Patents

Literature

62results about How to "Ensure contact status" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

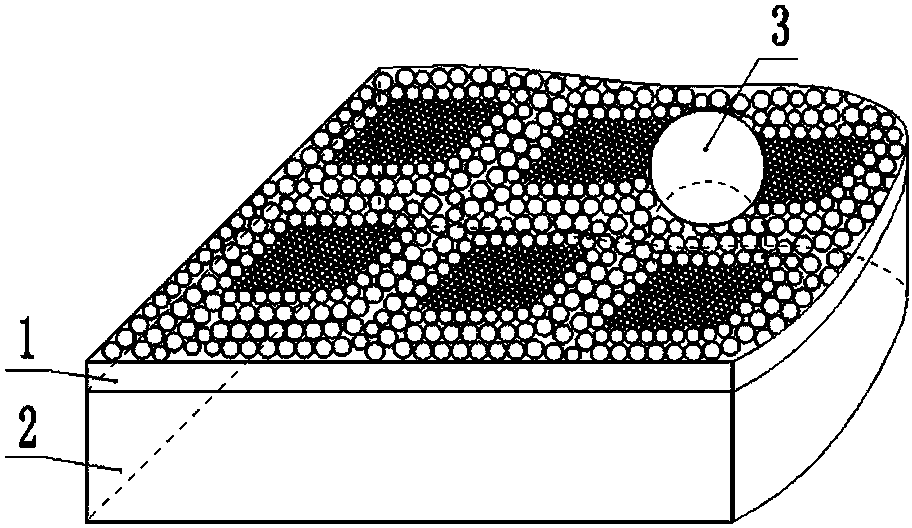

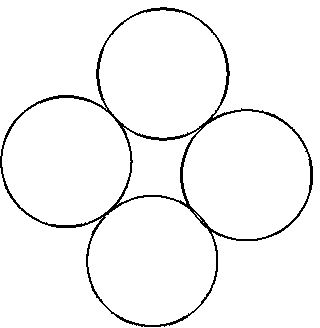

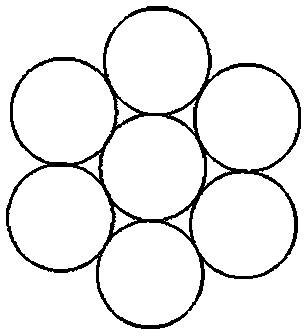

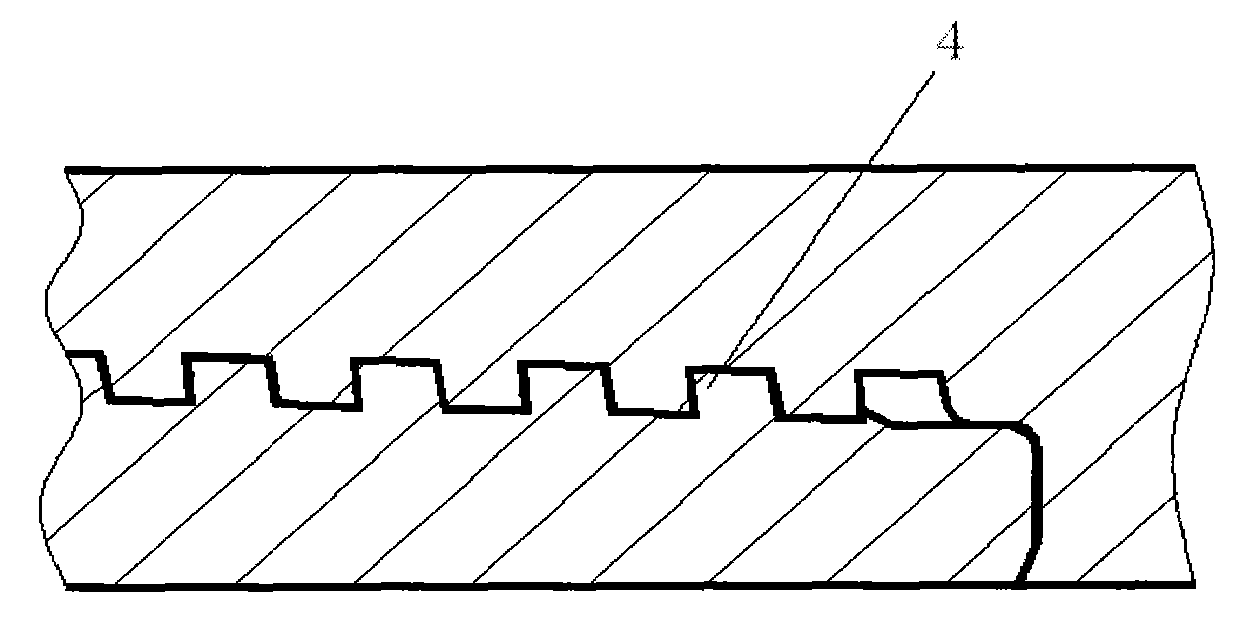

Surface texture of indium-iron grid-shaped spherical composite microcrystal composite layer

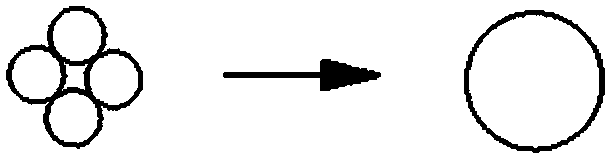

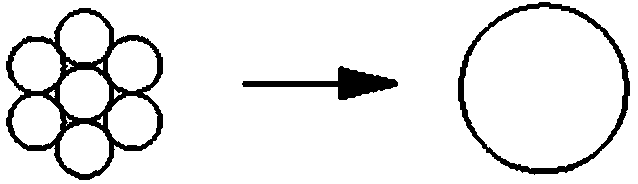

The invention discloses a surface texture of an indium-iron grid-shaped spherical composite microcrystal composite layer. A surface material layer is arranged on a part and mainly comprises larger indium-iron composite spherical microcrystal units of which the indium content exceeds 50% (Wt%) and the total content of indium and iron exceeds 55% (Wt%), each larger indium-iron composite spherical microcrystal unit is formed by close connection of at least four spherical crystal grains or nearly-spherical crystal grains, the larger indium-iron composite spherical microcrystal units are distributed regularly to form a grid, multiple single crystal grains or smaller indium-iron microcrystal units are closely distributed in the grid, each smaller indium-iron microcrystal unit is formed by close connection of at least two spherical crystal grains or nearly-spherical crystal grains, and the surface material layer and a base body material of the part are integrated to form the indium-iron grid-shaped spherical composite microcrystal composite layer; then a surface texture is machined on the part surface provided with the indium-iron grid-shaped spherical composite microcrystal composite layer and consists of multiple surface texture units, and the surface texture of the indium-iron grid-shaped spherical composite microcrystal composite layer is formed.

Owner:FUJIAN CHUANZHENG COMM COLLEGE

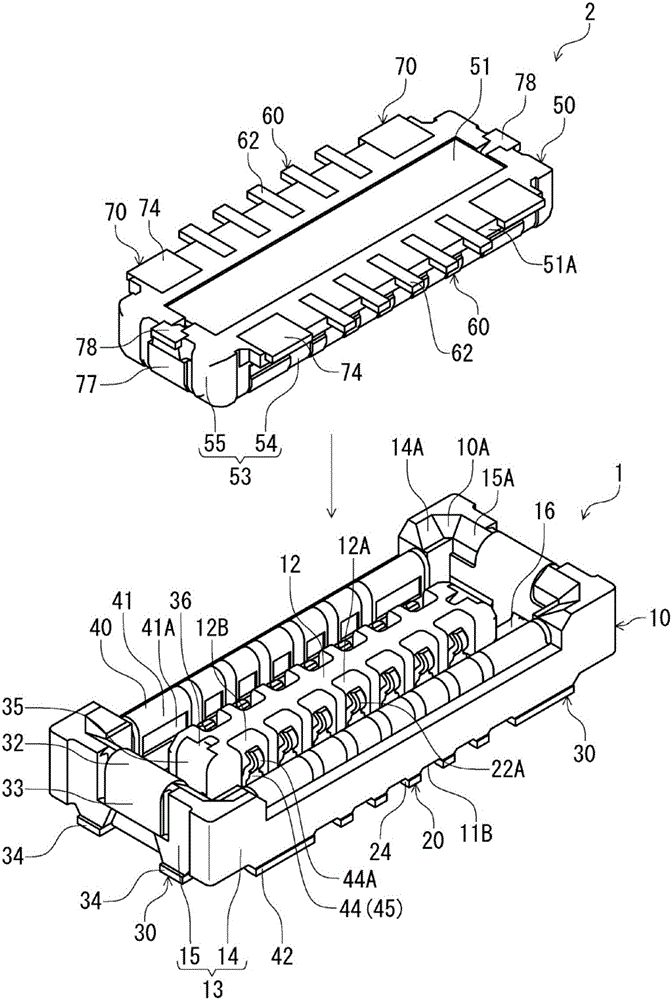

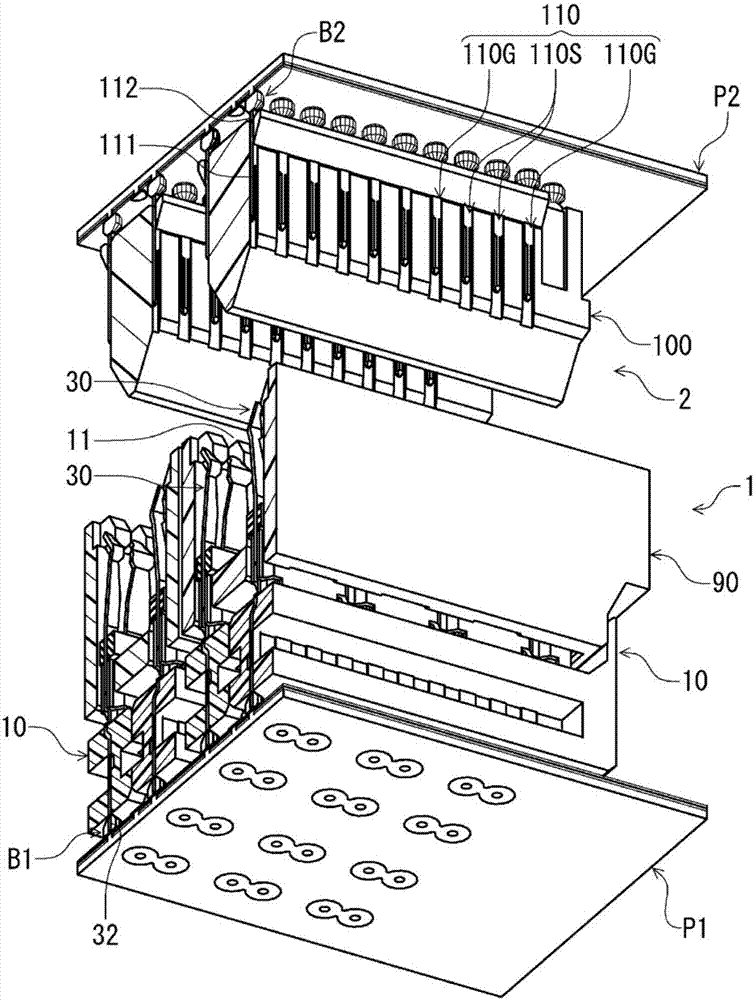

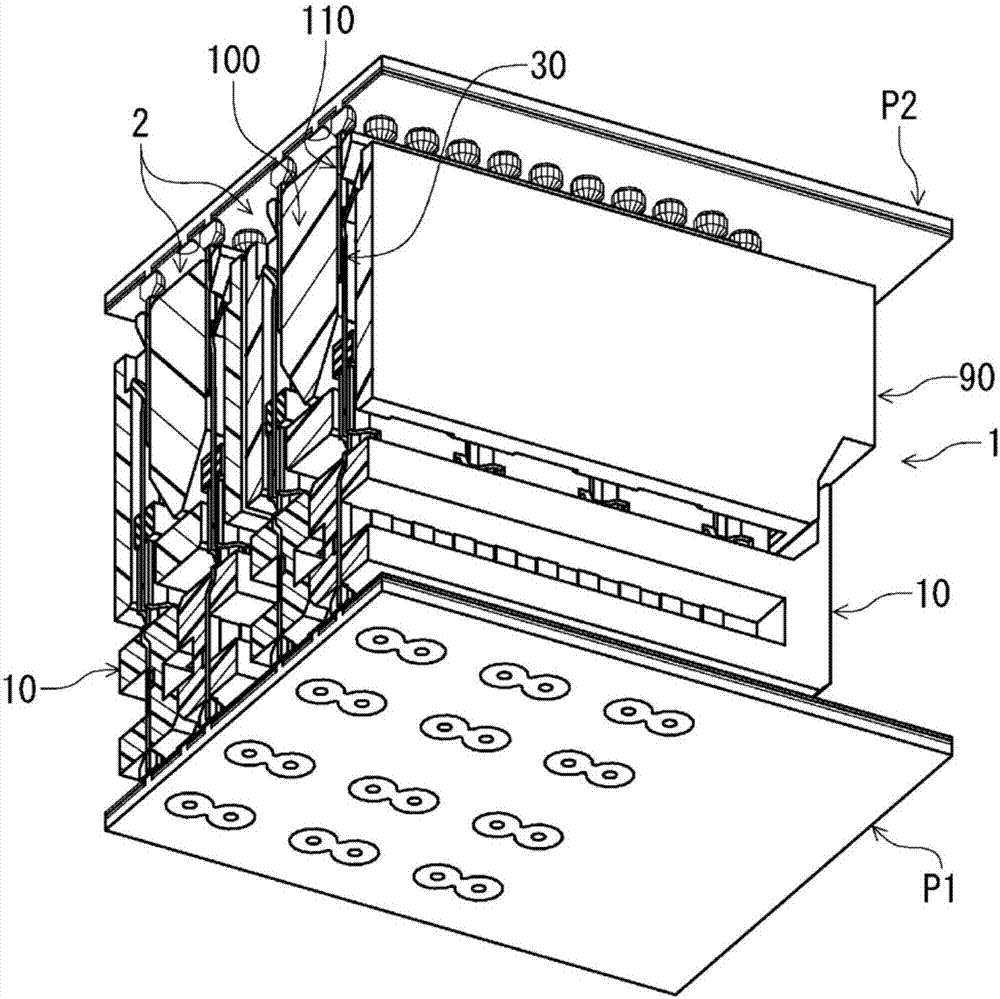

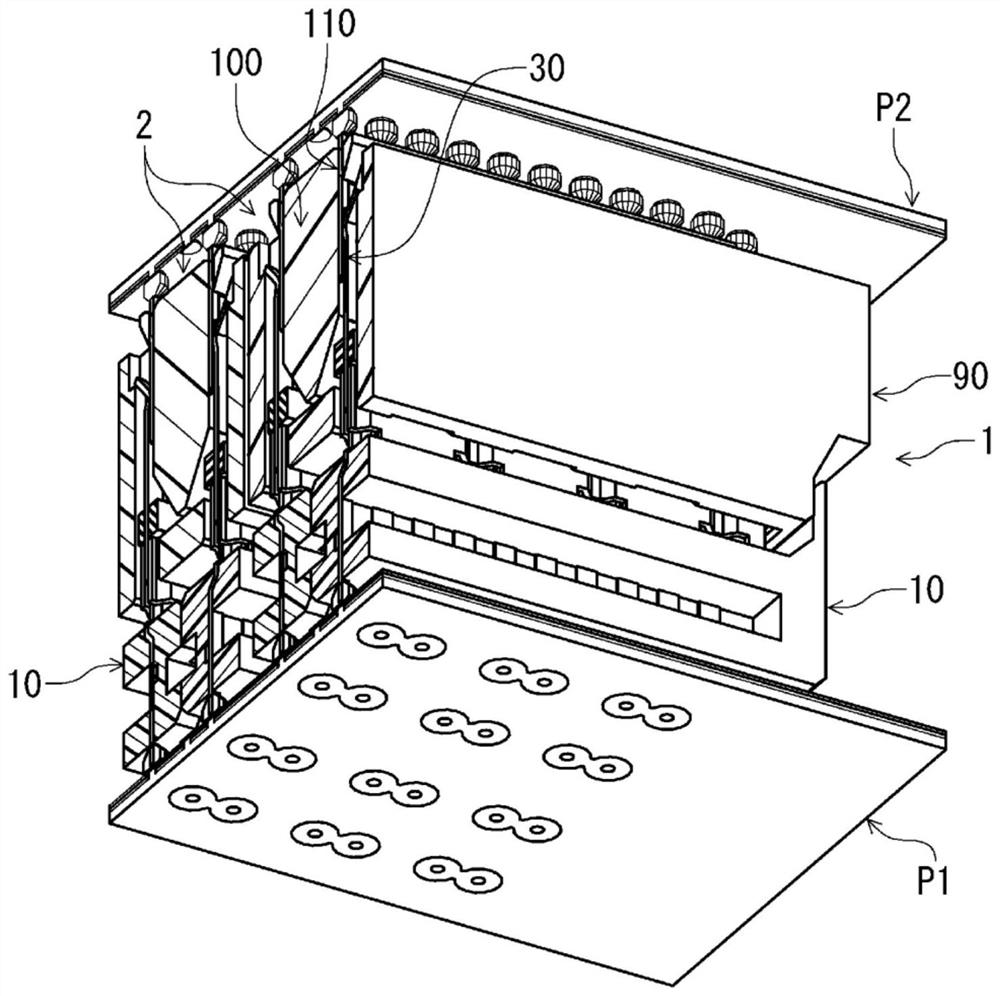

Electric connector for circuit board

ActiveCN106058518AEnsure elastic displacement statePrevent adhesionElectrically conductive connectionsCoupling contact membersEngineeringMechanical engineering

The invention provides an electric connector for circuit board which can prevent solder or coating agent on contact arms of terminals. The housing (10) is provided with a bottom wall (11) having a bottom face that is parallel to a mount surface of a circuit board,a protrusive wall 12 rising from the bottom wall 11 and extending in an array direction; the protrusive wall is provided with a slot part (12A) which depresses from the protrusive wall and extends along the inserting and pluging direction of the connector; a terminal(20) is provided with a base (21) which is integrated with the bottom wall and kept, a contact arm part (22) which extends along the inserting and pluging direction of the connector from one end of the base part, and a connecting part (24) which is formed at the part which extends fromt he other end of the base and can be welded with the mounting face; the slot part of the protrusive wall is formed on the whole region of the protrusive wall, the bottom wall is formed in the scope corresponding to the contact arm in the direction of the connector.

