Surface texture of indium-magnesium composite spherical microcrystal composite layer

A technology of surface texture and composite balls, which is applied in the direction of layered products, metal layered products, chemical instruments and methods, etc., to achieve the effect of overcoming relaxation and reducing fretting fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

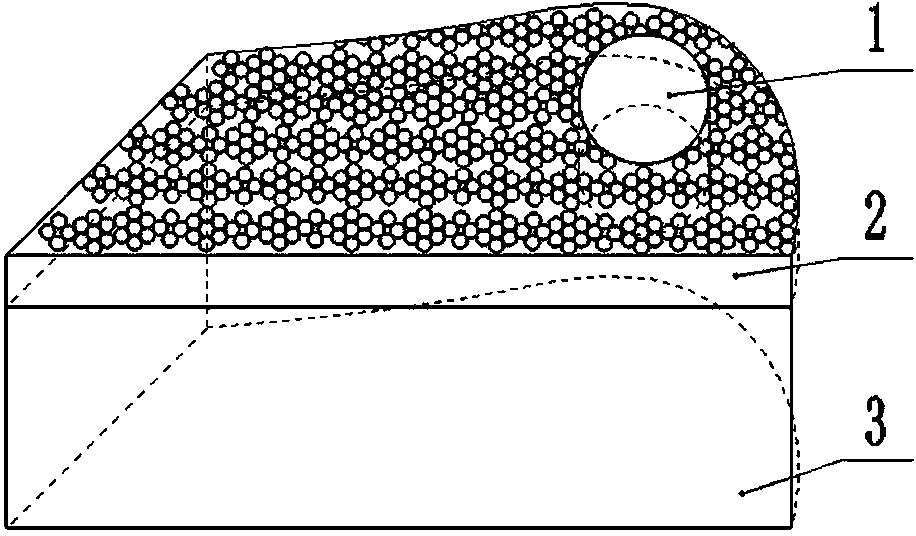

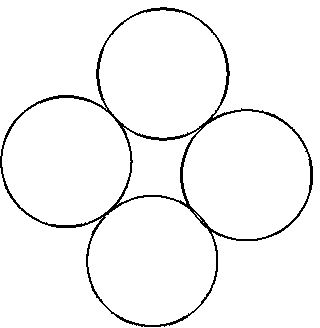

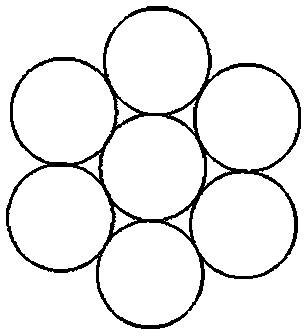

[0024] figure 1It is a structural schematic diagram of the surface texture of the indium-magnesium composite ball microcrystalline composite layer of Example 1 of the present invention; Fig. 2 (a) is the close connection of 4 spherical grains of the indium-magnesium composite spherical microcrystalline composite layer of Example 1 of the present invention Schematic diagram of the microcrystalline unit of indium-magnesium composite spheres with large volume, which is figure 1 One of the indium-magnesium composite sphere microcrystalline units; Fig. 2 (b) is that more than 4 spherical crystal grains of the indium-magnesium composite sphere microcrystalline composite layer of the embodiment 1 of the present invention are closely connected to form larger indium-magnesium composite sphere microcrystals. The schematic diagram of the crystal unit is figure 1 One of the indium-magnesium composite spherical microcrystalline units, the more spherical grains there are, the larger the co...

Embodiment 2

[0029] figure 1 It is a schematic structural view of the surface texture of the indium-magnesium composite ball microcrystalline composite layer of Example 1 of the present invention; Fig. 2 (a) is the close connection of 4 spherical grains of the indium-magnesium composite spherical microcrystalline composite layer of Example 1 of the present invention Schematic diagram of the microcrystalline unit of indium-magnesium composite spheres with large volume, which is figure 1 One of the indium-magnesium composite sphere microcrystalline units; Fig. 2 (b) is that more than 4 spherical crystal grains of the indium-magnesium composite sphere microcrystalline composite layer of the embodiment 1 of the present invention are closely connected to form larger indium-magnesium composite sphere microcrystals. The schematic diagram of the crystal unit is figure 1 One of the indium-magnesium composite spherical microcrystalline units, the more spherical grains there are, the larger the comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com