Moving contact assembly of molded case circuit breaker

A molded case circuit breaker and moving contact technology, which is applied to circuit breaker parts, circuit breaker contacts, contacts, etc., can solve the problems of damage to molded case circuit breakers and load equipment, arc generation, etc., and maintain contact pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

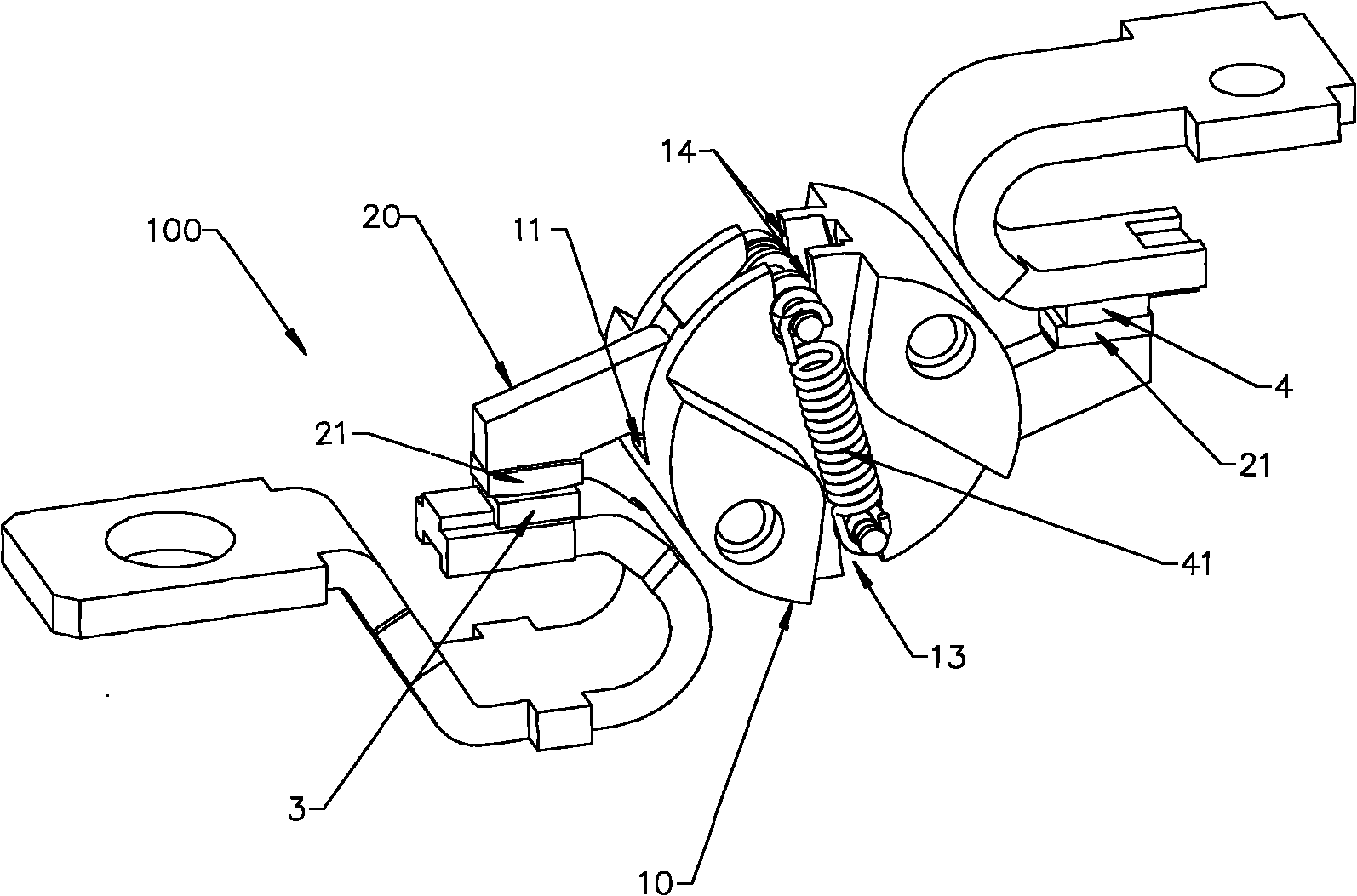

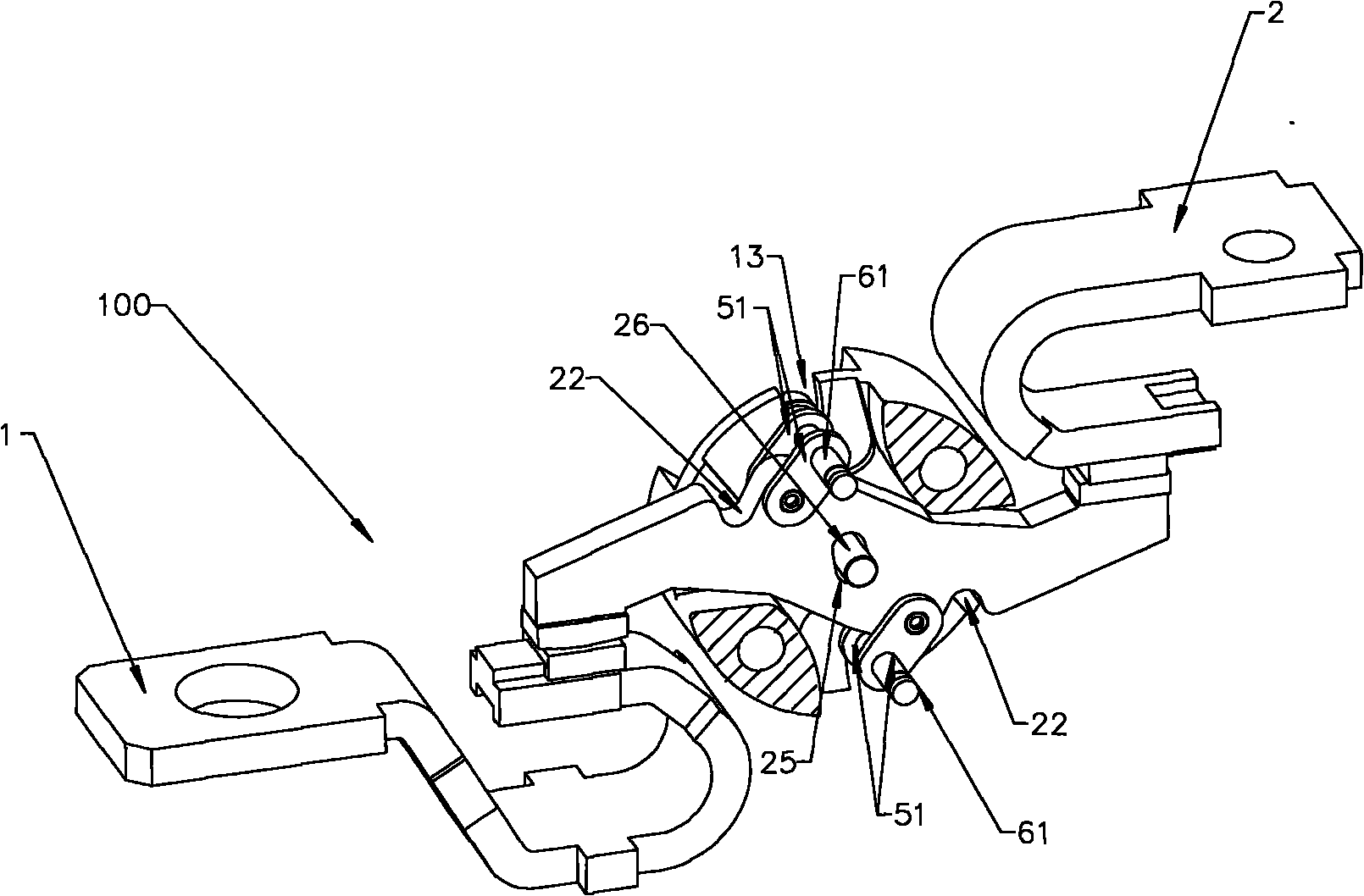