Owner:HIROSE ELECTRIC GROUP

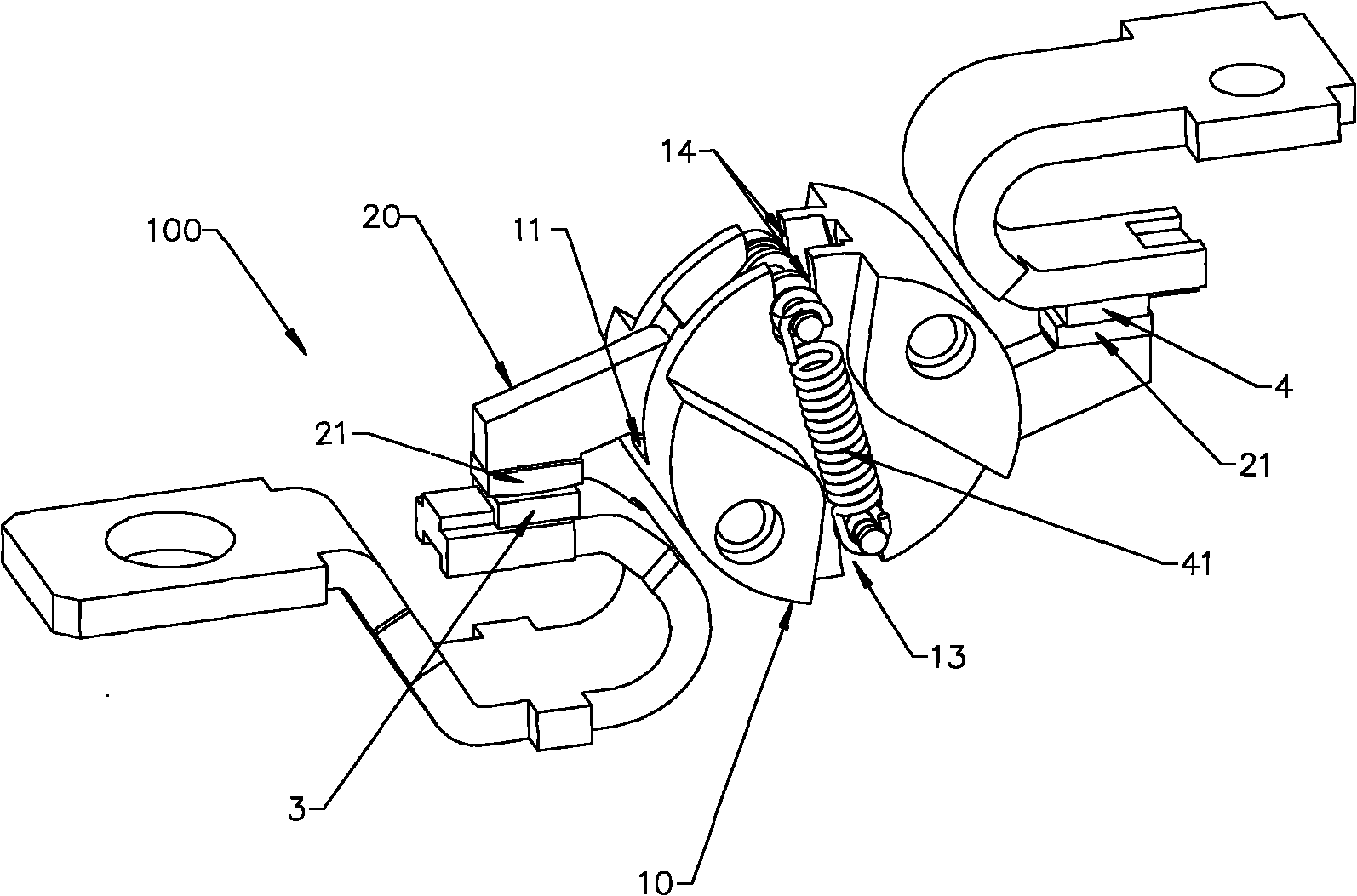

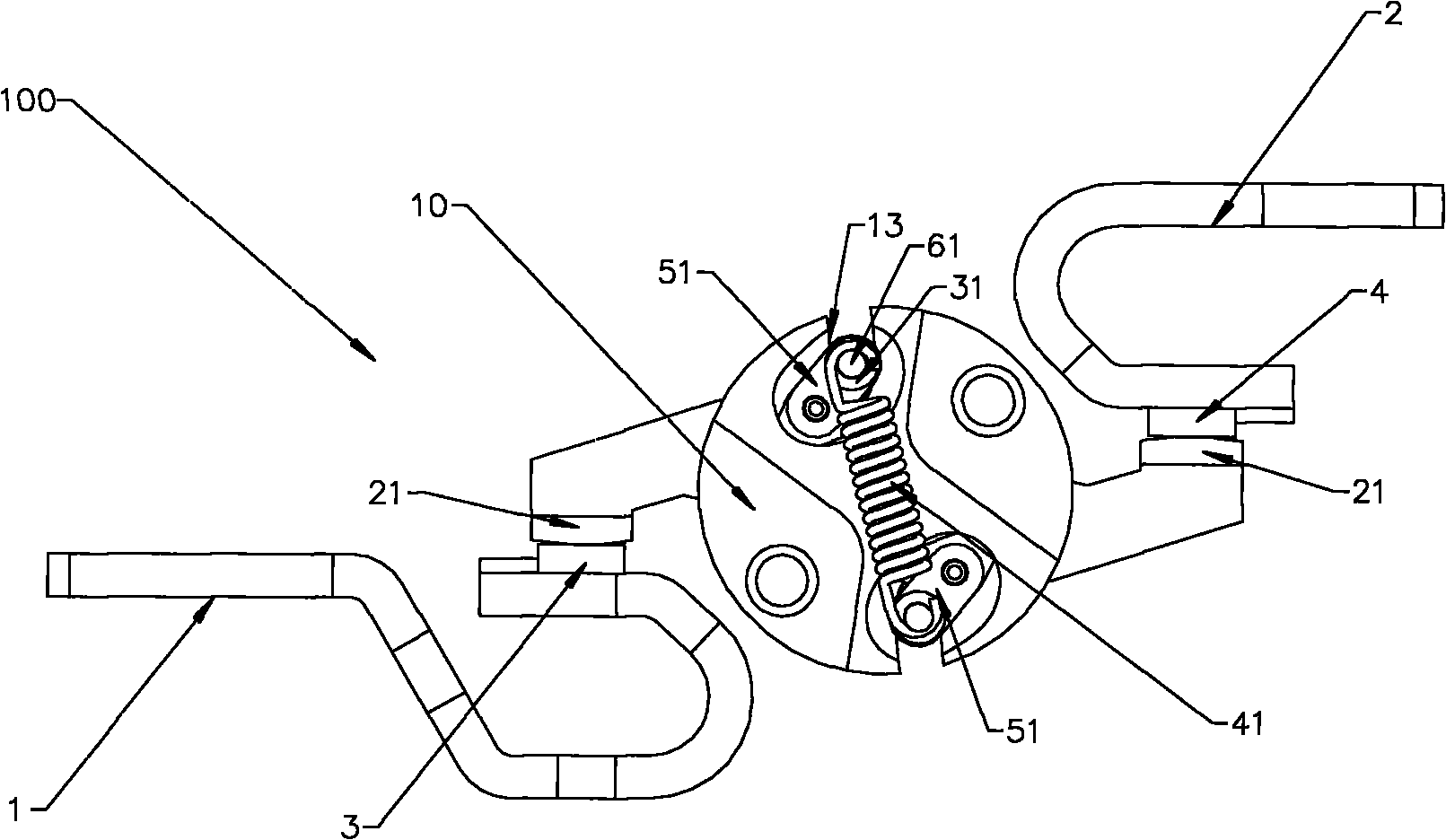

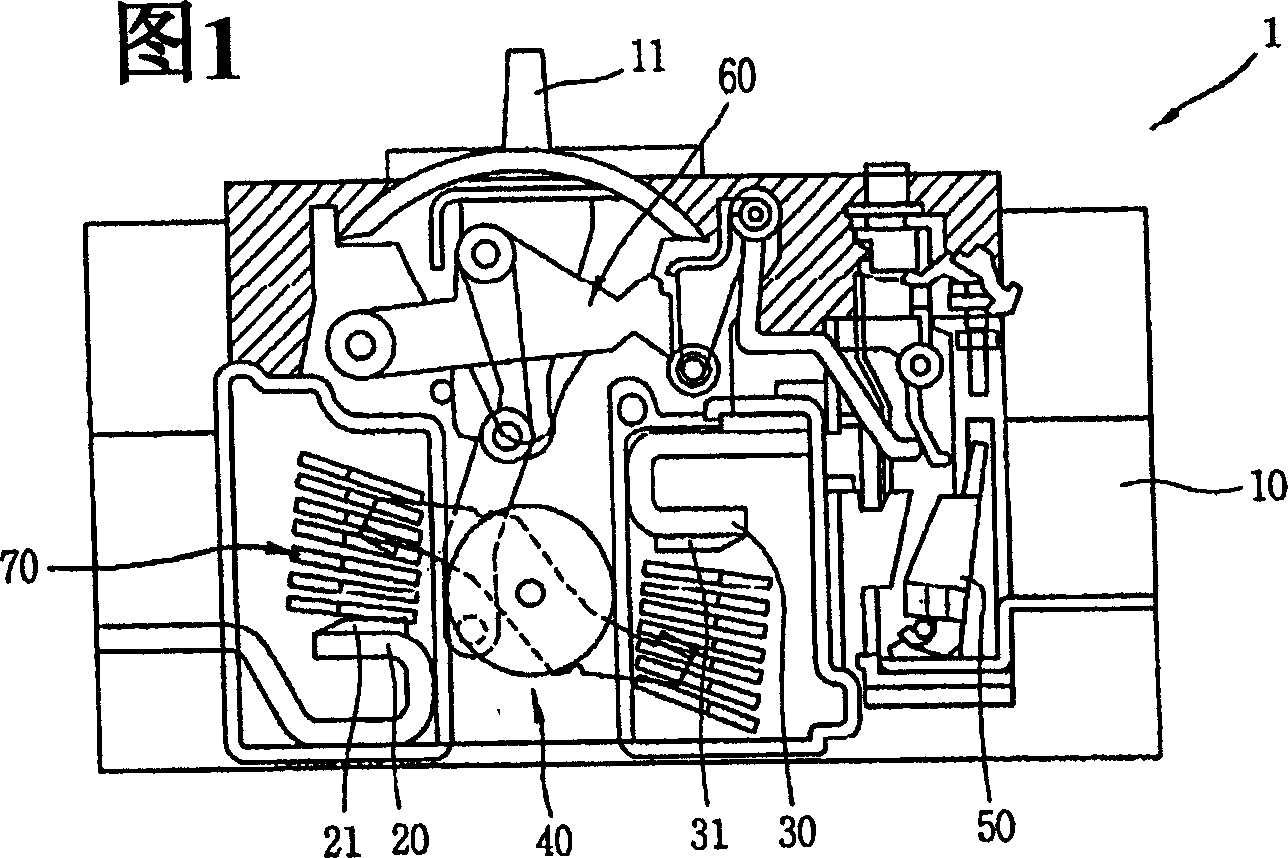

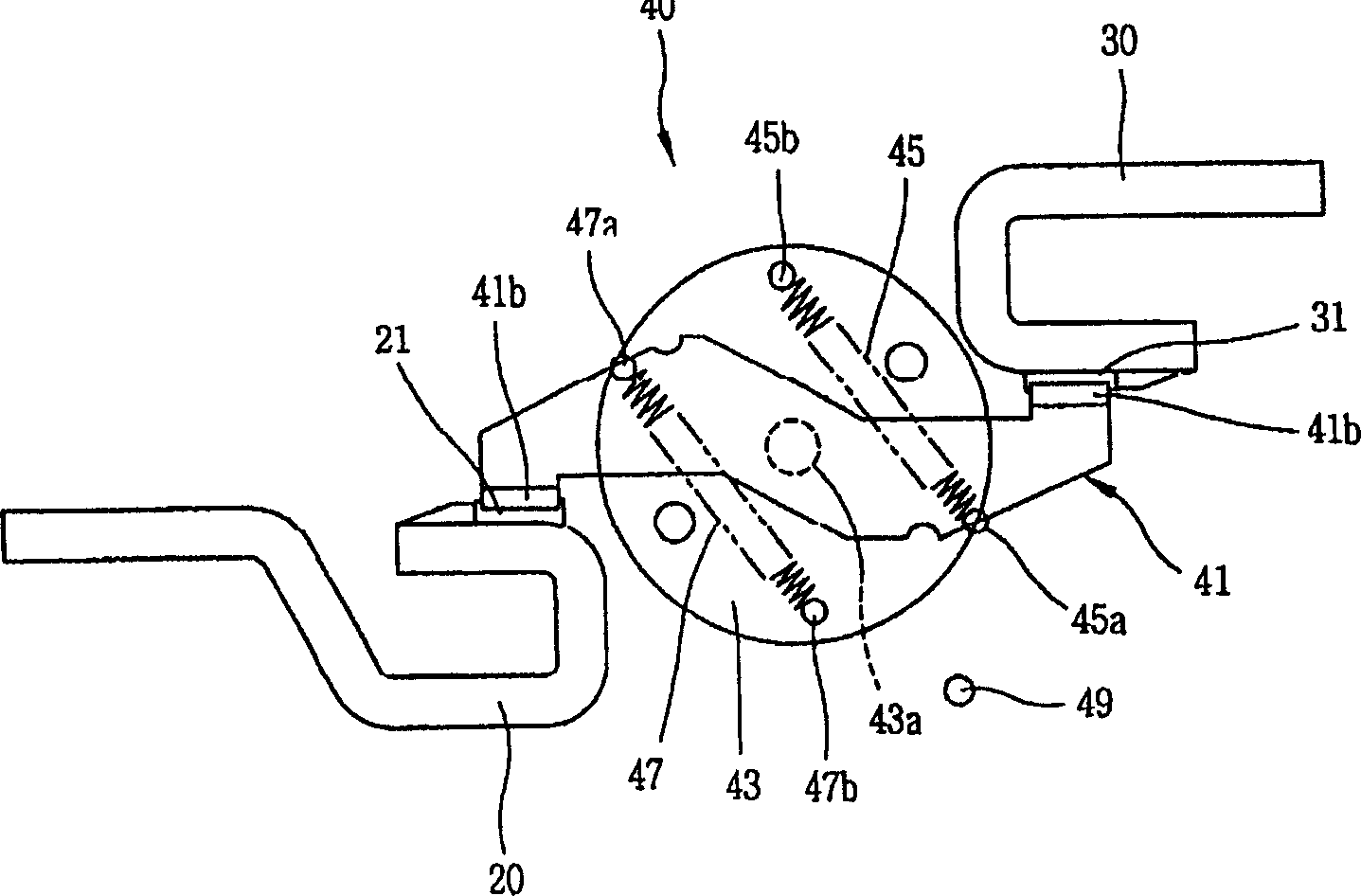

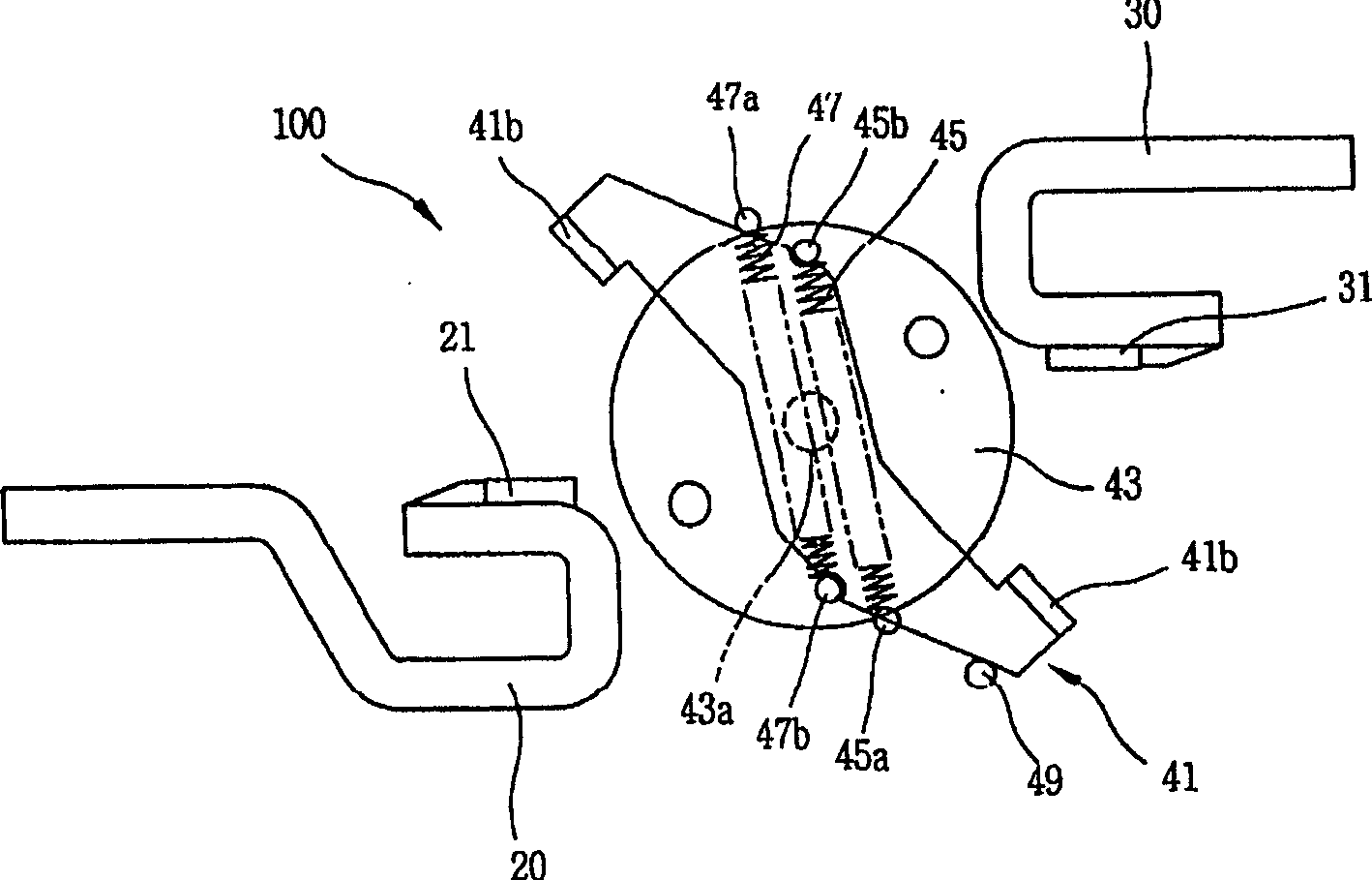

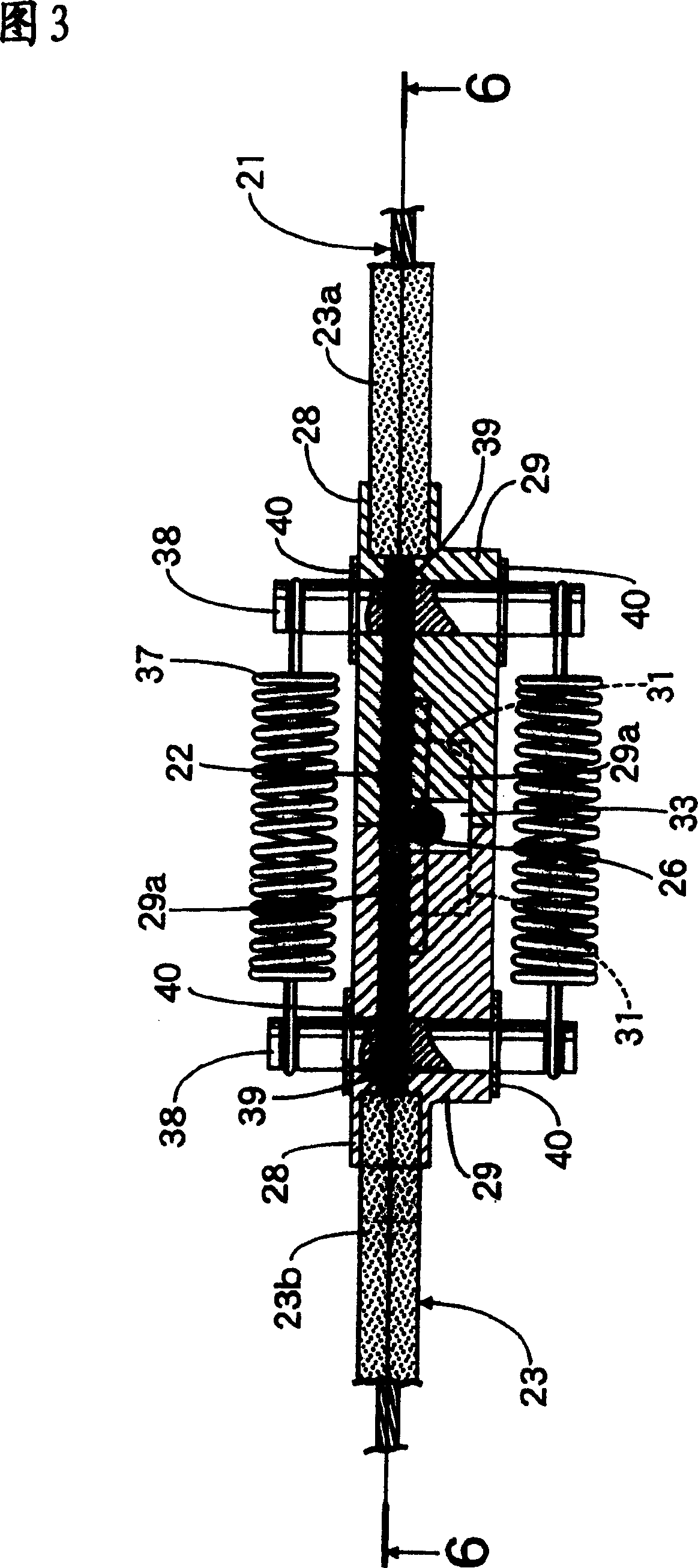

Moving contact assembly of molded case circuit breaker

InactiveCN102103948AEasy to separateKeep in touchContactsCircuit-breaking switch contactsLinear motionCircuit breaker

A moving contact assembly of a molded case circuit breaker comprises a rotary shaft rod, a moving contact, a pair of connecting rods and a pair of springs, wherein the rotary shaft is provided with an opening and a pair of symmetrically arranged arc-shaped linear movement guide grooves; the moving contact is rotationally connected with the rotary shaft rod through a rotary shaft; the two ends of the moving contact lean out of the opening of the rotary shaft rod; the two ends are respectively provided with a moving contact; the pair of connecting rods are symmetrically arranged; one end of each connecting rod is connected with the two side surfaces of the moving contact while the other end is connected with a sliding pin, wherein the two ends of the sliding pin pass through the arc-shaped linear movement guide groove and span the two side surfaces of the rotary shaft rod; and the pair of springs are symmetrically arranged on the two side surfaces of the rotary shaft rod; the two ends of the pair of springs are respectively connected with the two sliding pins. Compared with the prior art, the moving contact assembly of a molded case circuit breaker provided by the present invention can rapidly finish circuit transformation with high efficiency.

Owner:SHANGHAI RENMIN ELECTRICAL APP WORKS

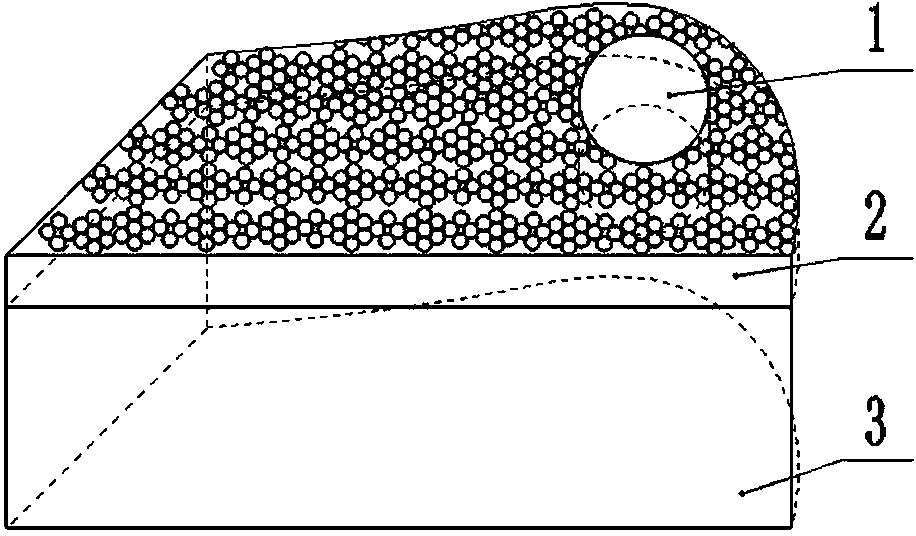

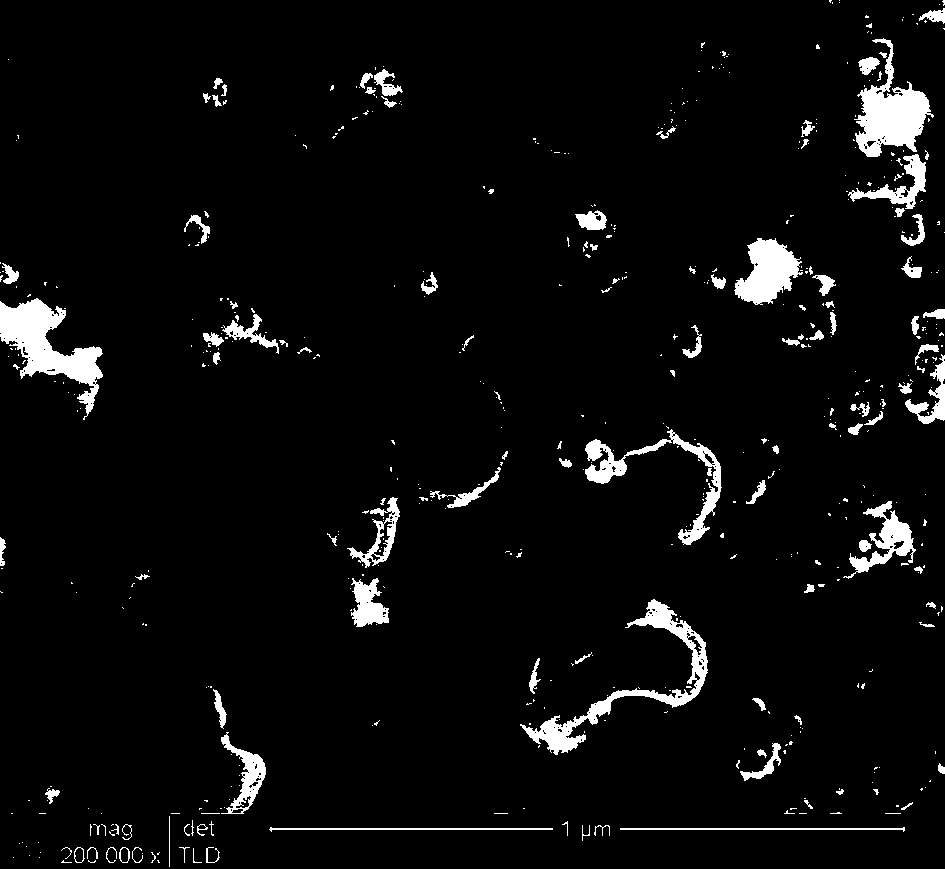

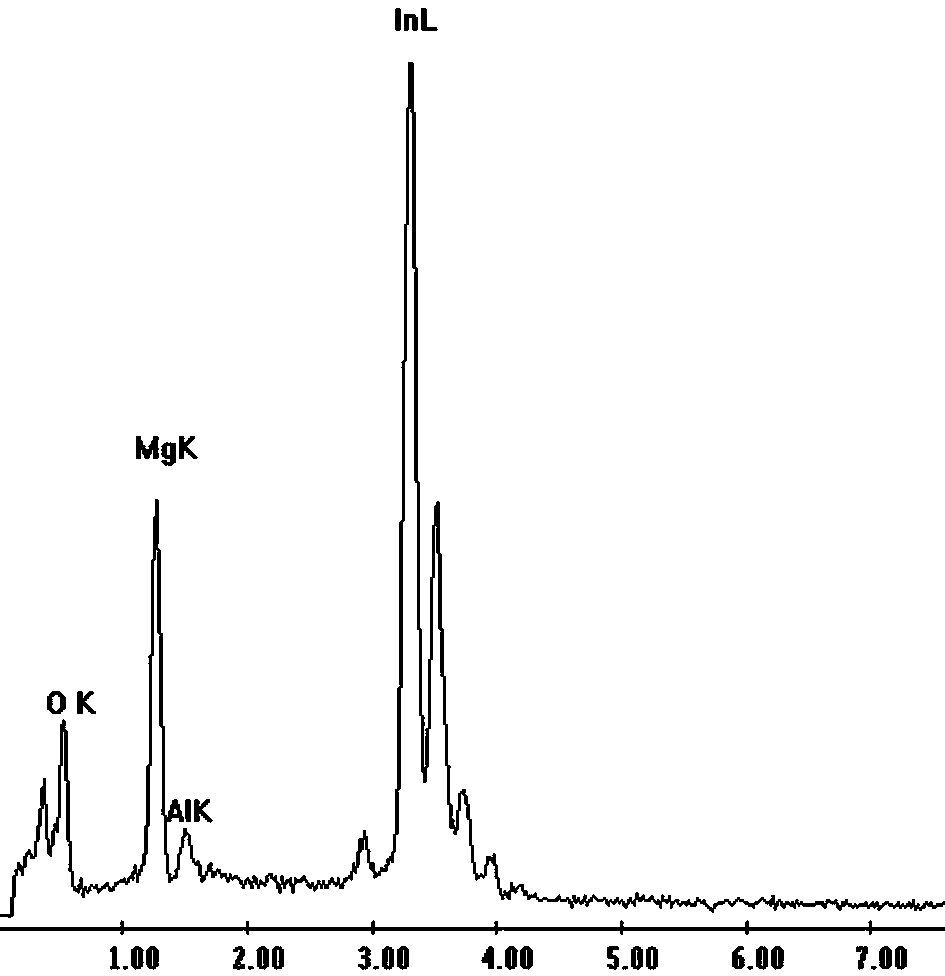

Surface texture of indium-magnesium composite spherical microcrystal composite layer

InactiveCN104228149AThe contact surface is resistant to compound fretting wear such as "tangential fretting + rotational fretting"Ensure contact statusMetal layered productsIndiumMaterials science

The invention discloses a surface texture of an indium-magnesium composite spherical microcrystal composite layer. A surface material layer is arranged on a part and comprises larger indium-magnesium composite spherical microcrystal units of which the indium content exceeds 50% (Wt%) and the total content of indium and magnesium exceeds 55% (Wt%), each larger indium-magnesium composite spherical microcrystal unit is formed by close connection of at least four spherical crystal grains or nearly-spherical crystal grains, and the indium-magnesium composite spherical microcrystal units are approximately regularly and closely distributed and arrayed in rows or in lines; a base body material can adopt metallographic structures which are made of other components and are in other shapes, and the surface material layer and the base body material are integrated; a surface texture is machined on the surface of the part and consists of multiple surface texture units, and the surface texture of the indium-magnesium composite spherical microcrystal composite layer is formed.

Owner:FUJIAN CHUANZHENG COMM COLLEGE

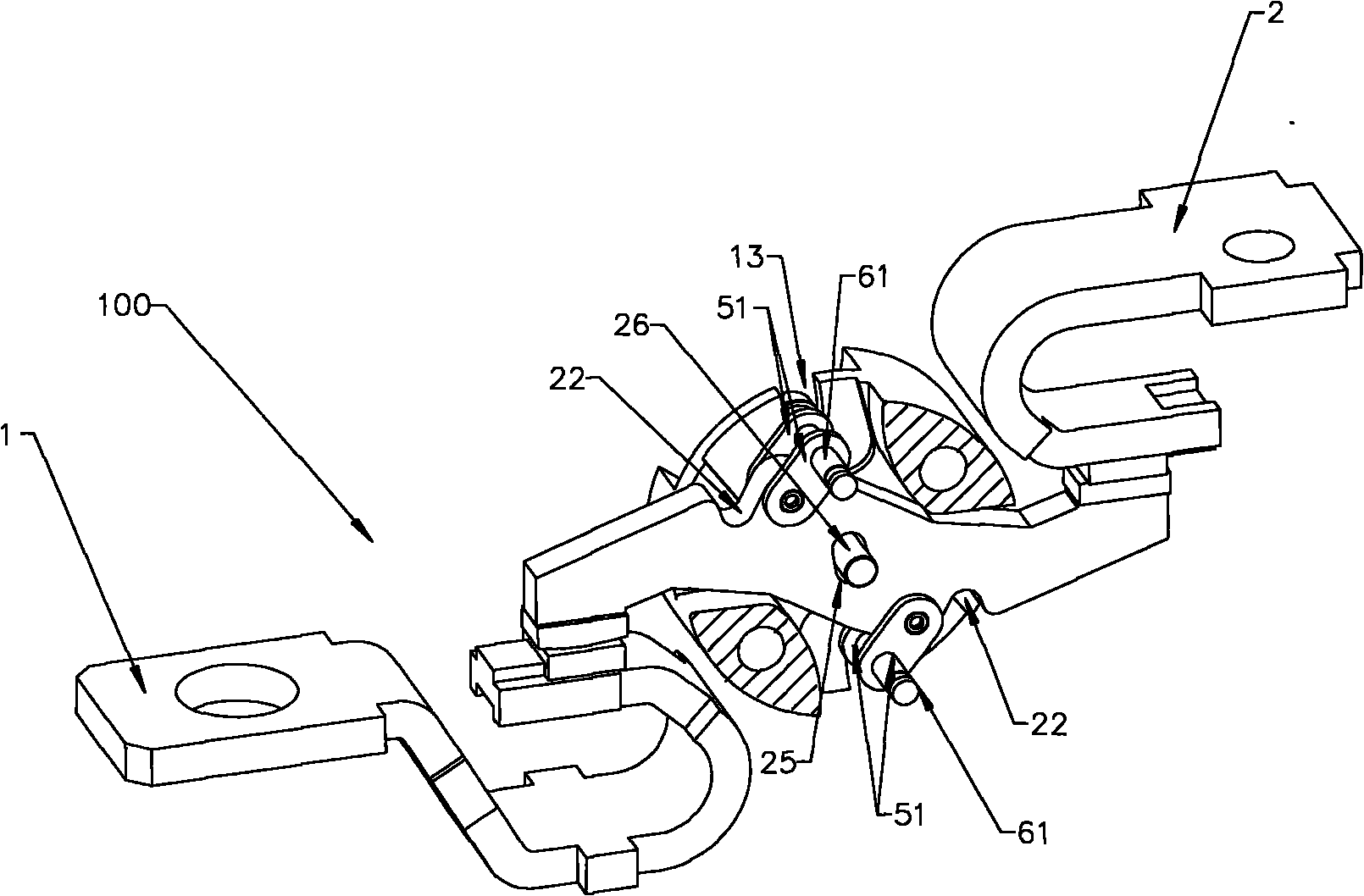

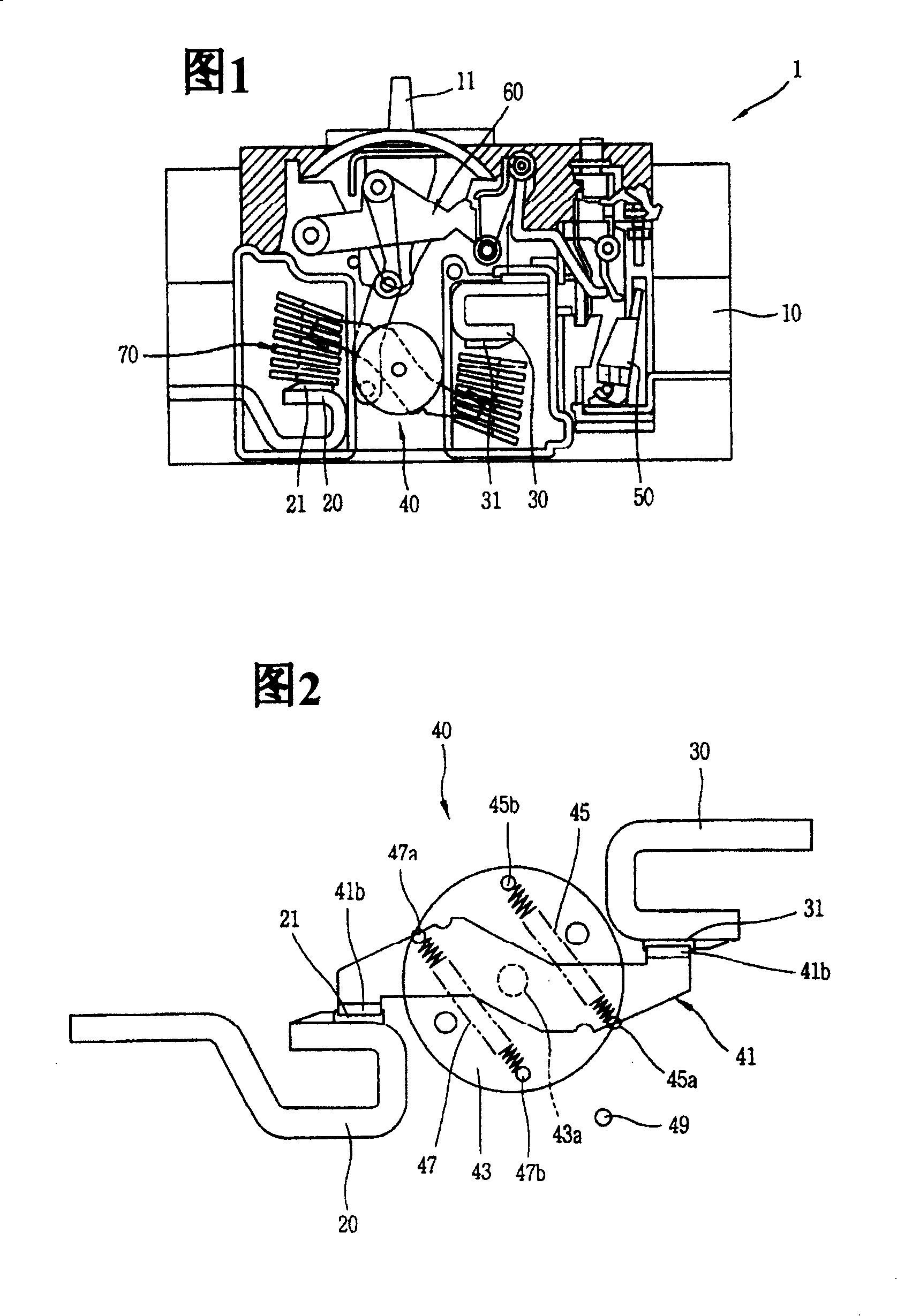

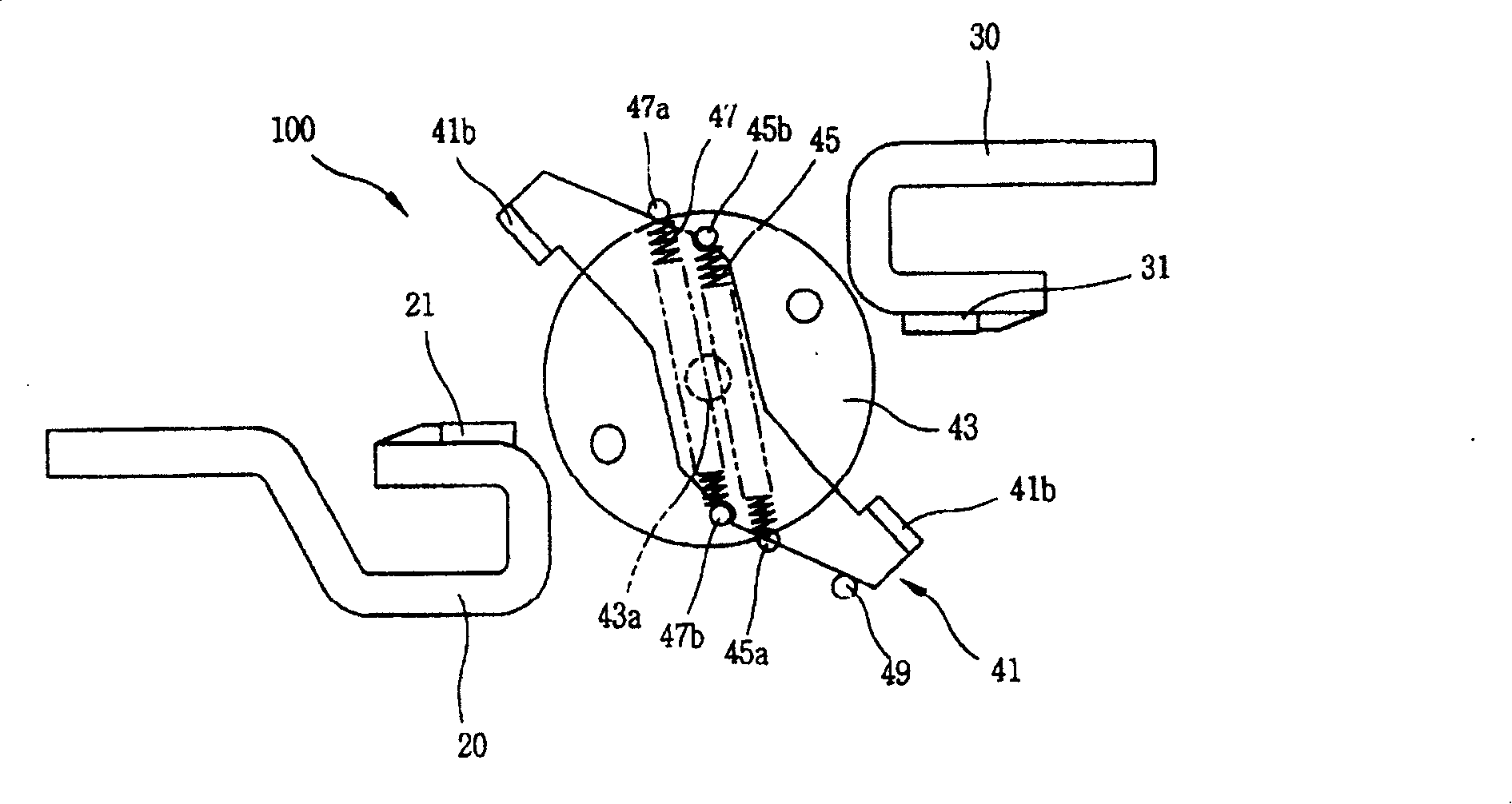

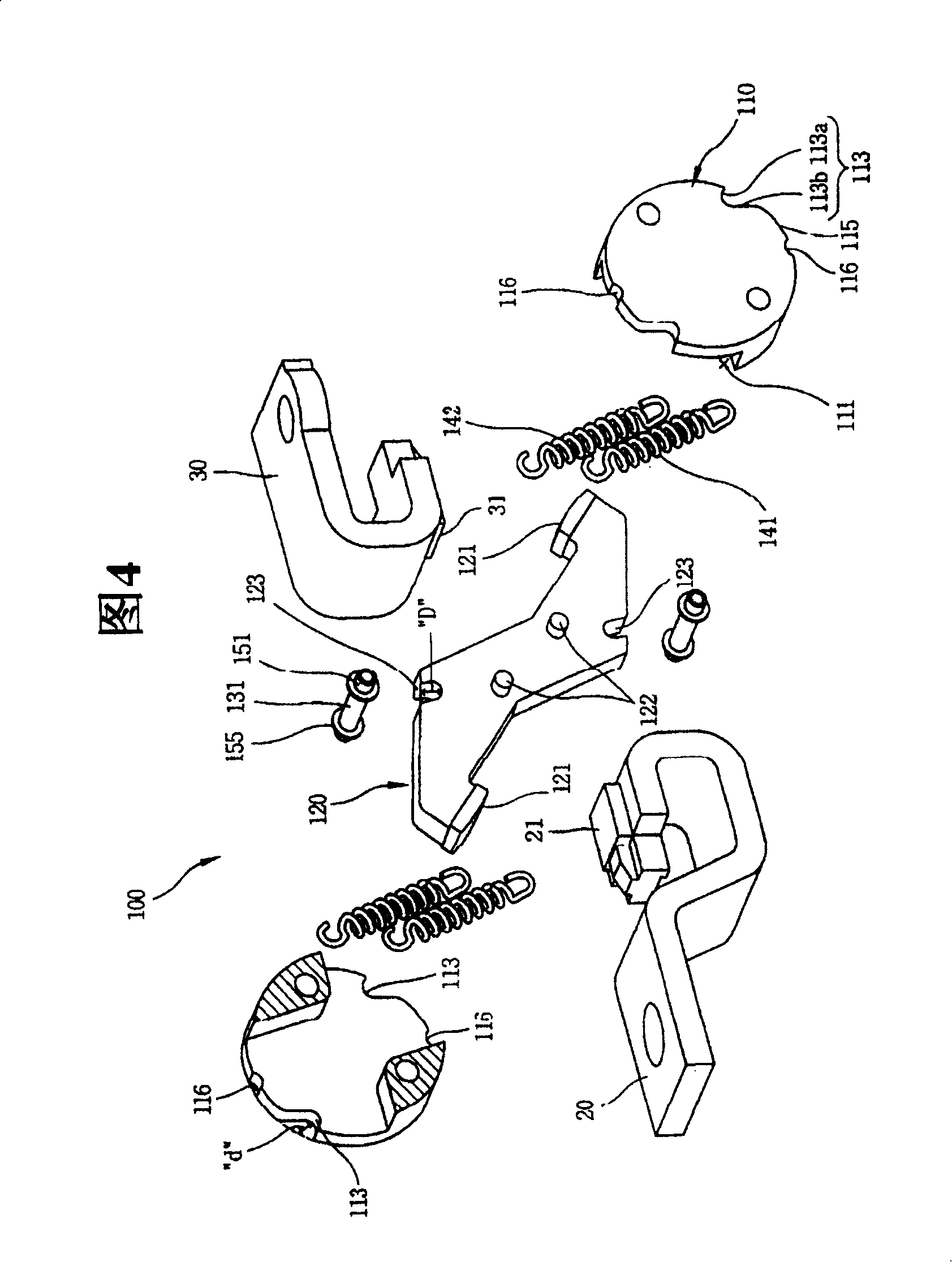

Movable contact assembly of circuit breaker for wiring

InactiveCN1750206AEasy to separatePrevent returnProtective switch operating/release mechanismsCircuit-breaking switch contactsSeparated stateCurrent limiting

Disclosed is a movable contactor assembly of a circuit breaker capable of enhancing a current limiting function by maintaining a contact state between a movable contactor and fixed contactors in a closed circuit state, by preventing the separated movable contactor from returning towards the fixed contactors at the time of a current limiting operation, by accelerating a separation operation of the movable contactor from the fixed contactors at the time of a current limiting operation, and by continuously maintaining a separated state of the movable contactor from the fixed contactors until a trip operation is performed by a trip mechanism.

