Device for removing irregular particles in spherical powder and removing method for same

A spherical powder and spherical particle technology, which is applied in the field of devices for removing irregular particles in spherical powder, can solve the problems of reducing production efficiency and capacity loss, and achieve the effects of improving quality, reducing material loss, and increasing performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

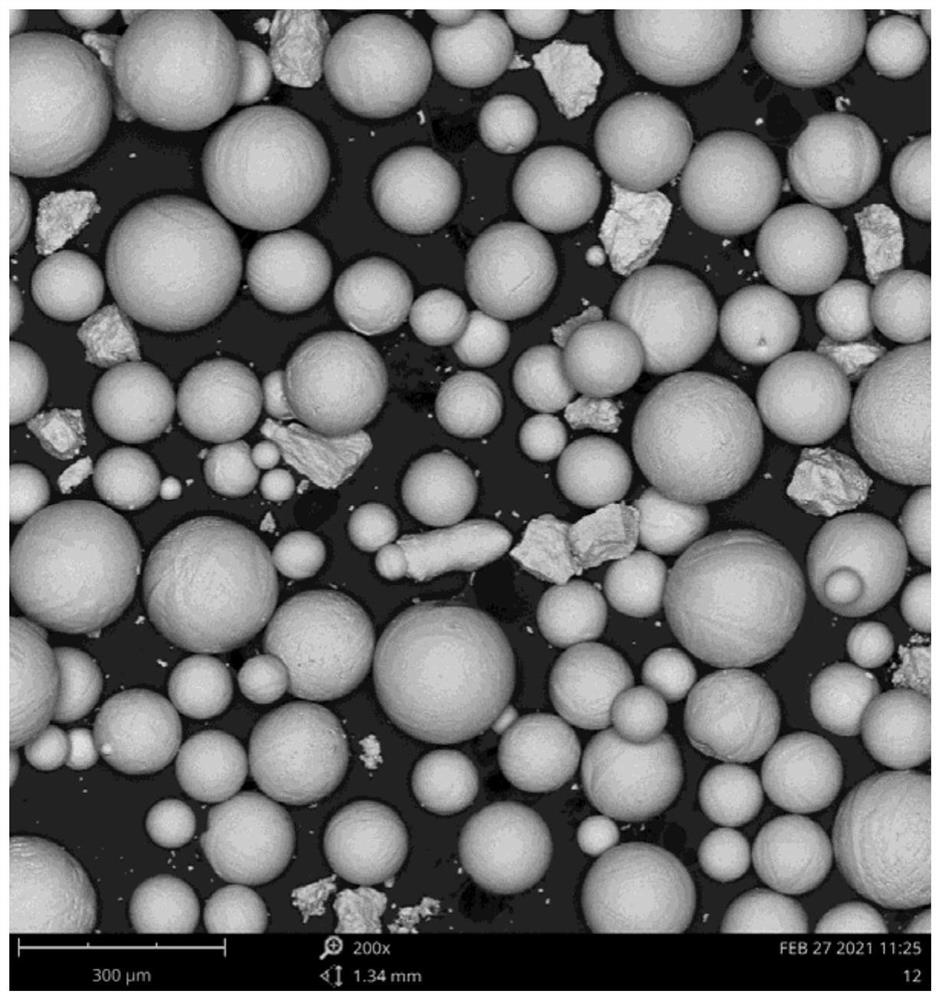

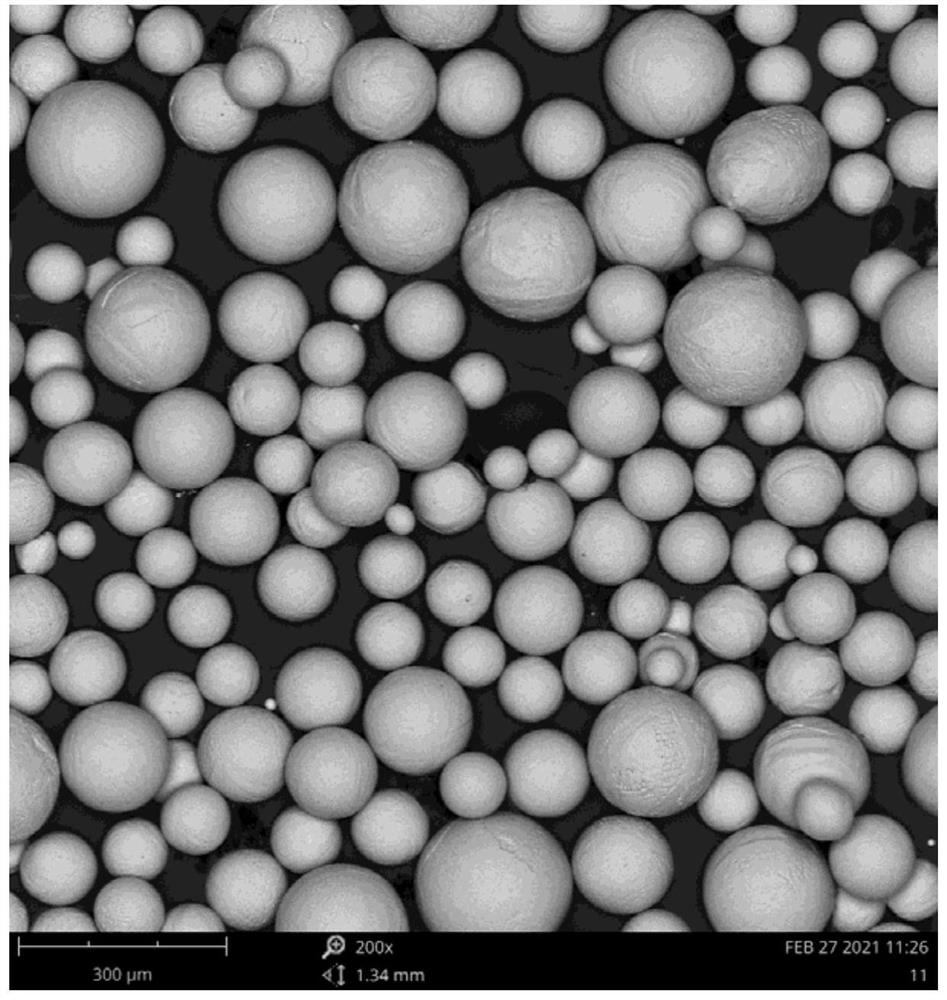

[0086] (1) With NiTi spherical powder (average particle diameter D50 is 53-250 micron) as raw material, from figure 2 It can be seen that the raw material contains irregular particles and spherical particles;

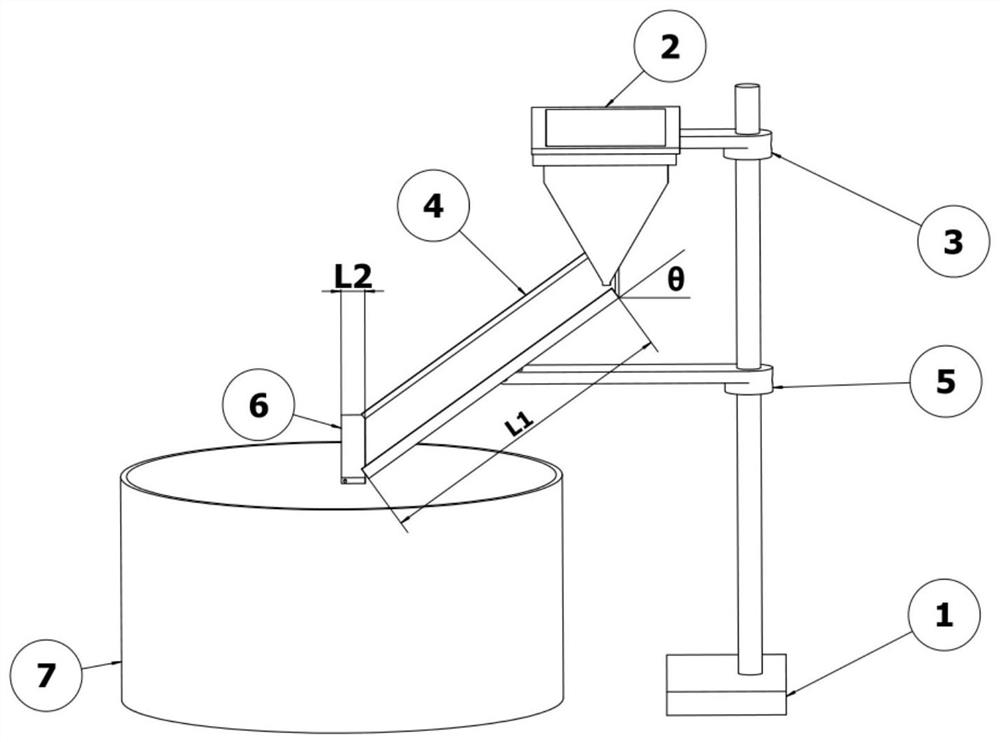

[0087] (2) adopt figure 1 For the device shown, the length of the inclined plate is set to L1=260mm, the slope θ=36°, the horizontal platform L2=20mm, and the powder gap D=2.5mm under the hopper;

[0088] (3) Quantitatively load 50 grams of raw material NiTi spherical powder with a spoon, fill it into the hopper, the powder will spread out in the hopper, and drop from the long narrow leak at the lower end of the hopper to the inclined plate below, and the powder will move along the inclined plate Slide down to the horizontal platform and fall into the collection tank, and a small amount of powder remains on the inclined plate and the horizontal platform;

[0089] (4) Remove the spherical powder collection tank and replace it with another collection tank for irregular...

Embodiment 2

