End cover of differential mechanism of racing automobile

A differential and end cover technology, applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of oil leakage, reduce the strength of the differential, etc., and achieve reliable connection and stable torque transmission , the effect of avoiding the danger of oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

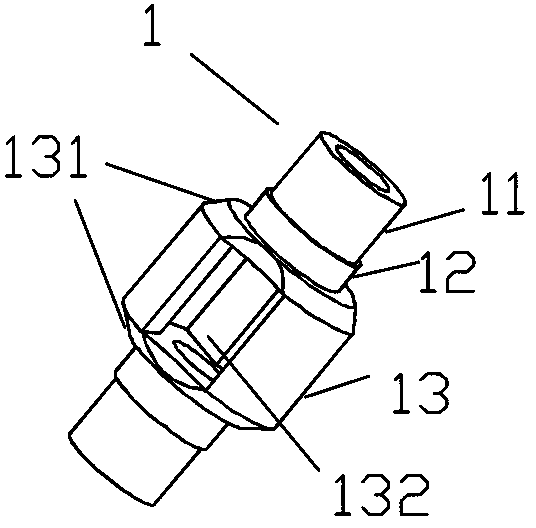

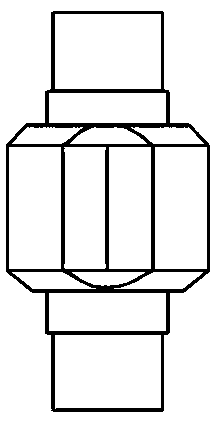

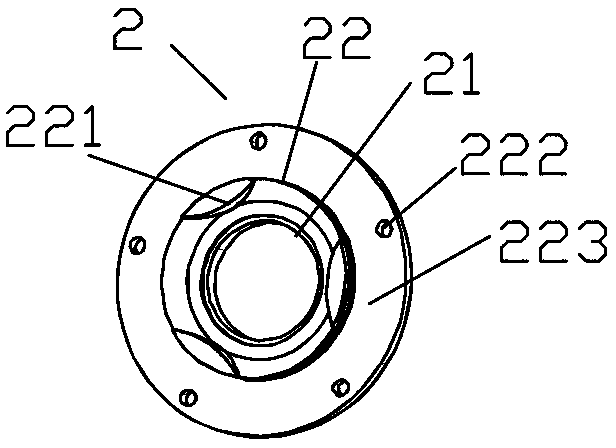

[0011] Such as Figure 1-5 As shown, the end cover of this racing differential, the racing differential 1 includes an upper end, a middle part, and a lower end, and the upper end includes a first cylinder 11 and a second cylinder with diameters D1 and D2 from top to bottom. Body 12, the middle part is a third cylinder 13 with a diameter D3, D1<D2<D3, the upper and lower ends of the third cylinder have chamfers 131, and three holes uniformly distributed around the circumference are opened on the side wall of the third cylinder. A through groove 132, the cross section of the through groove is fan-shaped with a radius r and a chord height h, the end cover 2 includes an upper bushing 21 and a lower bushing 22, the inner diameters of the upper and lower bushings are respectively D4, D3, D4=D2 =D3-2r+2h, the inner wall of the lower bushing has protrusions 221 fitted with three through grooves, the cross section of the protrusions is fan-shaped with radius r and chord height h, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com