Owner:LSIS CO LTD

Surface texture of indium-magnesium inwards-concave microcrystal composite layer

InactiveCN104228150AReduces fretting fatigueReduce fretting corrosionMetal layered productsIndiumMaterials science

The invention discloses a surface texture of an indium-magnesium inwards-concave microcrystal composite layer. The surface texture of the indium-magnesium inwards-concave microcrystal composite layer is characterized in that a surface material layer is arranged on a part, a metallographic structure of the surface material layer comprises inwards-concave groove-shaped or inwards-concave through-hole-shaped microcrystals of which the indium content exceeds 50% (Wt%) and the total content of indium and magnesium exceeds 55% (Wt%), and the inwards-concave groove-shaped or inwards-concave through-hole-shaped microcrystals account for more than 15% of total crystals constituting the surface material layer; a base body material can adopt metallographic structures which are made of other components and are in other shapes, and the surface material layer and the base body material of the part are integrated to form the indium-magnesium inwards-concave microcrystal composite layer; a surface texture is machined on the part surface provided with the indium-magnesium inwards-concave microcrystal composite layer and consists of multiple surface texture units, and the surface texture of the indium-magnesium inwards-concave microcrystal composite layer is formed.

Owner:FUJIAN CHUANZHENG COMM COLLEGE

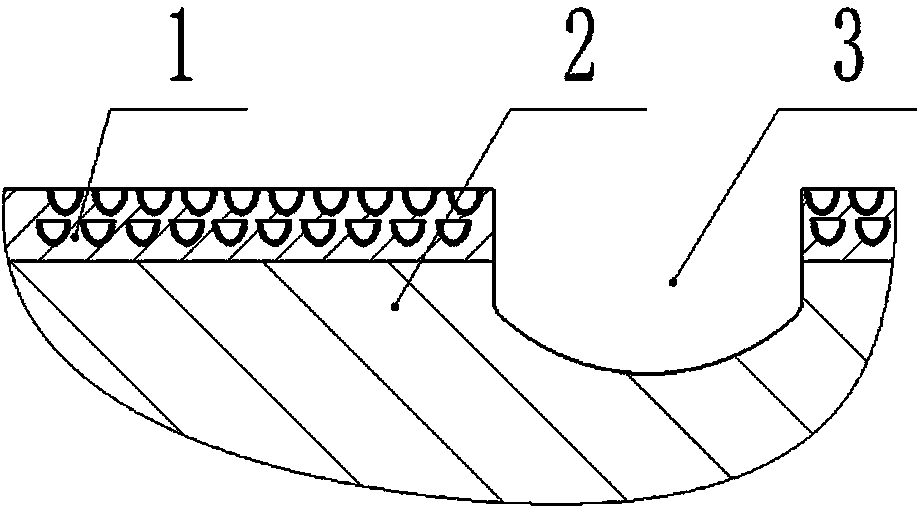

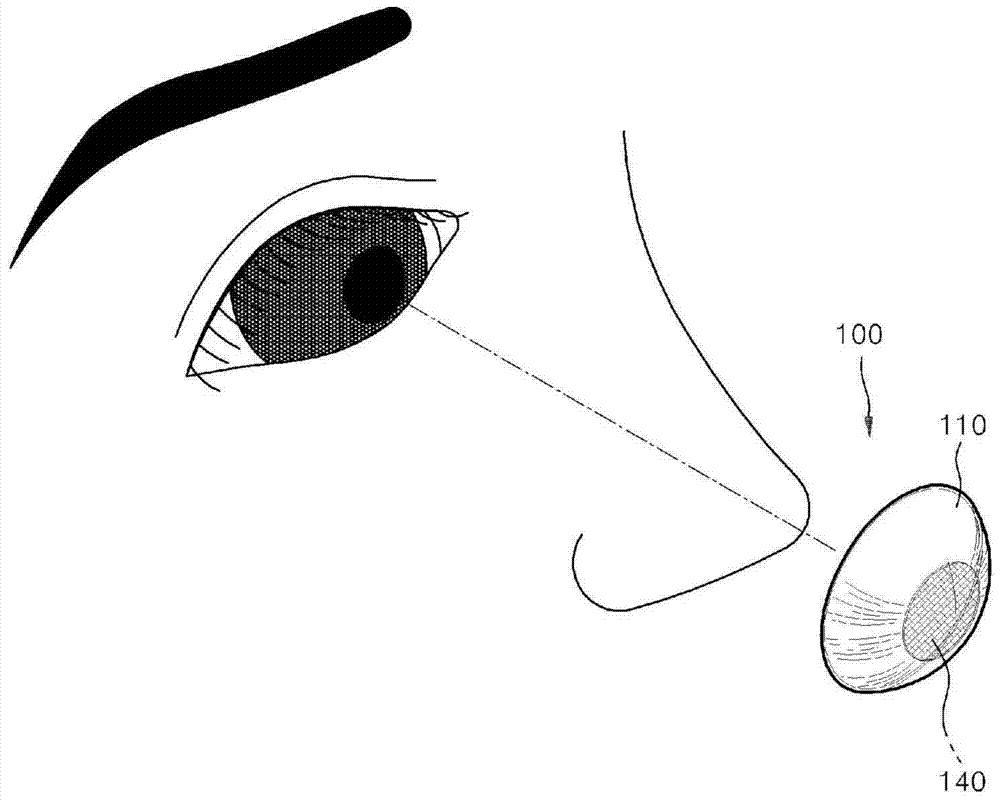

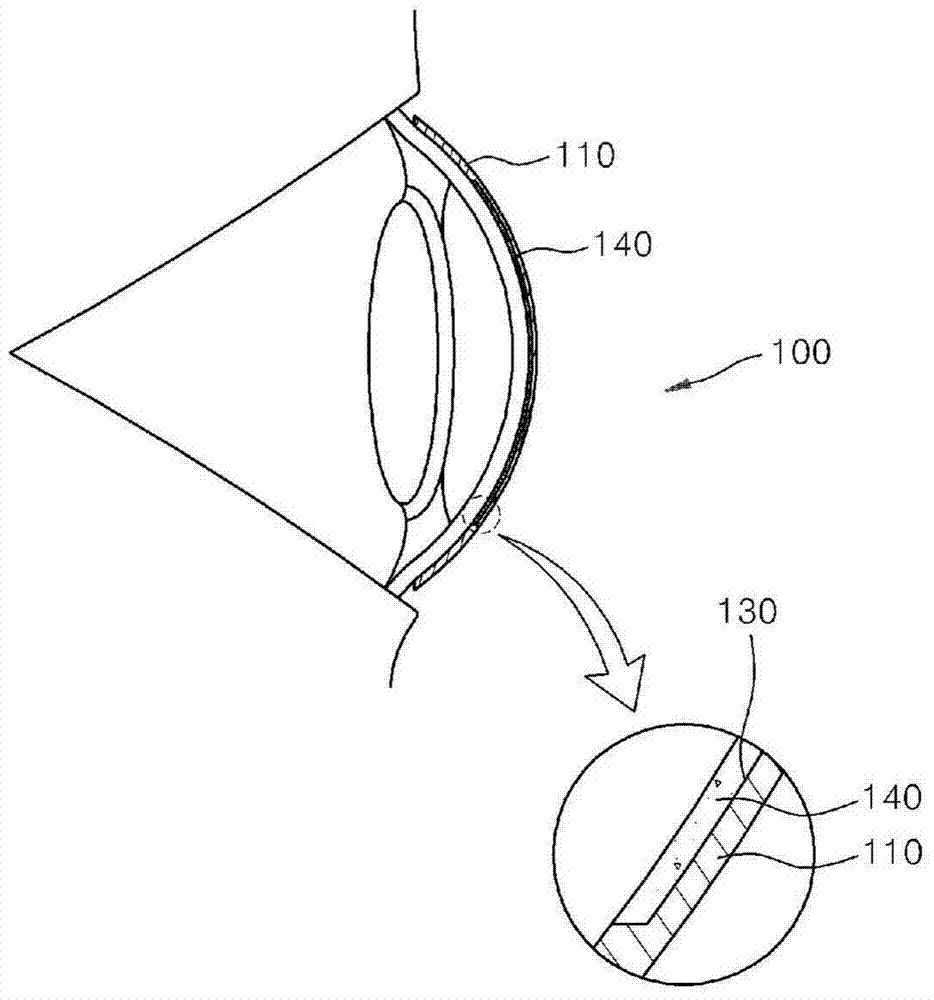

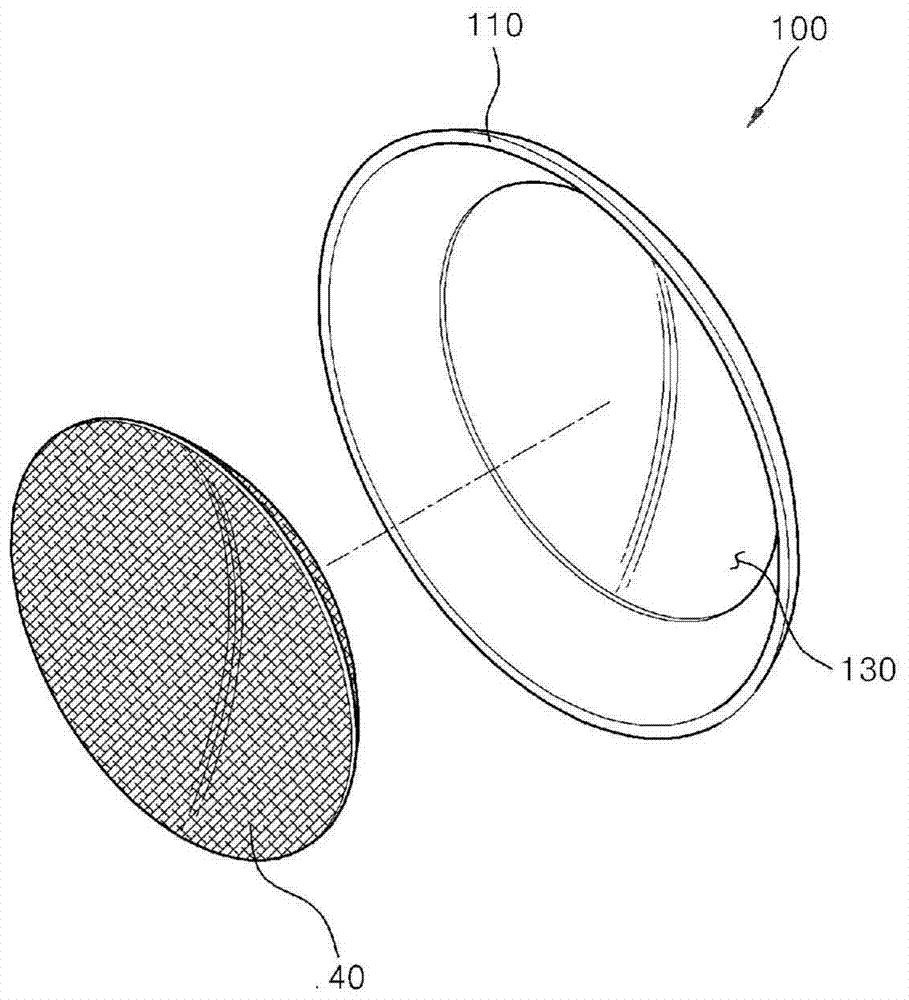

Therapeutic contact lens

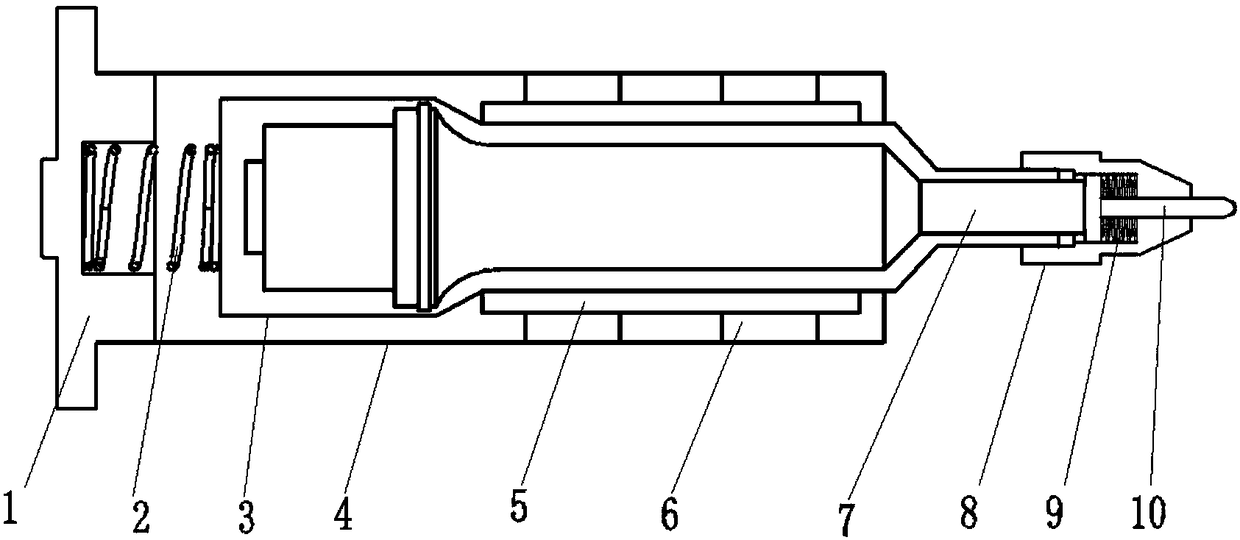

InactiveCN104737063AEnsure contact statusGood treatment effectMedical applicatorsEye treatmentAdditive ingredientTherapeutic effect

The present invention relates to a therapeutic contact lens wherein a therapeutic medicine can be accommodated between an eyeball and a lens, thereby improving the effect and speed of eye treatment. The therapeutic contact lens according to the present invention comprises: a main body of a lens having a spherical surface for allowing the lens to be worn on the eye; an accommodation portion formed to be inward facing the side at the inner surface of the main body of a lens coming in contact with an eyeball; and a medicine portion accommodated in the accommodation portion to deliver a medicine ingredient to the eyeball when the main body of a lens is worn. The accommodation portion can be formed in the form of a circular inlet groove having a predetermined diameter at the center of the inner surface of the main body of a lens, a light transmission portion is formed at the center of the main body of a lens to allow a wearer to see frontward, and the accommodation portion can be formed in a ring shape along the edge of the light transmission portion.

Owner:金善镐

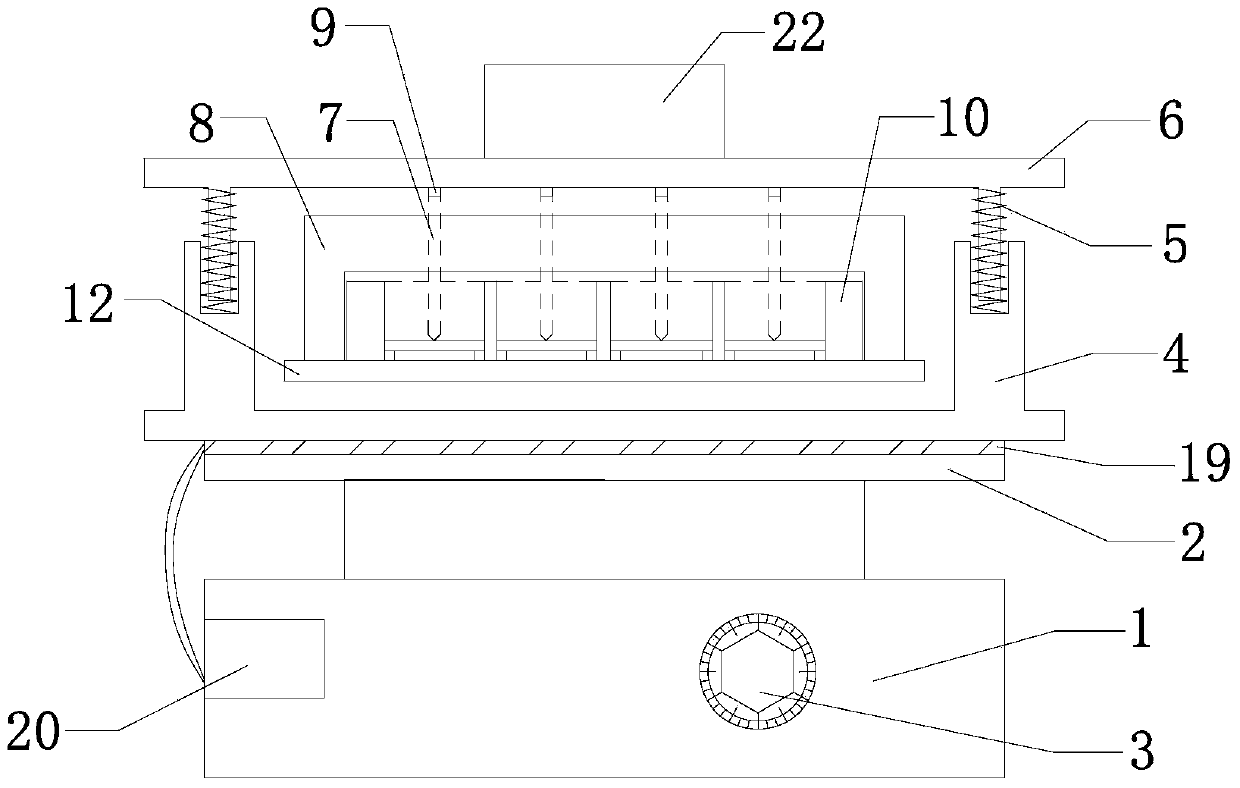

Dynamic mechanical experimental device and method for tissue engineering scaffold

ActiveCN104007029ARelax the design factorEasy to adjustMaterial strength using repeated/pulsating forcesExperimental methodsEngineering

The invention discloses a dynamic mechanical experimental device and a dynamic mechanical experimental method for a tissue engineering scaffold. The device comprises a pressure sensor, a reciprocating motor, a cyclic dynamic stress loading component and an assembling bracket used for placing the reciprocating motor and the cyclic dynamic stress loading component, wherein the pressure sensor comprises a sensing gasket and display equipment; the sensing gasket is arranged between the reciprocating motor and the cyclic dynamic stress loading component, and the sensing gasket and the display equipment are connected with the reciprocating motor; the cyclic dynamic stress loading component comprises a lower bracket used for transmitting driving force upwards, a spring used for transmitting dynamic force, an upper bracket used for transmitting pressure stress downwards, an ejector pin used for transmitting the stress to an experimental material, and a positioning porous cover used for fixing the ejector pin and an experimental porous plate. According to the device and method, a simulation experiment in tissue engineering scaffolds of different sizes under cyclic stress environmental loading under the frequency of 1-150Hz can be met, multi-group experiments can be simultaneously performed, and the experimental efficiency is improved.

Owner:SOUTH CHINA UNIV OF TECH

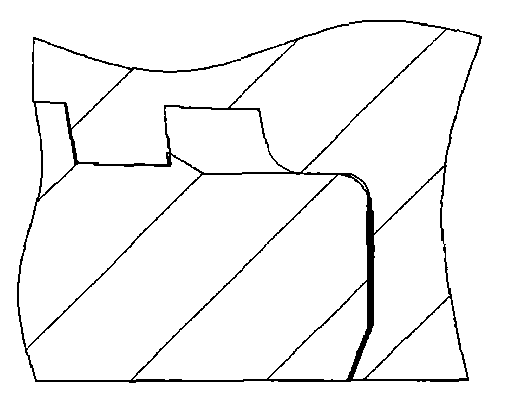

Torque shoulder of special screwed nipple for oil tubes and sleeves

InactiveCN102011558AReduce corrosionEnsure contact statusDrilling rodsDrilling casingsVertical planeScrew thread

The invention relates to a torque shoulder of a special screwed nipple for oil tubes and sleeves. An external thread reverse shoulder inclined plane inclines towards the inner part of a tube on the external thread end part of a tubular nipple connecting thread and on the position behind an internal thread tool withdrawal groove meshed with the external thread end part, the external thread reverse shoulder inclined plane and the tube forms an radial included angle of 15-20 degrees, and the external thread reverse shoulder inclined plane has the radial height of 1.5-2mm; the vertical plane of a triangular shoulder forms a 90-degree included angle with the center line of the oil tube and the sleeve; the reverse shoulder inclined plane is connected with a sealing face connected with a chamfer angle, and the chamfer angle is connected with the connecting thread; an internal thread reverse shoulder and the triangular shoulder are positioned on a position in contact with the end face of the external thread after screwed on; the reverse shoulder inclined plane, the vertical plane of the triangular shoulder and the sealing face are correspondingly matched with the external thread reverse shoulder inclined plane, the vertical plane of the triangular shoulder and the sealing face; an internal thread sealing face is near the thread tool withdrawal groove; and an external thread chamfer angle which is screwed on is clamped in the tool withdrawal groove. Thus, the invention ensures the sealing of the torque shoulder and has the capability of resisting torque, fatigue and corrosion.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

