Patents

Literature

42results about How to "High thermal conductivity material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

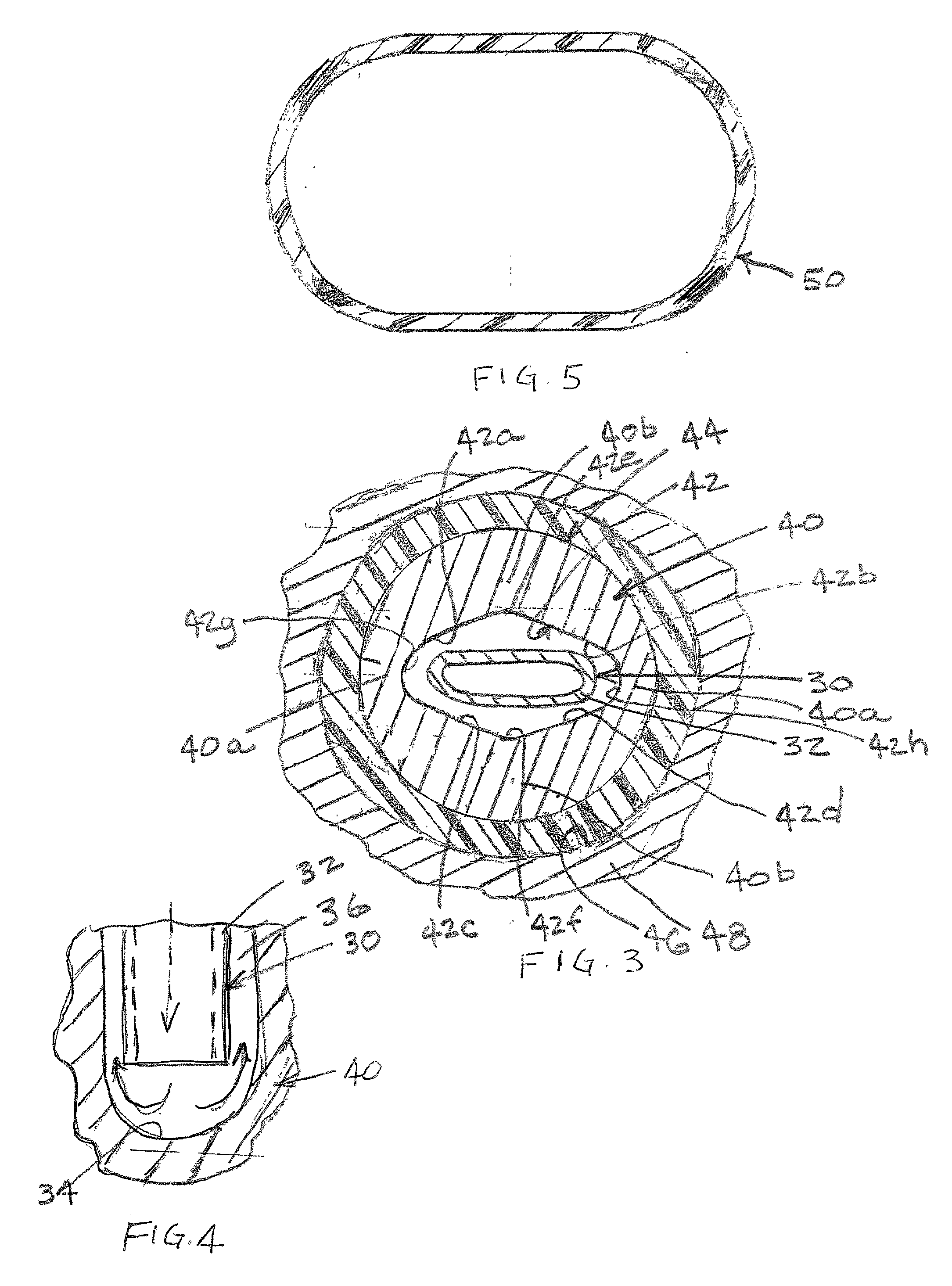

Compression of resin impregnated insulating tapes

ActiveUS20050274450A1Easy to disperseReduces phonon scatteringWindings insulation materialAdhesive processes with surface pretreatmentThermal conductivity

