Circuit board connecting structure

A technology for connecting structures and circuit boards, which is applied in the structural connection of printed circuits, printed circuits, printed circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

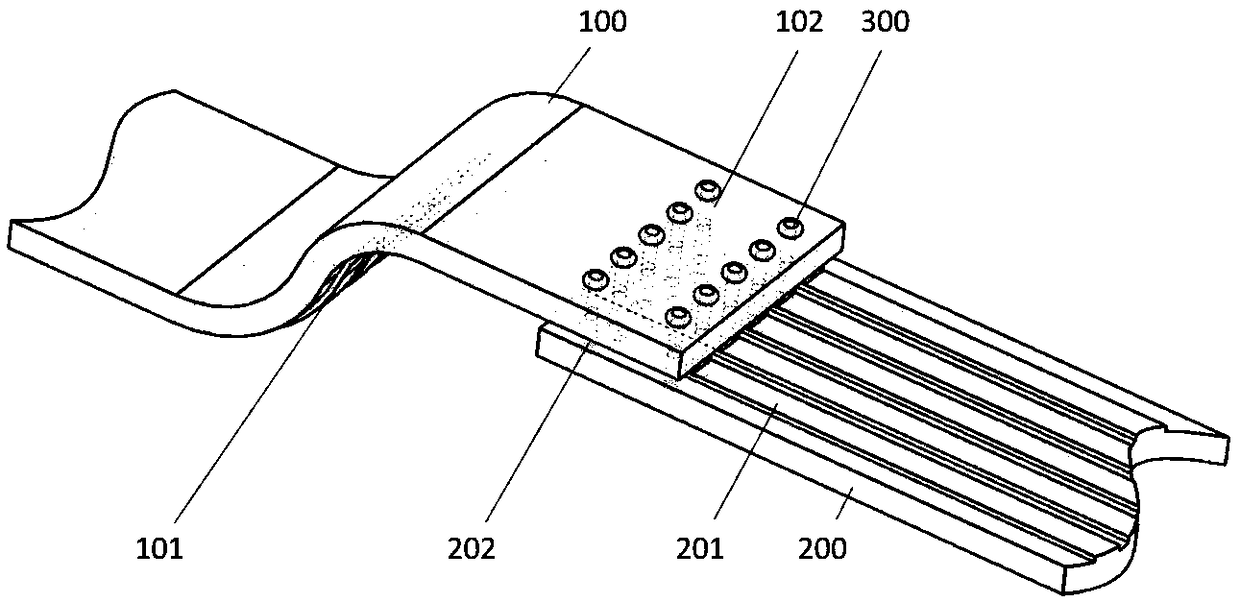

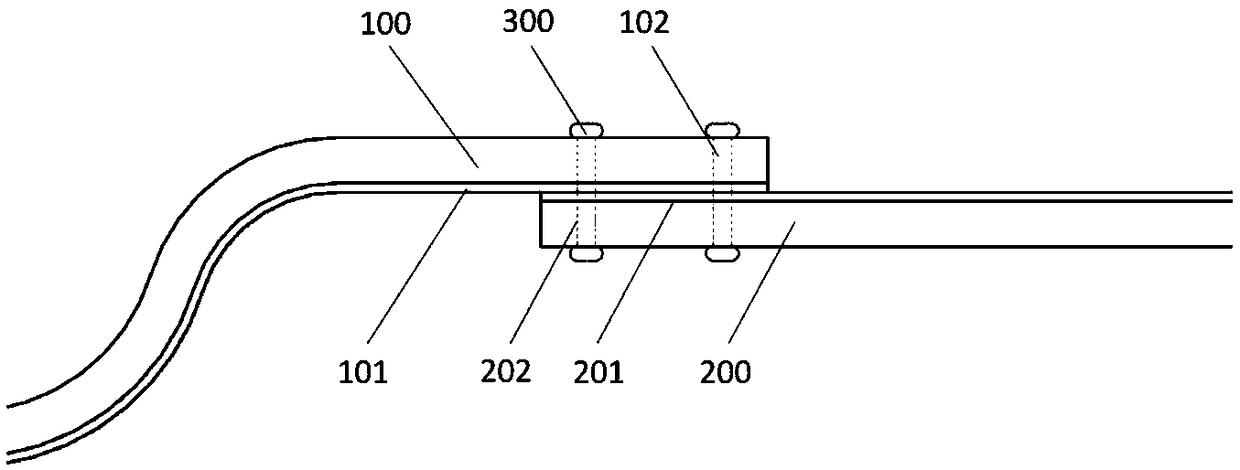

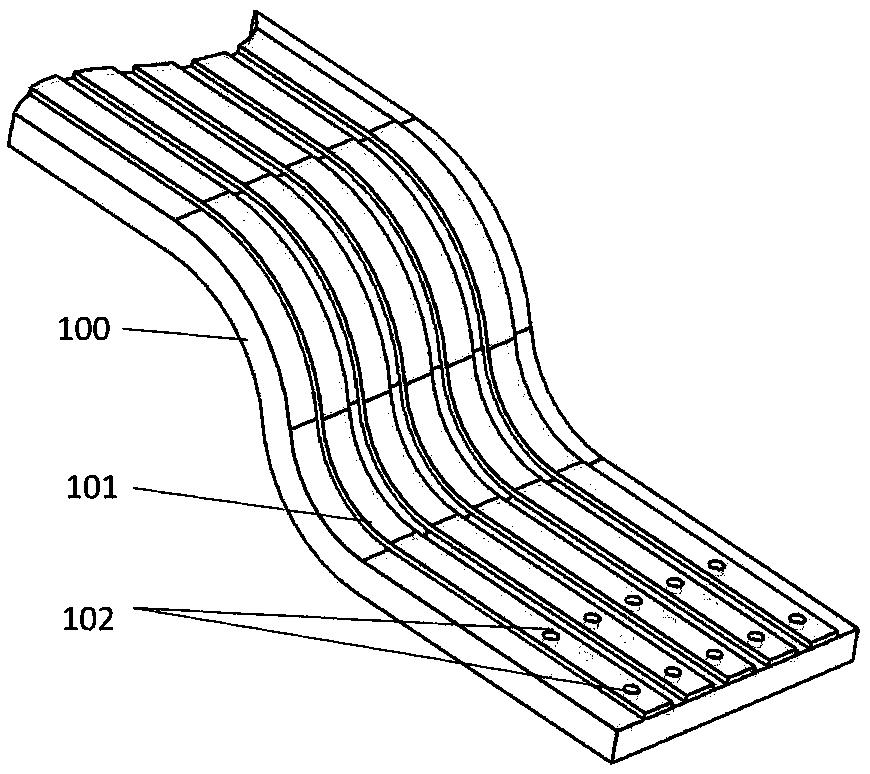

[0027] In the first example herein, figure 1 It is a schematic diagram of the overall structure of an embodiment of a flexible and hard printed circuit board connection structure. It can be seen from the figure that the example of the present invention includes a soft board 100 and a hard board 200, and the two are firmly connected by a pin-shaped structure 300 formed by a bonding material. In the embodiment of the present invention, the bonding material is solder, and the pin-shaped structure 300 formed Formed for solder cooling. The flexible board 100 described in this embodiment is a double-layer circuit board, and the other layer of the circuit board is a physiological indicator monitoring sensor, which is not shown in the figure; the hard board 200 is a double-layer circuit board, and the other layer of the circuit board is for data processing. circuit, not show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com