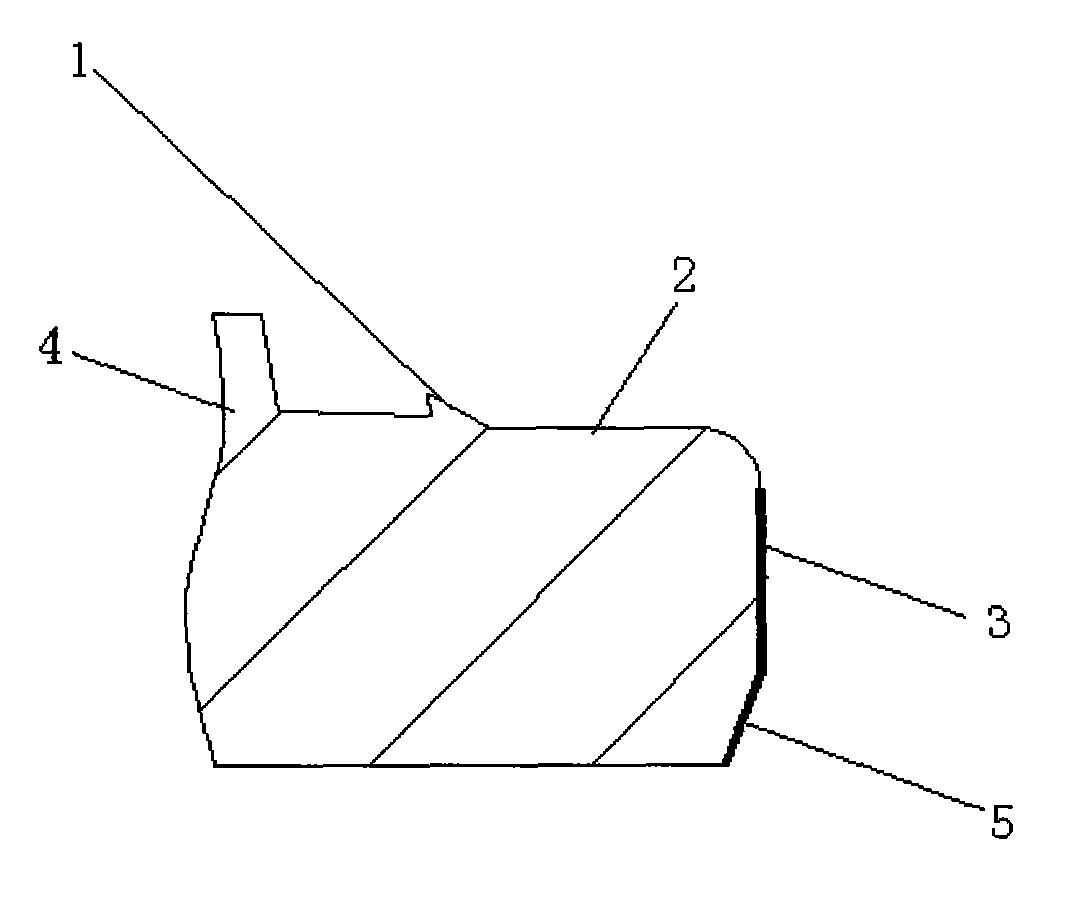

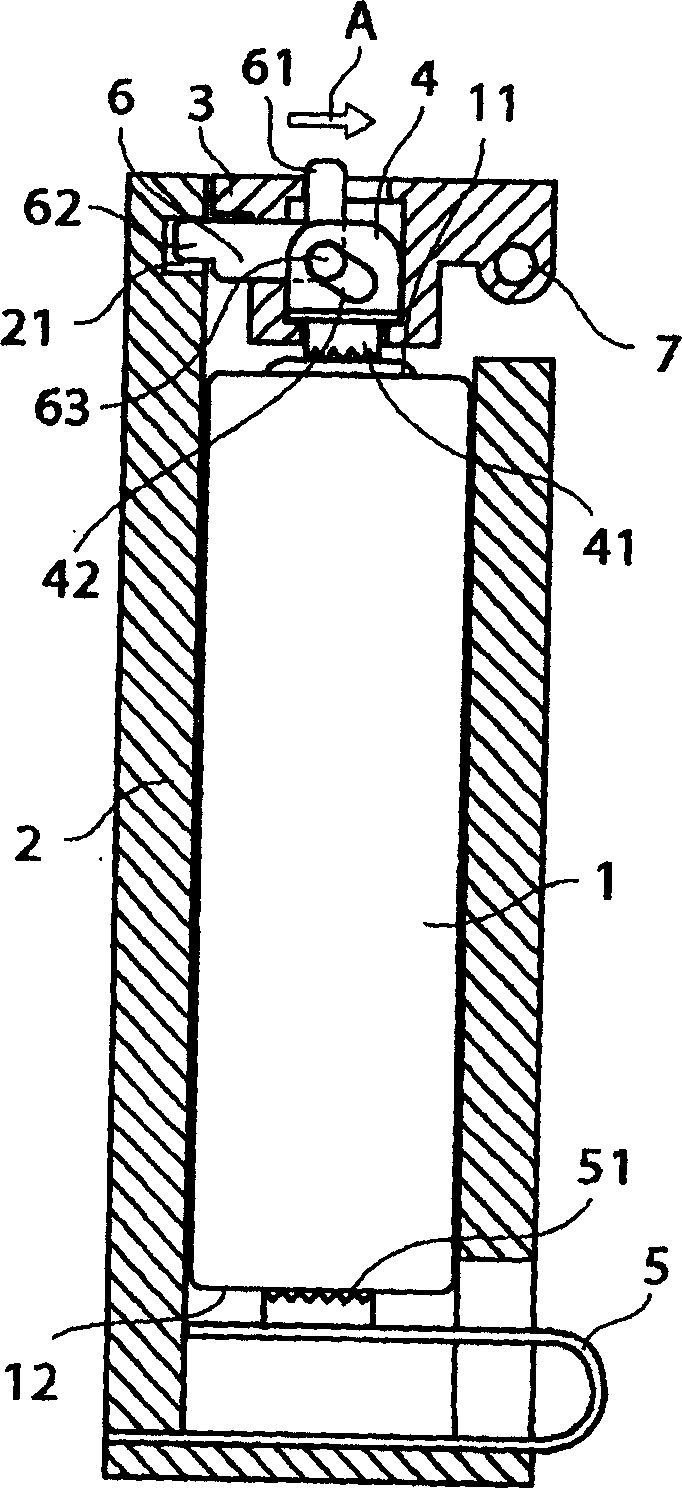

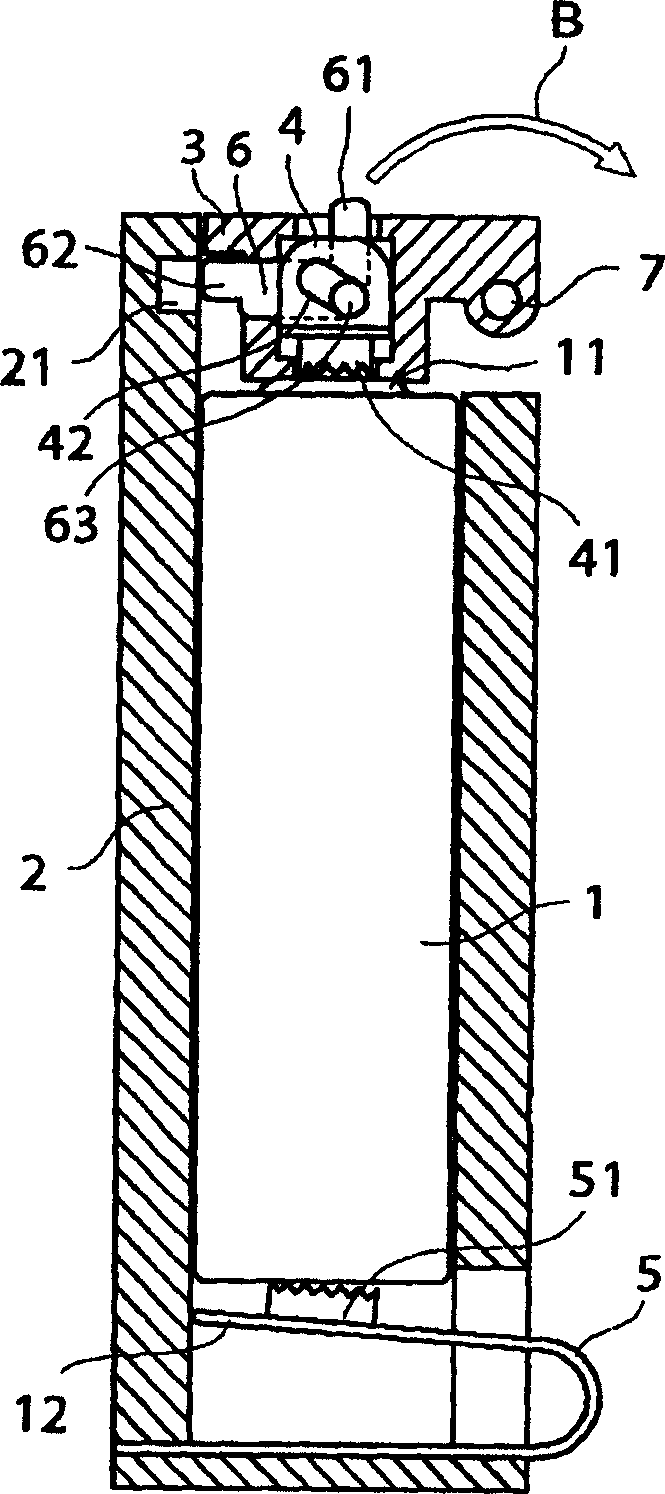

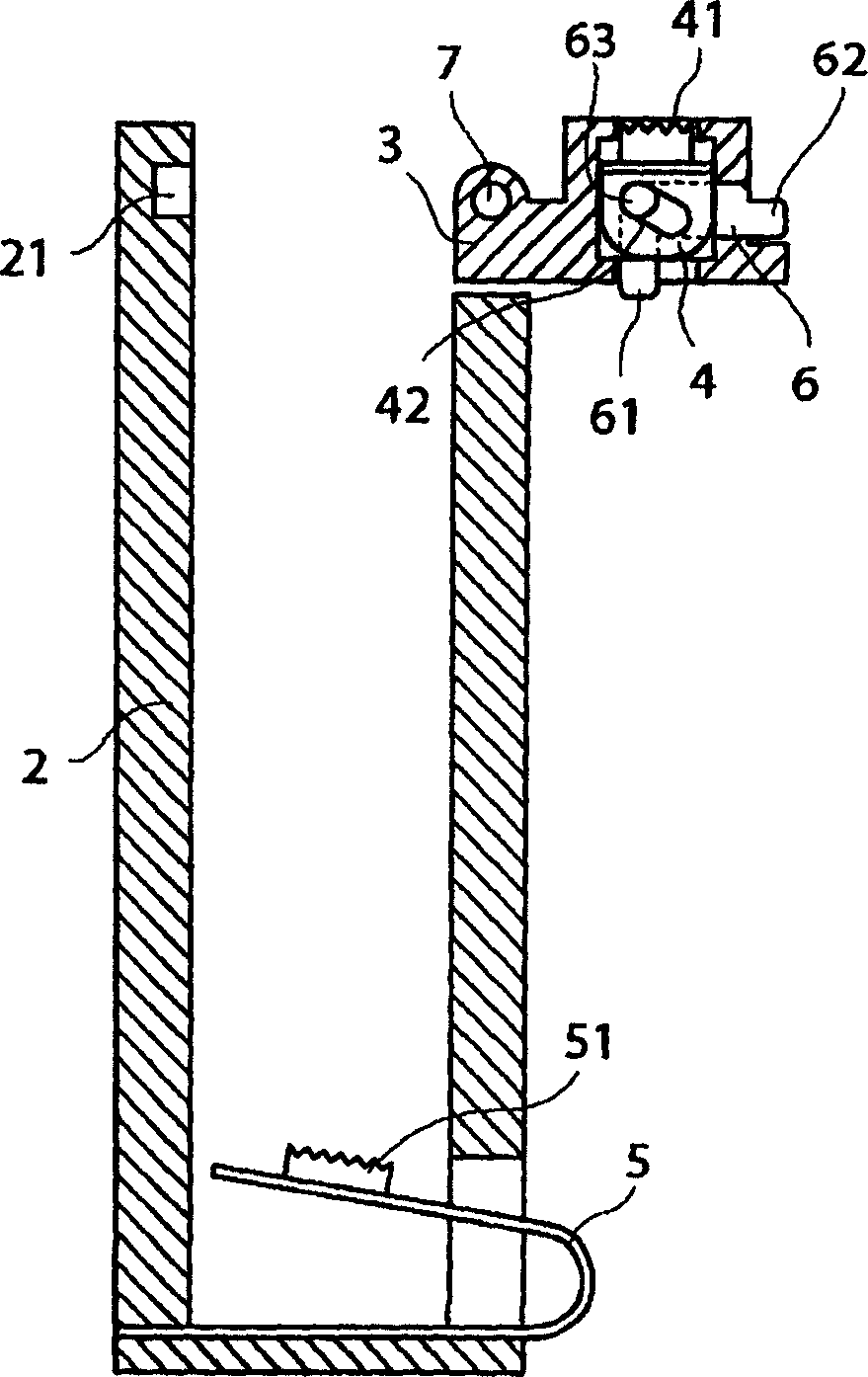

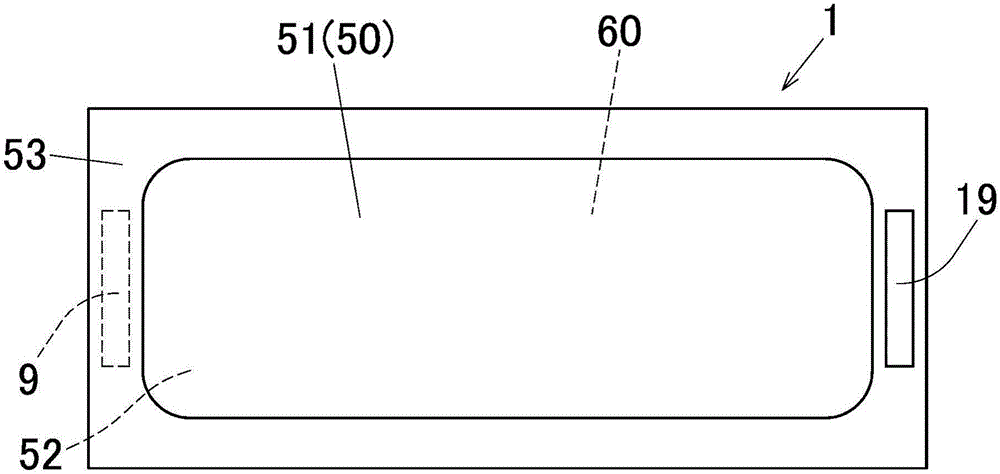

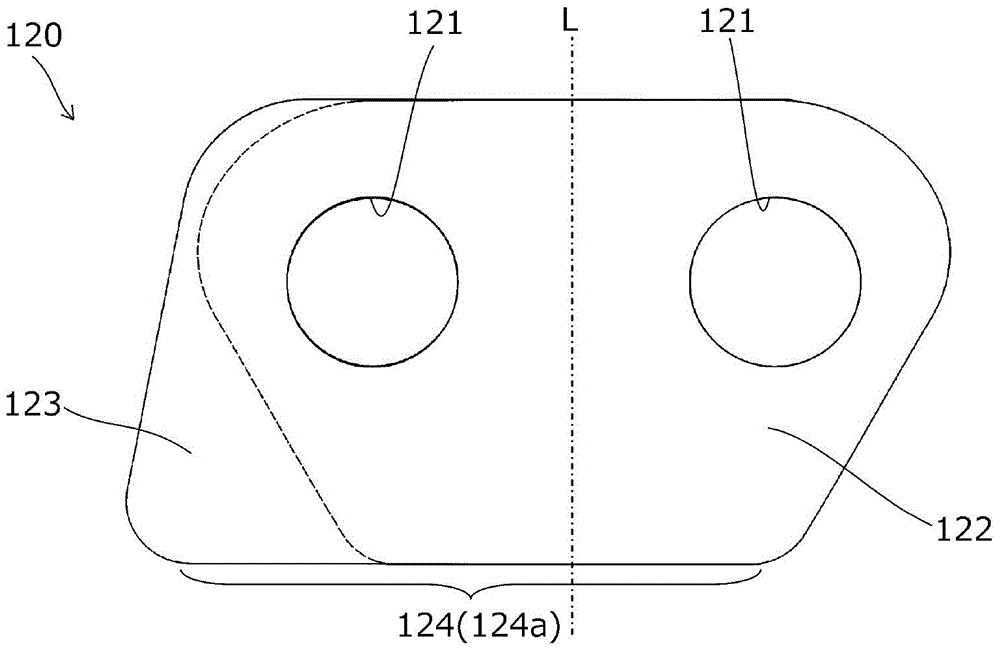

Battery receiving device

InactiveCN1624950AEnsure safetyEnsure contact statusTelevision system detailsBatteries circuit arrangementsEngineeringBattery storage

The present invention provides a battery storage device, the battery storage device is installed in the main body of the device to accommodate the battery in order to keep the contact state of the contact part of the contact terminal and the battery terminal part in good condition while maintaining the safety of the user when the battery is replaced. , which is characterized in that it has a battery cover configured to open and close the opening of the above-mentioned battery storage device, and can be locked when closed; The contact terminal is in contact with the contact portion of the battery terminal when the battery cover is closed. The contact terminal is configured such that when the battery cover is closed and the battery cover is locked, the contact portion protrudes toward the inside of the battery cover. When the lock is released , the above-mentioned contact portion is pulled into the above-mentioned battery cover.

Owner:CANON KK

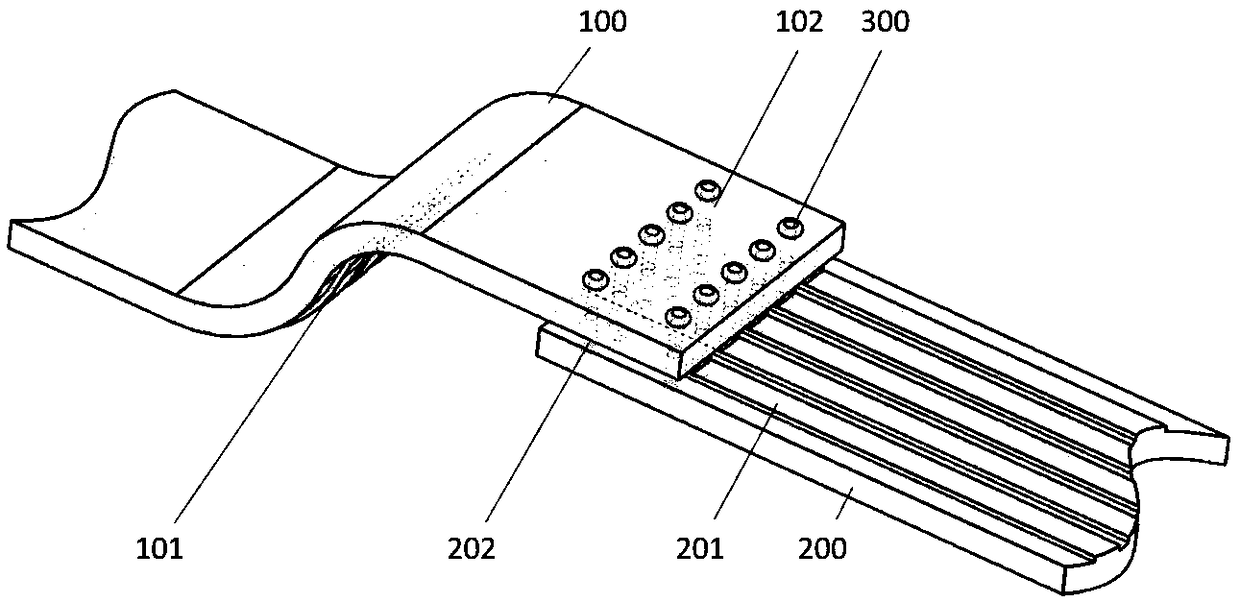

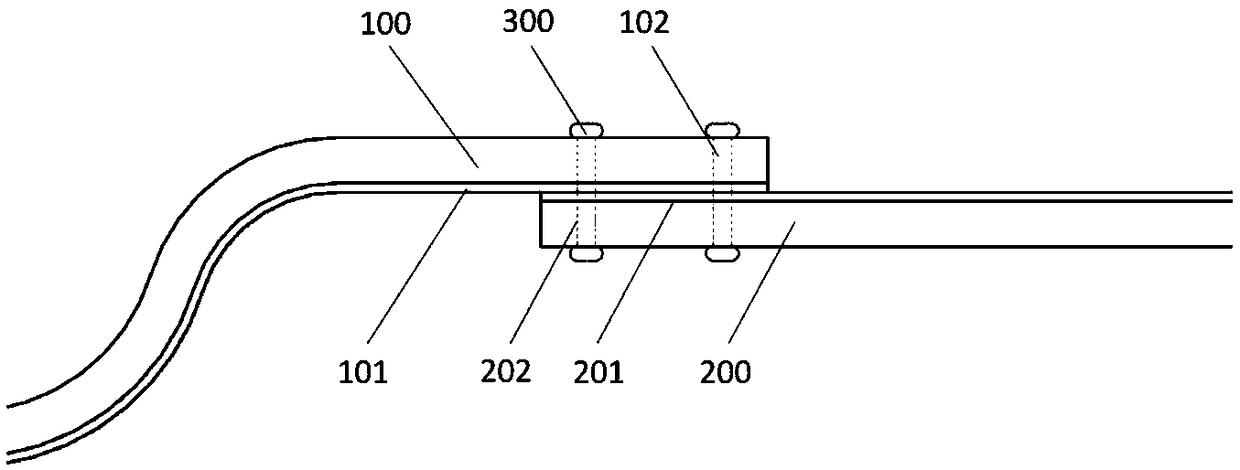

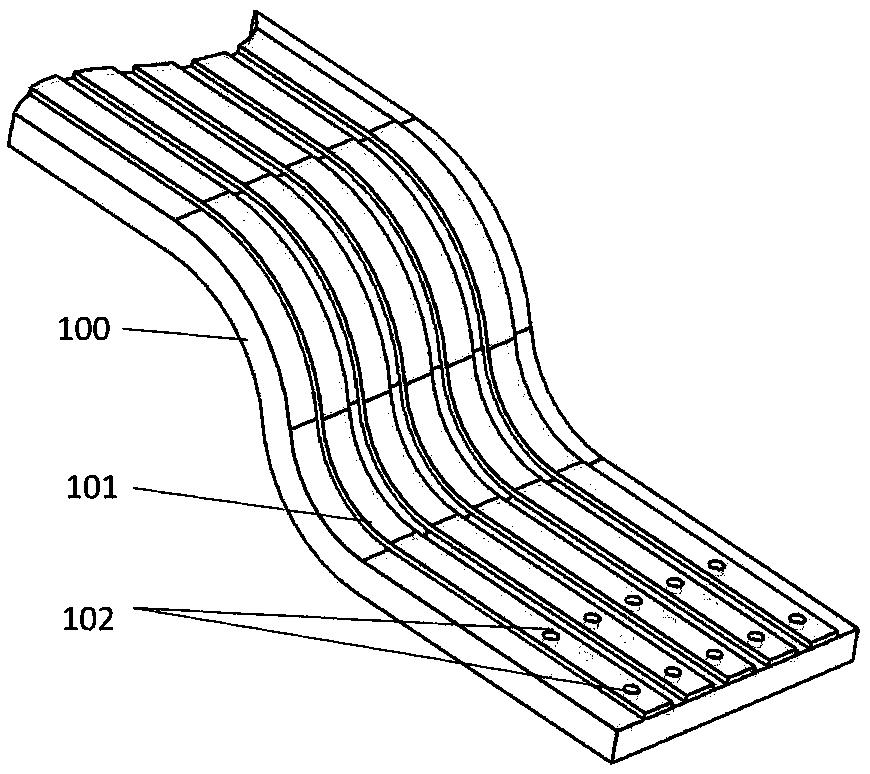

Circuit board connecting structure

ActiveCN108668435AImprove reliabilityStrong mechanical connectionPrinted circuit aspectsPrinted circuits structural associationsEngineeringHardboard

The invention discloses a circuit board connecting structure which comprises a first circuit board and a second circuit board. One of the two circuit boards is a soft board, the other of the two circuit boards is a hard board, or the two circuit boards are both soft boards. A plurality of signal transmission units are arranged on the surface of the first circuit board, through holes are reserved in the ends of the signal transmission units, and the through holes penetrate through the first circuit board and the signal transmission units. Signal transmission units and end through holes corresponding to the first circuit board are arranged on the surface of the second circuit board. The invention discloses a combing method of the circuit boards. Pin-shaped structures with the two ends thicker than the middles are formed in the corresponding through holes of the two circuit boards through combining materials, and firm connection of the two circuit boards is achieved.

Owner:宁波勇毅科技有限公司

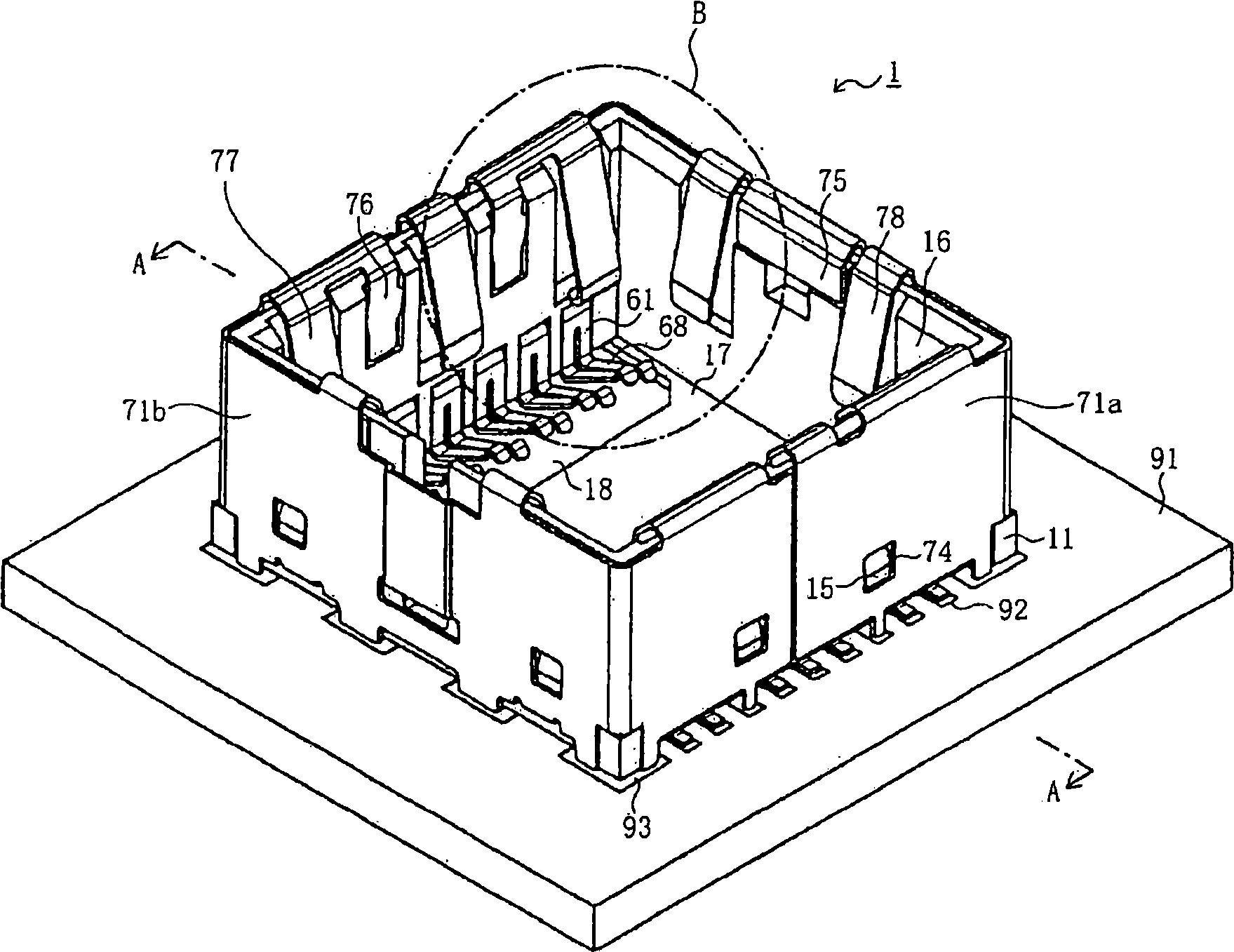

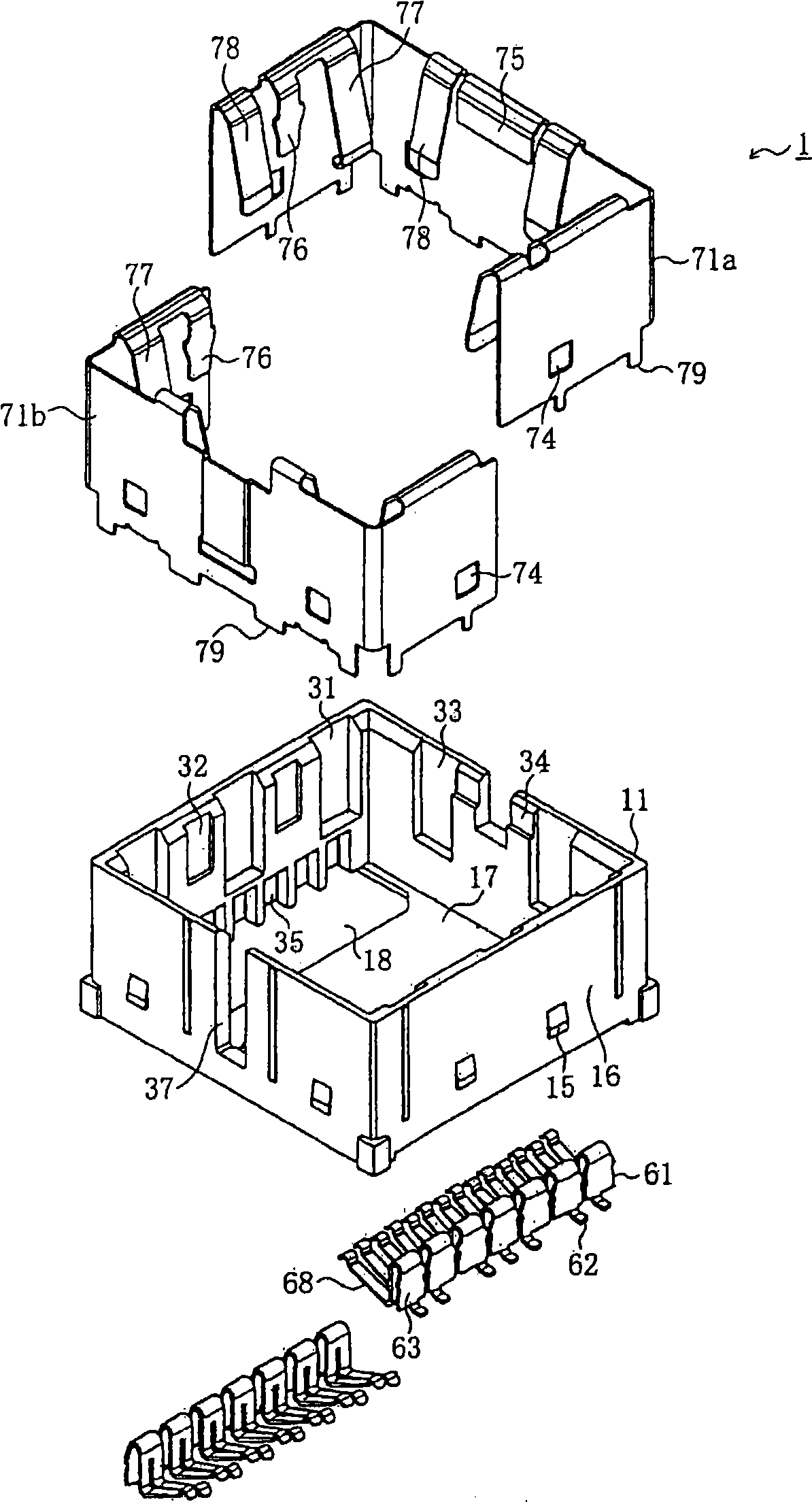

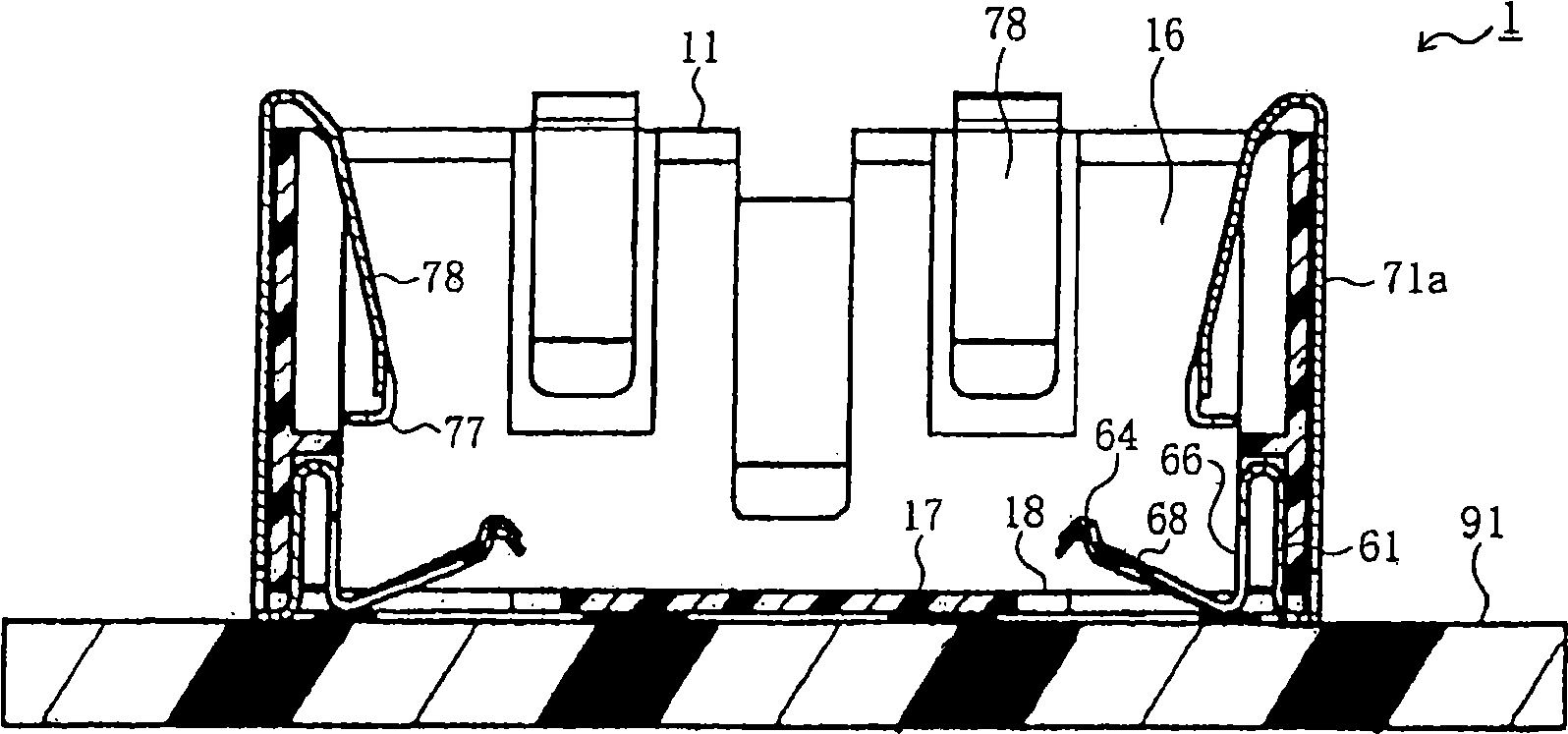

Integrated mail, internet, and telephony event tracking system

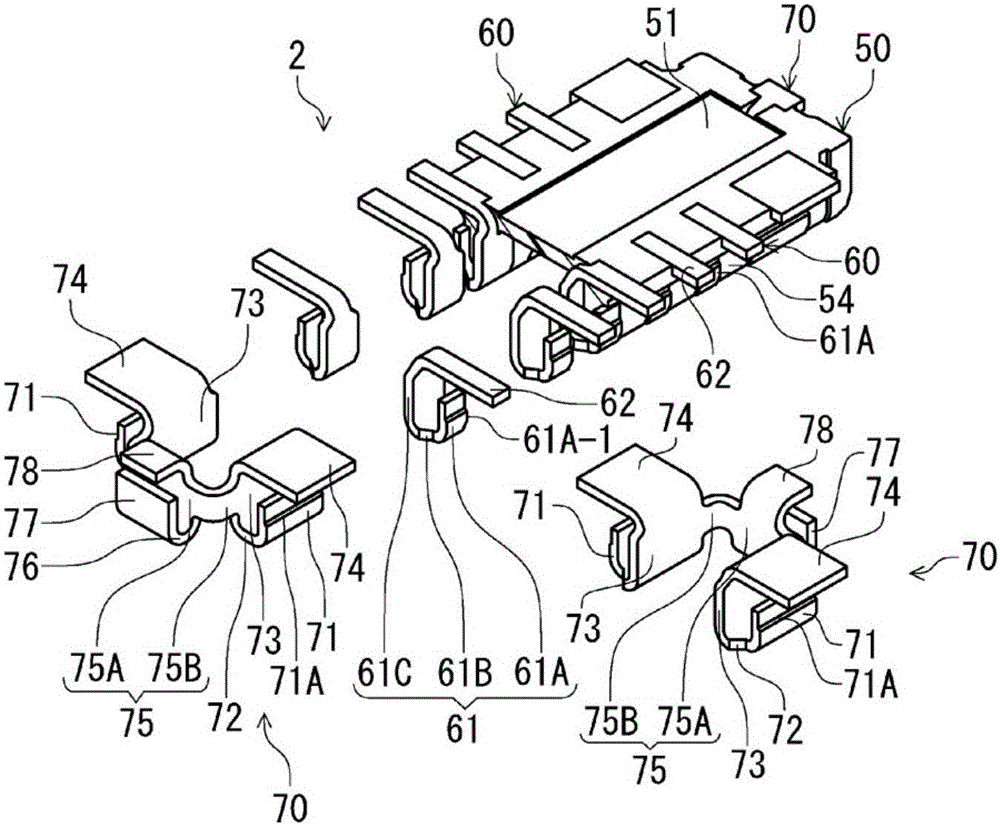

InactiveCN101536264APrevent slipping outEnsure contact statusElectric discharge tubesCoupling contact membersVariable thicknessThe Internet

A module socket 1, which is specifically suitable for use together along with a camera module in a mobile telephone, has a structure for compensating the manufacture deviation in the camera module. The socket has an insulation housing 11 surrounded by a conductive metal shell 71. Spring arms extends from the inside of the socket towards the housing bottom, and are jointed with the shoulder or surface formed oppositely on the module. A series of conductive terminals are supported by the housing, and the terminals extend from the housing bottom in the socket upward. The terminals respectively cleavage or bifurcated ends having two contact arms 68, the ends bend upwards at two different angles, so that each terminal has two different contact arms located at different heights. So that a plurality of contact arms can compensate and contact with modules with different thickness or variable thickness.

Owner:MOLEX INC

Movable contact assembly of circuit breaker for wiring

InactiveCN100409391CEasy to separatePrevent returnProtective switch operating/release mechanismsCircuit-breaking switch contactsSeparated stateCurrent limiting

Disclosed is a movable contactor assembly of a circuit breaker capable of enhancing a current limiting function by maintaining a contact state between a movable contactor and fixed contactors in a closed circuit state, by preventing the separated movable contactor from returning towards the fixed contactors at the time of a current limiting operation, by accelerating a separation operation of the movable contactor from the fixed contactors at the time of a current limiting operation, and by continuously maintaining a separated state of the movable contactor from the fixed contactors until a trip operation is performed by a trip mechanism.