[0097] The method for removing irregular particles in this embodiment is the same as in Example 1, the difference is that the slope θ=70° of the slope of the inclined plate is adjusted, and the spherical powder processed is TC4 spherical powder (average particle diameter D50 is 15-53 microns).

[0098] The irregular particle content in the TC4 spherical powder was calculated to be 20.10wt% after treatment. The fluidity results of TC4 spherical powder before and after treatment were tested respectively, as shown in Table 1. According to the results, the fluidity of TC4 spherical powder is improved, 34.24s / 50g before treatment and 26.38s / 50g after treatment.

[0099] Taking the TC4 spherical powder before and after the treatment in this example, under the same conditions (laser power 170W, pulse duty ratio 80%), the self-developed M100 laser 3D printer was used to carry out SLM 3D printing entities respectively. The density of TC4 spherical powder without removing irregular par...

Embodiment 3

[0101] The method for removing irregular particles in this embodiment is the same as in Example 1, the difference is that the slope θ=20° of the slope of the inclined plate is adjusted, the horizontal surface L2=30mm, and the spherical powder processed is a zirconia spherical powder (average particle diameter D50 is 150 microns).

[0102] The irregular particle content in the zirconia spherical powder was calculated to be 5.30% after the treatment.

[0103] The fluidity results of the zirconia spherical powder before and after treatment were tested respectively, as shown in Table 1. According to the results, the fluidity of zirconia spherical powder is improved, 20.23s / 50g before treatment, and 19.10s / 50g after treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com