Torque shoulder of special screwed nipple for oil tubes and sleeves

A special thread and shoulder technology, applied in casing, drill pipe, drilling equipment, etc., can solve the problems of insufficient over-torque performance, reduced sealing performance, poor air sealing performance, etc. Possibility, effect of increasing anti-torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

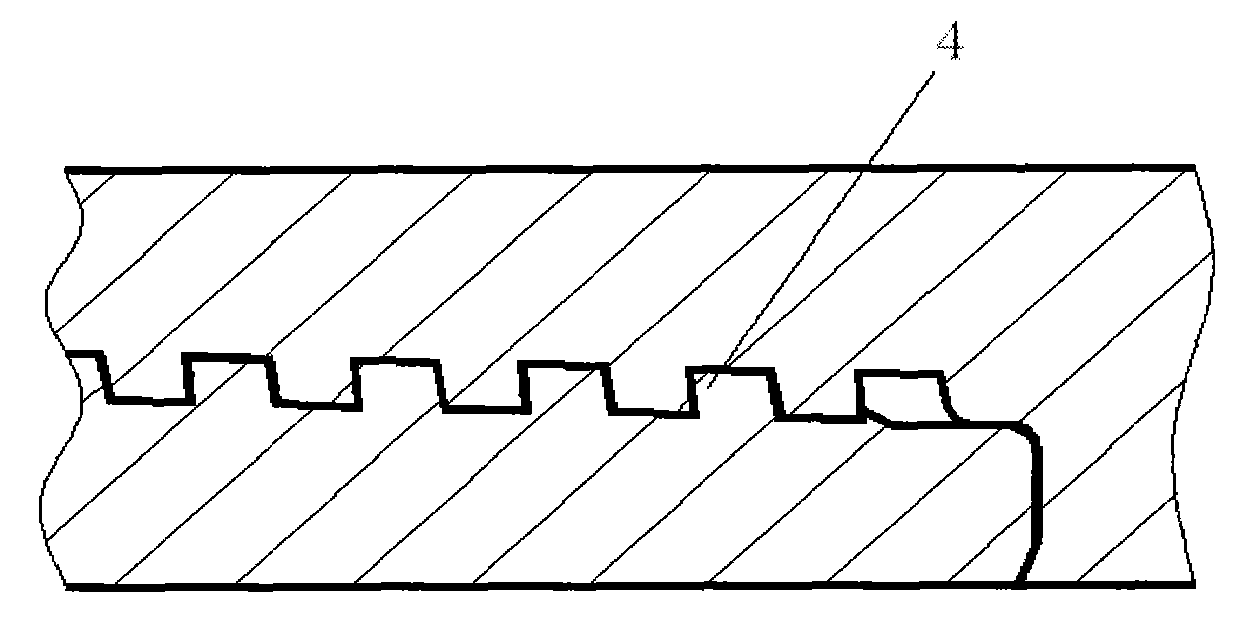

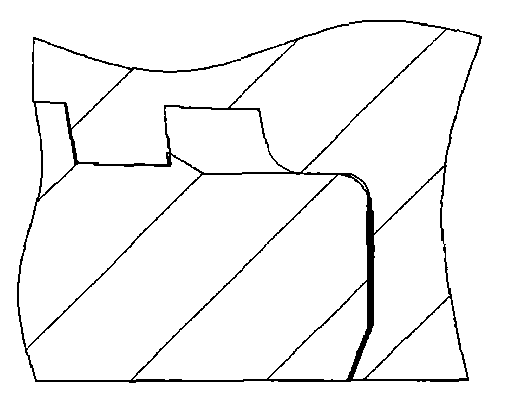

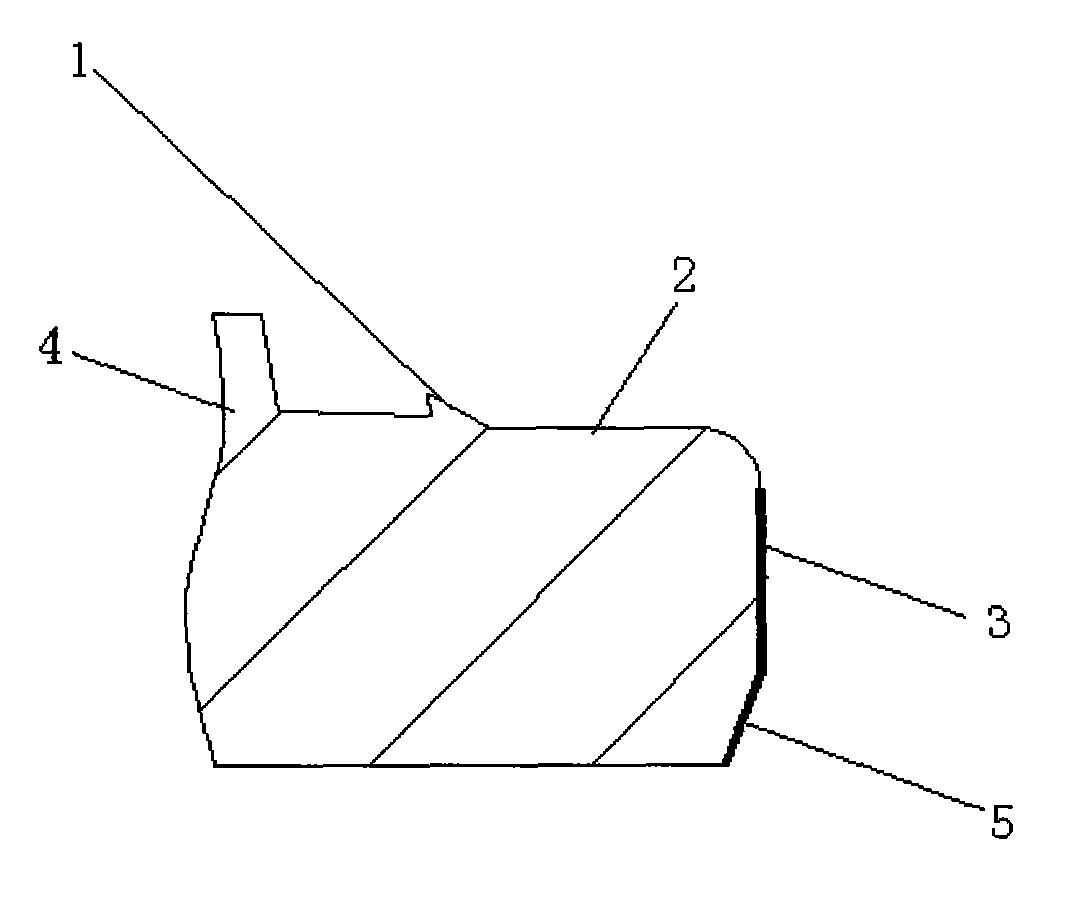

[0012] The torque shoulder of a special threaded joint for oil pipes and casings according to the present invention is composed of a right-angle shoulder and a reverse shoulder, which are located at the end of the external thread of the connecting thread of the pipe joint and the inner part that engages with the end of the external thread. At the part behind the thread relief groove, the reverse shoulder slope 5 of the external thread is inclined inwardly of the pipe, and the angle with the radial direction of the pipe is 15°~20°, and the height along the radial direction is 1.5mm~2mm. The center line of the casing forms an included angle of 90 degrees, connecting the reverse shoulder slope and the sealing surface 2 parallel to the center line of the oil pipe and casing, the sealing surface 2 is connected with the chamfer 1, and the chamfer is connected with the connecting thread 4; The shoulder and the right-angle shoulder are located at the part that contacts the end face of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com