Owner:LSIS CO LTD

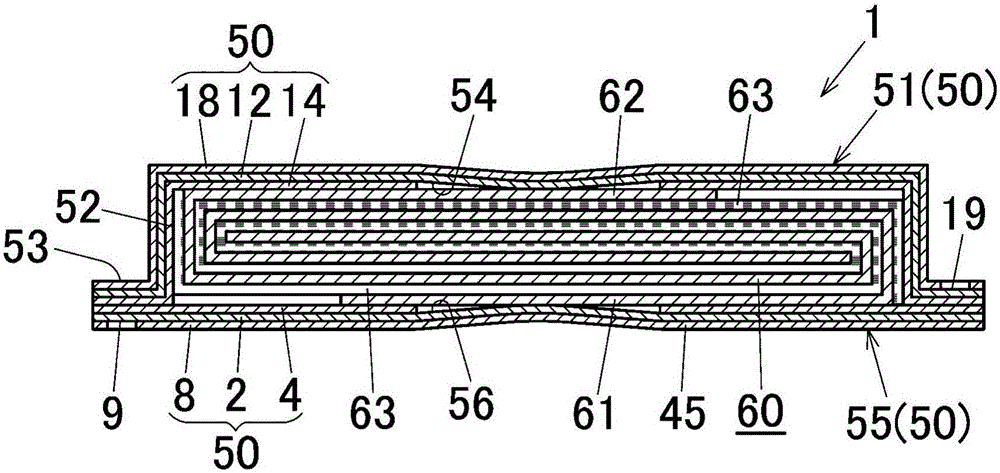

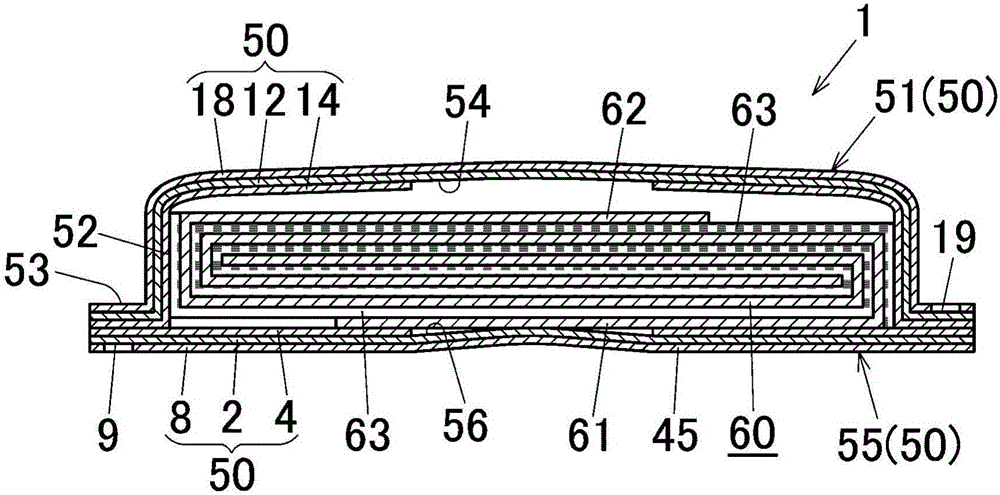

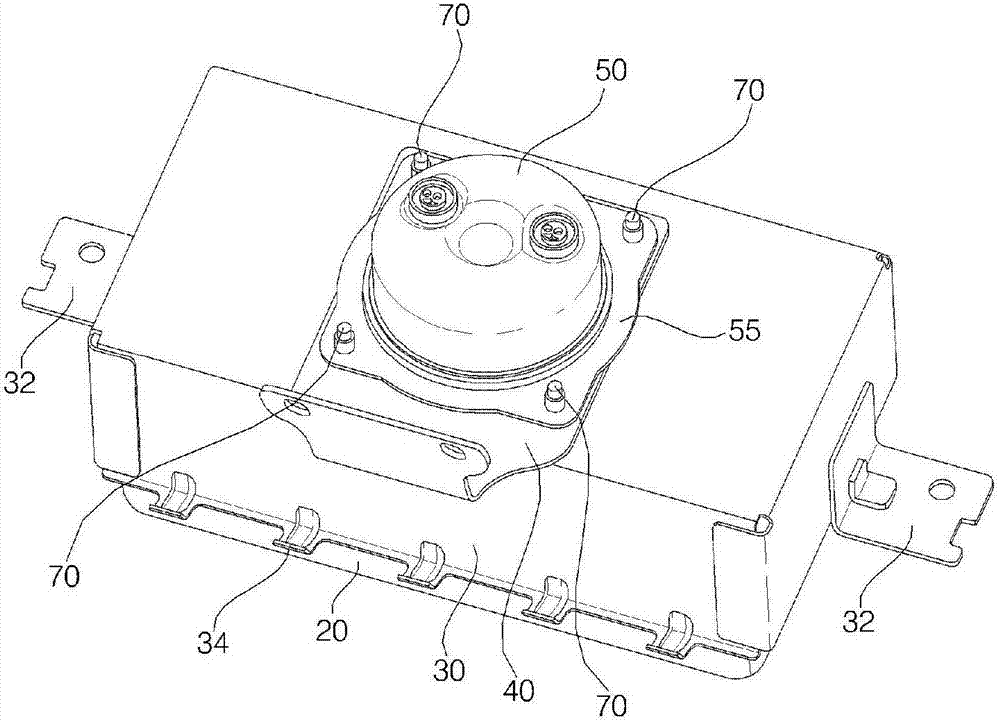

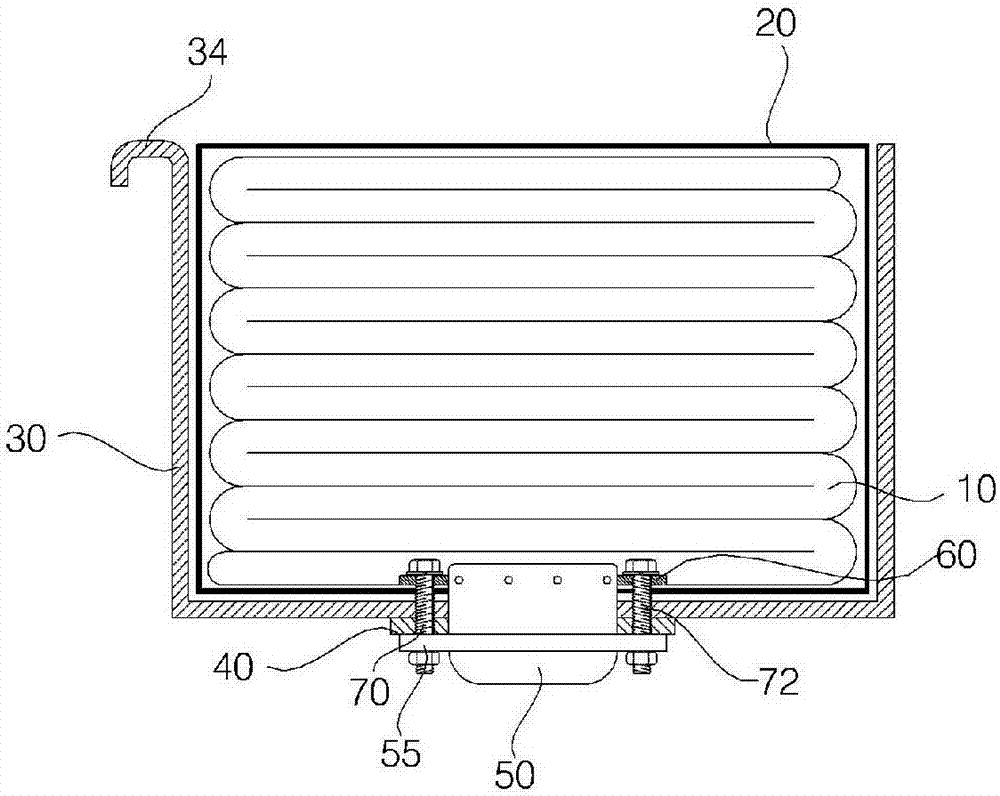

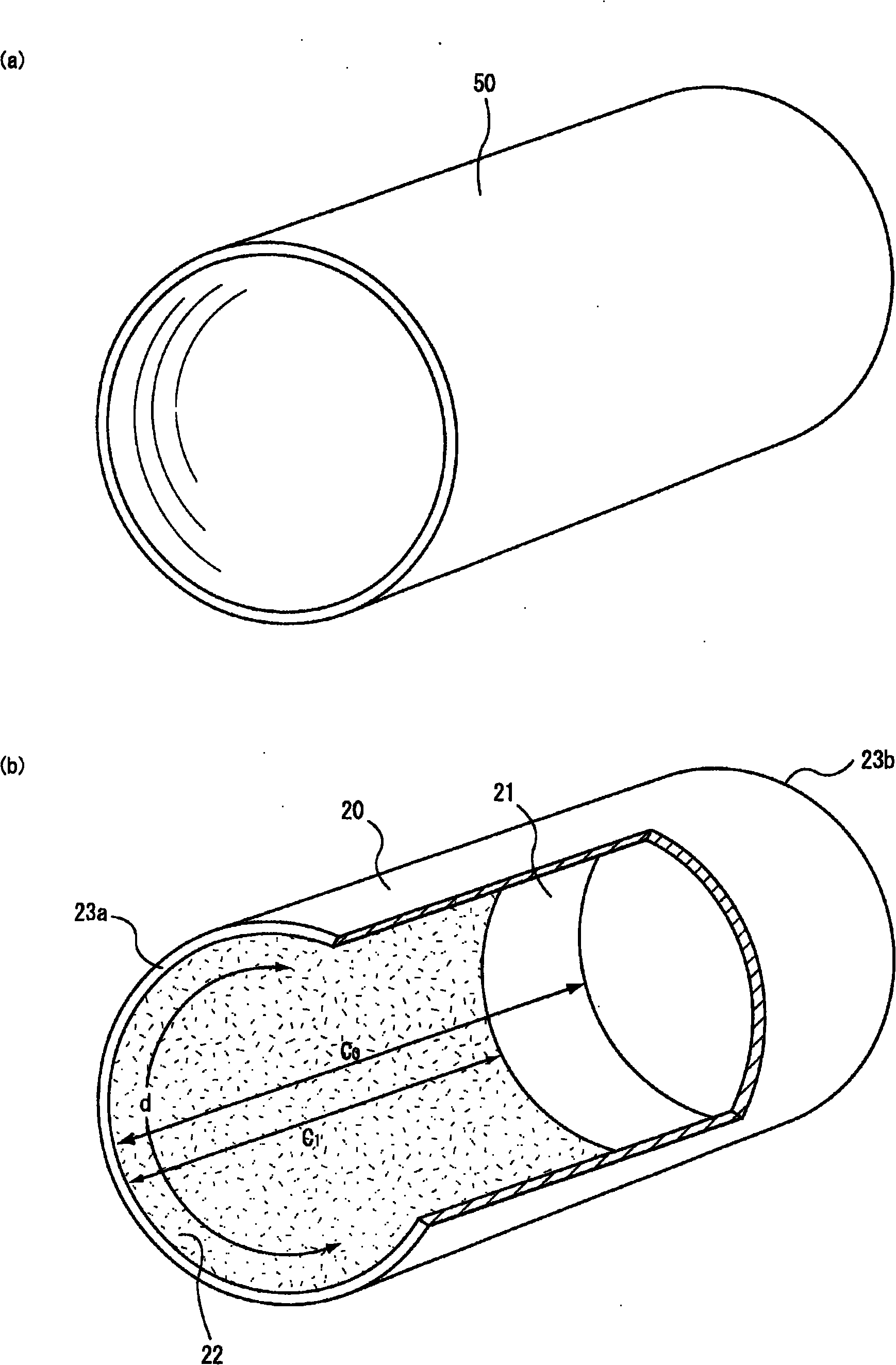

Electric energy storage device

InactiveCN106098969AAvoid breakingImprove the conduction stateSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsElectrical energy storageMetal foil

The invention provides an electric energy storage device which is provided with a device body (60) and two external packaging members for accommodating the device body. Each external packaging member (50) is provided with metal foil layers (2,12) and hot-melt resin layers (4,14) which are laminated on one surface of the metal foil layer. One surface of the metal foil layer is partially provided with conductive parts (54,56) which are not covered by the hot-melt resin layer. The anode (61) of the device body is electrically connected with the conductive part (56) of one external packaging member. The cathode (62) of the device body is electrically connected with the conductive part (54) of the other external packaging member. At least one electrode (62) in the anode and the cathode is electrically connected through a state of contacting with the conductive part (54). On the condition that an internal pressure increases, the conductive part (54) in the contacting state is separated from the anode (62), thereby realizing switching off conduction.

Owner:SHOWA DENKO PACKAGING CO LTD

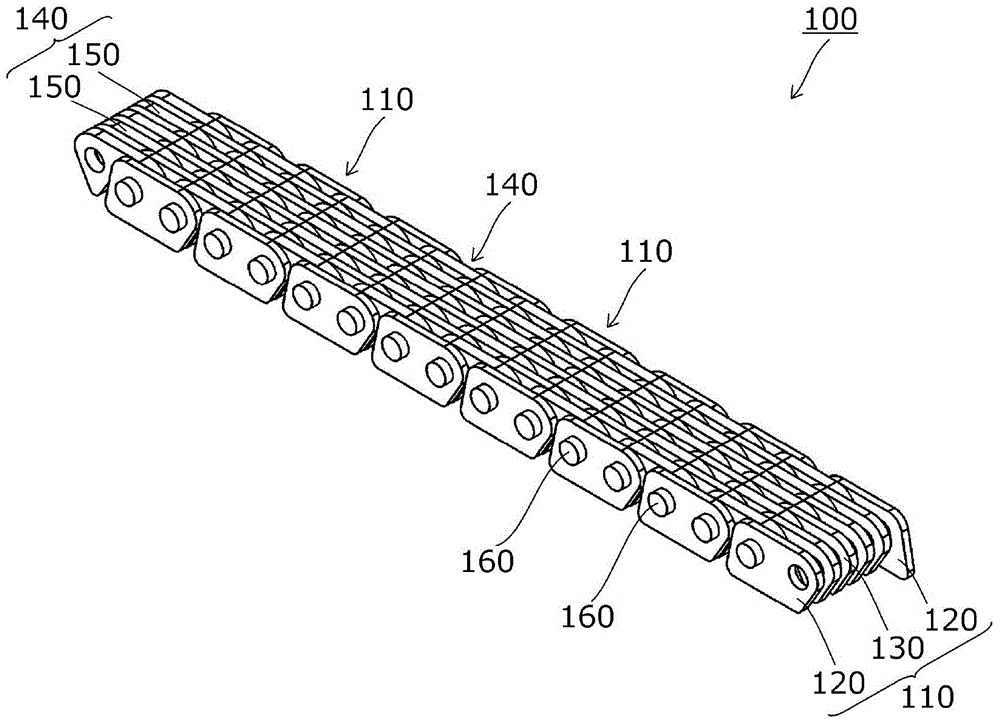

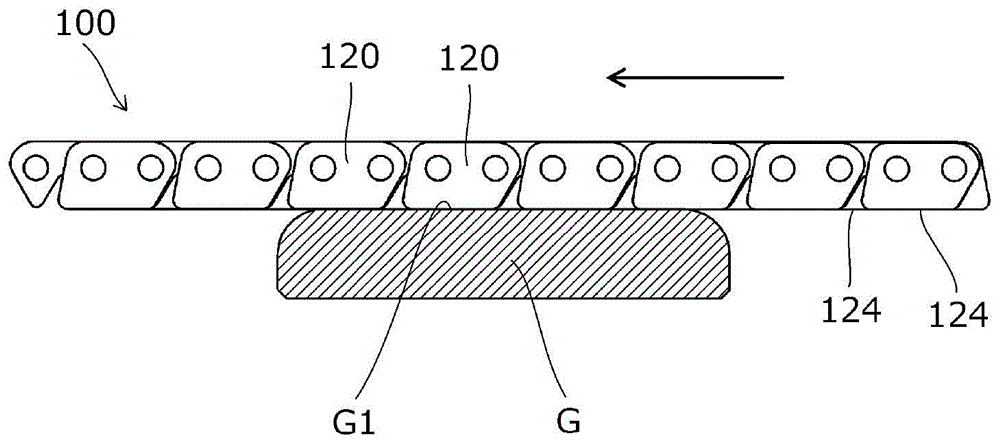

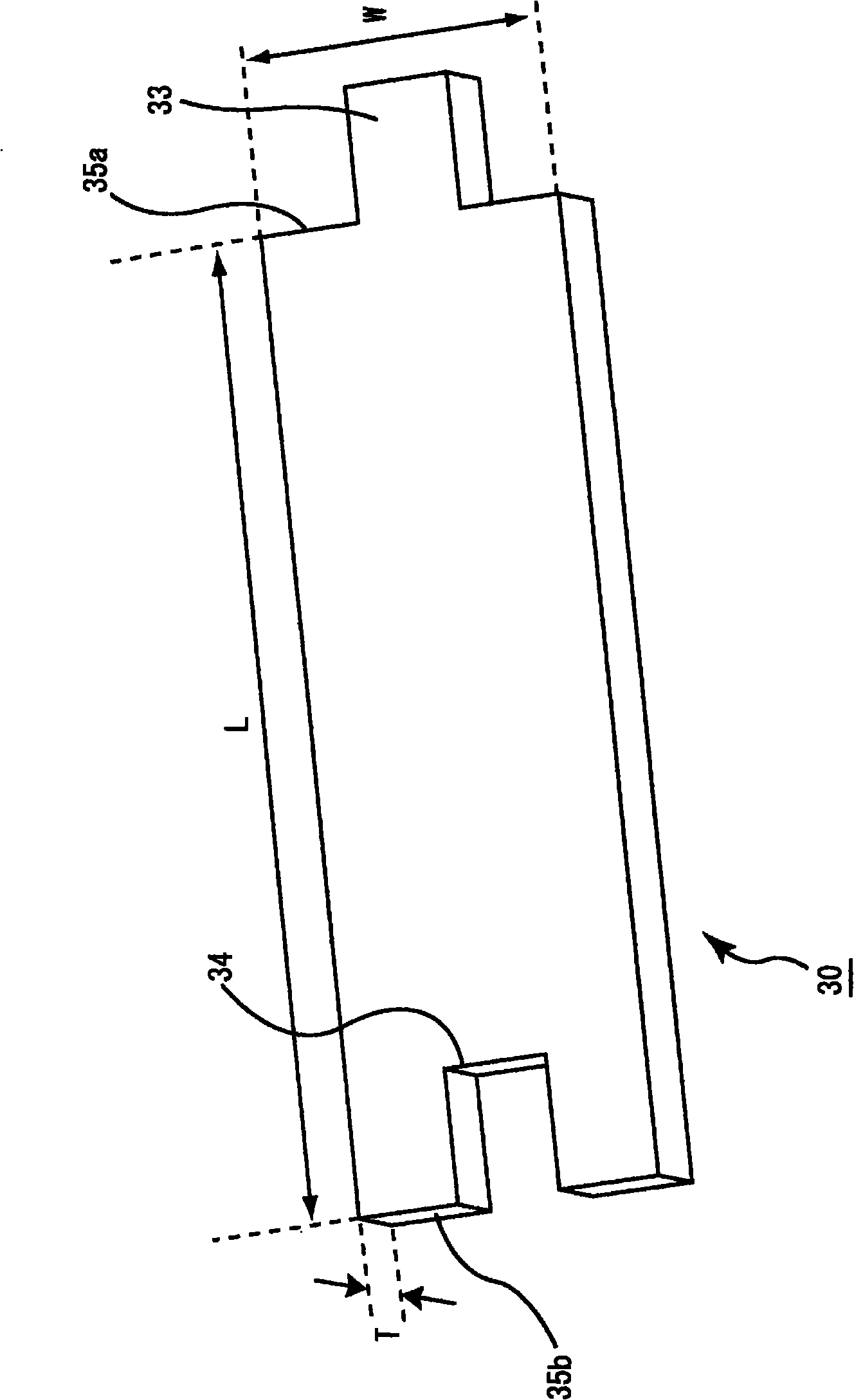

Chain and chain guide plate

ActiveCN104675924AAvoid complicationsAvoid increasing the number of blocksGearingDriving chainsSliding contact

The invention provides a chain and a chain guide plate that suppress occurrence of noise during chain traveling while attaining a reduction in costs and also attaining space saving. A chain includes first plate rows and second late rows. Each of the first plate rows includes a guide plate including a guide slide contact section for coming into slide contact with an inner side guide. The guide slide contact section extends in a chain longitudinal direction to be asymmetrical relative to an imaginary center line. During guiding by the inner side guide, lines drawn by the guide slide contact sections of a plurality of the guide plates are continuous in the chain longitudinal direction.

Owner:TSUBAKIMOTO CHAIN CO

Passenger airbag apparatus and method of manufacturing the same

ActiveCN107021056AEnsure contact statusSimple processPedestrian/occupant safety arrangementAerospace engineeringAirbag

According to a passenger airbag apparatus according to an exemplary embodiment of the present invention, a left chamber portion and a right chamber portion protrude forward at a front side of an airbag so as to be spaced apart from each other in a left and right direction, and a groove tether pulls the front side of the airbag between the left chamber portion and the right chamber portion, and as a result, a groove is formed at the front side of the airbag between the left chamber portion and the right chamber portion.

Owner:HYUNDAI MOBIS CO LTD

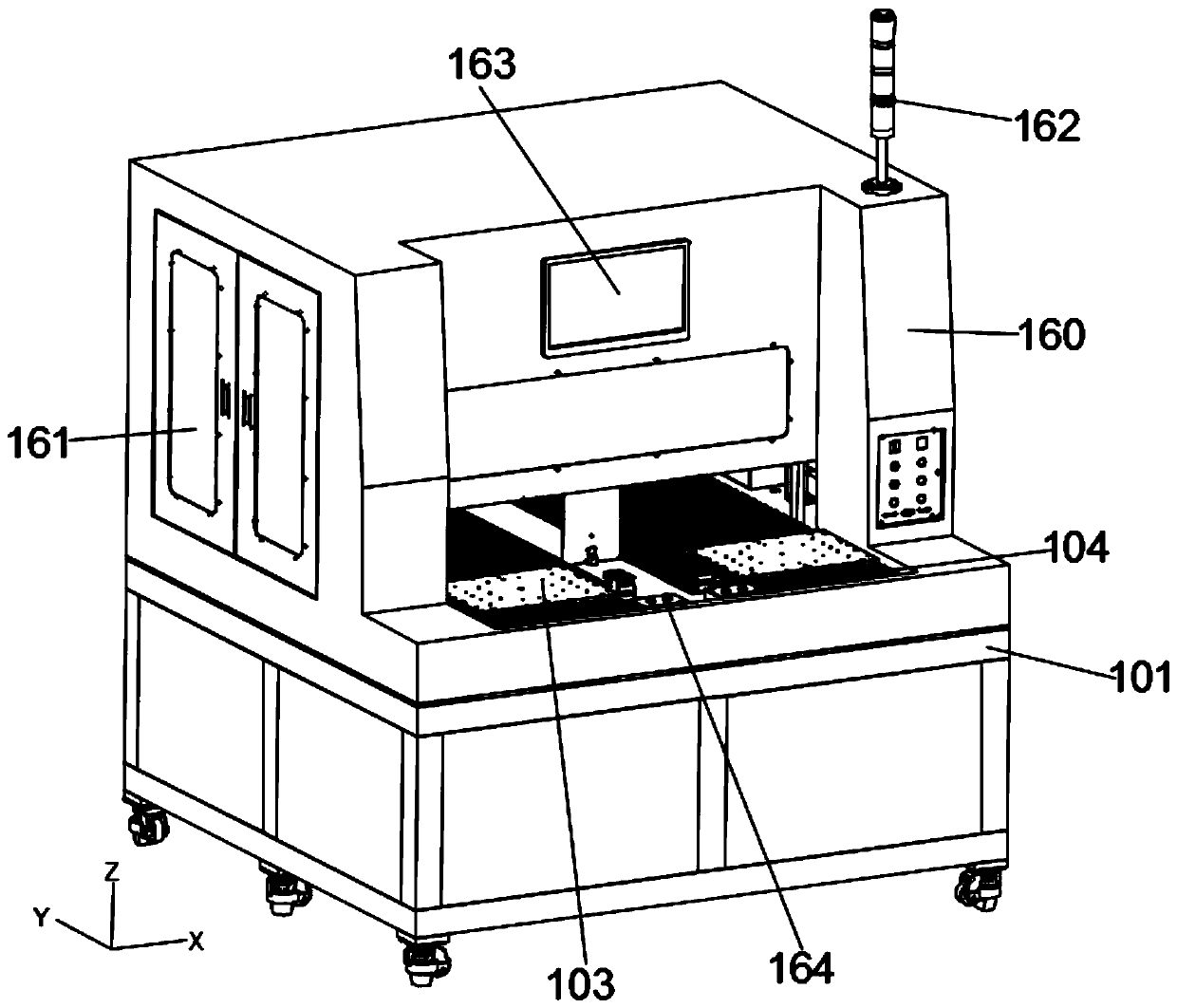

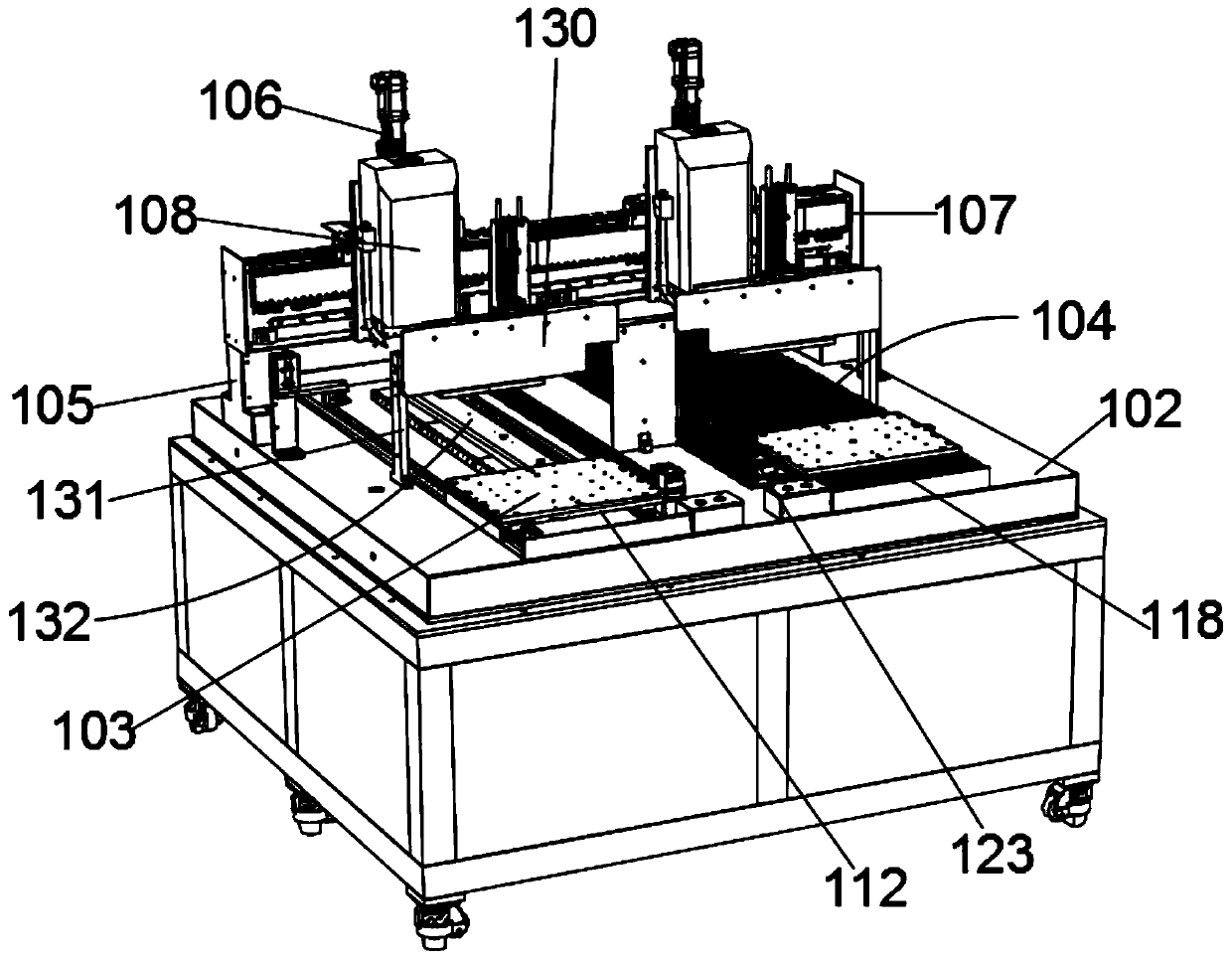

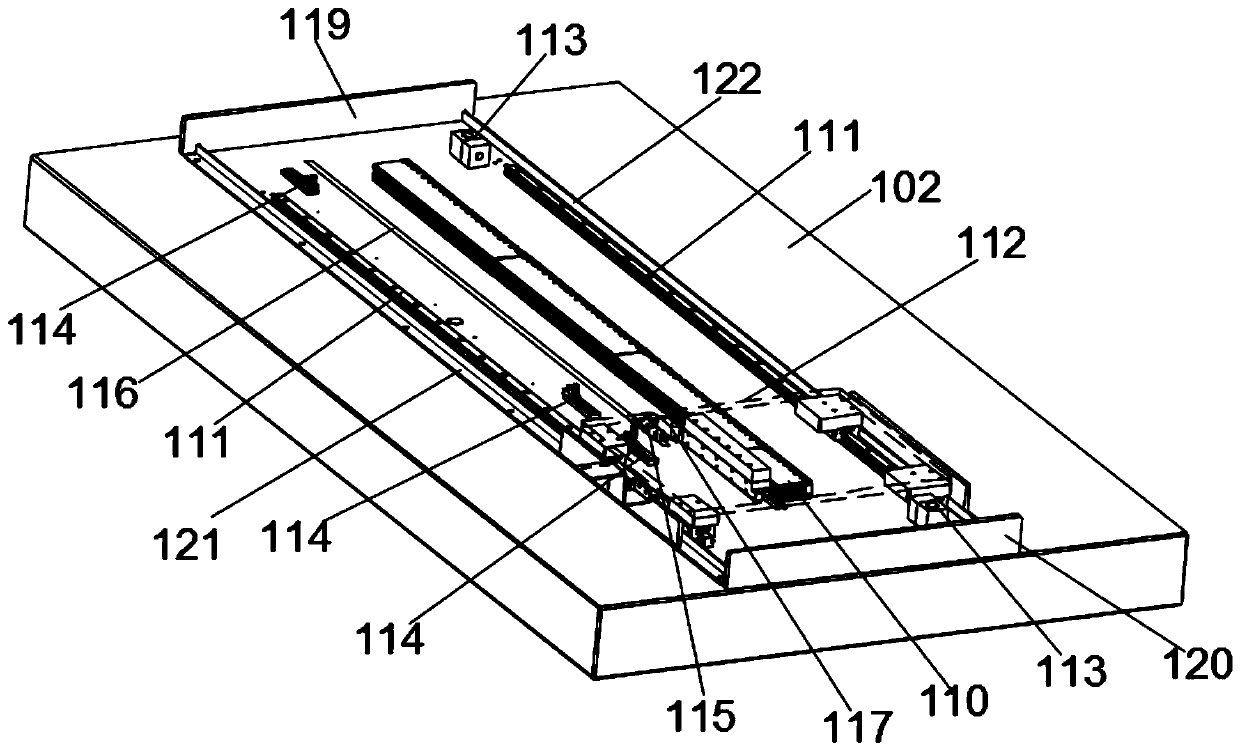

Paper-plastic ring cutting machine

PendingCN110722629AImplement the remove operationEnsure contact statusMetal working apparatusElectric machineryMachine

The invention discloses a paper-plastic ring cutting machine. The paper-plastic ring cutting machine comprises a marble platform, a portal frame made of marble, a control mechanism and an air blowingmechanism, wherein a first transmission mechanism for driving a bearing table to move back and forth along a first linear track is arranged on the marble platform, and a jig for placing a product to be cut is mounted on the bearing table; a second transmission mechanism for driving a Z-axis movement module to move back and forth along a second linear track is arranged on the portal frame, and thefirst linear track is perpendicular to the second linear track in different planes; the Z-axis movement module can drive a cutting mechanism to move up and down; the first transmission mechanism and the second transmission mechanism are driven by a linear motor; the control mechanism is connected with the first transmission mechanism, the second transmission mechanism and the Z-axis movement module; and the air blowing mechanism is used for cooling a blade of a cutter on the cutting mechanism. The marble platform and the portal frame structure are high in surface flatness precision, and the flatness of the product section is improved; and the linear motor form is adopted, friction is avoided, energy consumption is low, movement is stable, the speed is high, and the section quality is guaranteed.

Owner:苏州艾思泰自动化设备有限公司

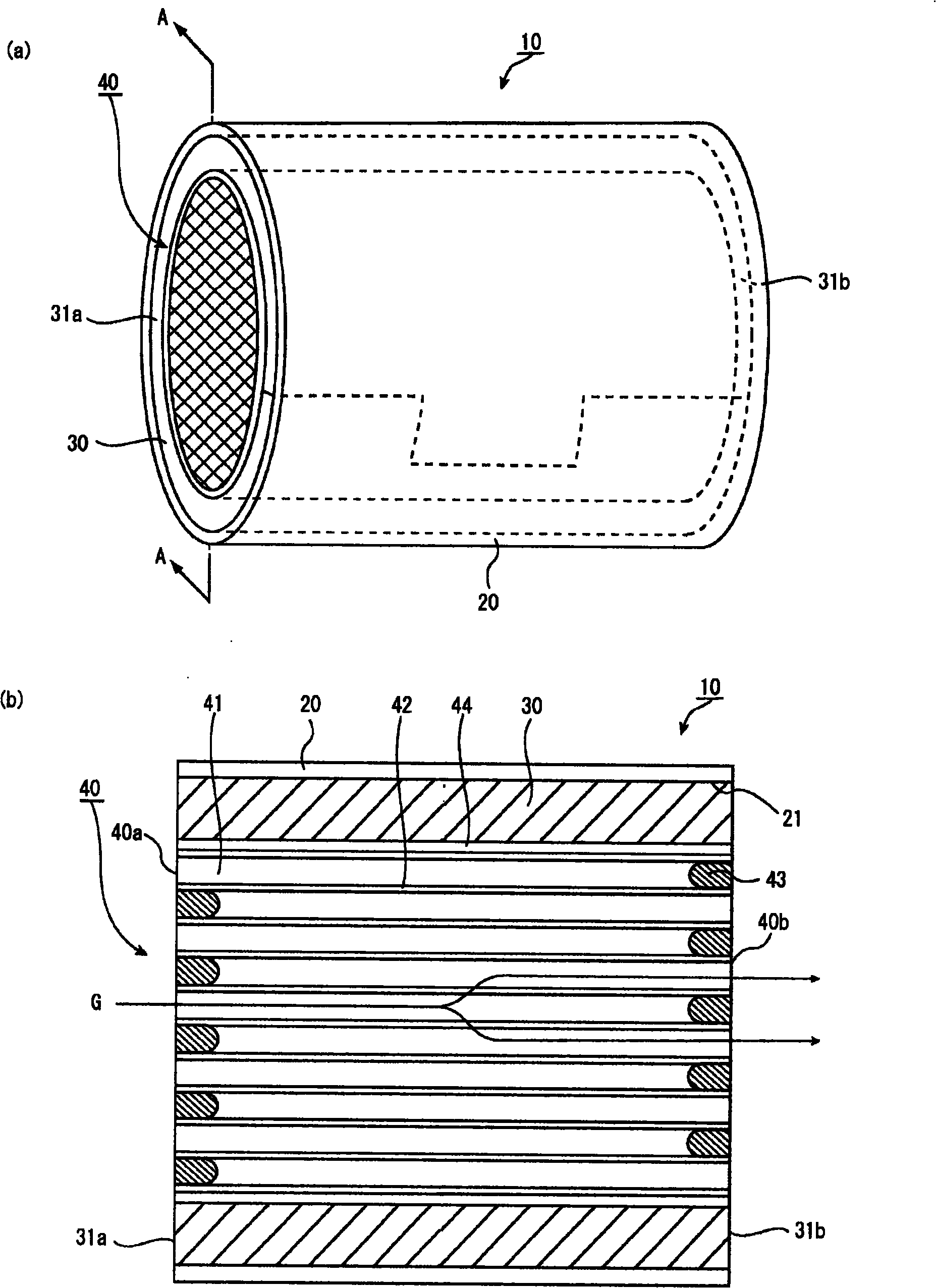

Exhaust gas purifying device and manufacturing method thereof

ActiveCN101845980AEnsure contact statusHold firmly and secureSilencing apparatusMachines/enginesFiberExhaust fumes

The invention provides an exhaust gas purifying device and a manufacturing method thereof. The exhaust gas purifying device can be manufactured through a simple manufacturing method. The exhaust gas treating body can be kept and fixed even the bulk density of assembled sealing materials is not increased and no additional external force is exerted on the sealing materials. The exhaust gas purifying device includes an exhaust gas treating body, a metal casing, and a holding sealing material, wherein the exhaust gas treating body is a columnar exhaust gas treating body formed by paralleling a plurality of ducts along the longitudinal direction to define duct walls; the metal casing is arranged for containing the exhaust gas treating body; and the holding sealing material includes an inorganic fiber aggregated body and is arranged between the exhaust gas treating body and the metal casing in order to hold the exhaust gas treating body. The exhaust gas purifying device is characterized in that at least one part of the metal casing opposite to the holding sealing material is provided with a corroded area formed by corroding the substrate of the metal casing.

