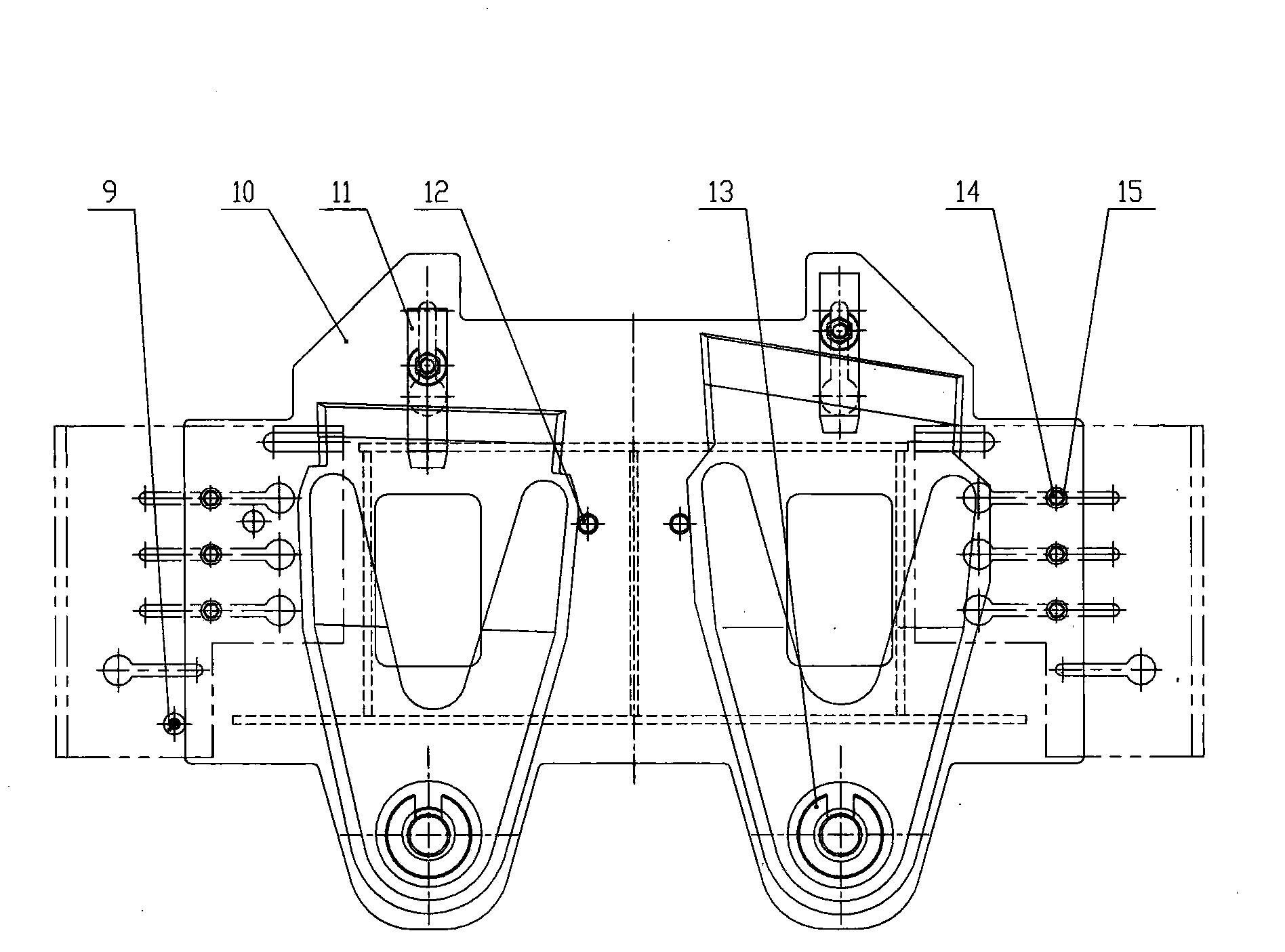

[0024] figure 1 and figure 2 Shown are schematic diagrams of the front view and top view of the universal robot welding tool for the arm support of medium and large excavators, and the processing method of the universal robot welding tool for the arm support of medium and large excavators, including the following steps:

[0025] Step 1: Select a plate that can be placed on the worktables of two welding robots and has roughly the same shape as the arm support of the excavator as the base 10;

[0026] Step 2: Assemble the first positioning pin 9 on the worktable of the welding robot on one side, which is used to locate the degree of freedom of the left and right directions of the base 10;

[0027] Step 3: Drill three through holes at both ends of the base 10, the positions of the through holes should correspond to the grooves on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com