Exhaust gas purifying device and manufacturing method thereof

A technology for an exhaust gas purification device and a manufacturing method, which is applied to exhaust devices, mufflers, catalyst carriers, etc., can solve the problems of reduced surface pressure of sealing materials, a large number of inorganic fibers, and reduced retention force, so as to prevent dislocation and increase frictional resistance. , the effect of simple manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0054] Hereinafter, a first embodiment, which is one embodiment of the exhaust gas purification device and the manufacturing method of the exhaust gas purification device of the present invention, will be described with reference to the drawings.

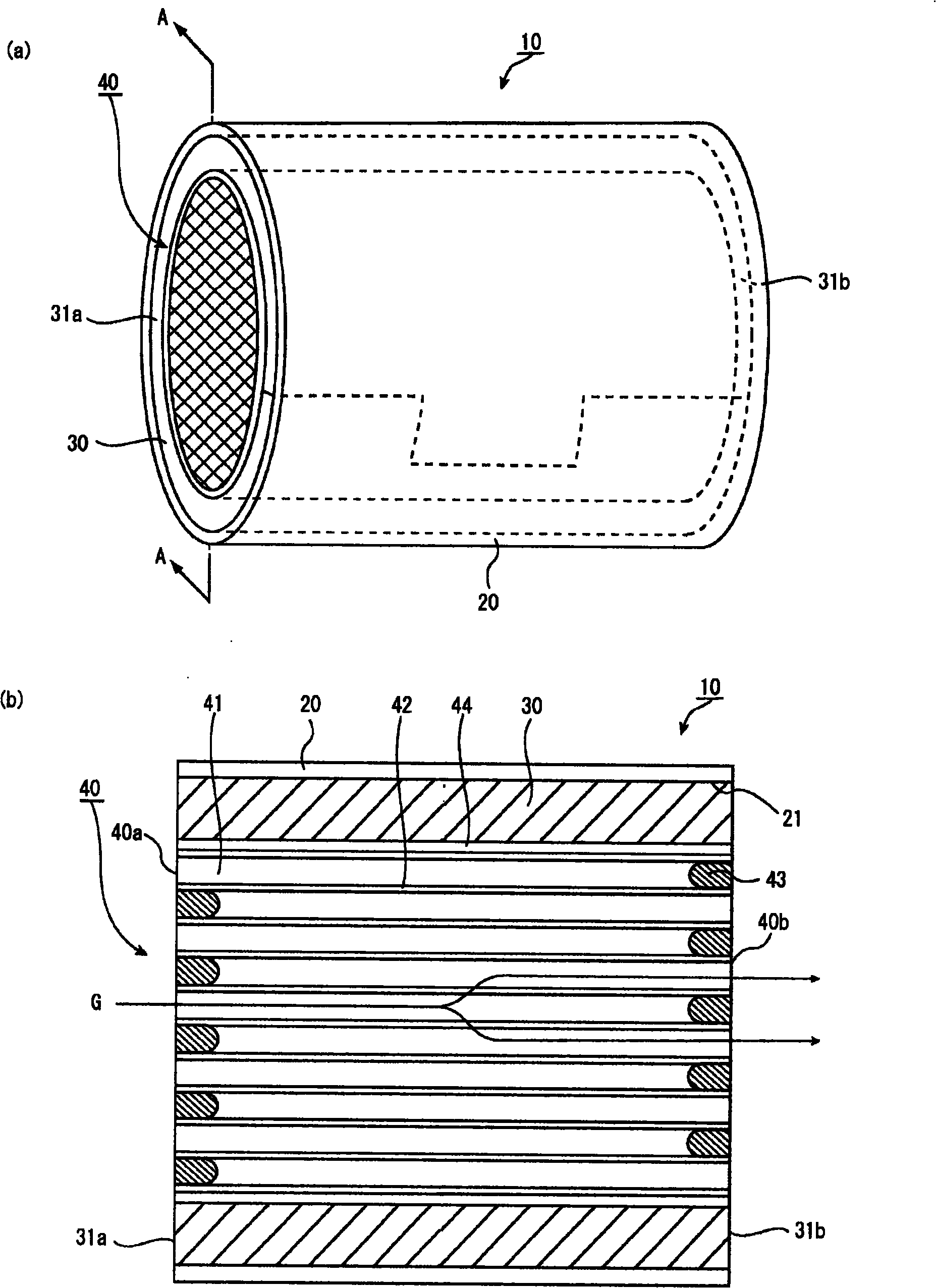

[0055] figure 1 (a) is a perspective view schematically showing the exhaust gas purifying device of this embodiment, figure 1 (b) is figure 1 A-A line sectional view of the exhaust gas purification device shown in (a).