Owner:IBIDEN CO LTD

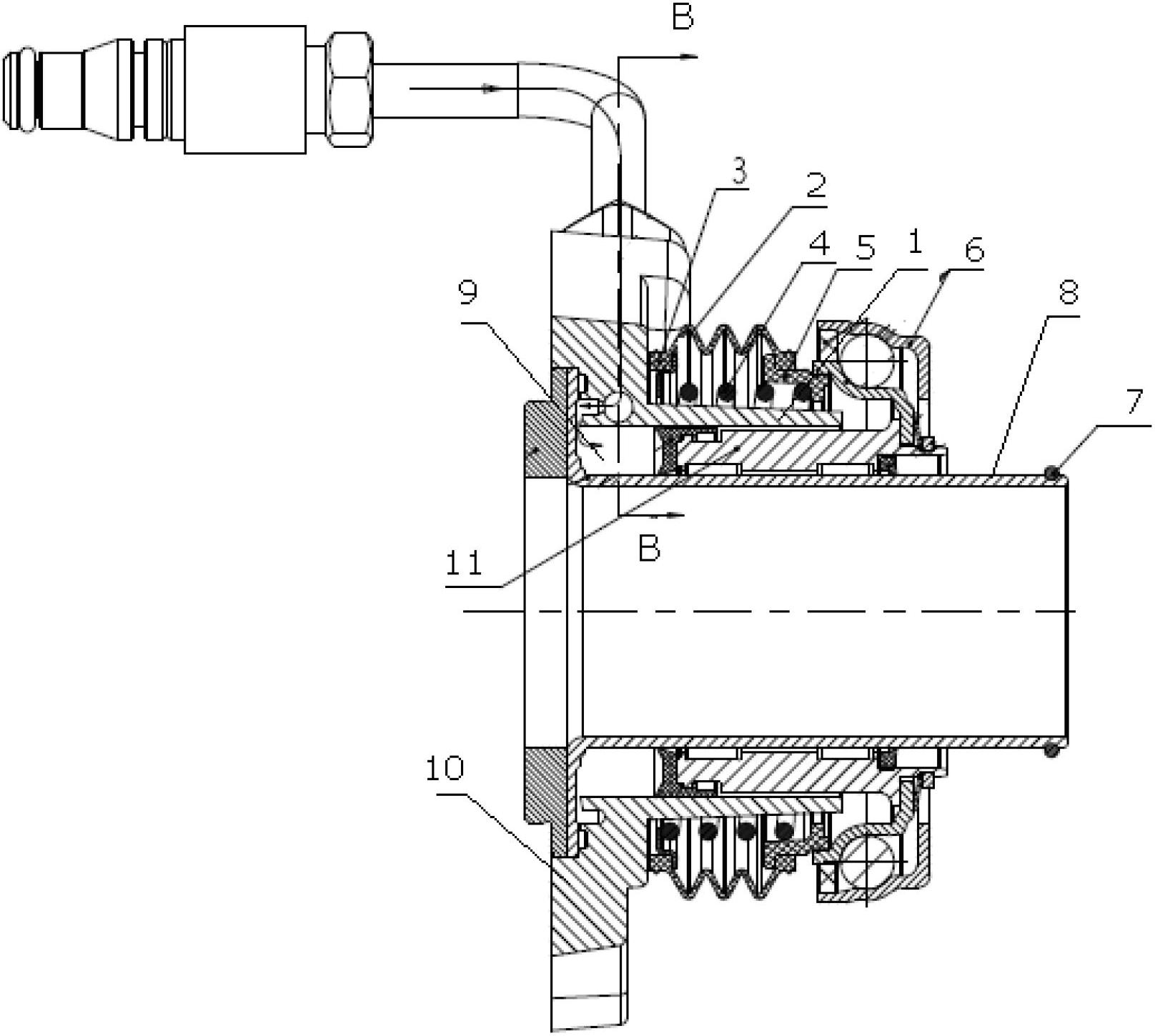

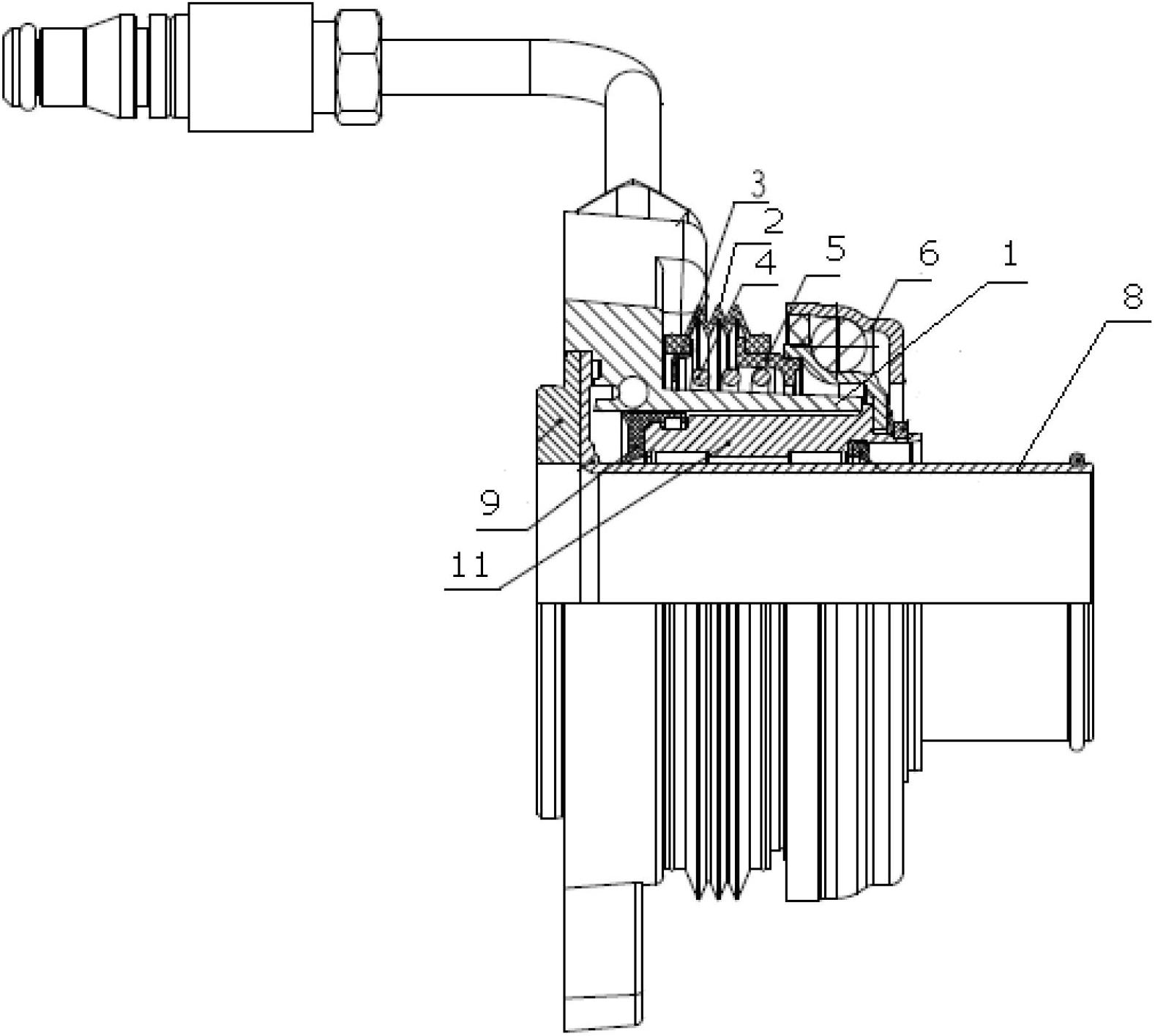

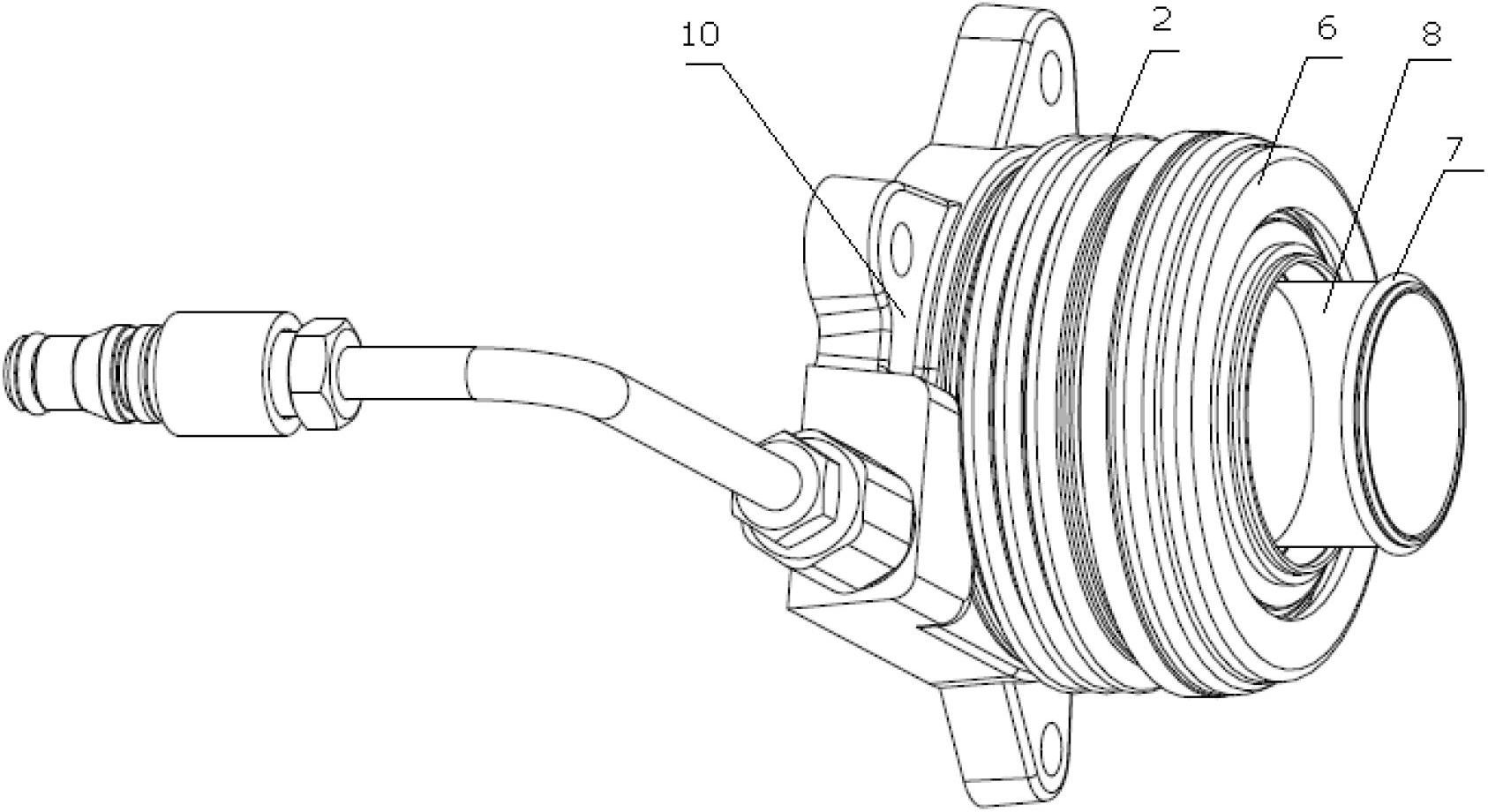

Connecting structure of clutch branch pump and release bearing

InactiveCN102661335AEasy to install and maintainImprove safety and reliabilityFluid actuated clutchesEngineeringCylinder block

The invention discloses a connecting structure of a clutch branch pump and a release bearing, solving the problems of inconvenience for operation and poor reliability caused by the condition that the conventional clutch branch pump and the release bearing are connected by a shifting fork. The technical scheme is as follows: the connecting structure comprises the clutch branch pump and a release bearing assembly, wherein the clutch branch pump comprises an inner cylinder body, an outer cylinder body and a hydraulic piston pump sleeved between the inner cylinder body and the outer cylinder body; the release bearing assembly is sleeved on the inner cylinder body; and the rear end of the release bearing assembly is connected with a piston of a hydraulic piston pump. The connecting structure of the clutch branch pump and the release bearing has the advantages of simplicity, high reliability, lower cost, small size and high transmission efficiency without regulating the clutch branch pump due to wearing of a clutch plate friction block of a clutch.

Owner:DONGFENG AUTOMOBILE COMPANY

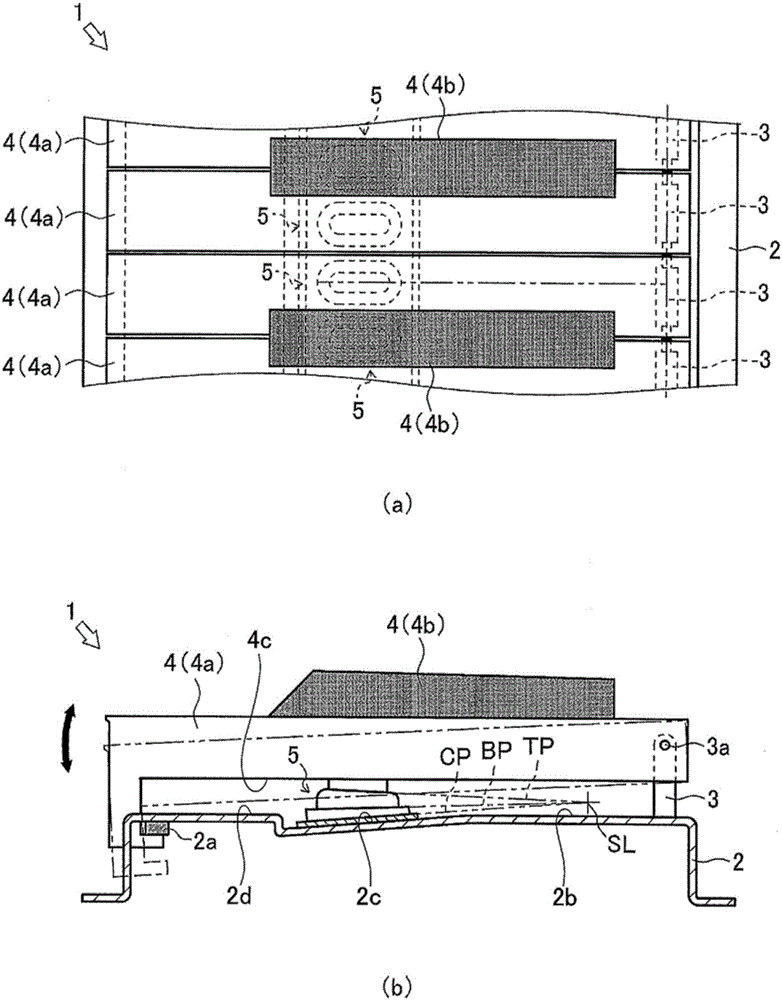

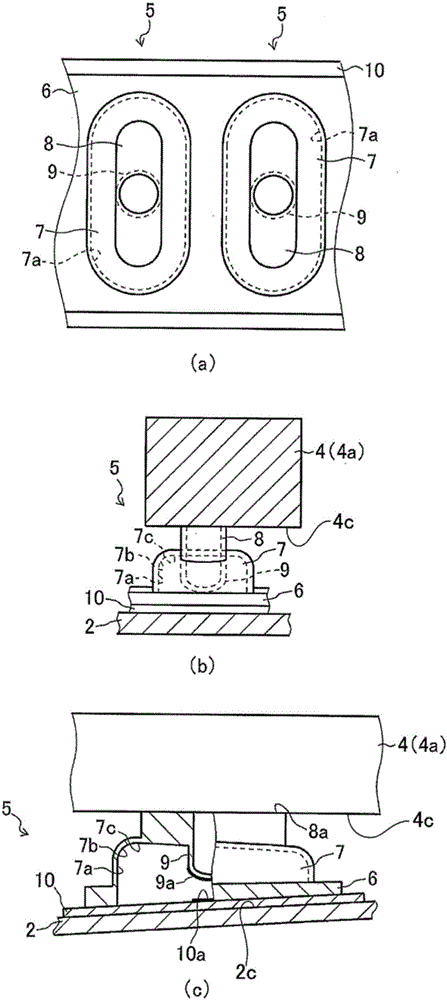

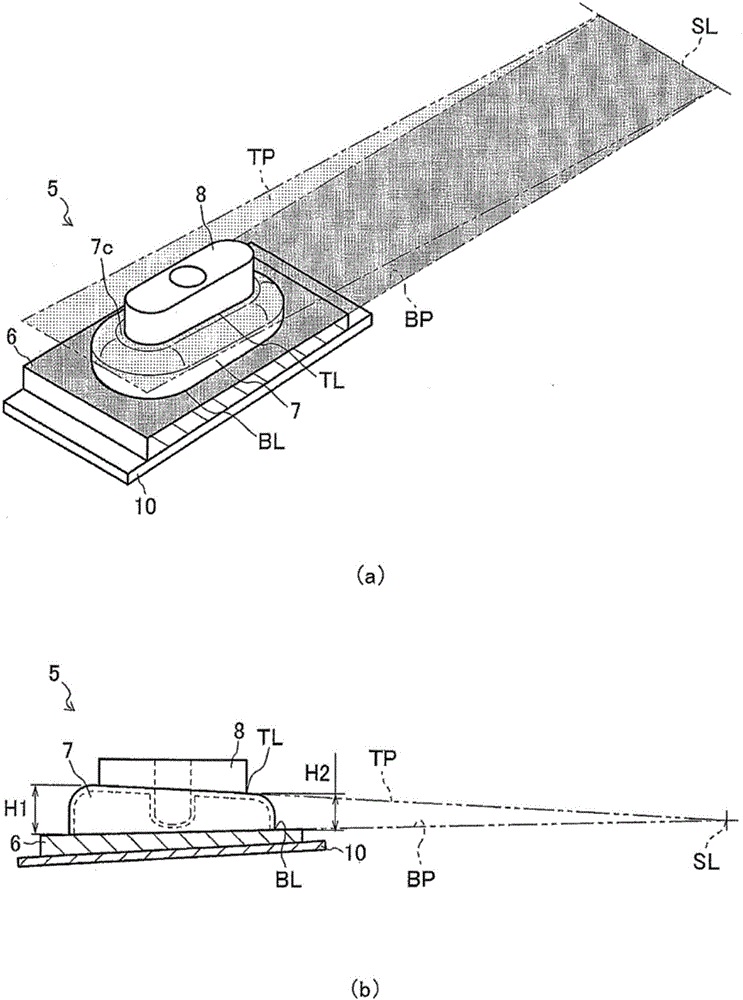

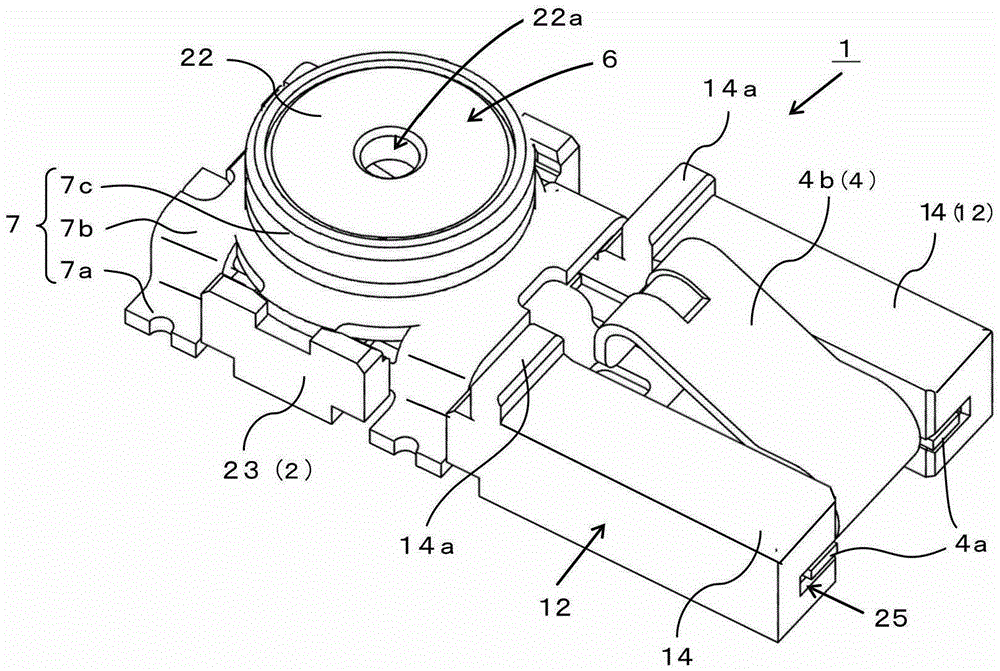

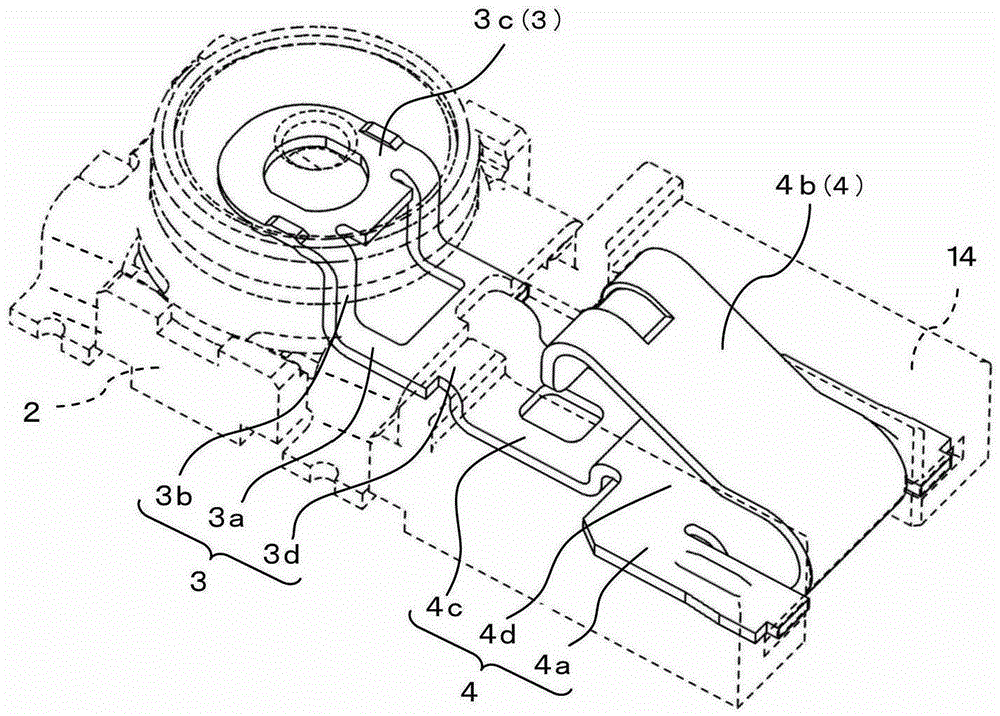

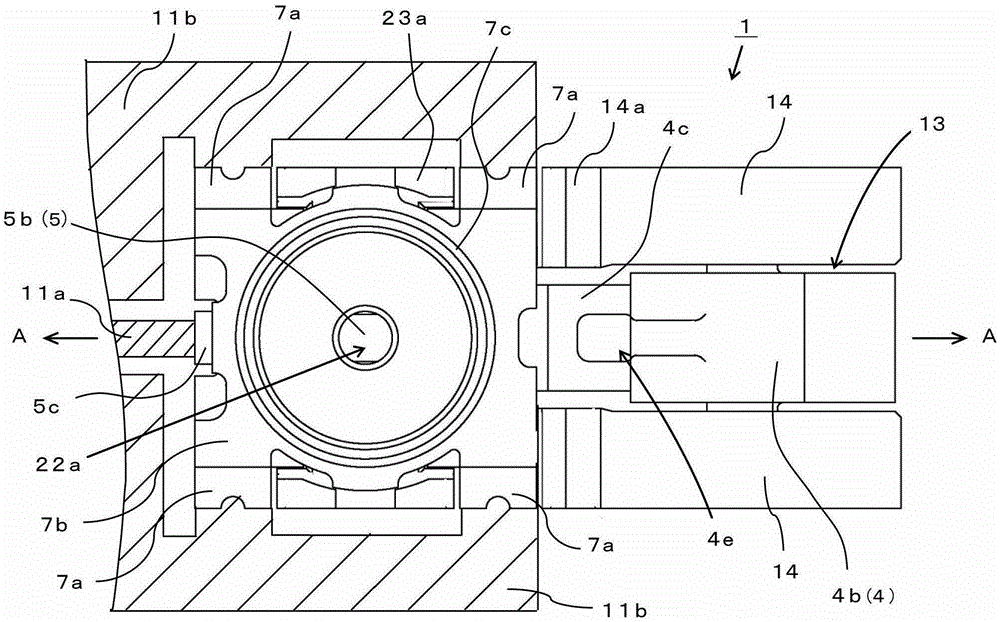

Operator operation detection device

ActiveCN106415709ASuppress tremorMaintain stabilityElectrophonic musical instrumentsRotational axisSI base unit

The purpose of the present invention is to provide a key operation detection device (5) that can suppress occurrences of chattering caused by slipping and floating between a fixed side contact surface (10a) and a movable side contact point (9a) and can maintain a stable contact state for the contact point. Provided is a key operation detection device (5), which is provided with a fixed side contact surface (10a) formed on a substrate (10) provided in a frame (2) wherein the key (4) is supported freely rotatably, a base unit (6) provided in the frame (2), a dome unit (7) protruding from the base unit (6), a top unit (8) provided on the protruding side end of the dome unit (7), and a movable side contact point (9a) provided on the top unit (8), and in which the fixed side contact surface (10a) and the movable side contact point (9a) are in contact by means of elastic deformation of the dome unit (7) and thereby an operation signal for a key (4) is transmitted. A base end side plane (BP) that includes lines of intersection for the base unit (6) and the dome unit (7) and a tip end side plane (TP) that includes intersecting lines for the dome unit (7) and the top unit (8) intersect on the rotational axis (3a) side of the key (4), and a contact point side plane (CP) that includes the fixed side contact surface (10a) and the base end side plane (BP) intersect at the rotational axis (3a) of the key (4).

Owner:YAMAHA CORP

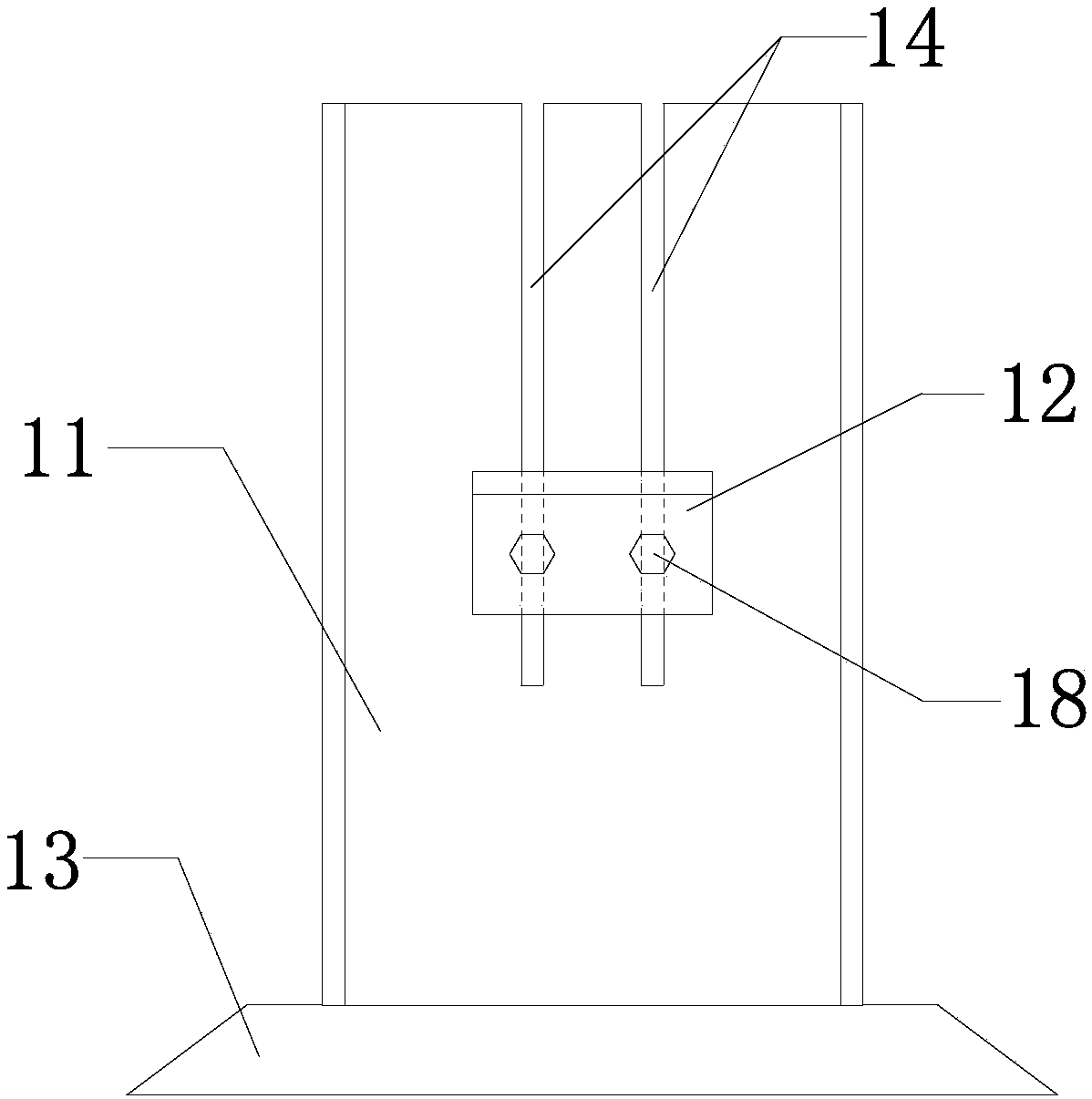

Device and method for testing tensile strength of rock core under confining pressure condition based on Brazilian splitting

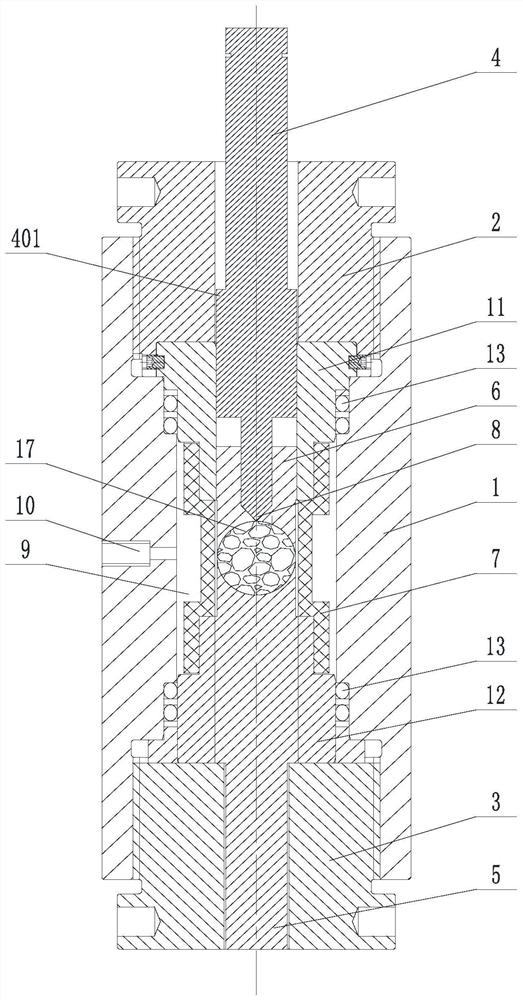

ActiveCN112665987AAvoid shakingAvoid displacementMaterial strength using tensile/compressive forcesTool bitRock core

The invention discloses a device and method for testing the tensile strength of a rock core under the confining pressure condition based on Brazilian splitting. The device comprises a cylinder, and the upper end and the lower end of the cylinder are connected with an upper pressing head and a lower pressing head correspondingly; and a guide cylinder, a rubber sleeve, a pressing rod penetrating through the upper pressing head and the guide cylinder and a supporting rod penetrating through the lower pressing head are arranged in the cylinder, and the bottom end of the pressing rod and the top end of the supporting rod are both inserted into the rubber sleeve. The bottom surface of the guide cylinder and the top surface of the supporting rod are cambered surfaces matched with the outer diameter of a rock core to be measured, and when the pressing rod descends to the bottom end of the stroke, the expanding part on the pressing rod is in contact with the top end of the guide cylinder; a splitting tool bit is arranged at the bottom of the pressing rod; and a closed annulus is formed between the rubber sleeve and the cylinder body, and a confining pressure inlet is formed in the cylinder body. The device is used for solving the problems that in the prior art, confining pressure cannot be applied to a rock core to simulate the geological environment in petroleum and natural gas development, and accurate positioning of a small-size rock core is difficult to meet, so that the accuracy of an experiment result is insufficient, and the purposes of accurately positioning the small-size rock core and conveniently applying the confining pressure are achieved.

