Connecting structure of clutch branch pump and release bearing

A technology of separation bearings and clutch cylinders, which is applied in the field of automobile transmission systems, can solve problems such as poor reliability and inconvenient operation, and achieve the effects of low cost, easy installation and maintenance, and improved safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further explained below in conjunction with accompanying drawing and embodiment:

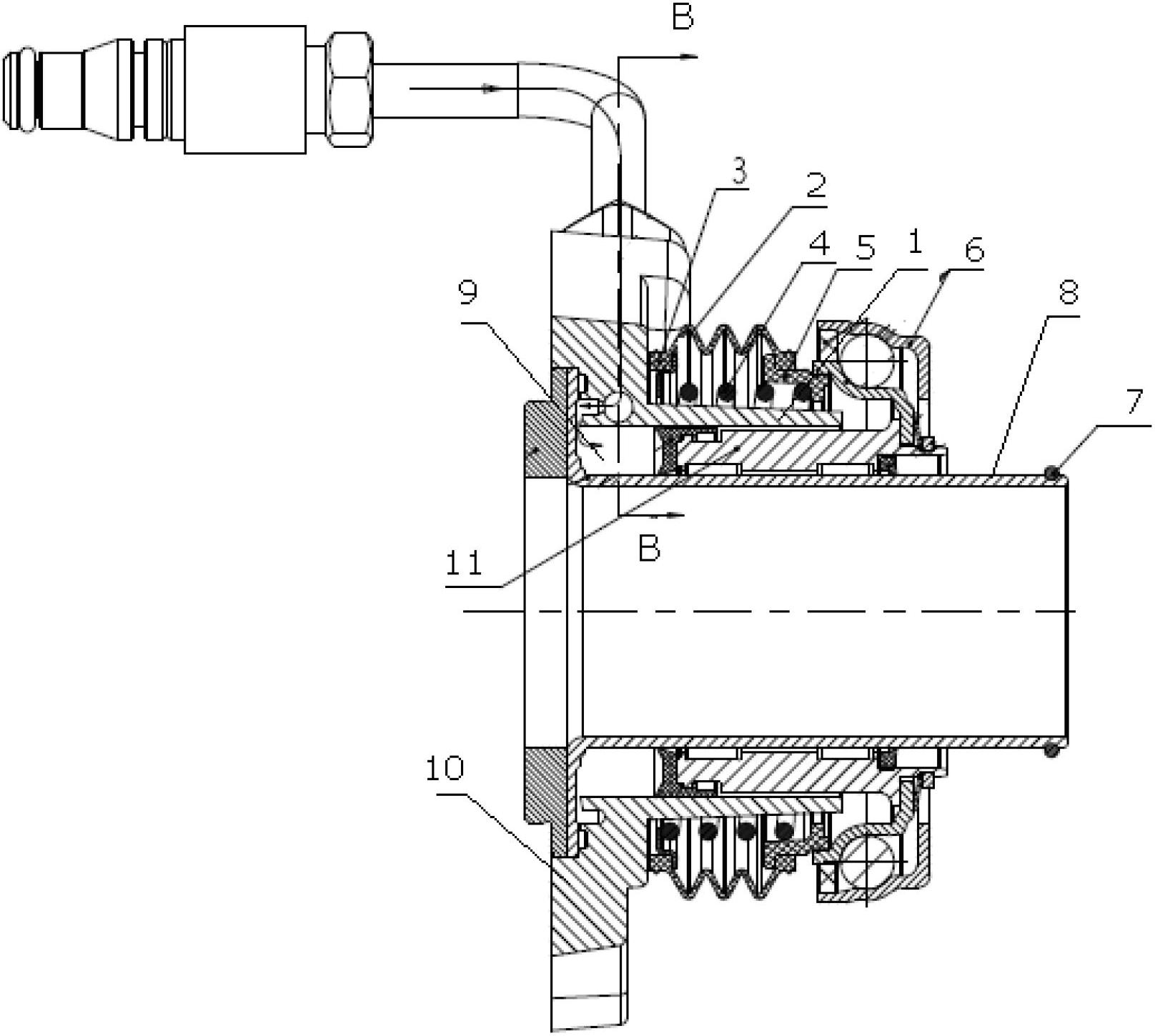

