Ultrasonic impacting device for robot and application of ultrasonic impacting device

An ultrasonic impact, robot technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of reducing labor intensity, stress relief, flexible and convenient stress relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

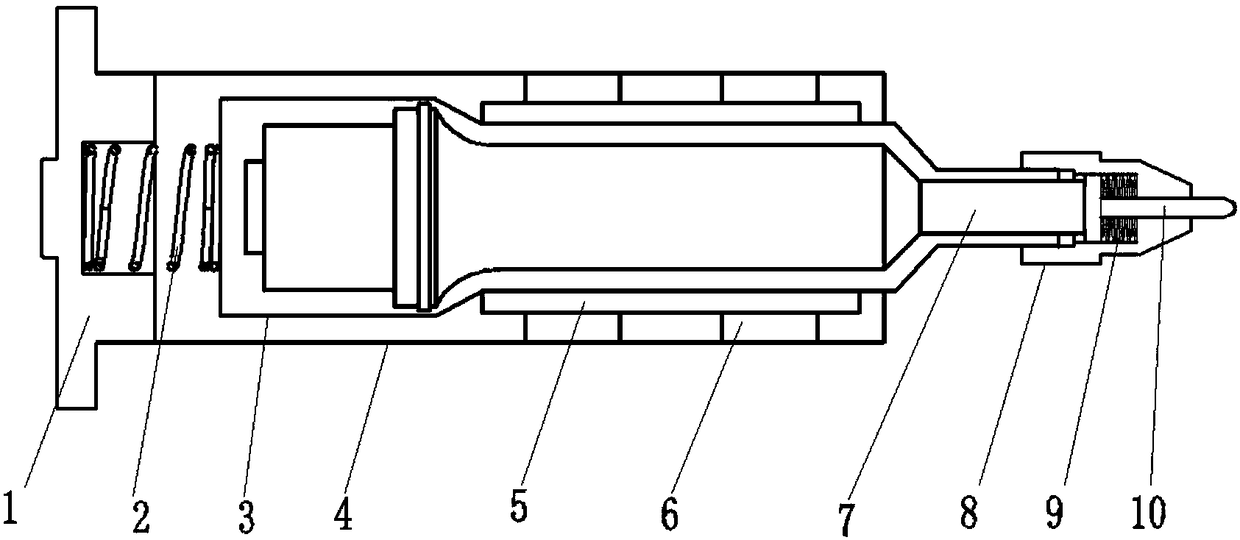

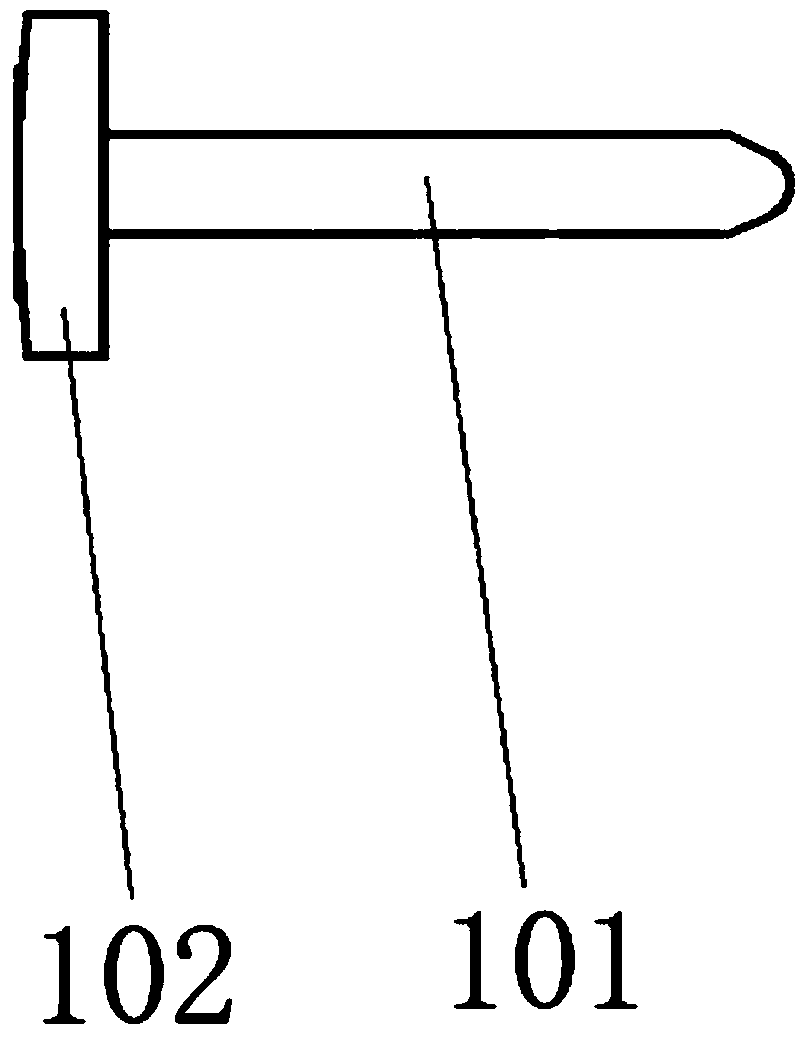

[0034] This embodiment provides an ultrasonic impact device for a robot, which includes a housing 4, a transducer horn assembly 7, an impact seat 8 and an impact needle 10, an elastic component, an inner sleeve 3 and a sliding assembly are placed inside the housing 4, and the inner sleeve The tail end of 3 is connected to the elastic part, the front end of the inner sleeve 3 protrudes from the outer shell 4 and the inner sleeve 3 is displaced by means of a sliding assembly, the transducer horn assembly 7 is located in the inner sleeve 3, and the impact needle 10 is connected inside by the impact seat 8 The front end of the sleeve 3 is in contact with the horn assembly 7 of the transducer, and the impact seat 8 is provided with an elastic pressing device connected to the impact needle 10 .

[0035] In this embodiment, the spring 2 is selected as the elastic component, and the spring 2 is connected to the inner wall of one end of the shell 4 and connected to the tail end of the i...

Embodiment 2

[0041] An ultrasonic impact device for a robot as described in Embodiment 1, the difference lies in that the elastic component is a compressed air bag (not shown in the figure). The elastic pressing device selects bellows (not shown in the figure) for use.

[0042] The inner wall of the chamber is provided with threads, and the impact seat 8 is threadedly connected to the front end of the inner sleeve 3, which facilitates the installation and replacement of the impact seat.

Embodiment 3

[0044] An ultrasonic impact device for a robot as described in Embodiment 1, the difference lies in that the elastic member is a hydraulic cylinder (not shown in the figure). Elastic pressing device selects compressed air bag (not shown in the figure) for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com