Owner:SOUTHWEST PETROLEUM UNIV

Ultrasonic impacting device for robot and application of ultrasonic impacting device

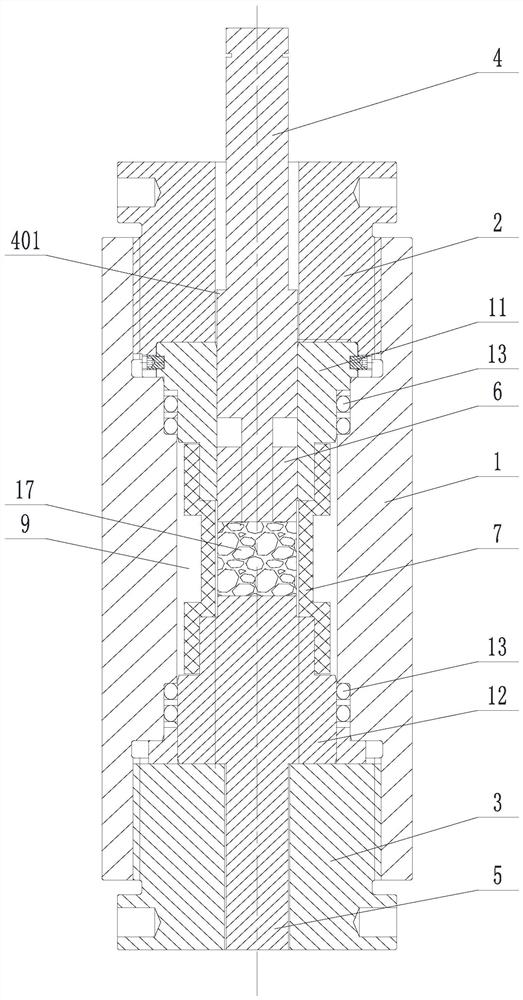

PendingCN108411103AFlexible and convenient strain reliefReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesElastic componentSonification

The invention relates to an ultrasonic impacting device for a robot and application of the ultrasonic impacting device. The ultrasonic impacting device comprises a shell, a transducer amplitude varying pole component, an impacting seat and an impacting needle; the shell is internally provided with an elastic component, an inner sleeve and a sliding component; the tail end of the inner sleeve is connected with the elastic component; the front end of the inner sleeve extends out of the shell, and the inner sleeve realizes displacement by virtue of the sliding component; the transducer amplitudevarying pole component is arranged in the inner sleeve; the impacting needle is connected to the front end of the inner sleeve through the impacting seat and is contacted with the transducer amplitudevarying pole component; and the impacting seat is internally provided with an elastic compression device which is connected with the impacting needle. The ultrasonic impacting device provided by theinvention can be used to be directly connected with the robot, treatment can be performed on welding seams in regular shapes, such as horizontal welding seams and vertical welding seams and also on annular welding seams and welding seams of weldments with complex structures, the stress is flexibly and conveniently eliminated, the labor intensity is greatly lowered, and the production efficiency ishigh.

Owner:SHANDONG HUAWIN ELECTRICAL & MECHANICAL TECH

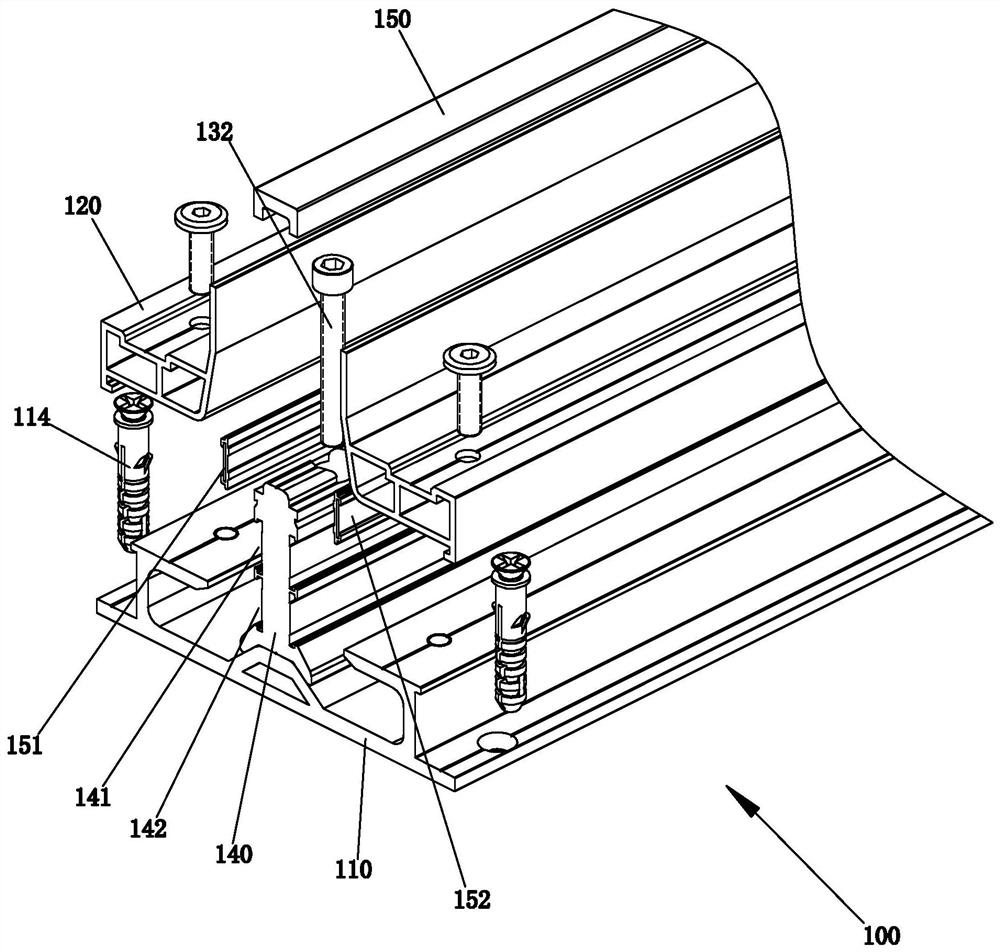

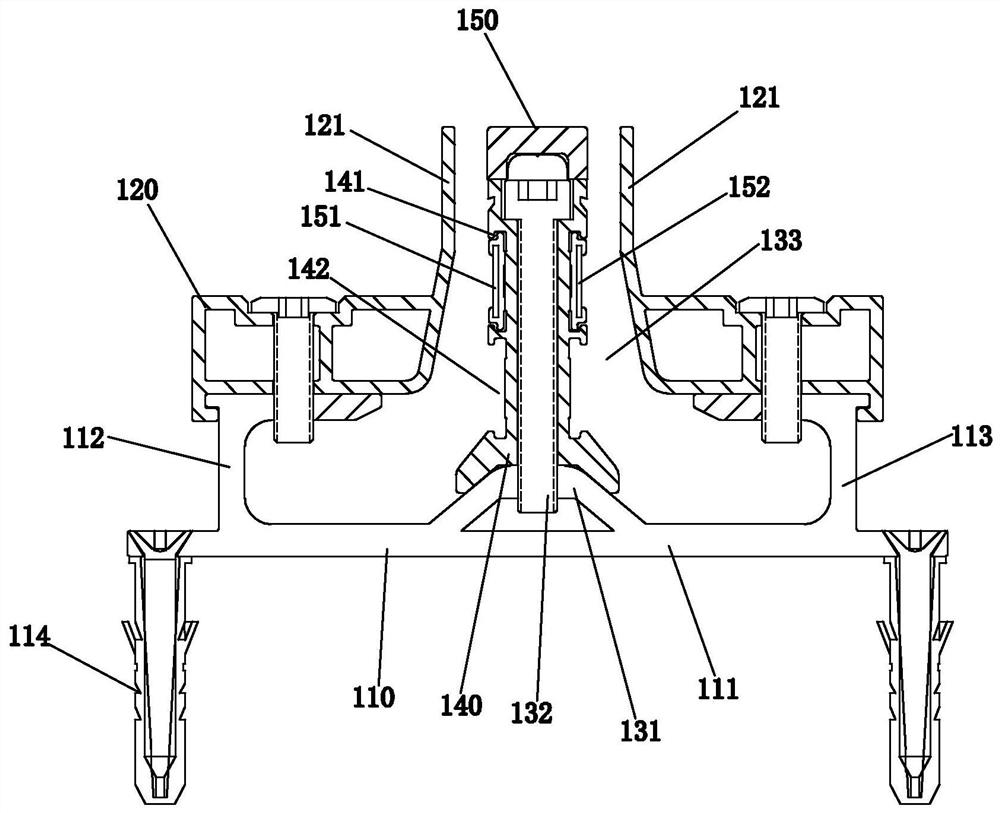

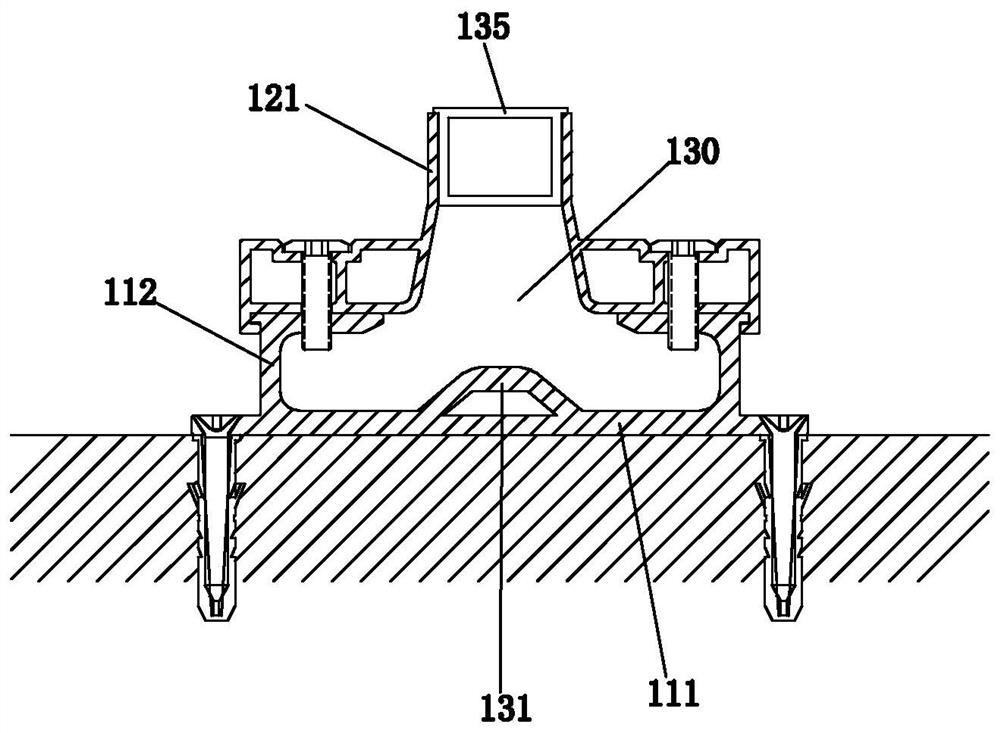

Power supply track system

PendingCN113809606AEasy maintenanceEasy to cleanCoupling device detailsControl theoryMechanical engineering

The invention discloses a power supply track system which comprises a power supply track, the power supply track comprises a bearing part, two side baffles and a conductive assembly, the two side baffles are fixedly connected to the two sides of the bearing part respectively, and a power taking space with an opening in the top end is defined by the two side baffles and the bearing part, and the conductive assembly is detachably installed in the electricity taking space. The conductive assembly is detachably installed in the electricity taking space, when the conductive assembly needs to be maintained, the conductive assembly can be directly detached from the conductive space, the whole power supply track does not need to be detached, the conductive assembly can be installed again after maintenance is completed, and great convenience is brought to later maintenance work.

Owner:SUNTOP XIAMEN DISPLAY SYST

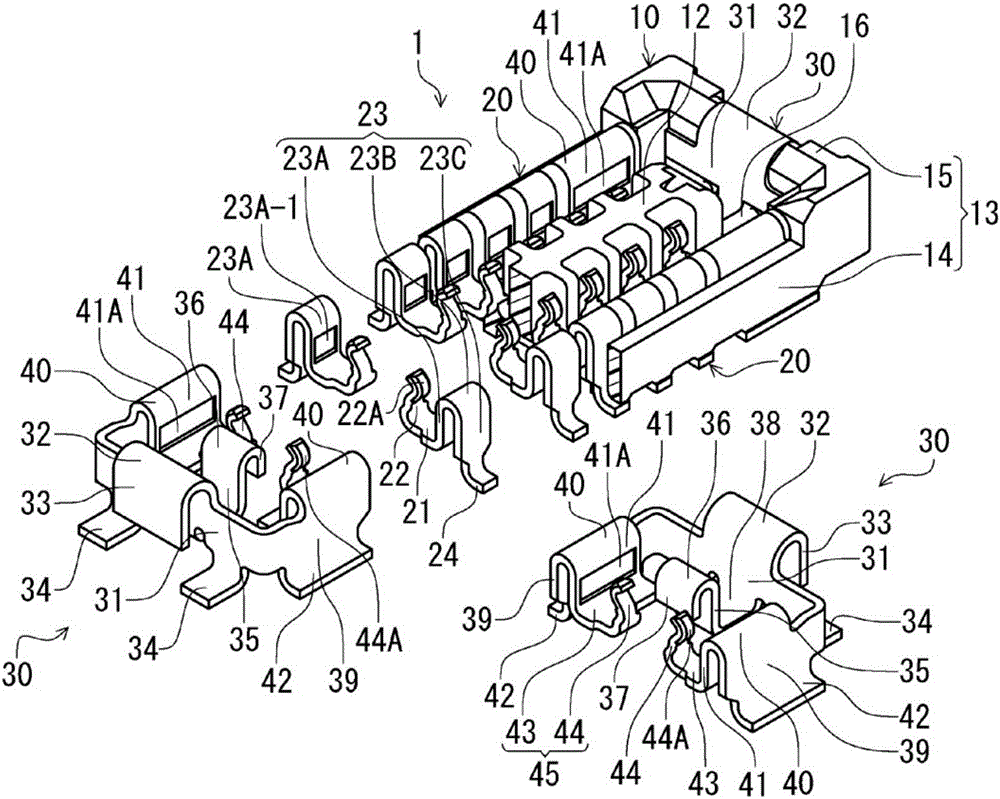

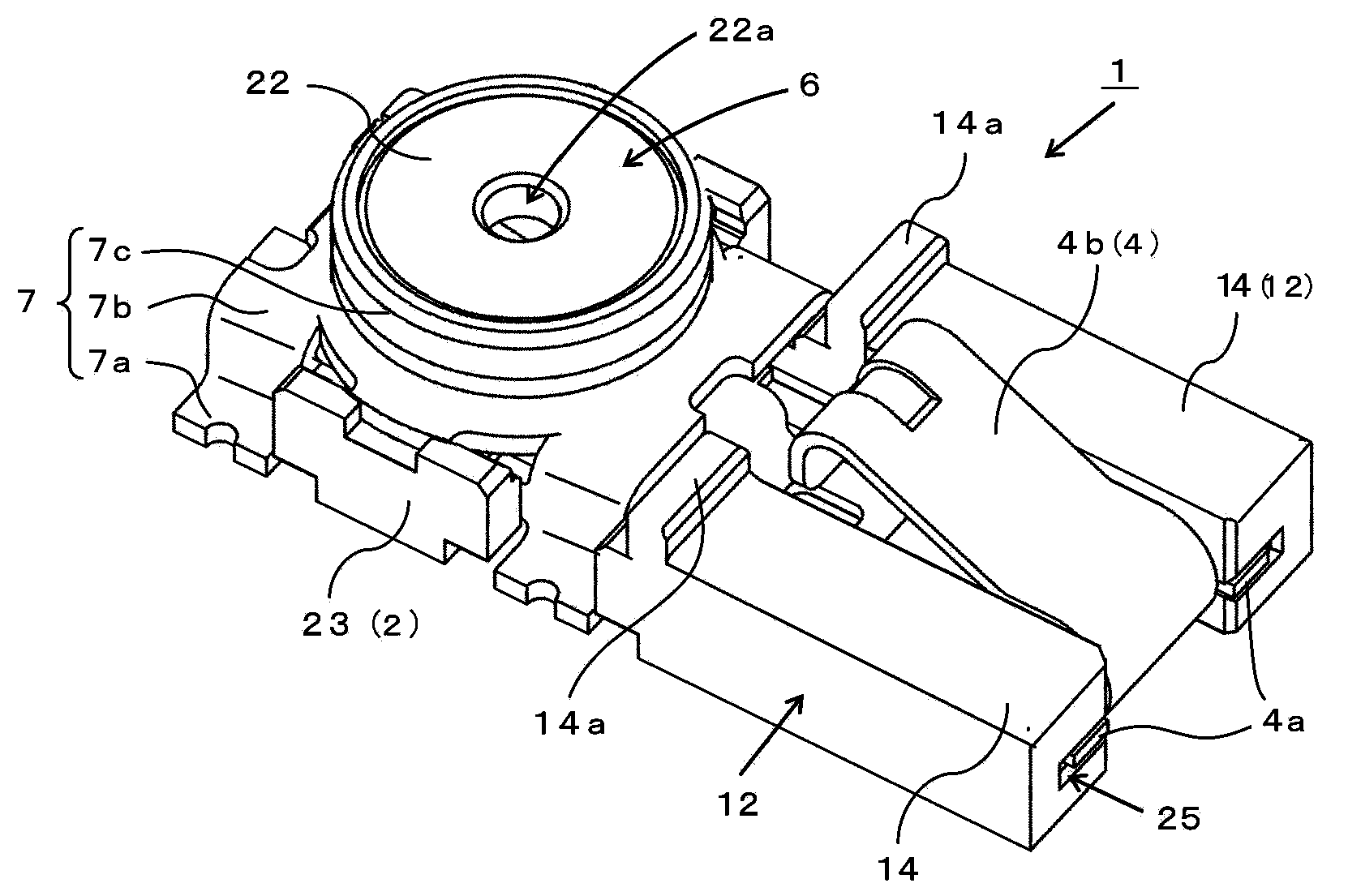

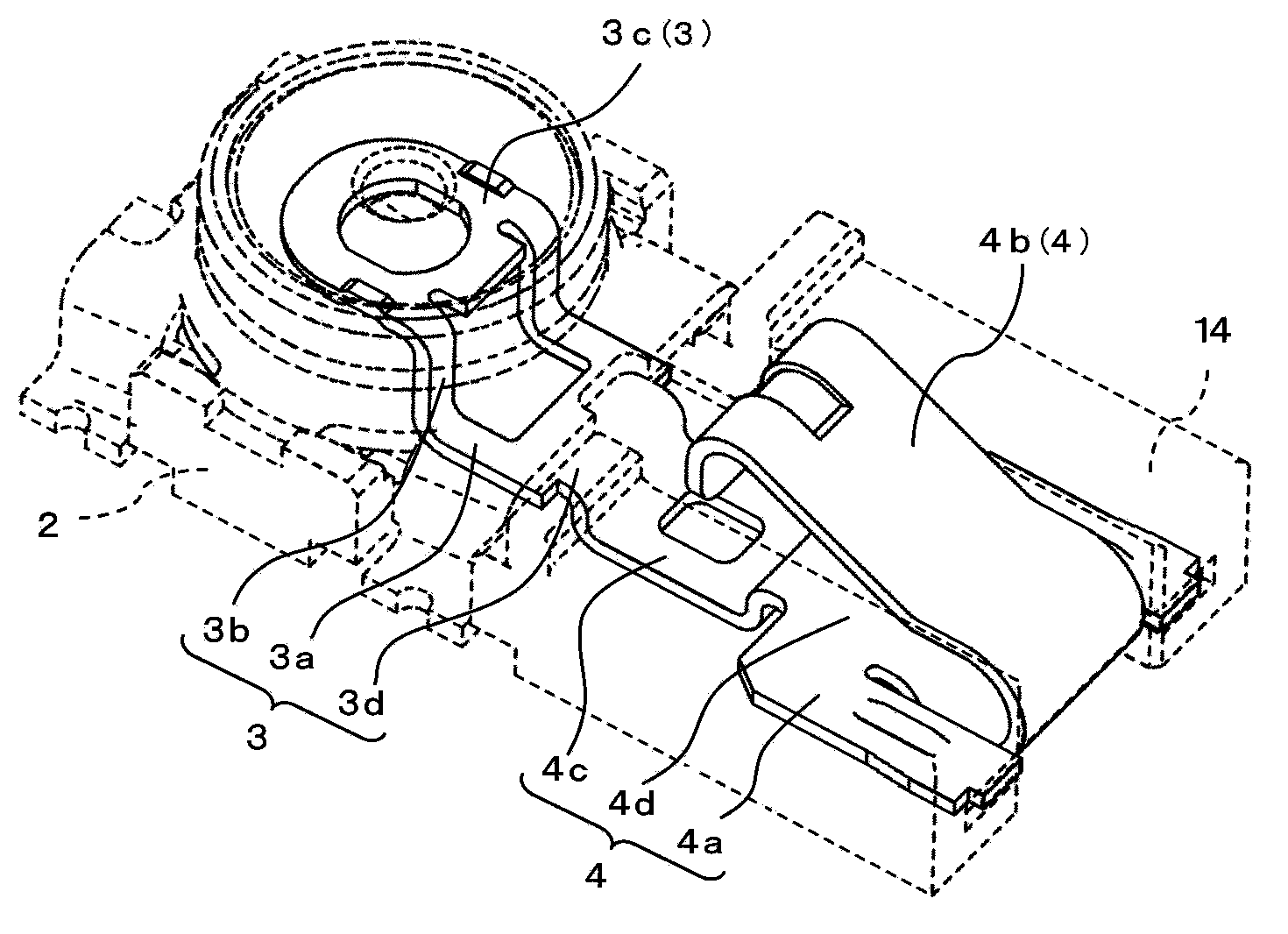

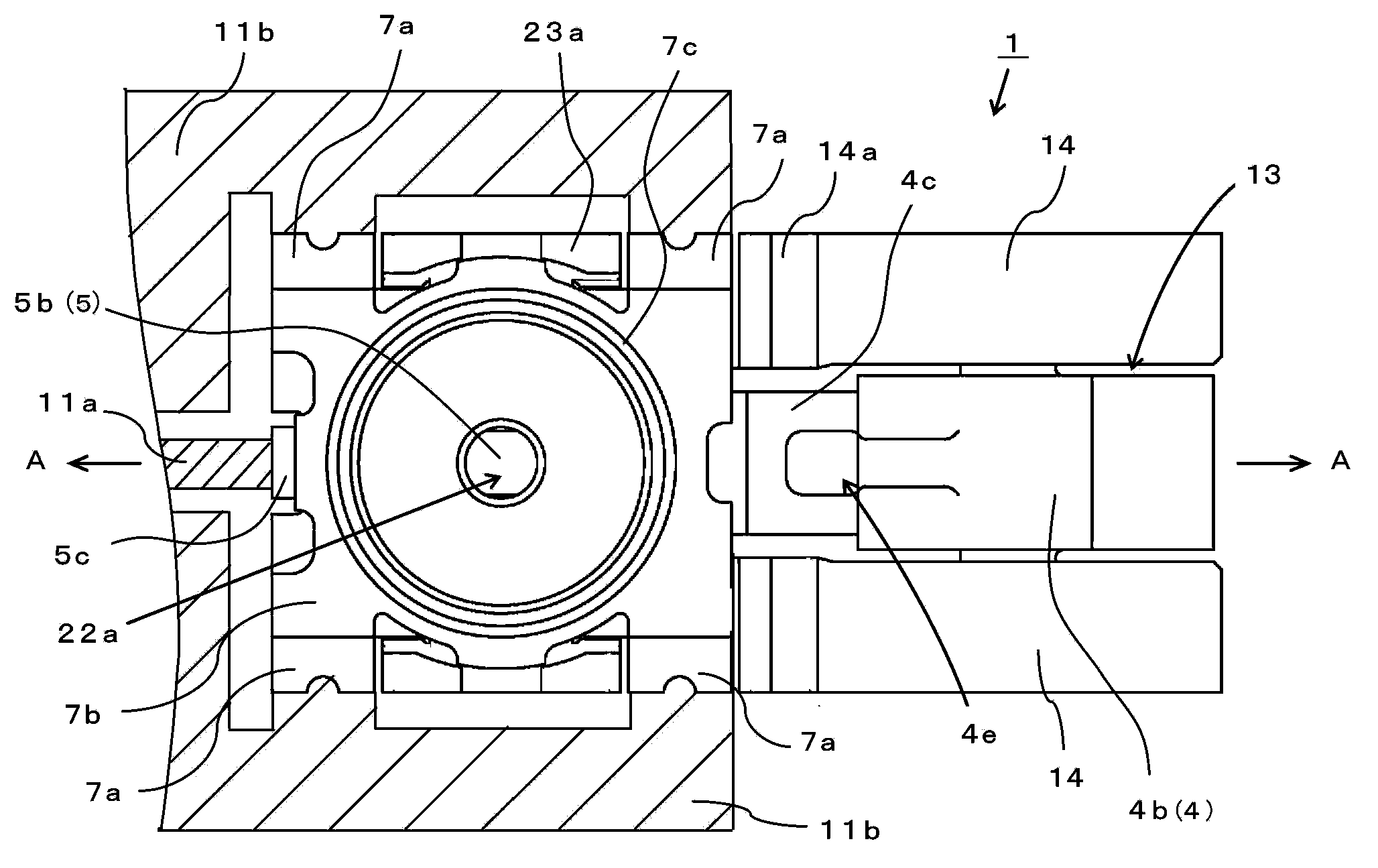

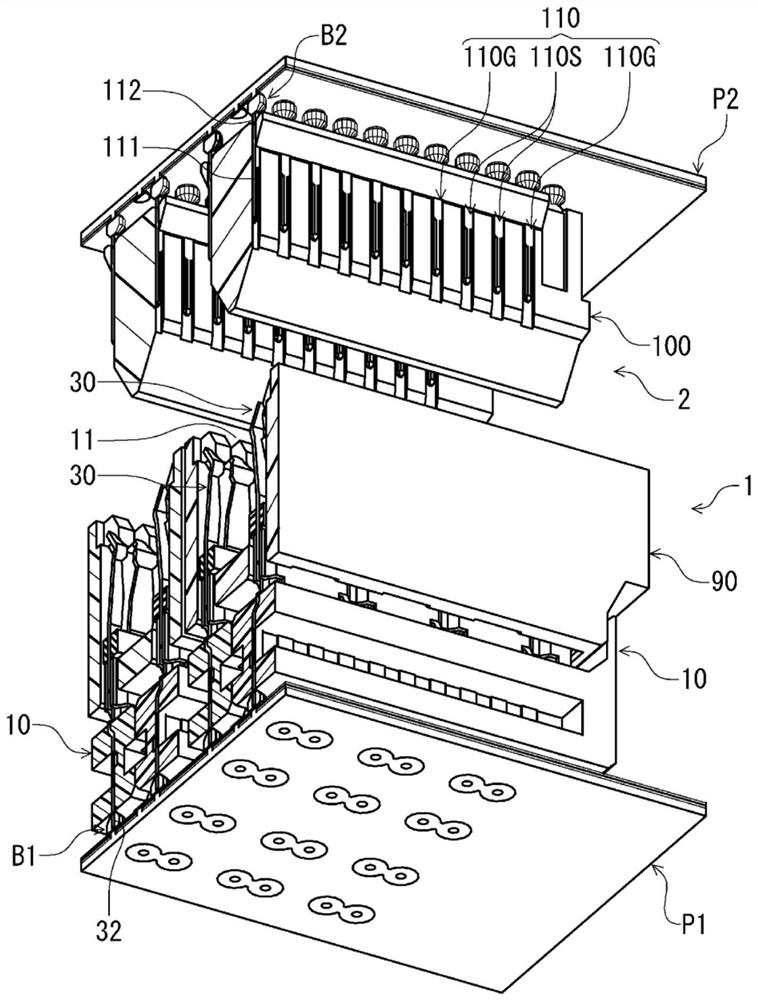

Electrical connector and test method for electrical connector

ActiveCN107492729AEnsure contact statusConfirm electrical continuitySecuring/insulating coupling contact membersElectric connection testingElectricityEngineering