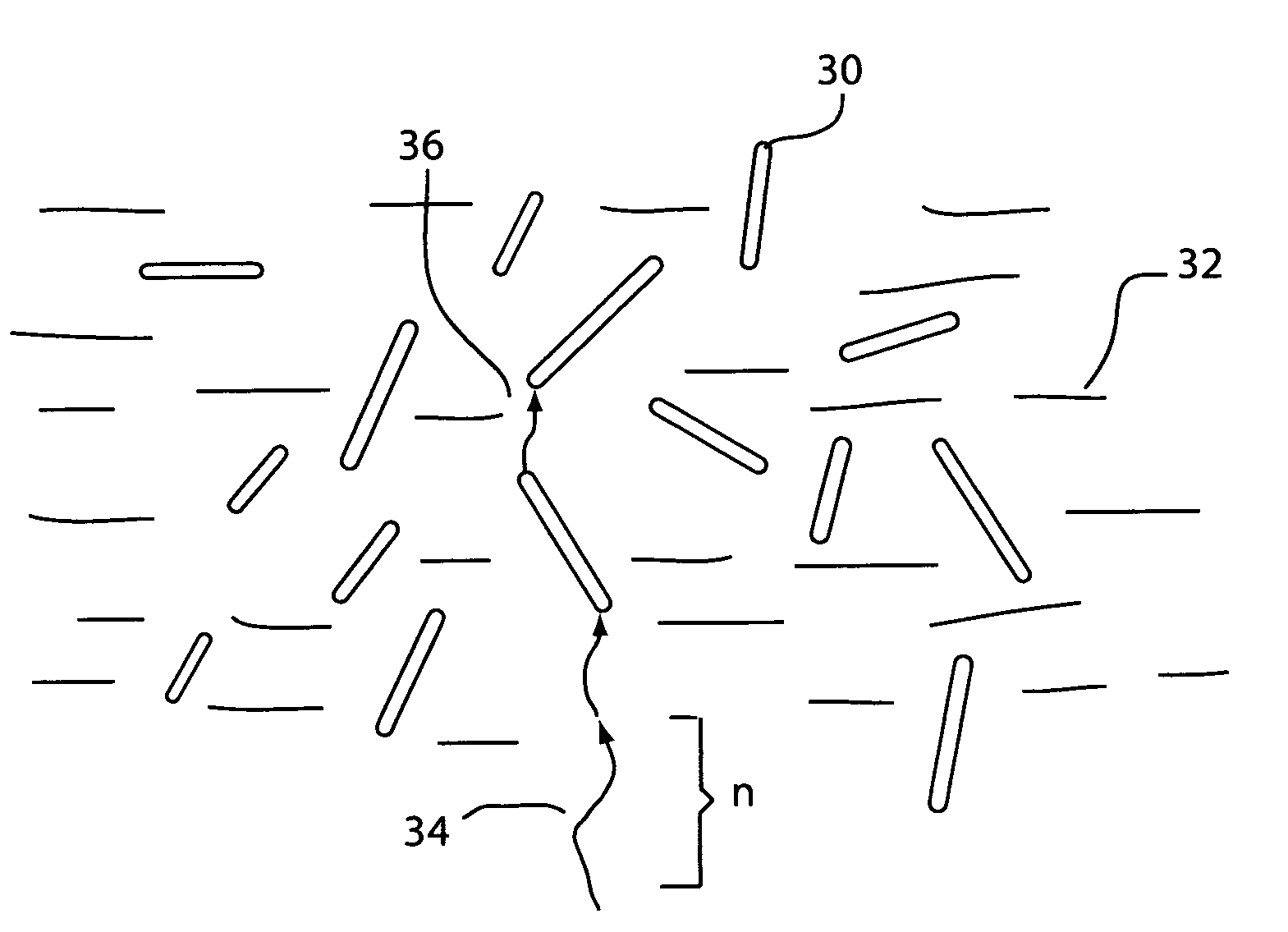

The present invention provides for a method of impregnating a matrix with a high thermal conductivity filled resin 32, which produces a resin impregnated matrix. The high thermal conductivity material 30 comprises 5-60% by volume of the resin 32. This is compressed by approximately 5-30%, and the distances between the high thermal conductivity materials loaded in the resin are reduced, and the resin is then cured.

