Hydraulically driven reducer release device

A technology of disengagement device and reducer, which is applied to fluid-driven clutches, non-mechanical-driven clutches, mechanical equipment, etc., can solve the problems of long time, high risk, and high installation errors, and achieve the effect of avoiding tedious work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention mainly relates to a hydraulically driven reducer release device, in particular to a reducer release device for walking machinery.

[0025] The hydraulically driven speed reducer disengaging device according to the present invention will be described in detail below with reference to the accompanying drawings. Throughout the drawings, structurally or functionally identical or similar elements are denoted by the same reference numerals.

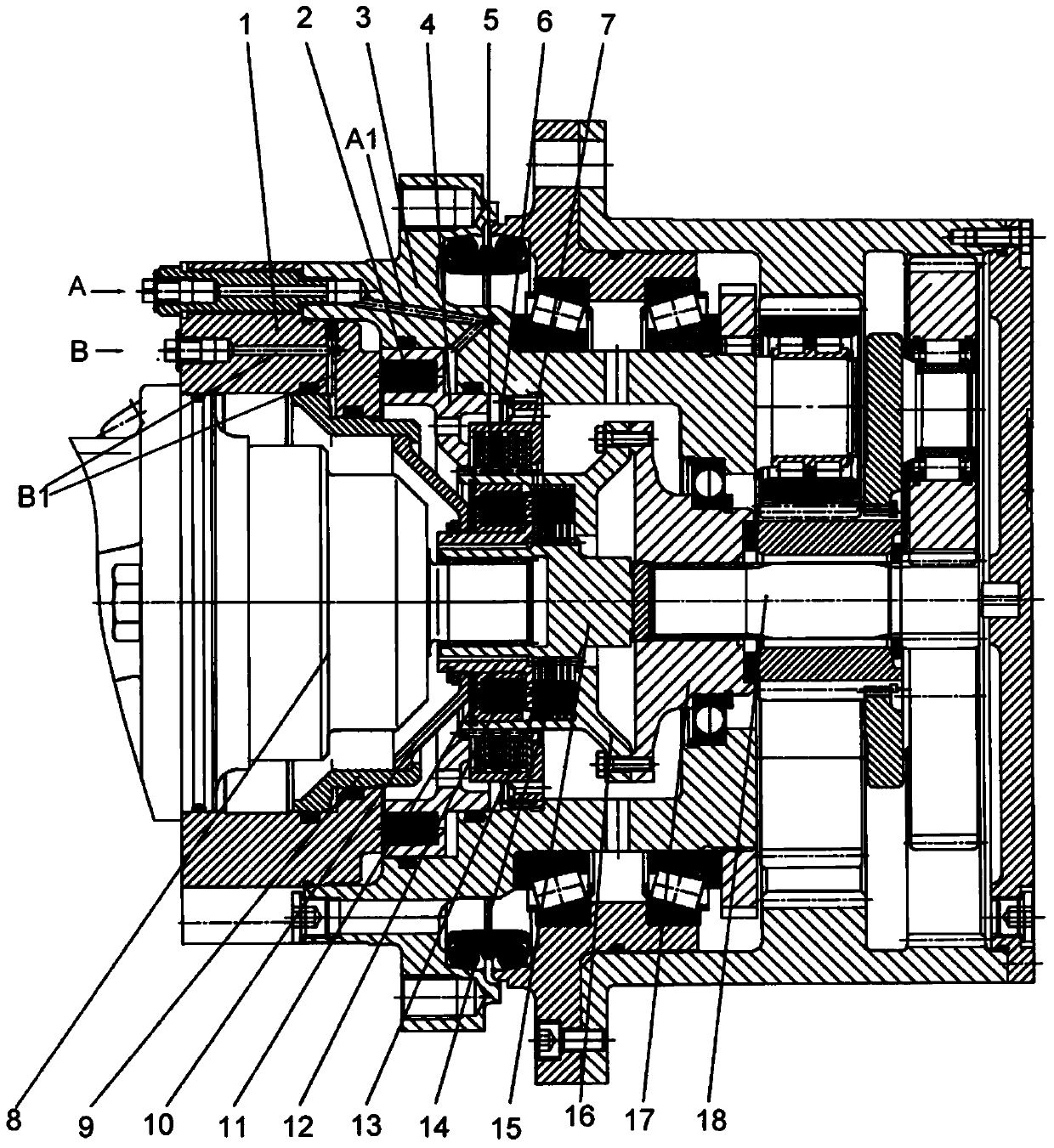

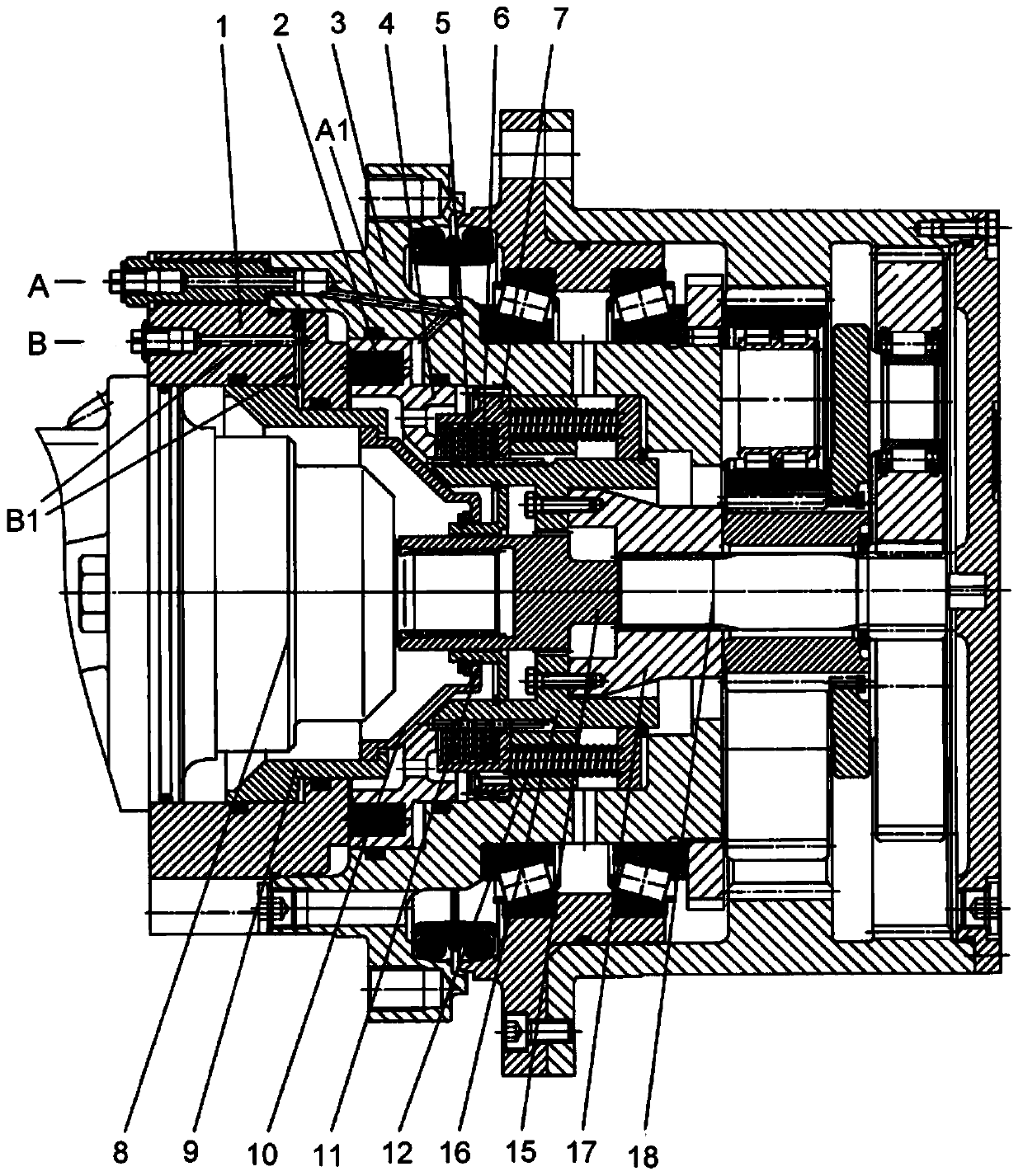

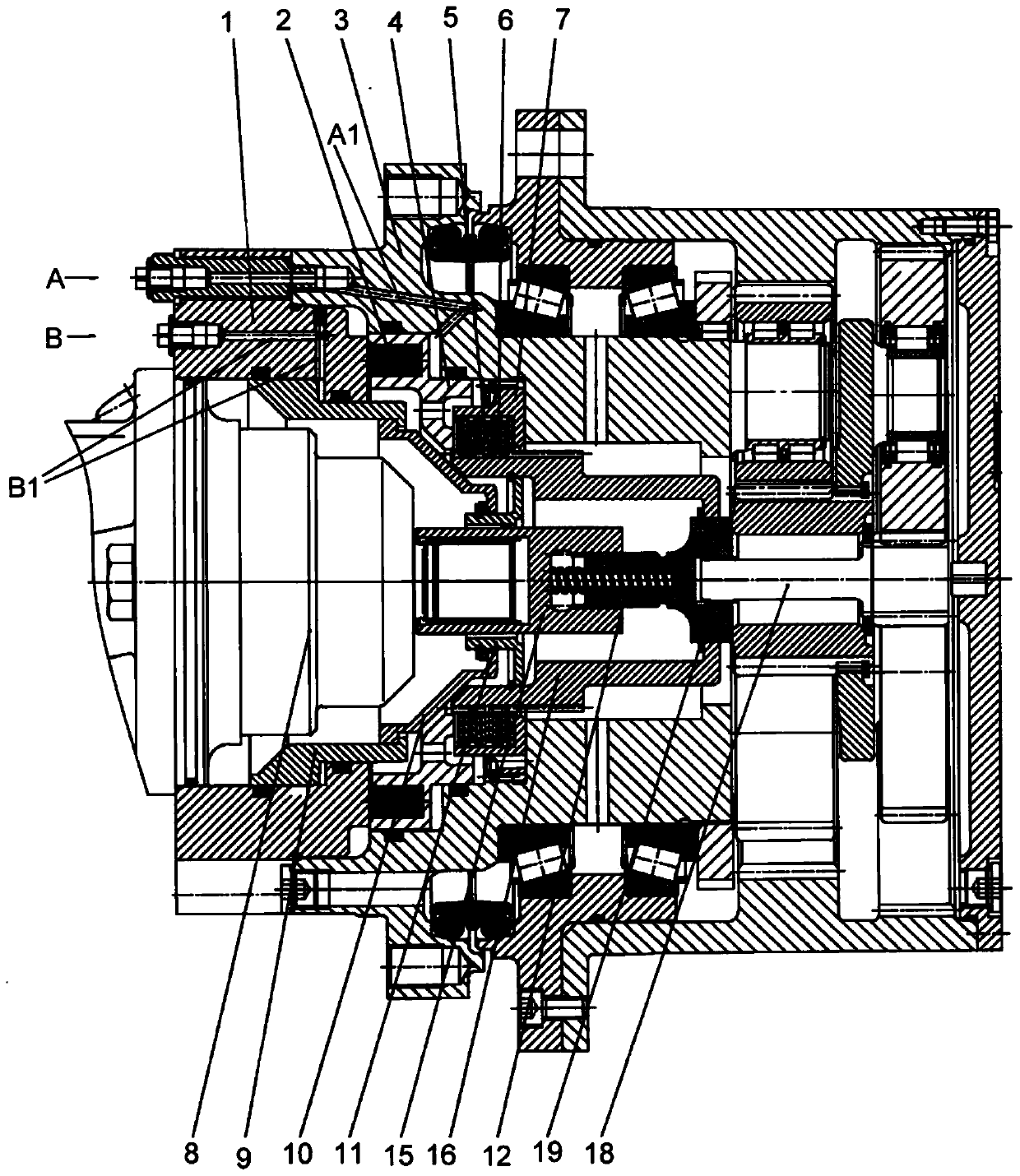

[0026] Figure 1 to Figure 3 Three hydraulically driven reducer disengagement devices according to the present invention are shown.

[0027] refer to Figure 1 to Figure 3 , shows the motor housing 1, the motor 8 and the main shaft 3, the motor housing 1, the motor 8 are connected with the main shaft 3 by screws (not shown), and the main shaft 3 is fixed to a fixed frame (not shown). figure 1 Also shown is the drive shaft 15 connected to the output shaft of the motor, and the central gear shaft 18 of the reducer. In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com