Owner:HIROSE ELECTRIC GROUP

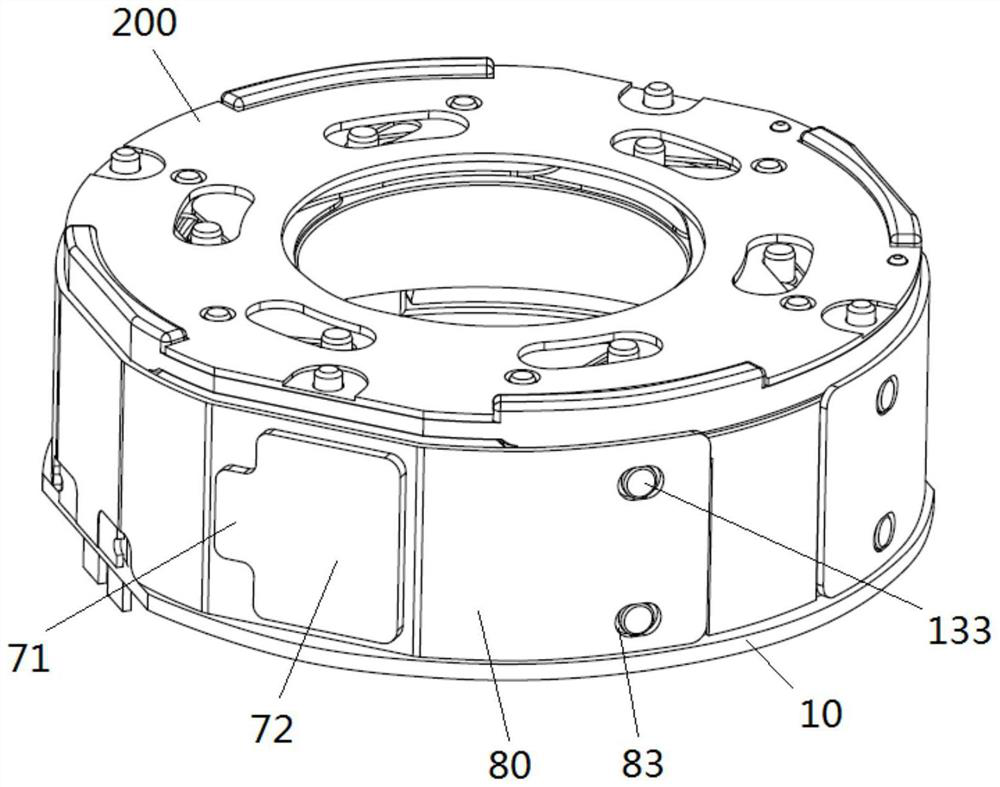

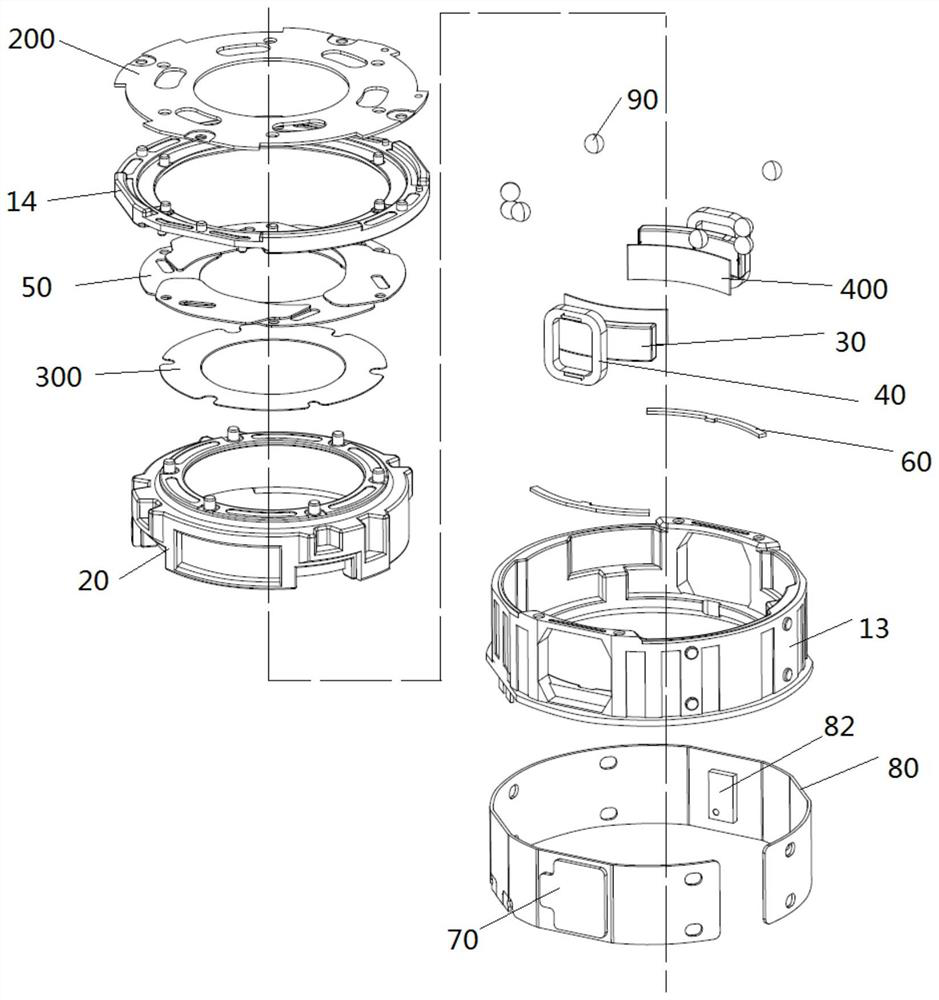

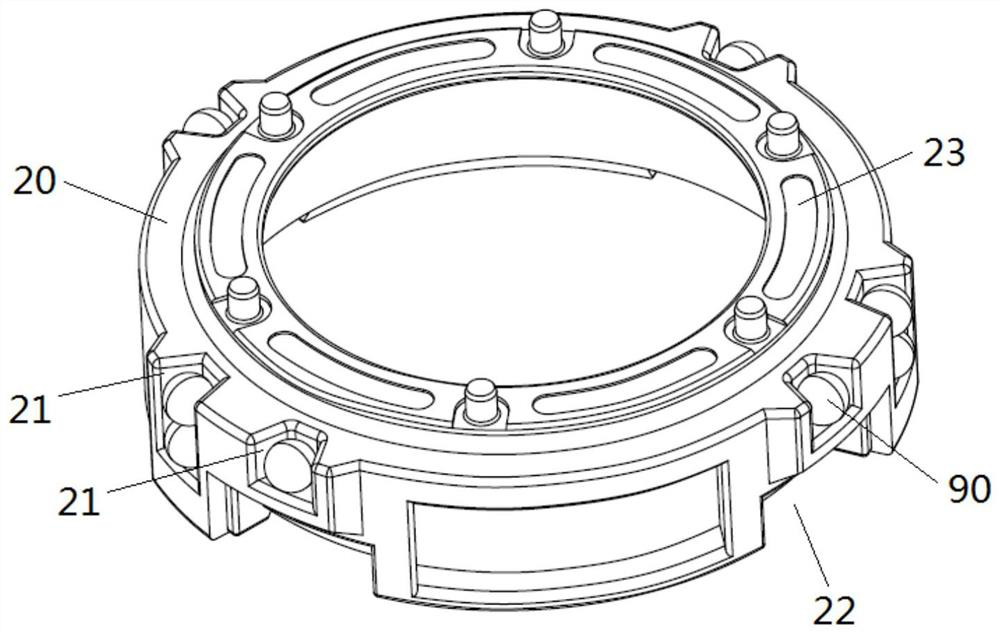

Variable aperture drive motor, imaging device, and electronic apparatus

ActiveCN114285242ASolve problems that cannot be changedEnsure contact statusAssociation with control/drive circuitsCamera diaphragmsDrive motorMagnet

The invention provides a variable aperture driving motor, an image pickup apparatus, and an electronic apparatus. The variable aperture driving motor comprises a base assembly which is provided with an accommodating cavity; at least one part of the lens supporting body is movably arranged in the accommodating cavity; the plurality of driving magnets are arranged, and the driving magnets are arranged on the circumferential side wall of the lens supporting body; the driving coils correspond to the driving magnets and are arranged on the side wall of the base assembly, and the driving magnets and the driving coils conduct relative induction so that the lens supporting body can rotate relative to the base assembly; the first end of the blade set is arranged at the top end of the base assembly, and the second end of the blade set is connected with the lens supporting body; the number of the first magnetic attraction plates is multiple, and the multiple first magnetic attraction plates are arranged at the bottom end of the base assembly corresponding to the driving magnets. The problem that the aperture of the camera module of the electronic equipment cannot be changed in the prior art is solved.

Owner:SHANGHAI BILLU ELECTRONICS CO LTD

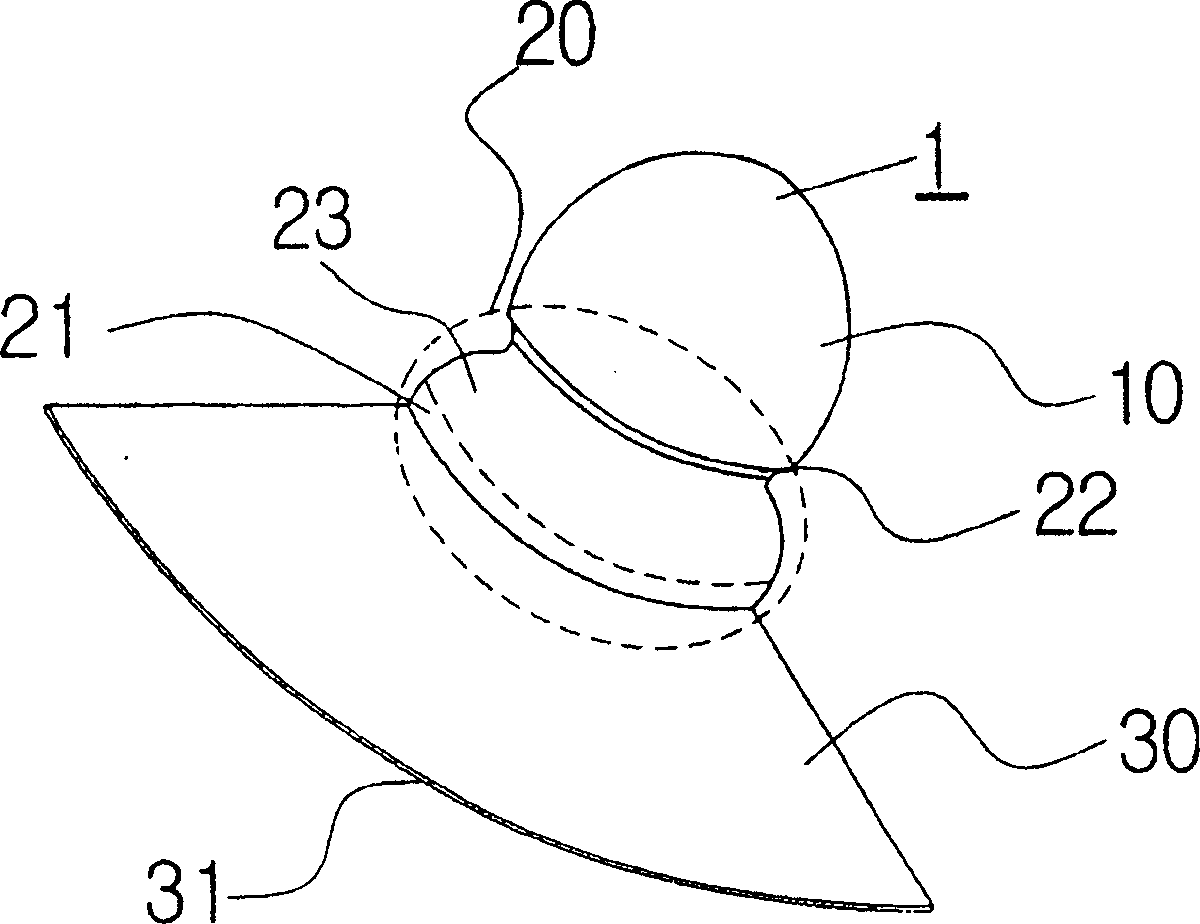

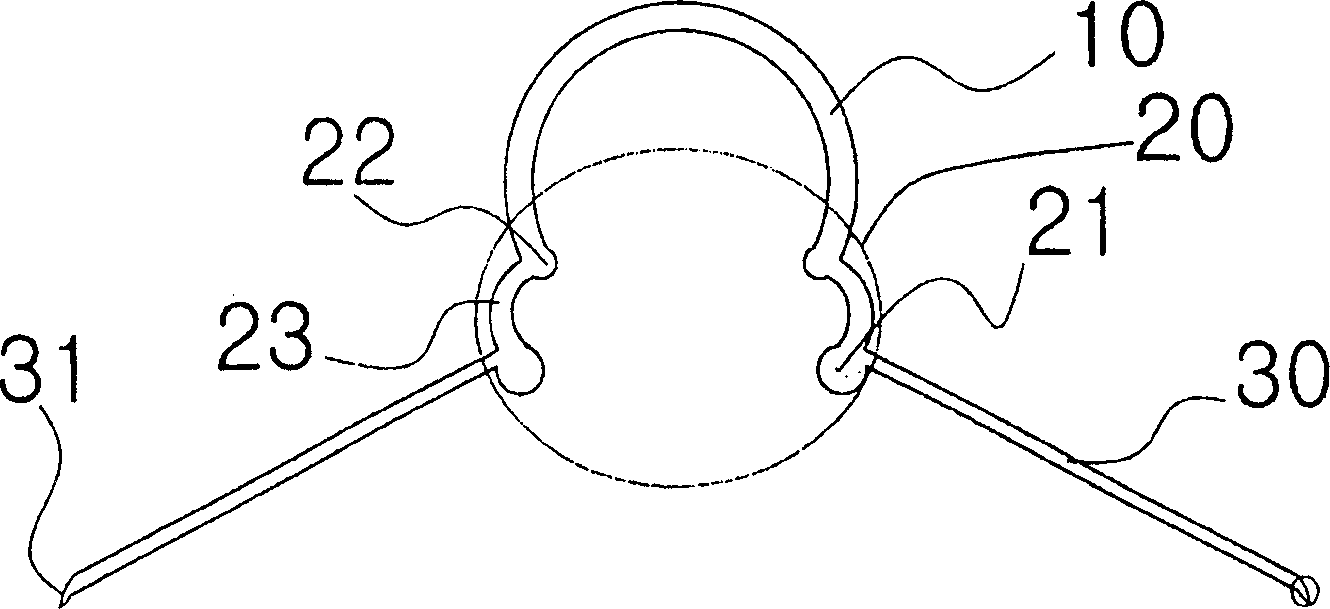

Corrector for inverted nipple

InactiveCN1529576AEasy to carryEasy to storePneumatic massageBreast-nipple shieldsSurgical operationMedicine

Disclosed is a corrector for an inverted nipple comprising an absorption part, a nipple mould for receiving the nipple, and a narrow neck part, which obviates the need for a surgical operation or other procedures, thereby being conveniently worn by users. The corrector comprises the nipple mould for receiving the nipple protruding from the center of the breast, the narrow neck part for pressing the border line between the nipple and the mammary areola and maintaining a pressure of the inside of the nipple mould, and the absorption part for containing the center of the breast so as to maintain the vacuum state of the corrector, wherein the narrow neck part includes a supporting element, a hollow core, and a pressing element so as to improve a holding force of the nipple by the corrector, and the absortion part includes and inclined end at a designated obtuse inside angle so as to improve a contact force of the absorption part with the breast.

Owner:朴月仙

Antenna connecting and switching device

InactiveCN103457012AHigh frequency signals are not attenuatedWill not deformTwo-part coupling devicesAntennas earthing switches associationInductanceElectrical and Electronics engineering

The invention provides an antenna connecting and switching device, which is capable of preventing the high-frequency signal flowing between the antenna and a supply circuit, and the welding connection between the antenna connecting and switching device and a printing and wiring substrate is not easy to be damaged. A universal terminal, a normally closed type terminal and an antenna connecting terminal are configured in that the projection of the printing and wiring substrate on the installing surface is continuously shown on the same line, with respect to a leg part welded to the universal terminal of the power supply image. The leg part of the antenna connecting terminal is welded to the welding disc image of the printing and wiring substrate at the separating position of the line. As no required inductance is generated at the transmitting path from the antenna to the power supply image, the high-frequency signal will not be reduced. Images connected to the printing and wiring substrate can be welded to the two separating positions of the line. Accordingly, even if the rotating torque in the same direction is generated, the welding connection part is not easy to be damaged.

Owner:SMK CO LTD

Antenna Connection Switching Device

InactiveCN103457012BHigh frequency signals are not attenuatedWill not deformTwo-part coupling devicesAntennas earthing switches associationInductanceElectrical and Electronics engineering

The invention provides an antenna connecting and switching device, which is capable of preventing the high-frequency signal flowing between the antenna and a supply circuit, and the welding connection between the antenna connecting and switching device and a printing and wiring substrate is not easy to be damaged. A universal terminal, a normally closed type terminal and an antenna connecting terminal are configured in that the projection of the printing and wiring substrate on the installing surface is continuously shown on the same line, with respect to a leg part welded to the universal terminal of the power supply image. The leg part of the antenna connecting terminal is welded to the welding disc image of the printing and wiring substrate at the separating position of the line. As no required inductance is generated at the transmitting path from the antenna to the power supply image, the high-frequency signal will not be reduced. Images connected to the printing and wiring substrate can be welded to the two separating positions of the line. Accordingly, even if the rotating torque in the same direction is generated, the welding connection part is not easy to be damaged.

Owner:SMK CO LTD

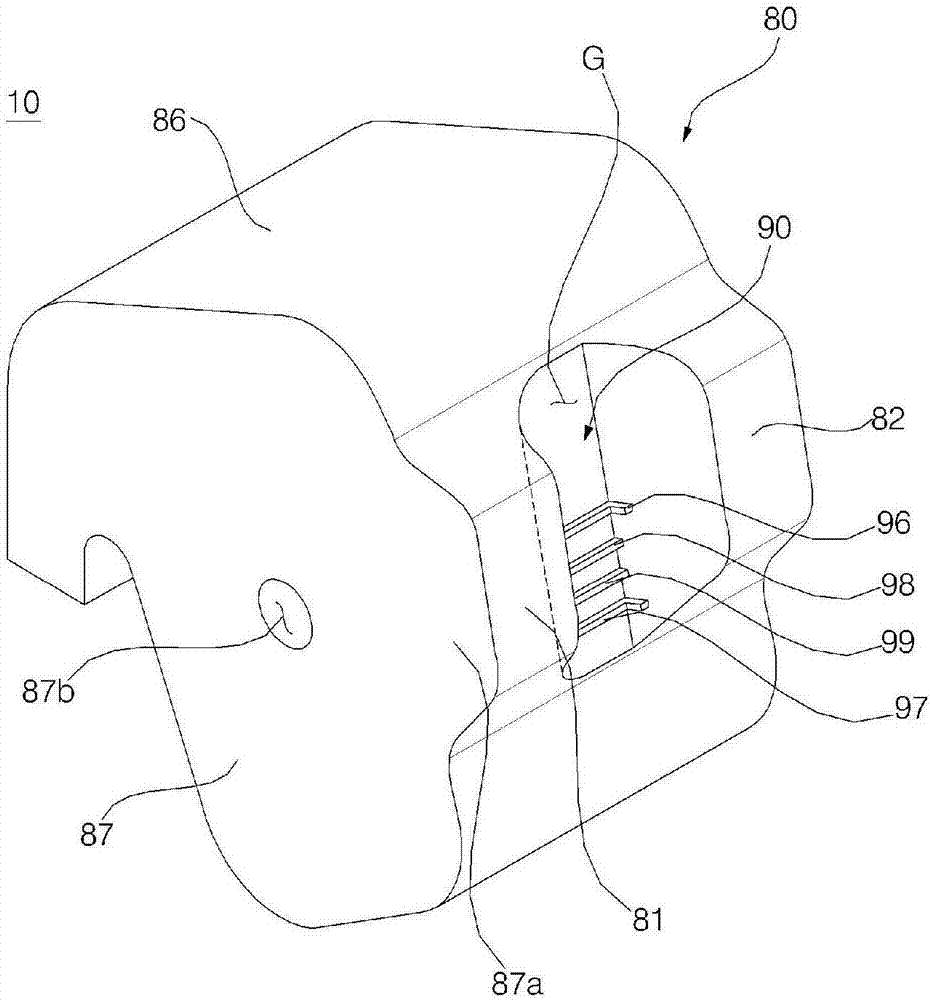

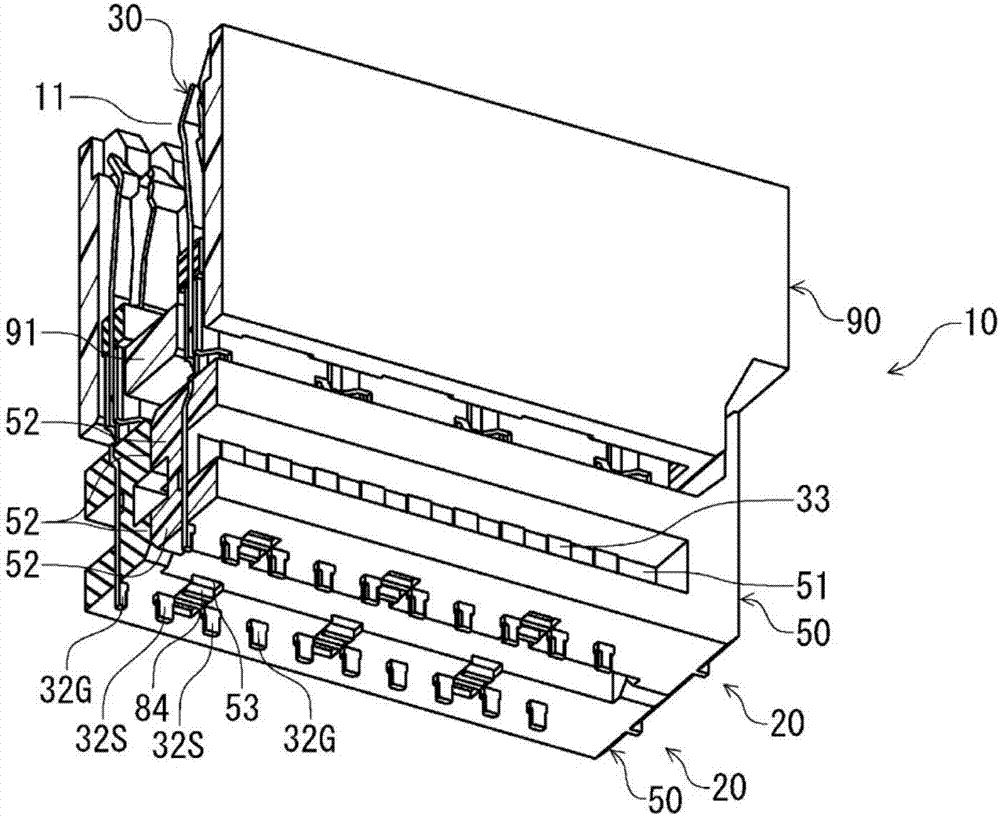

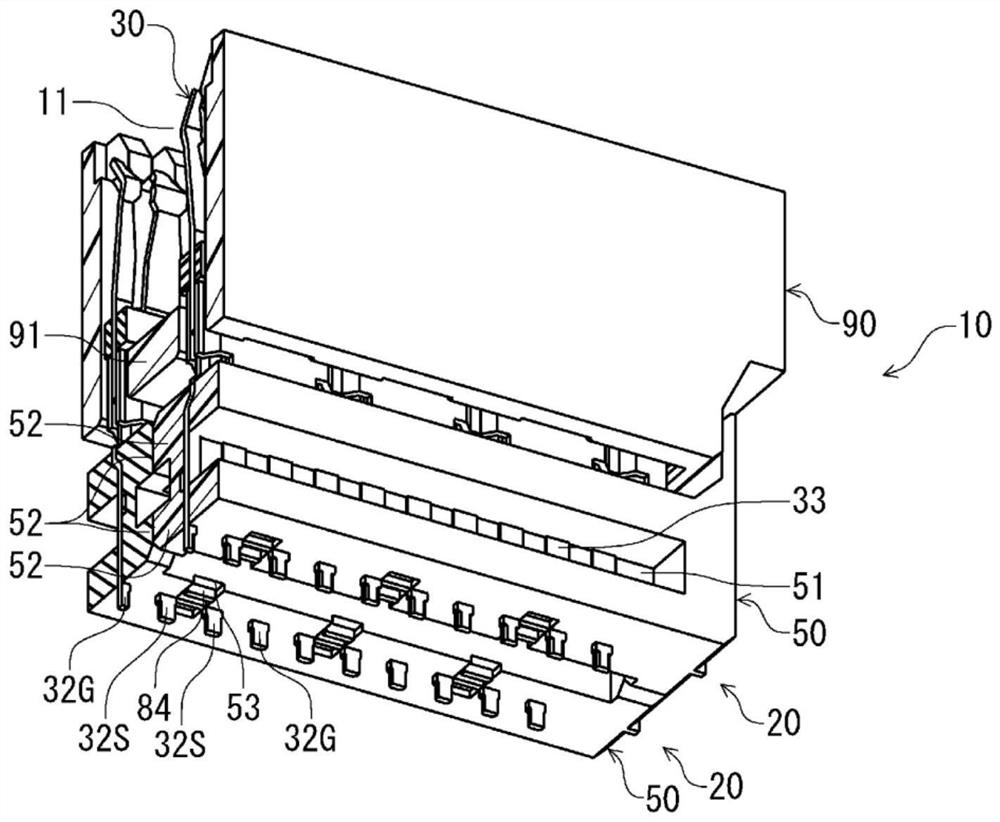

Electrical connector and inspection method of electrical connector

ActiveCN107492729BEnsure contact statusConfirm electrical continuitySecuring/insulating coupling contact membersElectric connection testingElectrical connectionStructural engineering

The present invention provides an electrical connector and an inspection method of the electrical connector which allow a grounding member to be in reliable contact with a grounding terminal and to easily confirm the state of electrical conduction between the grounding member and the grounding terminal. An electrical connector (1) is provided with: a plurality of terminals (30) having two types of terminals, a signal terminal (30S) and a ground terminal (30G); A holding body (50) made of an insulating material in which the terminals are arranged and held; and a grounding member (80) held by the holding body inside the holding body in a state of being in contact with at least two grounding terminals, and the grounding member has A detection unit (84) exposed from the holder for detecting a state of electrical conduction between the ground terminal and the ground member.

Owner:HIROSE ELECTRIC GROUP

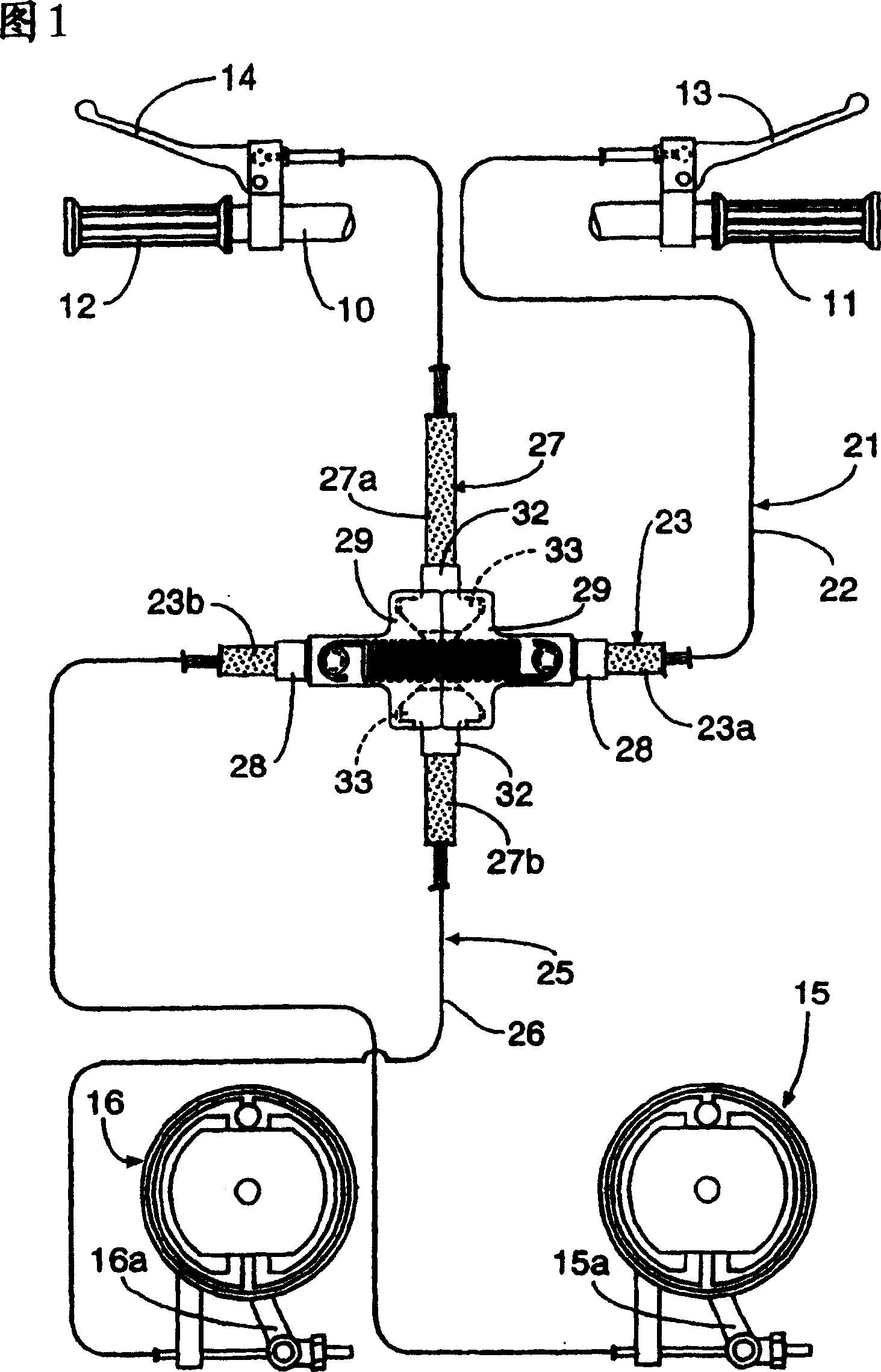

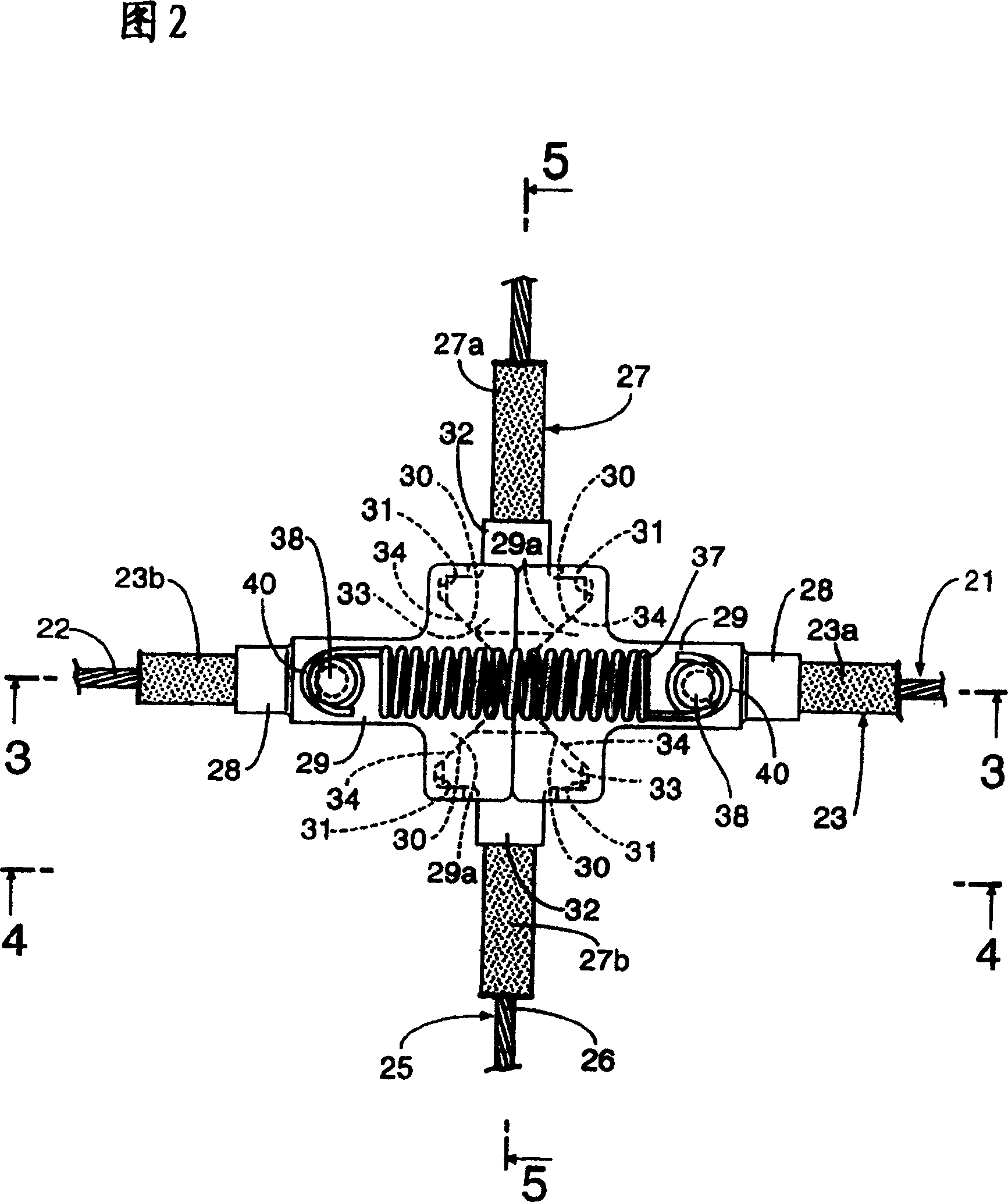

Braking device for small vehicle

To enhance flexibility on layout and reduce a number of parts by eliminating the need of disposing additional parts such as an interlocking link in a braking device for a small sized vehicle enabling the braking operation of one wheel brake even either of the two braking operation members is operated. A first outer cable of a first brake cable is divided into a first input side outer cable, and a second output side outer cable, and a pair of pressure receiving surfaces are formed on a pressure receiving part provided on an opposed end part of the first input side and first output side outer cables respectively. A pair of pressing parts with an inclined pressing surface so as to contact to the pressure receiving surface of the pressure receiving part on both sides respectively are provided so as to mutually move to close to each other according to towing operation of a second brake cable on a second brake cable 25 disposed so as to intersect with the first brake cable.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com