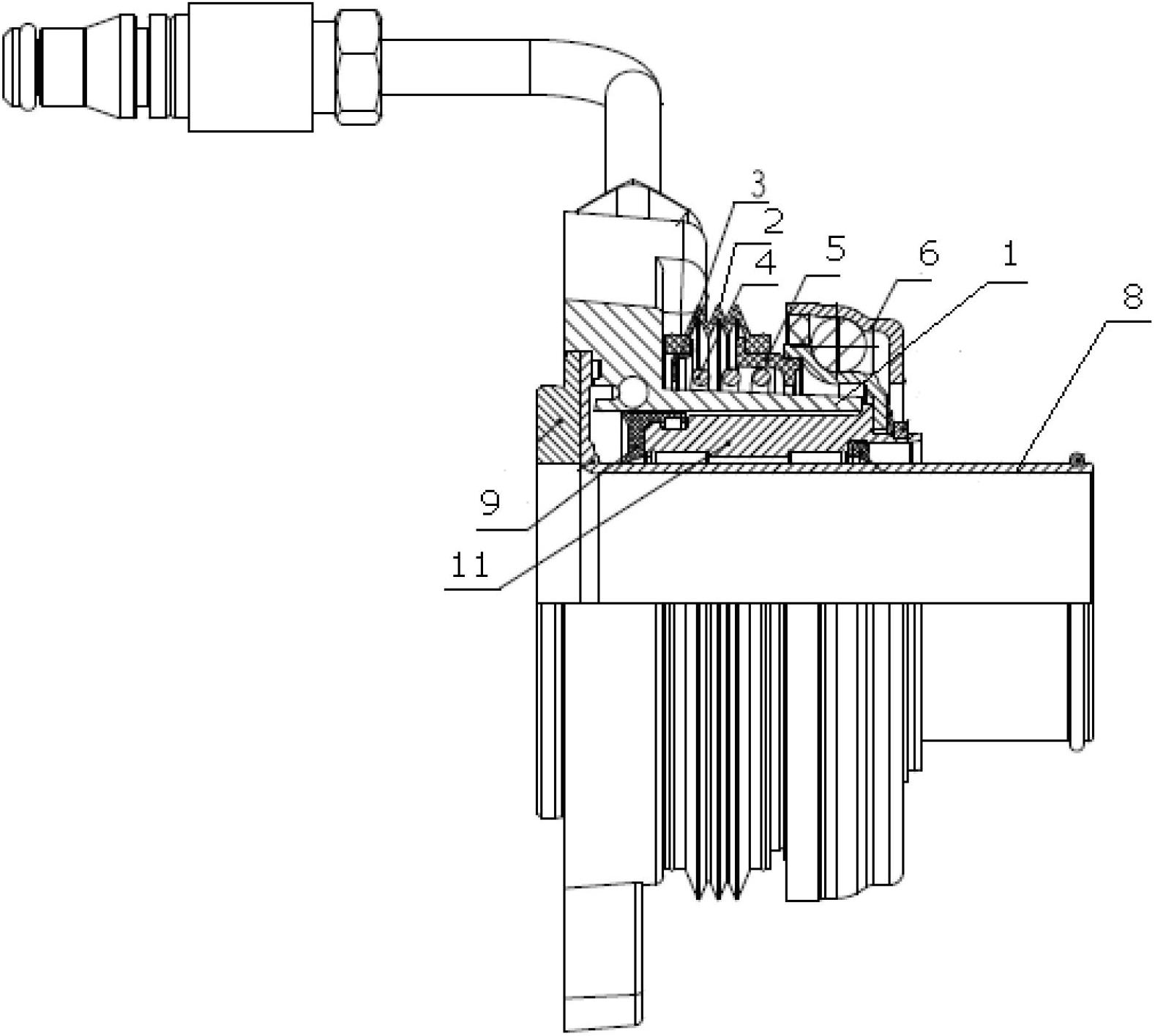

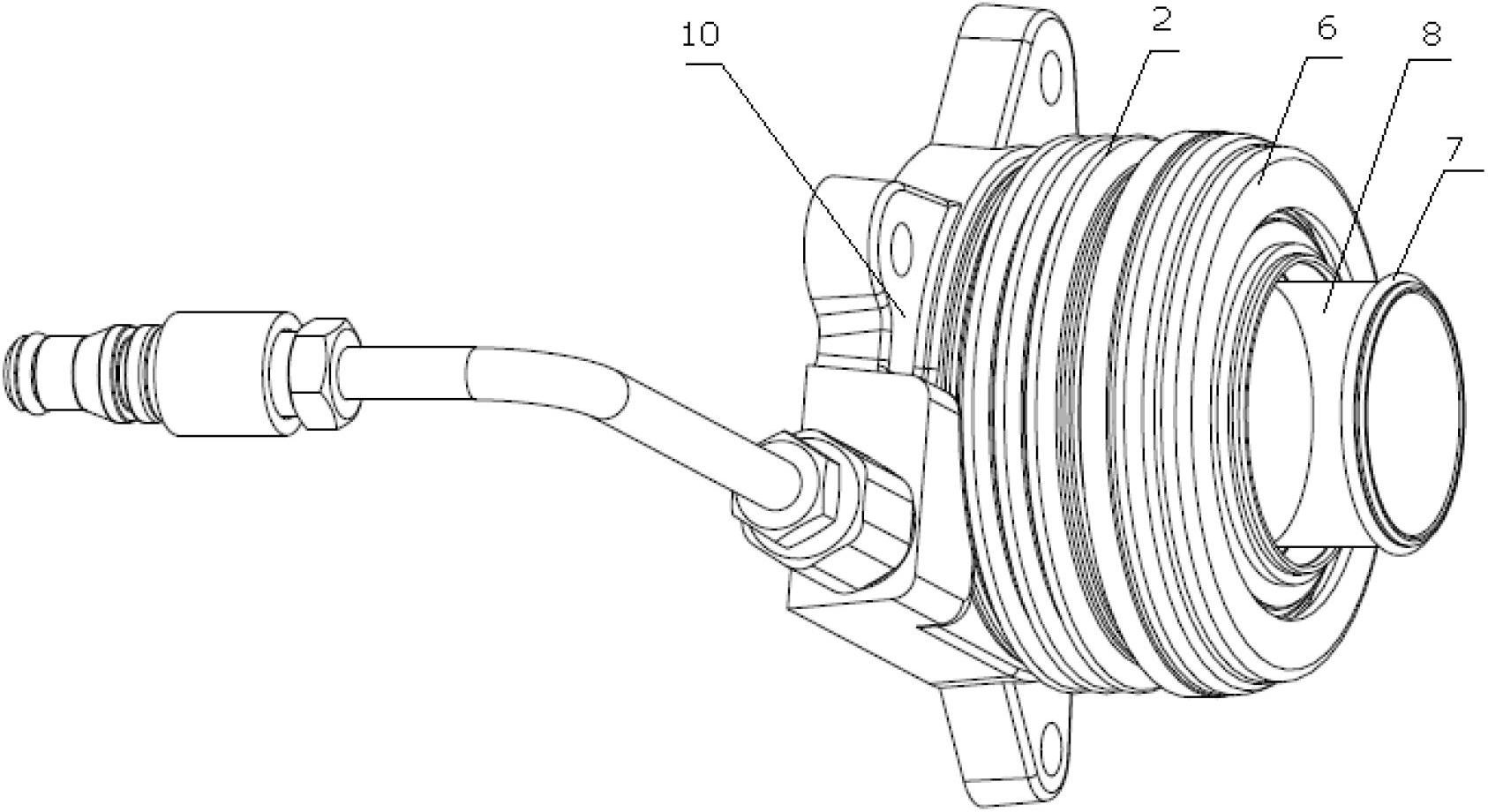

[0016] refer to figure 1 and image 3 A hydraulic piston pump 9 is provided between the inner cylinder 8 and the outer cylinder 1 of the clutch cylinder 10, and the outer cylinder 1 is also covered with a compression spring 4 enclosed in a dust cover 2. Both ends of the dust cover 2 are provided with a front fixing ring 5 which contacts (or connects) with the front end of the compression spring 4 and a rear fixing ring 3 which contacts (or connects) the rear end of the compression spring 4, and the dust cover 2 is deformable The material (such as rubber, etc.) can be deformed correspondingly with the compression deformation of the compression spring 4. The inner cylinder 8 of the clutch cylinder 10 is also covered with a release bearing assembly 6, and the rear end surface of the release bearing assembly 6 is in contact with the hydraulic pressure. The pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com