Insulating structure and production for vacuum-pressure immersing process of high-voltage motor

A technology of vacuum pressure impregnation and vacuum pressure, which is applied to the shape/style/structure of winding insulation, inorganic insulators, insulators, etc., and can solve problems such as poor applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

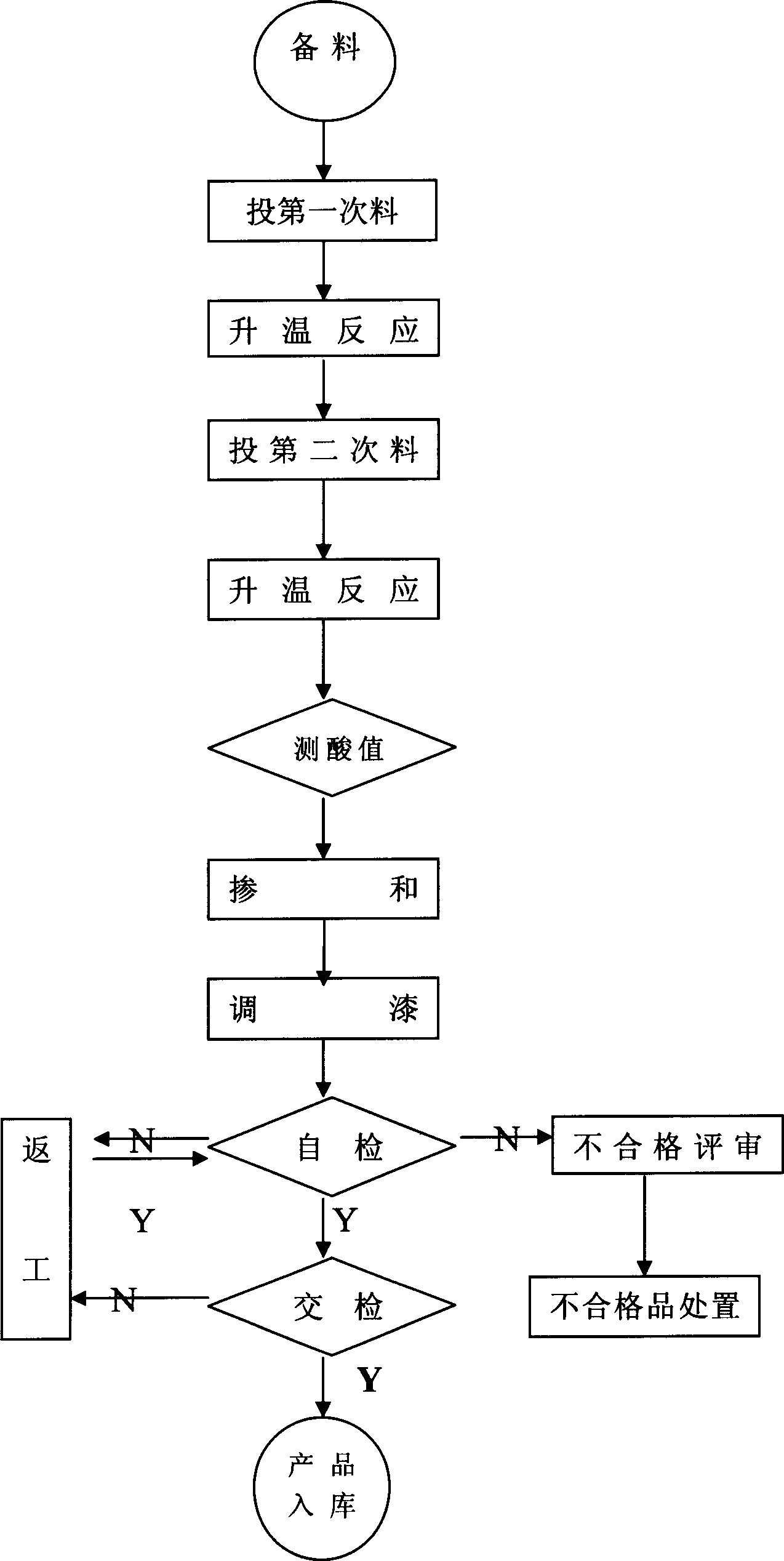

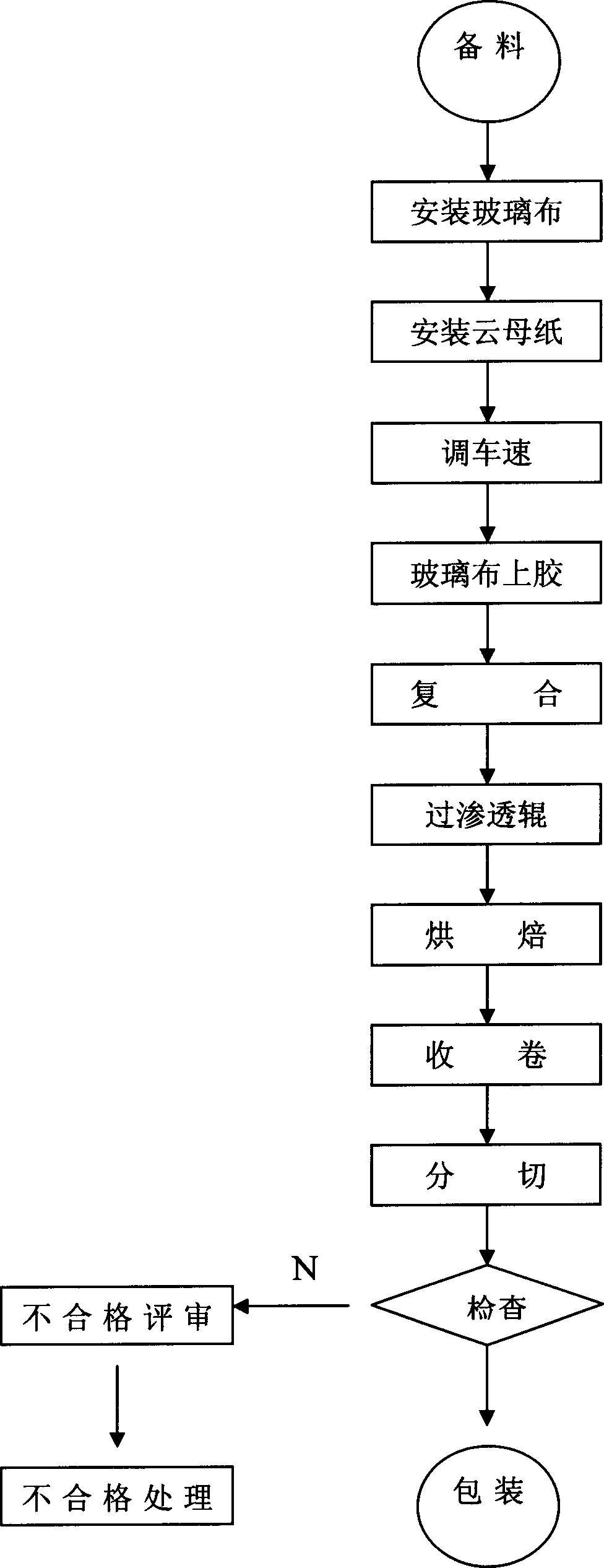

Method used

Image

Examples

Embodiment 1

[0034] A main insulation structure for the stator coil of an F-class high-voltage motor. It adopts the vacuum pressure impregnation insulation method of the less-adhesive full-impregnation type insulation stator, and wraps it with less-adhesive powder mica tape. Composite insulation structure of vacuum pressure impregnation process; its feature is that the epoxy resin of the insulation structure of the motor vacuum pressure impregnation process contains unsaturated bonds, which is a synthetic unsaturated epoxy ester resin. After diluting with active diluent, it can be obtained Low-viscosity, high-permeability, and wide-ranging impregnation insulating resin. This fully impregnated insulating resin containing unsaturated bonds has good compatibility with epoxy glass powder mica less adhesive tape. Optional, the insulation structure of the less glue vacuum pressure impregnation process composed of the two can adapt to the requirements of the insulation structure of 3KV, 6KV and 1...

Embodiment 2

[0062] A main insulation structure for the stator coil of an F-class high-voltage motor. It adopts the vacuum pressure impregnation insulation method of the less-adhesive full-impregnation type insulation stator, and wraps it with less-adhesive powder mica tape. Composite