Transporting and hoisting device and transporting and hoisting method for super-long and super-heavy glass

A hoisting device and glass technology, used in transportation and packaging, load hoisting components, etc., can solve problems such as extremely high requirements for personnel quality, unsatisfactory requirements, and inability of cranes to be in place.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

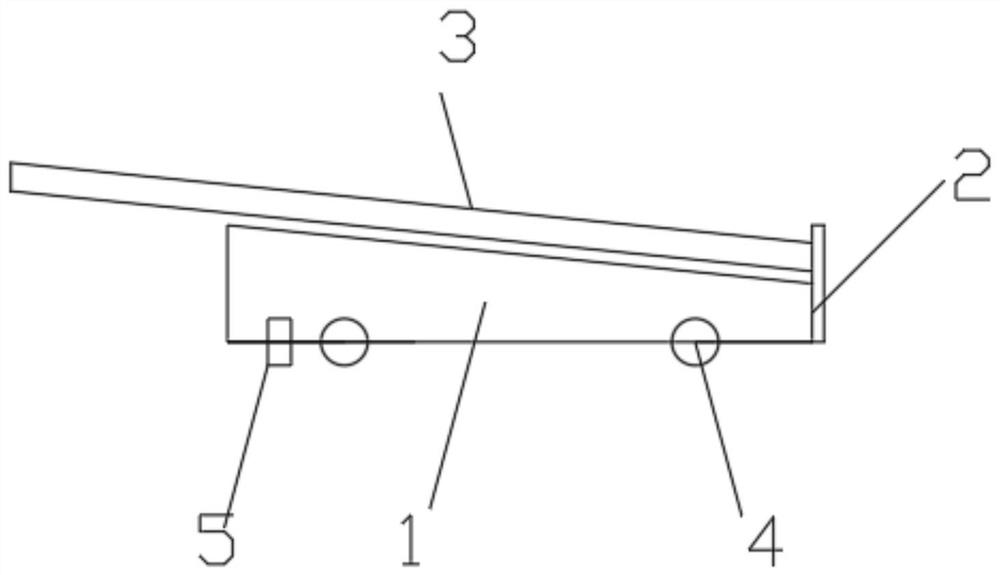

[0017] Such as figure 1 As shown, in this embodiment, a transport and hoisting device for ultra-long and overweight glass includes a transport trolley with an inclined upper surface, a baffle set on the lowest side of the upper surface of the transport trolley, and several undersides of the transport trolley. The universal wheel and the connecting shaft arranged on the transport trolley and capable of being connected with the hand hoist. When the glass needs to be transferred, install the super-long and heavy glass on the upper surface of the transport trolley, so that one side of the glass leans against the baffle to keep it stable. The universal wheels enable the transport trolley to have the function of convenient movement, so that it can be moved to the desired place on the ground, avoiding the use of hoisting equipment to transfer glass, and reducing safety risks. Moreover, the scheme is simple in structure and easy to use, which is beneficial to the rapid transfer of gl...

Embodiment 2

[0019] On the basis of the above embodiments, in this embodiment, several equal-thick rubber bumps are arranged on the upper surface of the transport trolley. The glass is supported by a plurality of rubber bumps, which can reduce the vibration transmitted to the glass when the transport trolley moves, and prevent the glass from being damaged due to the vibration. And it can avoid the rigid contact between the glass and the transport trolley, and prevent the glass from being damaged due to collision with the transport trolley when the glass is installed.

[0020] In this embodiment, the baffle is provided with a groove capable of holding glass. Utilizing the groove can limit the glass installed on the transport trolley to a certain extent, reduce the degree of freedom of the glass, improve the connection strength between the glass and the transport trolley, and prevent the glass from detaching from the transport trolley within a certain range.

[0021] In this embodiment, the...

Embodiment 3

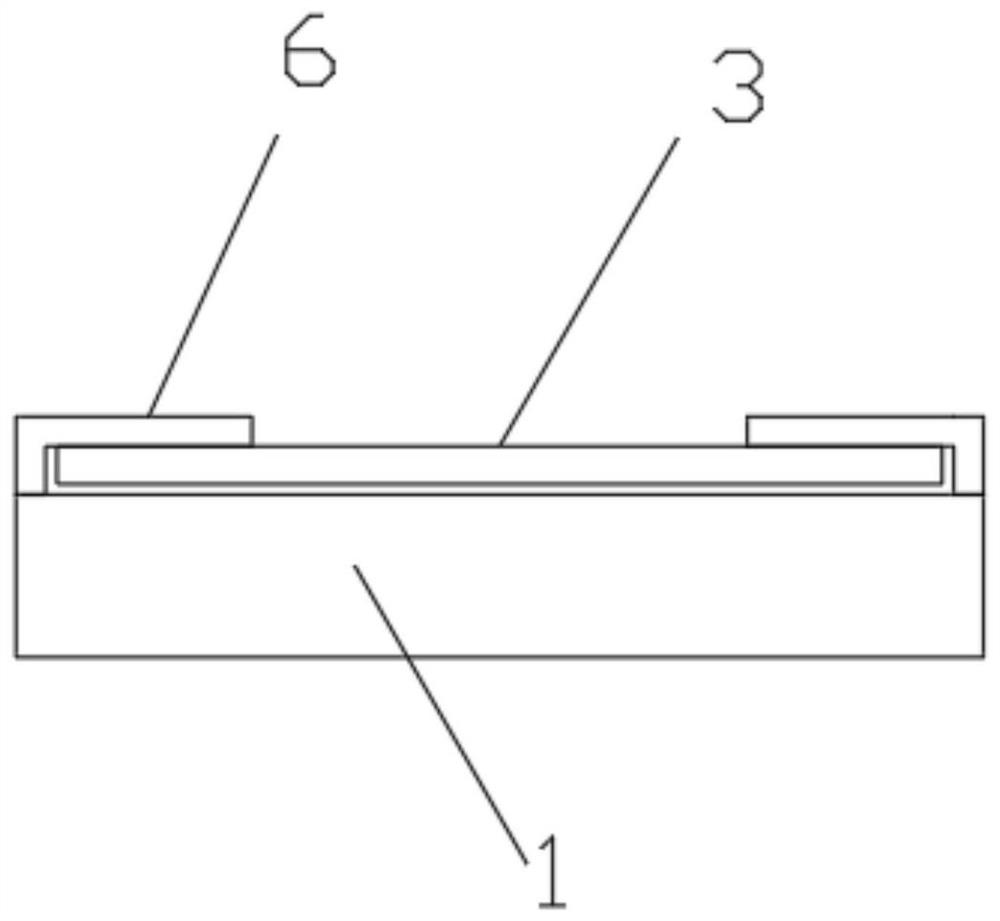

[0023] Such as figure 2 As shown, on the basis of the above-mentioned embodiments, in this embodiment, the two sides of the transport trolley are rotated to be provided with L-shaped pressing plates, and when the pressing plate rotates to the limit position on the upper surface of the transport trolley, it is compatible with the transport trolley. The upper surface is parallel. Pressing the upper surface of the glass with the pressing plate can improve the stability of the glass during transfer and hoisting, and prevent the glass from falling off the transport trolley.

[0024] In this embodiment, a rubber pad is provided on the side of the pressing plate close to the transport trolley. The use of rubber pads can prevent the glass from being damaged due to collision between the pressing plate and the glass. When the pressure plate is pressing the glass, the glass can be clamped by using the rubber pad on the upper surface of the glass and the rubber bump under the lower sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com