Owner:SIEMENS ENERGY INC

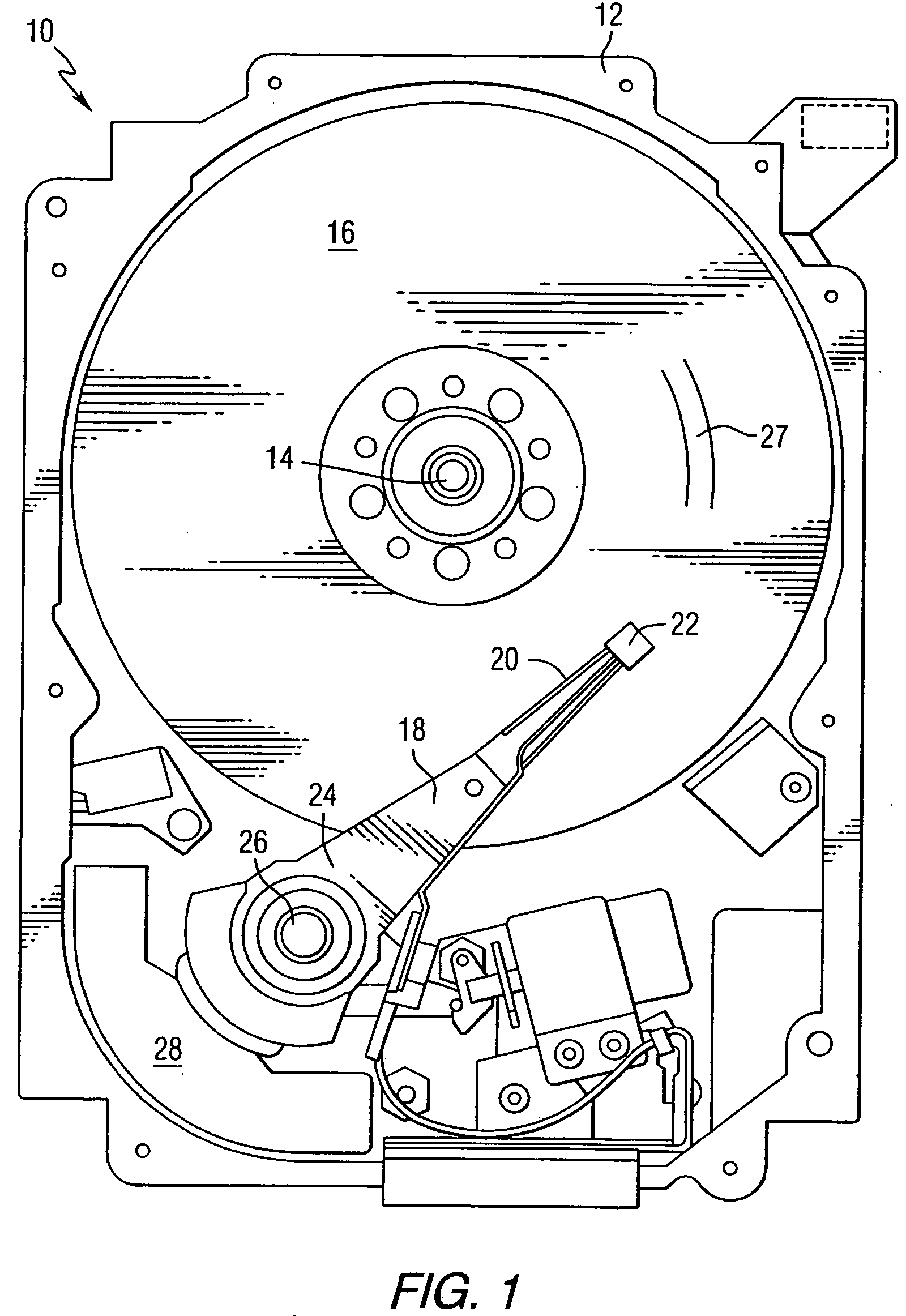