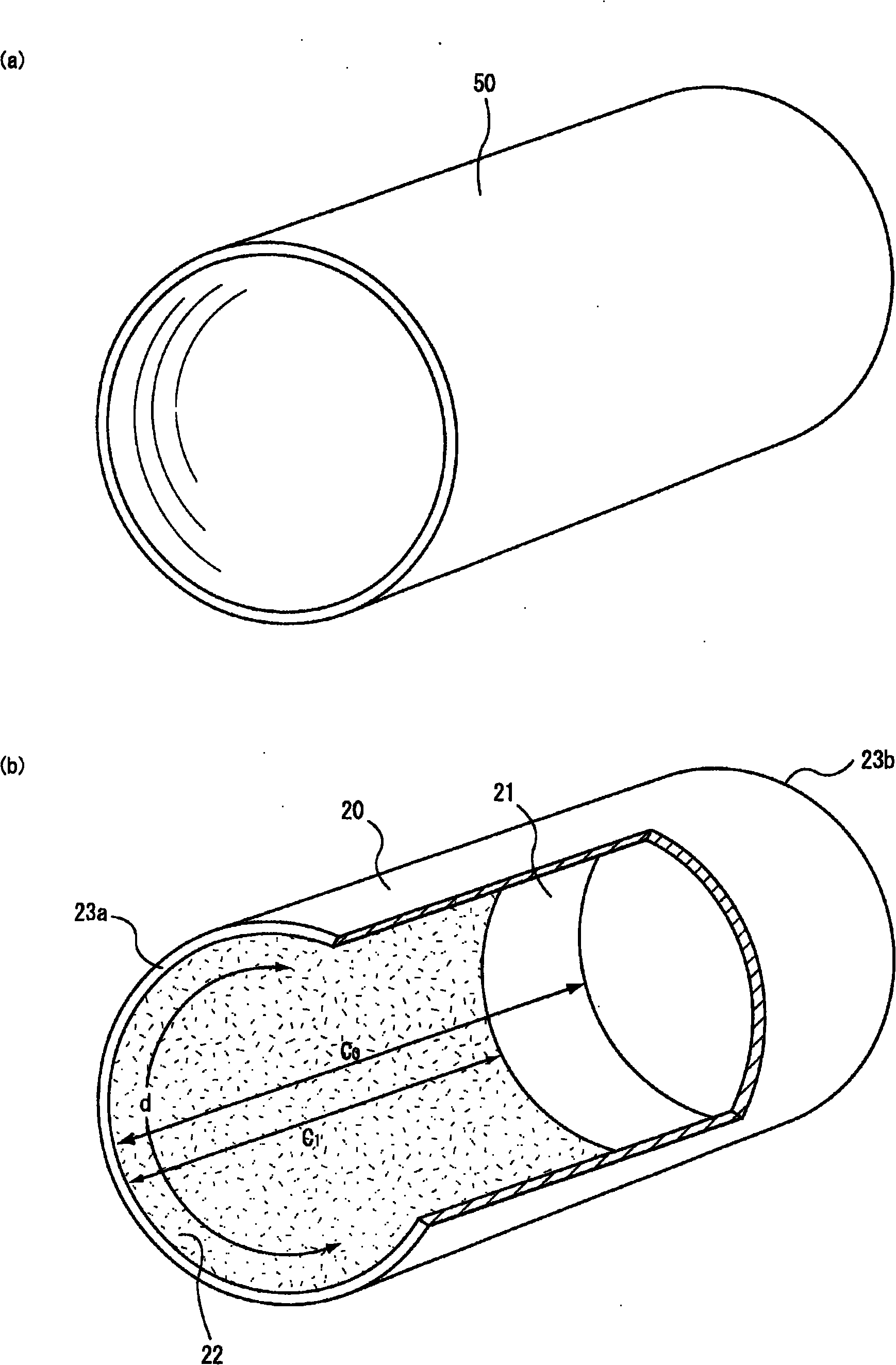

[0056] Such as figure 1 (a) and figure 1 As shown in (b), the exhaust gas purification device 10 is composed of an exhaust gas treatment body 40, a metal casing 20 and a holding sealing material 30, wherein the exhaust gas treatment body 40 is a columnar column in which a plurality of channels 41 are arranged side by side across the channel wall 42 in the longitudinal direction. Exhaust gas treatment body; metal casing 20 accommodates exhaust gas treatment body 40 ; holding sealing material 30 is provided betwee...

Embodiment 1

[0111] (1) Production of holding sealing material

[0112] Prepare a composition ratio of Al 2 o 3 : SiO 2 = 72:28 base mat. A bulk density of 0.15g / cm 3 , The weight per unit area is 1050g / m 2 acupuncture treatment pads.

[0113] Separately, an acrylic latex emulsion in which acrylic latex was dispersed in water was prepared and used as a binder.

[0114] Next, the needle-punched mat was cut to a size of 265 mm×83 mm in plan view. The trimmed needle-punched mat was uniformly sprayed with a binder in an amount of 1.0% by weight relative to the amount of alumina fibers of the trimmed needle-punched mat using a sprayer.

