Indium aluminum composite ball microcrystalline composite layer

An aluminum composite and composite layer technology is applied in the direction of layered products, metal layered products, chemical instruments and methods, etc. It can solve the problems that there are no patent literature reports on the indium-aluminum composite ball and microcrystalline composite layer, and achieve suitable application costs. The effect of strong applicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

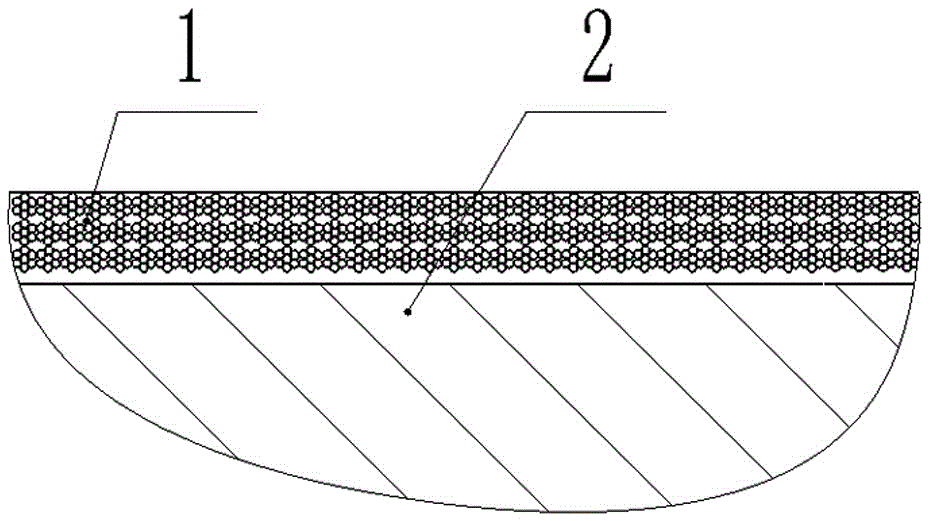

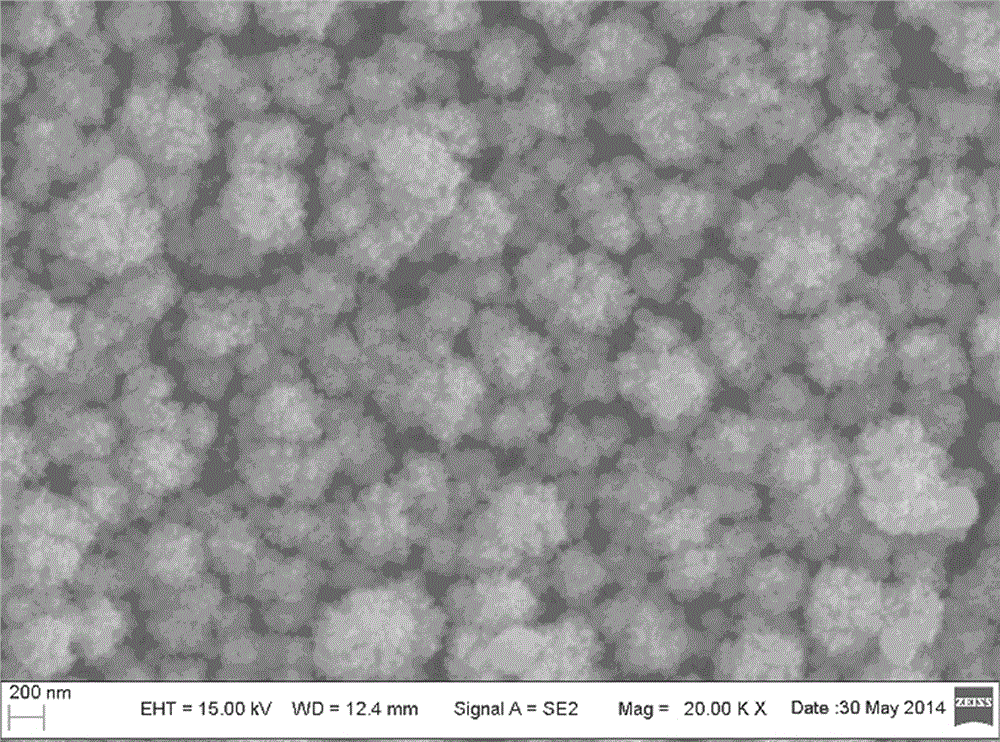

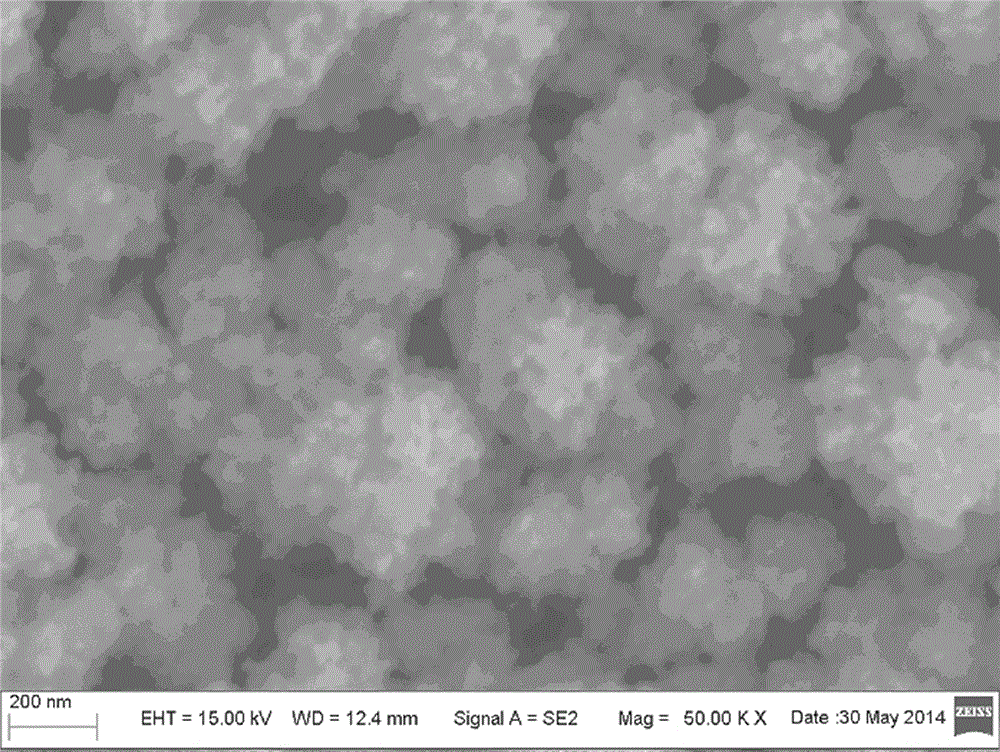

[0018] figure 1 It is a schematic structural diagram of the indium-aluminum composite ball microcrystalline composite layer in Example 1 of the present invention, figure 2 It is a 20,000-fold scanning electron microscope image of the indium-aluminum composite ball microcrystalline composite layer of Example 1 of the present invention, image 3 It is the 50,000 times scanning electron microscope image of the indium-aluminum composite ball microcrystalline composite layer of Example 1 of the present invention, Fig. 4 (including Pic 4-1 , Figure 4-2 ) is the embodiment 1 of the present invention figure 2 One crystallite energy spectrum of the indium-aluminum composite ball microcrystalline composite layer in . In the accompanying drawings, 1 is a surface material layer, and 2 is a matrix material.

[0019] The indium-aluminum composite ball microcrystalline composite layer of the present invention is characterized in that: the purified and impurity-removed 3003 aluminum a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com