Paper-plastic ring cutting machine

A ring cutting and paper-plastic technology, applied in metal processing and other directions, can solve the problems of poor cutting accuracy and low response efficiency, and achieve the effects of smooth movement, low energy consumption, and high surface flatness accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

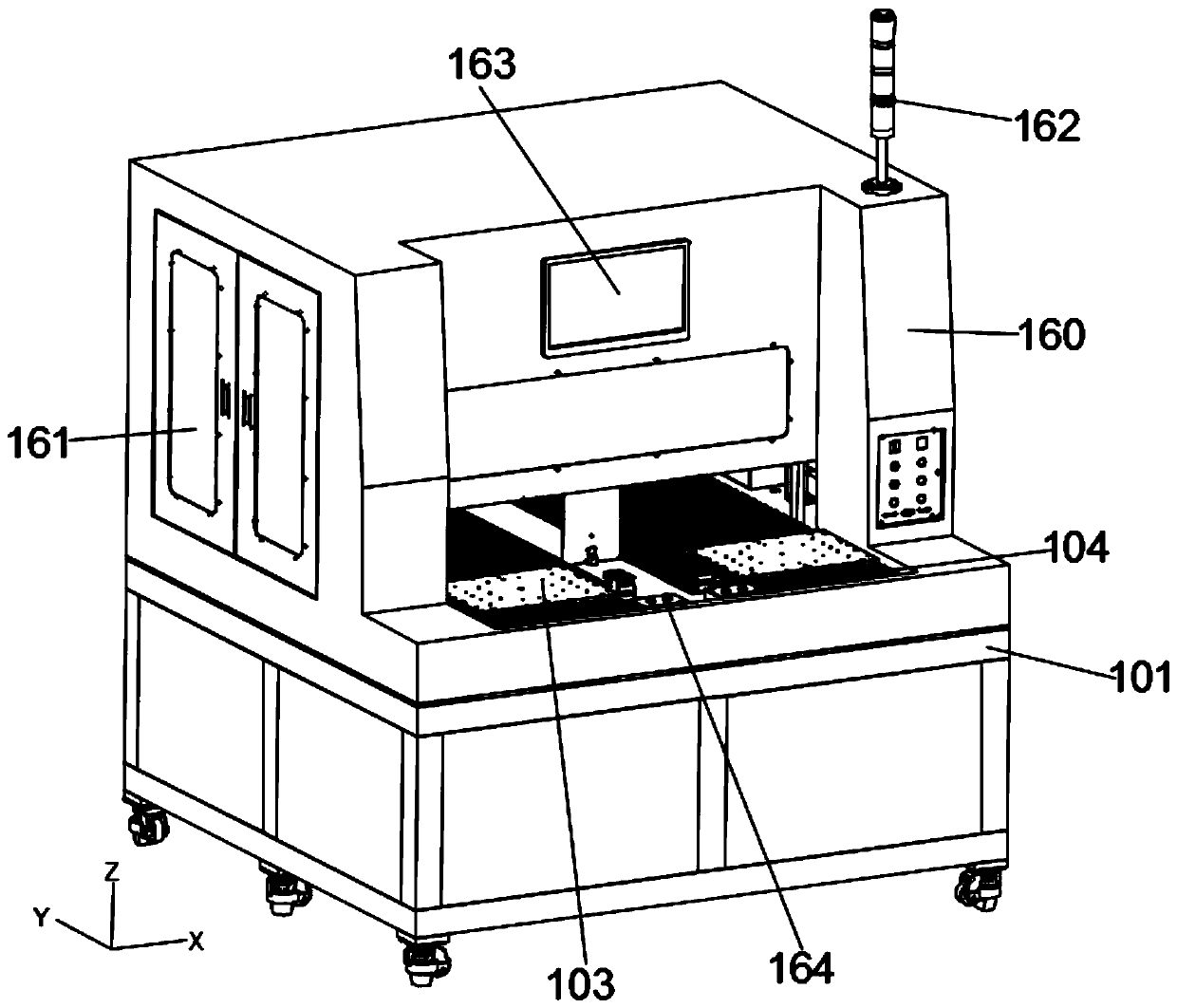

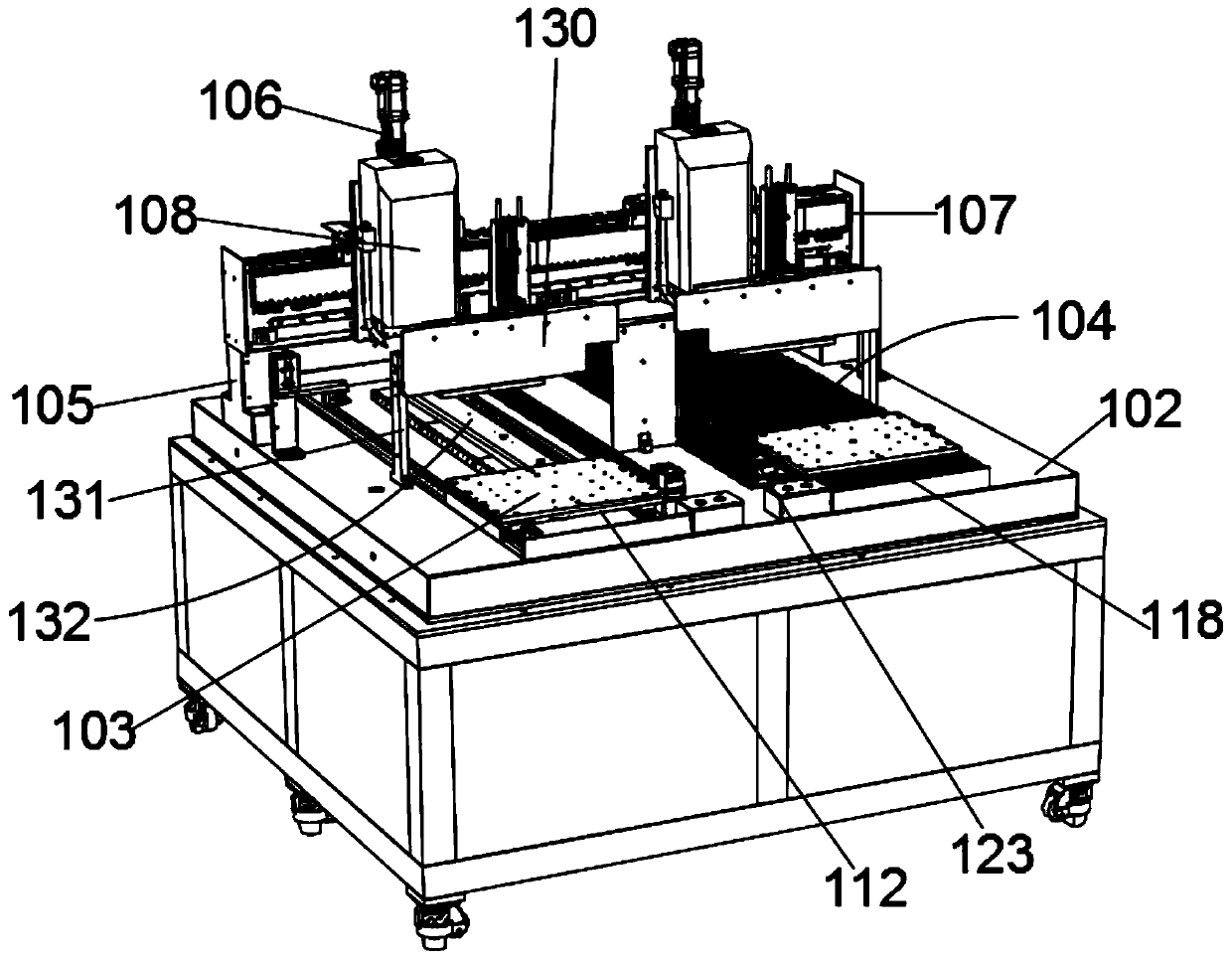

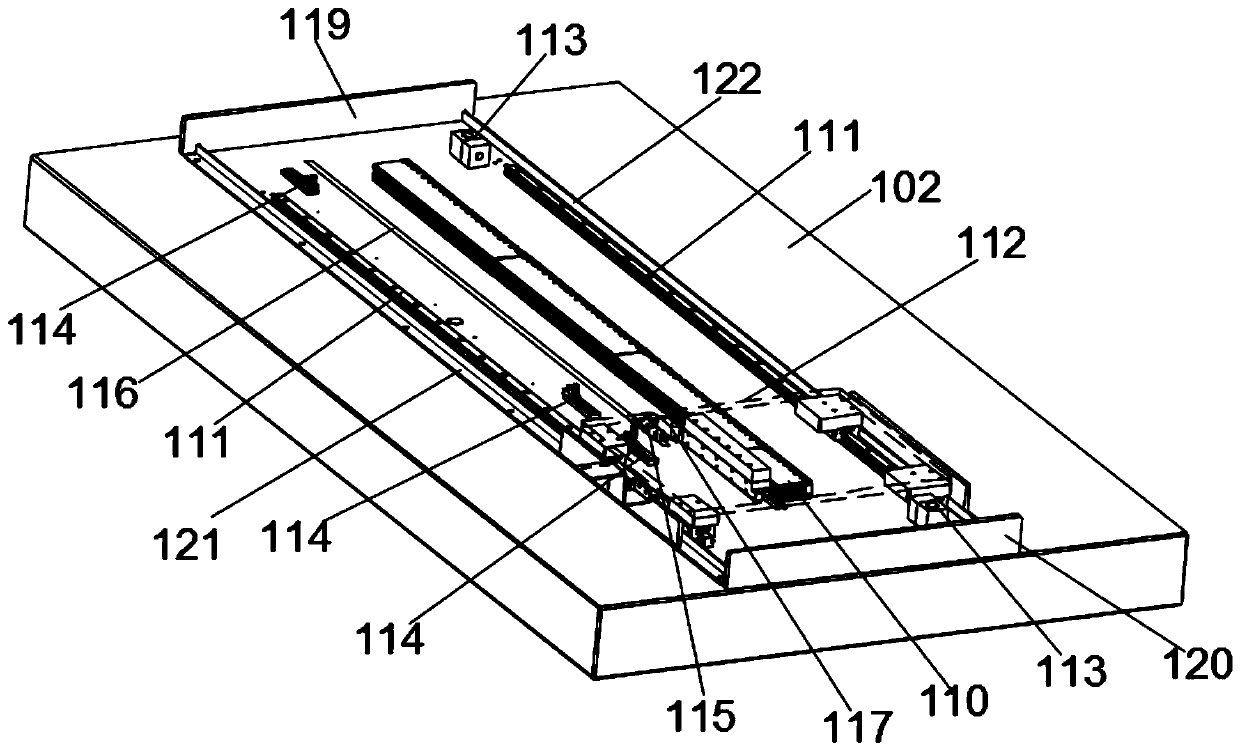

[0031] See attached Figure 1 ~ Figure 3 As shown, a paper-plastic ring cutting machine in this embodiment includes a machine platform 101. The table top of the machine platform 101 is a marble platform 102. The first transmission mechanism 104, a jig for placing products to be cut is installed on the bearing table 103; a gantry 105 of marble material is provided on the marble platform 102, and a Z-axis movement module is provided on the gantry 105 106 is a second transmission mechanism 107 that moves back and forth