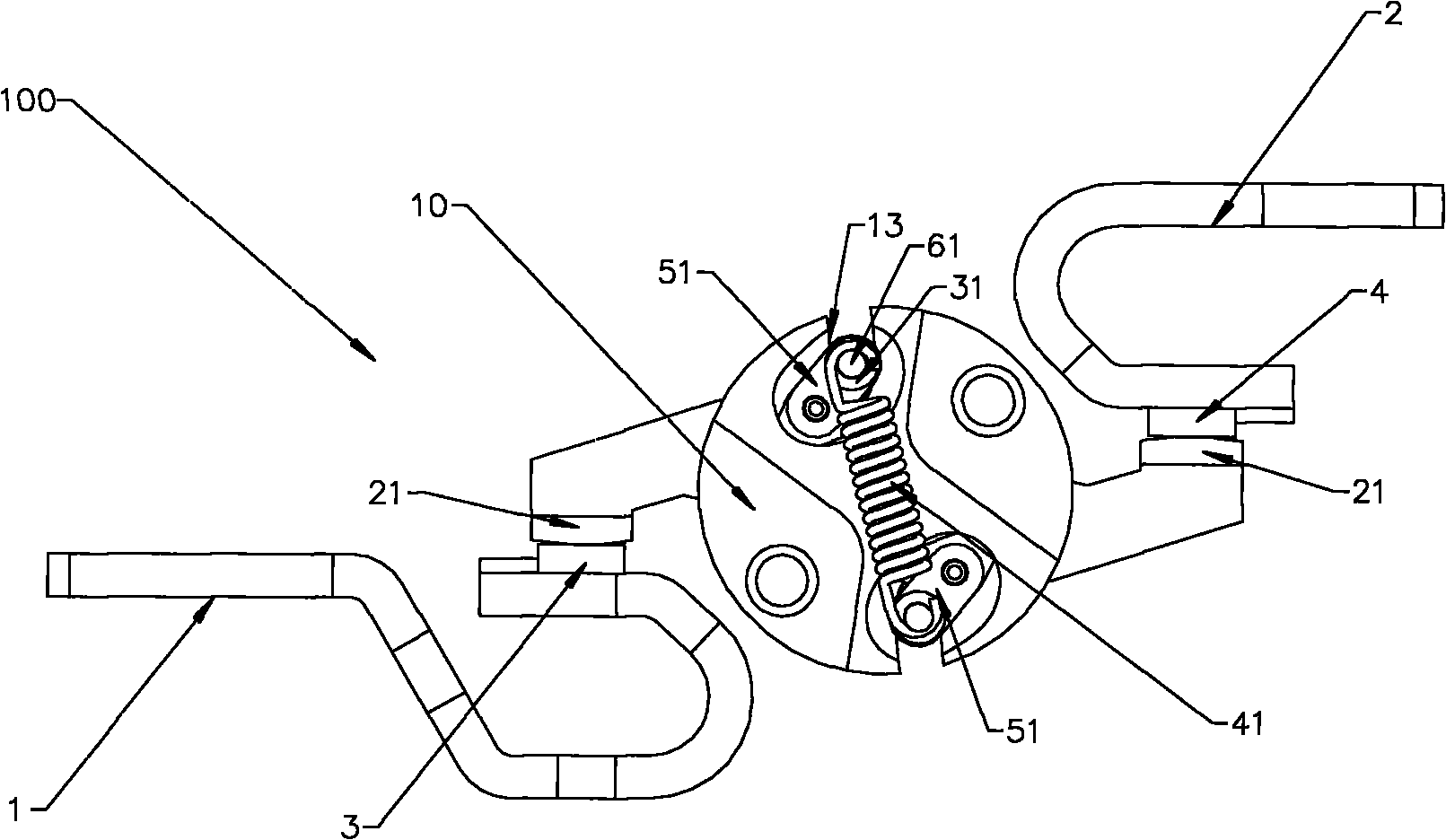

[0021] Such as Figure 1-5 As shown, a moving contact assembly of a molded case circuit breaker includes a rotating shaft 10, a moving contact 20, a pair of connecting rods 51 and a pair of springs 41. The opening 11 that allows the movable contact 20 to rotate independently during flow operation and a pair of symmetrically arranged arc-shaped linear motion guide grooves 13 for supporting the movable contact 20 in a rotatable manner. The movable contact 20 passes through a rotating shaft 26 Rotationally connected with the rotating shaft 10, the two ends of the moving contact 20 are protruded outside the opening 11 of the rotating shaft, and a moving contact 21 is symmetrically provided at both ends, and the pair of connecting rods 51 are symmetrically arranged, each connecting One end of the rod is connected to both sides of the movable contact 20, and the other end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com