Ride-type motorcycle tail pipe assembly processing clamp and processing method thereof

A technology for riding motorcycles and tail pipes, which is applied in motorcycles, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing the installation accuracy of shock absorbers, reducing the installation accuracy of shock absorbers, and difficult to achieve precise positioning. Fast and reliable positioning, simplified relative position accuracy, and improved welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

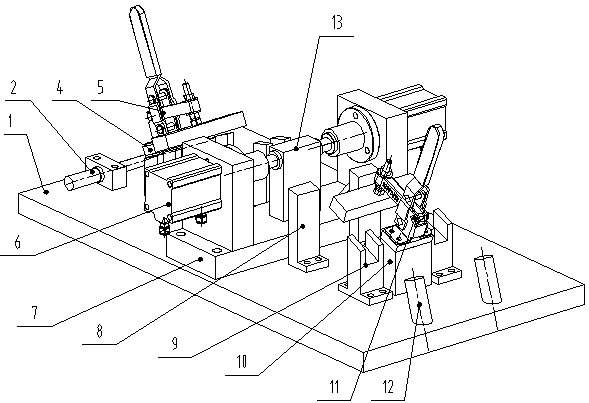

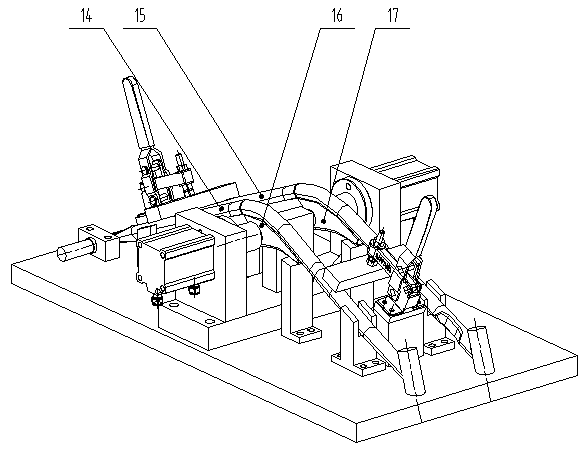

[0018] Such as Figure 2-3 As shown, the ride-on motorcycle tail pipe assembly processing fixture disclosed in this specific embodiment includes a rectangular bottom plate 1, and a shock absorbing box fixing seat 13 is arranged in the middle of the bottom plate, and the shock absorbing box fixing seat 13 extends along the width direction of the bottom plate. There are outwardly protruding positioning round tables on both sides, the positioning round tables match the shock absorbing shaft mounting holes on the left and right shock absorbing boxes and the positioning round tables have positioning holes, and the base plates 1 on both sides of the shock absorbing box holder 13 are also provided There is a cylinder 6, and the cylinder 6 is fixed on the base plate 1 by the cylinder fixing seat 7. The front end of the telescopic arm of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com