Toughened glass and manufacturing method of toughened glass

A tempered glass and manufacturing method technology, applied in the direction of glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve the unresolved differences in environmental temperature changes of tempered glass, affect the structural stability of tempered glass, reduce the service life of tempered glass, etc. problems, to achieve the effect of avoiding resonance effect, preventing self-explosion phenomenon, and strengthening the fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

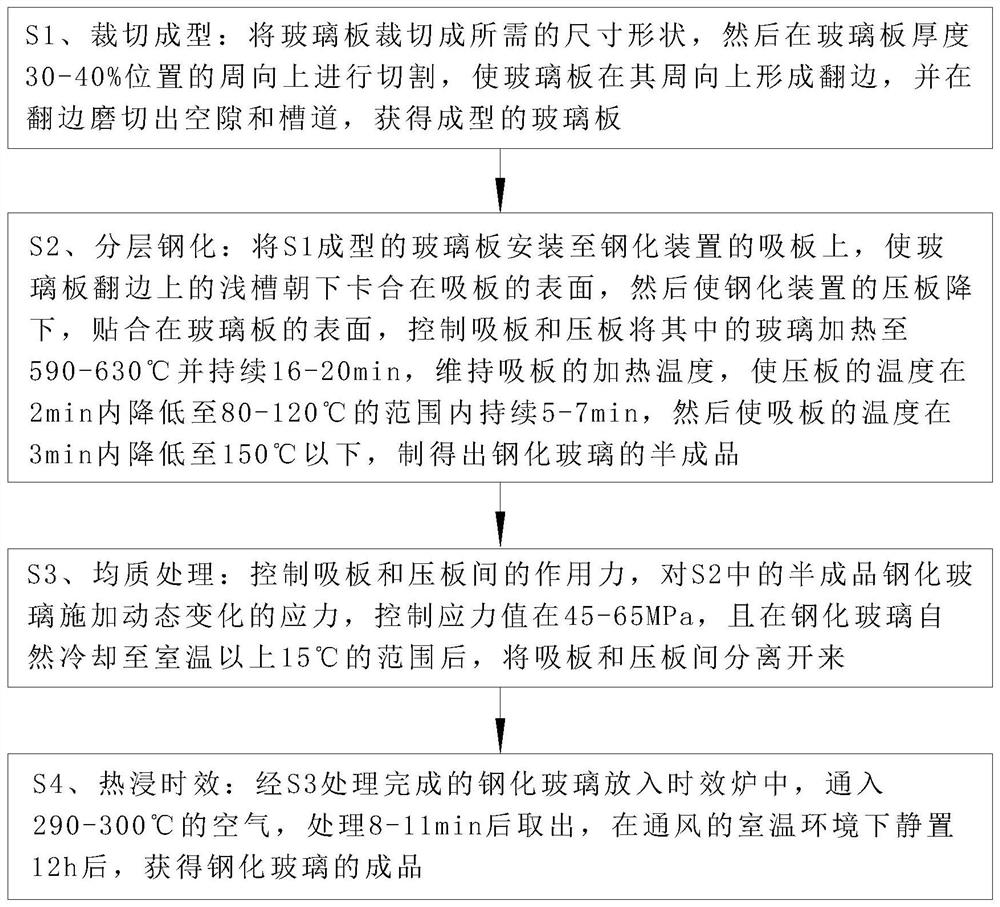

Method used

Image

Examples

Embodiment approach

[0036] As an embodiment of the present invention, the tempering device includes a machine 3, a suction plate 4, a pressure plate 5 and a controller; the top of the machine 3 is provided with a suction plate 4, and the machine 3 is provided with a stand 6 , a sliding press plate 5 is installed in the stand 6; the surface of the suction plate 4 is provided with a mesh 41, and the bottom of the suction plate 4 is provided with a vacuum pump 7, and the vacuum pump 7 is installed on the machine platform 3, and the vacuum pump 7 and the mesh 41 The top of the suction plate 4 is provided with a heating wire 42, and the side of the suction plate 4 is provided with a heat dissipation air outlet 43, and an axial flow fan 431 is installed on the heat dissipation air outlet 43; a driven oil cylinder is provided above the pressure plate 5 51, the same electric heating wire 42 and heat dissipation tuyere 43 as on the suction plate 4 are also set in the pressing plate 5; the controller is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com