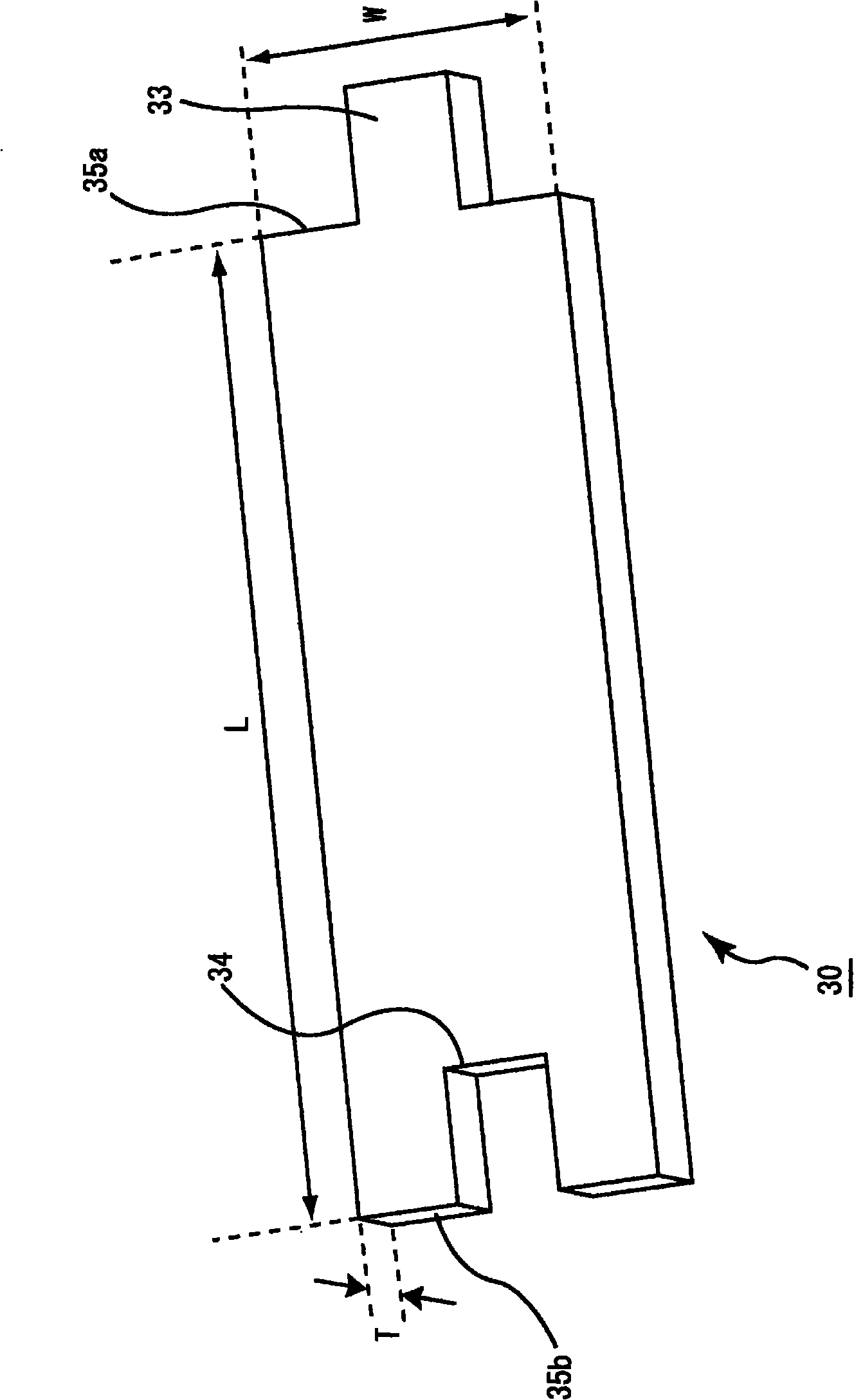

[0115] Thereafter, the needle-punched mat to which the adhesive was attached was ventilated and dried at a temperature of 140° C. for 5 minutes under a pressure of 70 kPa to produce a image 3 The shape shown holds the sealing material.

[0116] (2) Fabrication of wound body

[0117] A cylindrical exhaust gas treatment body mainly composed of porous c...

no. 2 approach

[0137] In the exhaust gas purification device of the present embodiment, the corrosion area is formed not by an acid solution but by a chloride solution. The exhaust gas purification device and the manufacturing method of the exhaust gas purification device which generate|occur|produce a corrosion area using sodium chloride as the chloride of a chloride solution are demonstrated below.

[0138] The exhaust gas purifying device of this embodiment has the same configuration as that of the first embodiment except that the formation of the corrosion region is completed using a sodium chloride solution. However, since the corrosion ability of the sodium chloride solution to corrode the base material of the shell is lower than that of the hydrochloric acid solution, although the degree of corrosion of the base material of the shell depends on the concentration of sodium chloride and hydrochloric acid, it is generally the case when the same molar concentration of the etchant is used. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com