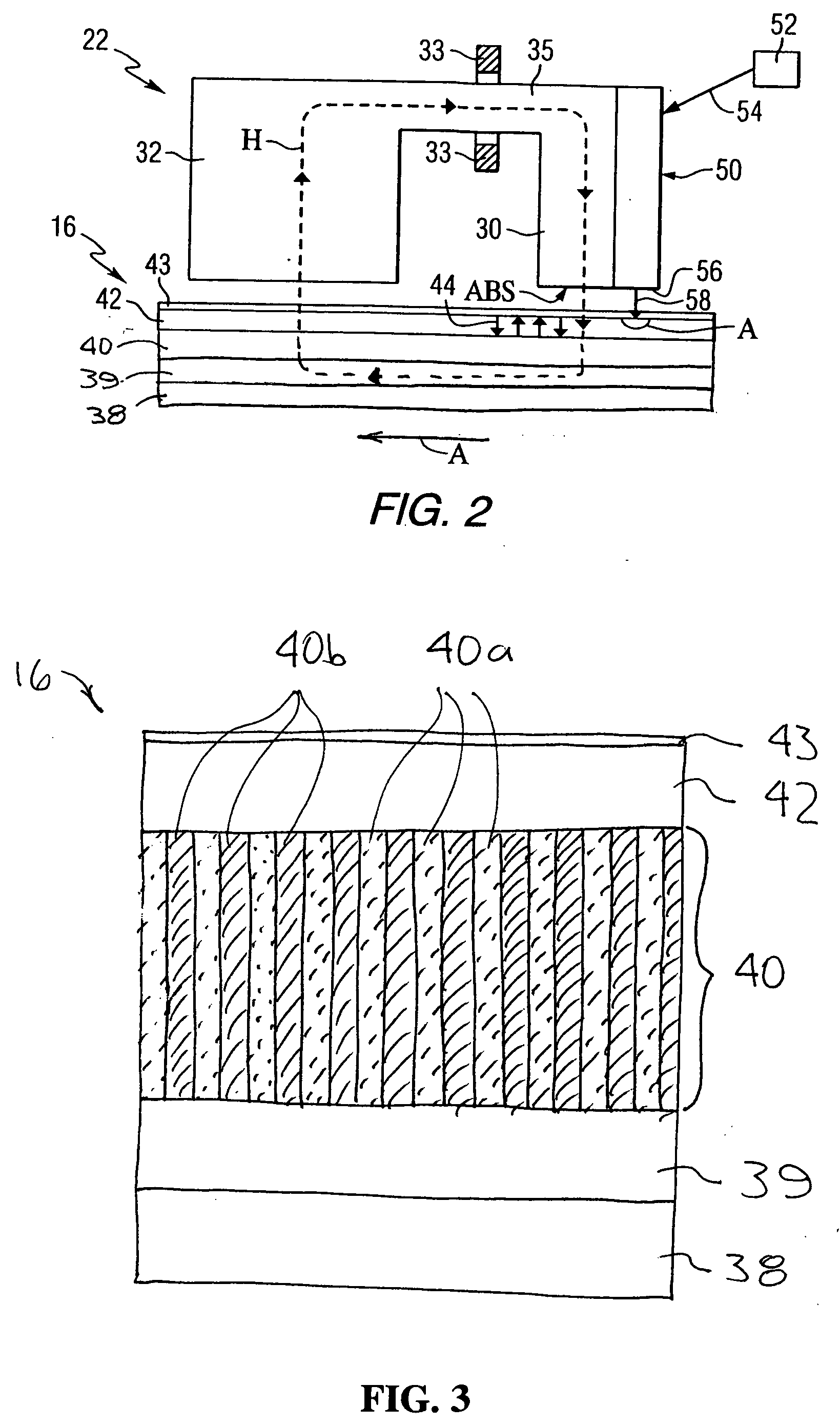

