Device and method for testing tensile strength of rock core under confining pressure condition based on Brazilian splitting

A Brazilian splitting and tensile strength technology, used in measuring devices, using stable tension/pressure to test material strength, strength characteristics, etc. Problems such as inability to apply confining pressure to the core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

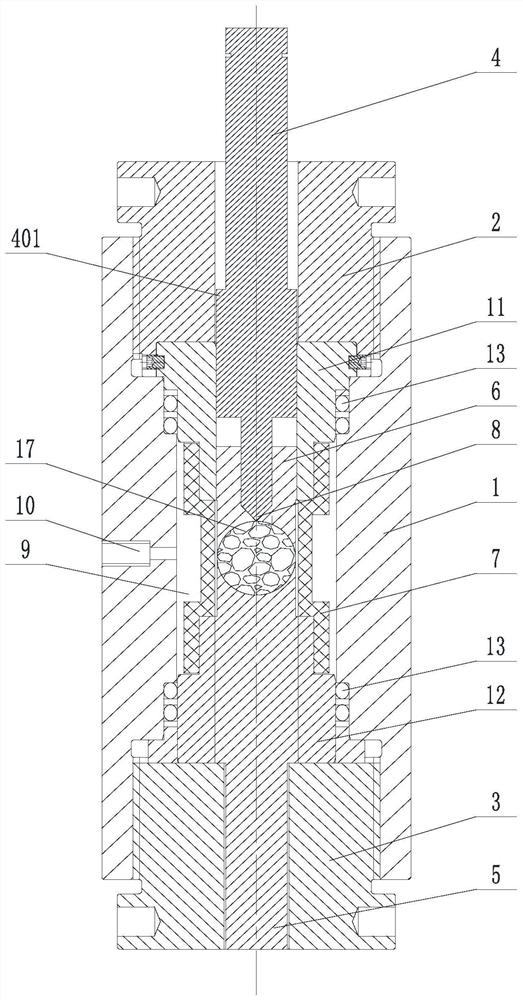

[0053] Such as Figure 2 to Figure 3 , Figure 6 to Figure 7 The shown rock core tensile strength test device under the confining pressure condition based on Brazil splitting, wherein figure 2 and image 3 It is a schematic diagram of the same structure in different sections; it includes a cylinder body 1, and the upper and lower ends of the cylinder body 1 are respectively detachably connected to the upper pressure head 2 and the lower pressure head 3; the cylinder body 1 is provided with a guide cylinder 6 and a rubber sleeve 7, It also includes a pressing rod 4 passing through the upper pressing head 2 and the guide cylinder 6 in the axial direction, and a support rod 5 passing through the lower pressing head 3 in the axial direction. The pressing rod 4 is slidingly fitted with the upper pressing head 2 and the guiding cylinder 6, The supporting rod 5 is detachably fixedly connected with the lower pressing head 3, and the bottom end of the pressing rod 4 and the top end ...

Embodiment 2

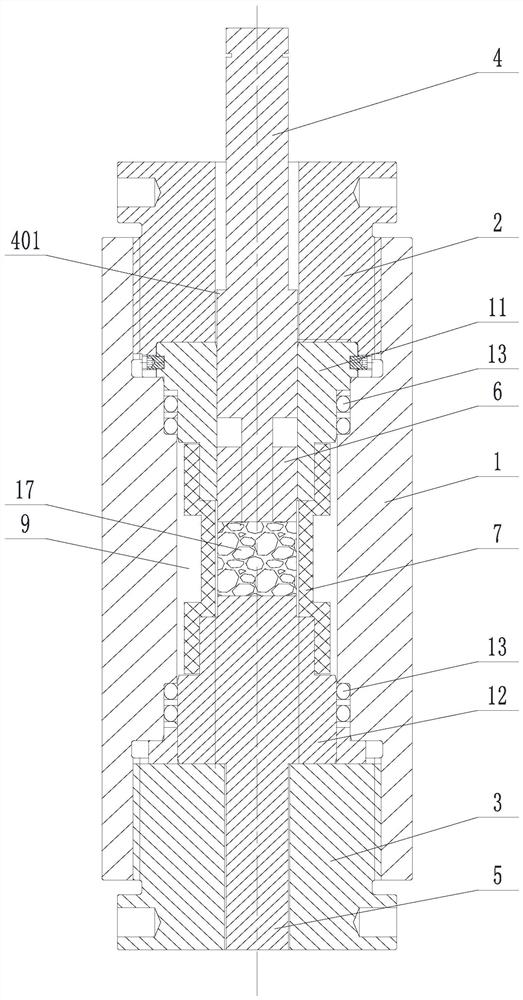

[0069] Such as Figure 4 to Figure 7 The shown rock core tensile strength test device under the confining pressure condition based on Brazil splitting, wherein Figure 4 and Figure 5 It is a schematic diagram of the same structure in different sections; the difference between this embodiment and Embodiment 1 is that it also includes an annular piston 14 outside the pressure rod 4, the outer wall of the annular piston 14 is in contact with the inner wall of the upper pressing head 2, and the annular piston 14 is in contact with the pressure rod. 4 is relatively fixed in the axial direction; it also includes a piston fluid inlet 15 provided on the barrel 1 and / or the upper pressure head 2, and the fluid applied to the piston fluid inlet 15 pushes the annular piston 14 downward. The top of the pressure rod 4 is sleeved with a hollow tightening bolt 16. The pressure rod 4 includes a diameter-expanding portion 401. The tightening bolt 16 is located above the diameter-expanding po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com