insulation structure of vacuum pressure impregnation process; its feature is that the epoxy resin of the insulation structure of the motor vacuum pressure impregnation process contains unsaturated bonds, which is a synthetic unsaturated epoxy ester resin. After diluting with active diluent, it can be obtained Low-viscosity, high-permeability, and wide-ranging impregnation insulating resin. This fully impregnated insulating resin containing unsaturated bonds has good compatibility with epoxy glass powder mica less adhesive tape. Optional, the insulation structure of the less glue vacuum pressure impregnation process composed of the two can adapt to the requirements of the insulation structure of 3KV, 6KV and 1...

Embodiment 3

[0091] A main insulation structure for the stator coil of an F-class high-voltage motor. It adopts the vacuum pressure impregnation insulation method of the less-adhesive full-impregnation type insulation stator, and wraps it with less-adhesive powder mica tape. Composite insulation structure of vacuum pressure impregnation process; its feature is that the epoxy resin of the insulation structure of the motor vacuum pressure impregnation process contains unsaturated bonds, which is a synthetic unsaturated epoxy ester resin. After diluting with active diluent, it can be obtained Low-viscosity, high-permeability, and wide-ranging impregnation insulating resin. This fully impregnated insulating resin containing unsaturated bonds has good compatibility with epoxy glass powder mica less adhesive tape. Optional, the insulation structure of the less glue vacuum pressure impregnation process composed of the two can adapt to the requirements of the insulation structure of 3KV, 6KV and 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com