Device for installing crank shaft rear oil seal

A technology for oil seals and crankshafts, which is applied in the installation field of crankshaft rear oil seals, can solve problems such as oil leakage of rear oil seals, achieve the effects of ensuring the installation position and installation accuracy, being practical and convenient, and preventing installation from tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

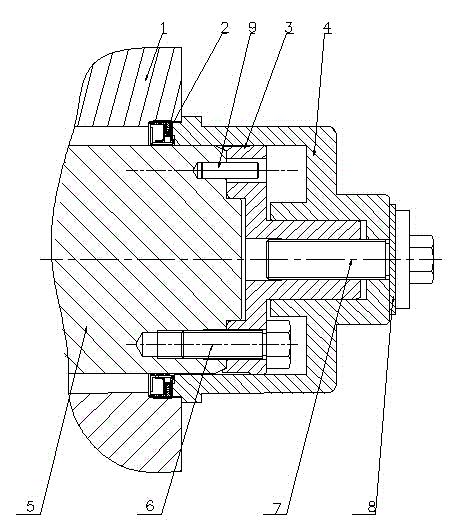

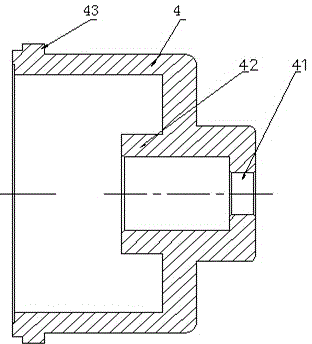

[0021] combine figure 1 As shown, a device for installing a crankshaft rear oil seal includes a crankcase housing 1, a crankshaft located in the crankcase housing 1, and an oil seal 2 sleeved between the crankshaft 5 and the crankcase housing 1. The oil seal 2 A mounting device is provided at the rear end of the rear oil seal, and the rear oil seal installation device includes a connecting plate 3, a sliding gland 4 sleeved on the outside of the connecting plate 3 and slidingly fitted with the connecting plate 3, and a sliding gland 4 passing through the connecting plate 3 The threaded hole 33 matches the compression nut 7.

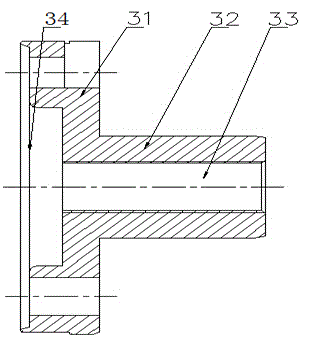

[0022] combine figure 2 As shown, the connecting plate 3 includes a disc 31, and the center of the left end face of the disc 31 is provided with an open mounting hole 34. and three fixing bolts 6 to fix the disk 31 on the rear end su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com