along the second straight track, the first straight track is perpendicular to the second straight track; the Z-axis motion module 106 can drive the cutting mechanism 108 to move up and down; A transmission mechanism 104 and a second transmission mechanism 107 are both driven by linear motors; a control mechanism connected with the first transmission mechanism 104 , the second transmission mechanism 107 and the Z-axis motion module 106 .

[0032]In this embodiment,...

Embodiment 2

[0054] This embodiment provides a kind of paper-plastic ring cutting machine, such as Figure 8 As shown, its structure is the same as the overall structure of the paper-plastic ring cutting machine in Embodiment 1, the difference is that the second linear motor on the second transmission mechanism has only one mover, and the mover slides in the stator magnetic track . The carrier plate A connected to the mover, the Z-axis motion module, and the cutting mechanism are the same as those in Embodiment 1. That is to say, the paper-plastic ring cutting machine has two loading tables for feeding, and a cutting mechanism for cutting the products to be cut on the two loading tables.

Embodiment 3

[0056] This embodiment provides a kind of paper-plastic ring cutting machine, such as Figure 9 As shown, its structure is the same as the overall structure of the paper-plastic ring cutting machine in Embodiment 1, the difference is that the second linear motor on the second transmission mechanism has only one mover, and the mover slides in the stator magnetic track . The carrier plate A, Z-axis motion module, and cutting mechanism connected to the mover are the same as those in Embodiment 1; the number of the first transmission mechanism is one, and the number of auxiliary mechanisms matched with it is one. That is to say, the paper-plastic ring cutting machine has a feeding table and a cutting mechanism, and the two cooperate with each other to cut the products to be cut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com