Surface texture of indium-magnesium inwards-concave microcrystal composite layer

A technology of surface texture and composite layer, which is applied in the field of surface texture of indium magnesium concave microcrystalline composite layer, to achieve the effects of enhanced lubrication, enhanced lubrication and reduced fretting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

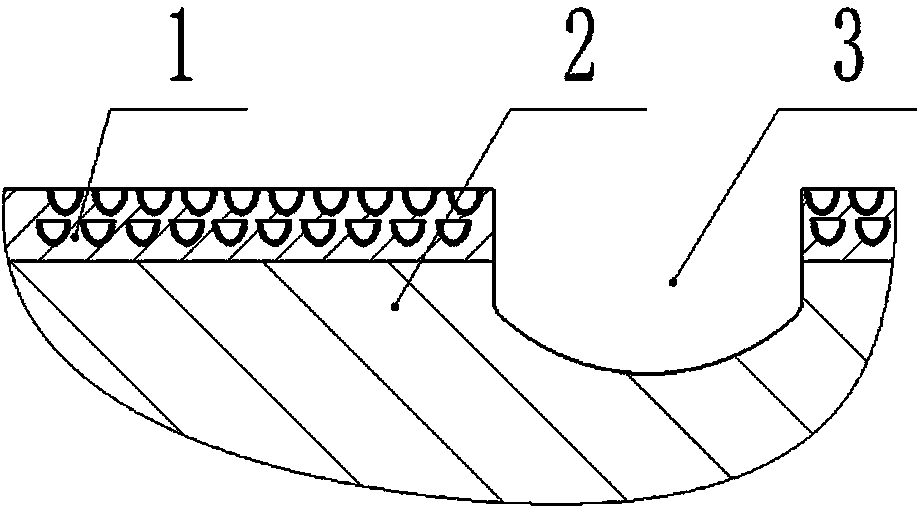

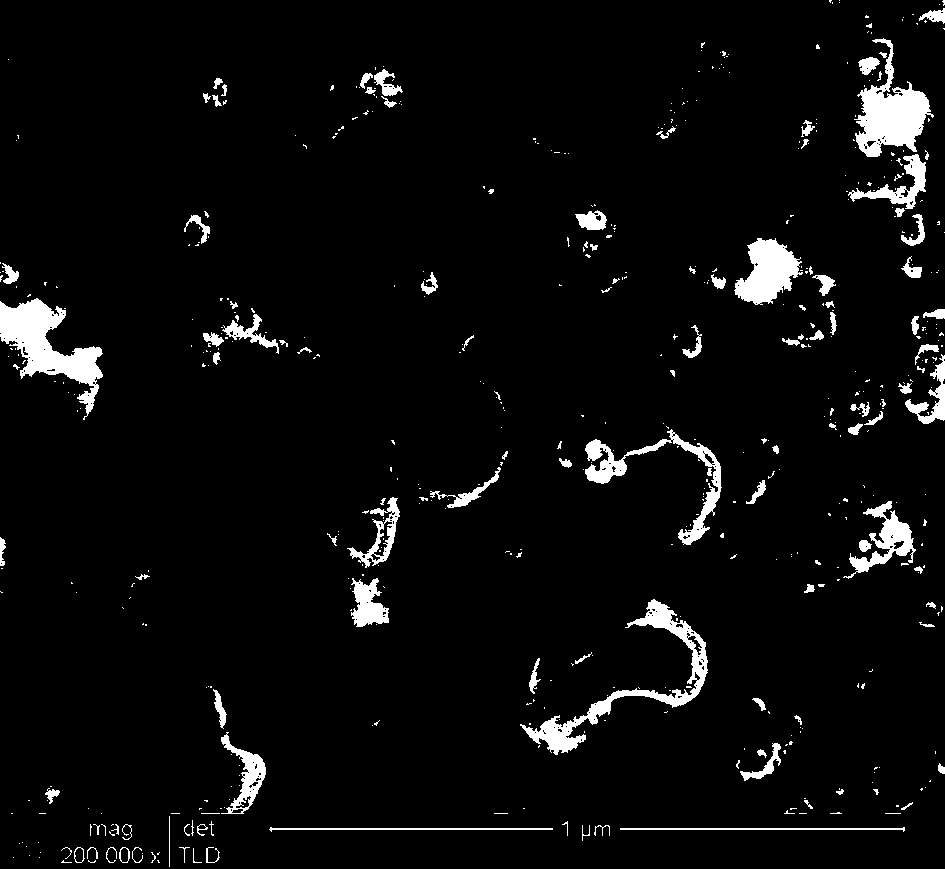

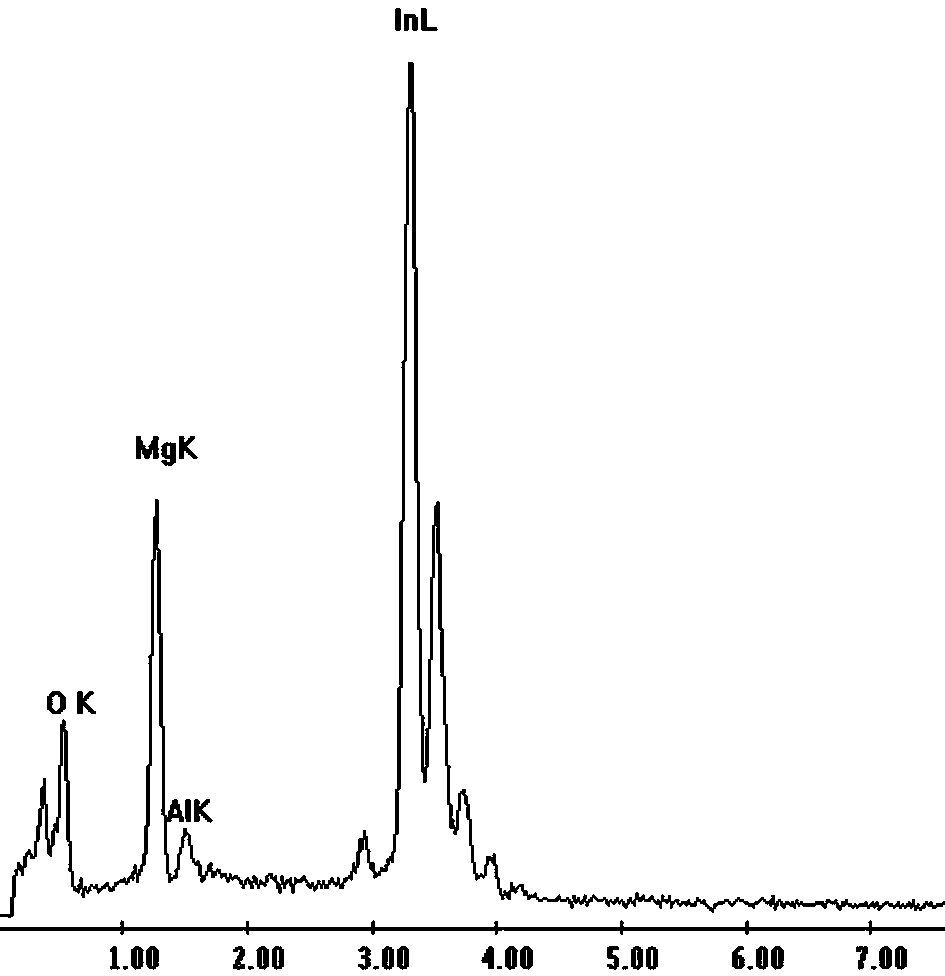

[0022] figure 1 It is a schematic structural view of the surface texture of the indium magnesium concave microcrystalline composite layer in Example 1 of the present invention, figure 2 It is a 200,000 times scanning electron microscope image of the indium magnesium concave microcrystal composite layer surface texture of the part surface material layer indium magnesium concave microcrystal in Example 1 of the present invention, image 3 For embodiment 1 of the present invention figure 2 The energy spectrum of an indium magnesium concave crystallite textured on the surface of the indium magnesium concave crystallite composite layer. In the drawings, 1 is the surface material layer of the part, 2 is the matrix material, and 3 is the circular surface texture unit.

[0023]The surface texture of the indium-magnesium concave microcrystalline composite layer of the present invention is to use AZ91D magnesium alloy materials to make mechanical parts through mechanical processing ...

Embodiment 2

[0027] figure 1 It is a schematic structural view of the surface texture of the indium magnesium concave microcrystalline composite layer in Example 1 of the present invention, figure 2 It is a 200,000 times scanning electron microscope image of the indium magnesium concave microcrystal composite layer surface texture of the part surface material layer indium magnesium concave microcrystal in Example 1 of the present invention, image 3 For embodiment 1 of the present invention figure 2 The energy spectrum of an indium magnesium concave crystallite textured on the surface of the indium magnesium concave crystallite composite layer, Figure 4 It is a schematic structural view of the surface texture of the indium magnesium concave microcrystalline composite layer in Example 2 of the present invention.

[0028] This embodiment is on the basis of embodiment 1, only the depth of the surface texture unit 3 is changed, and other contents are the same as embodiment 1, such as Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com