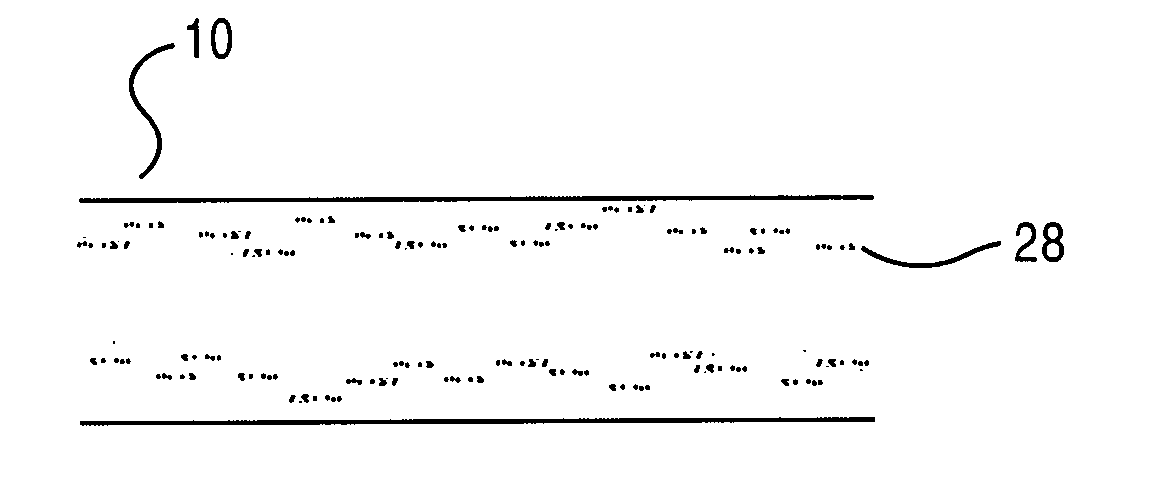

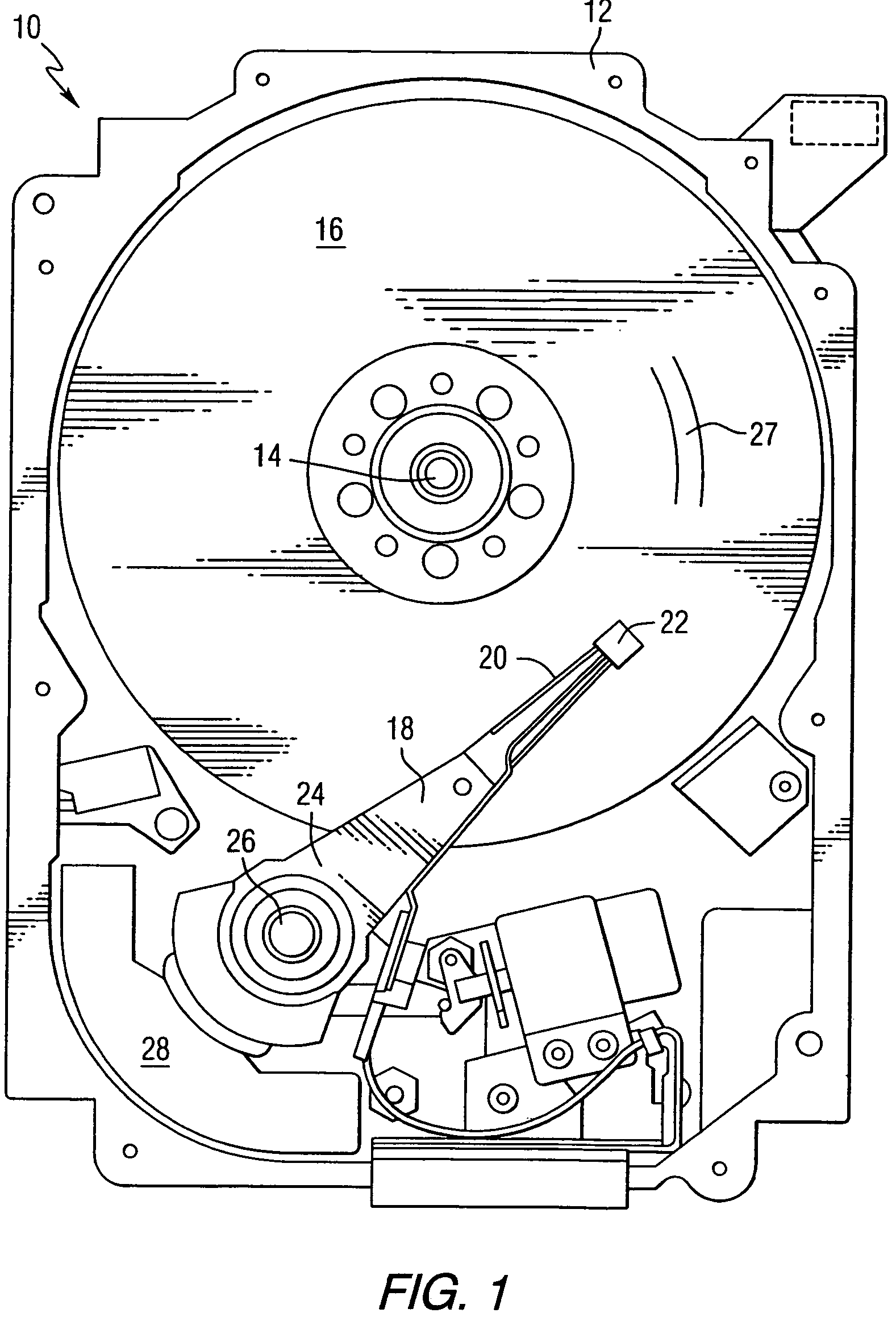

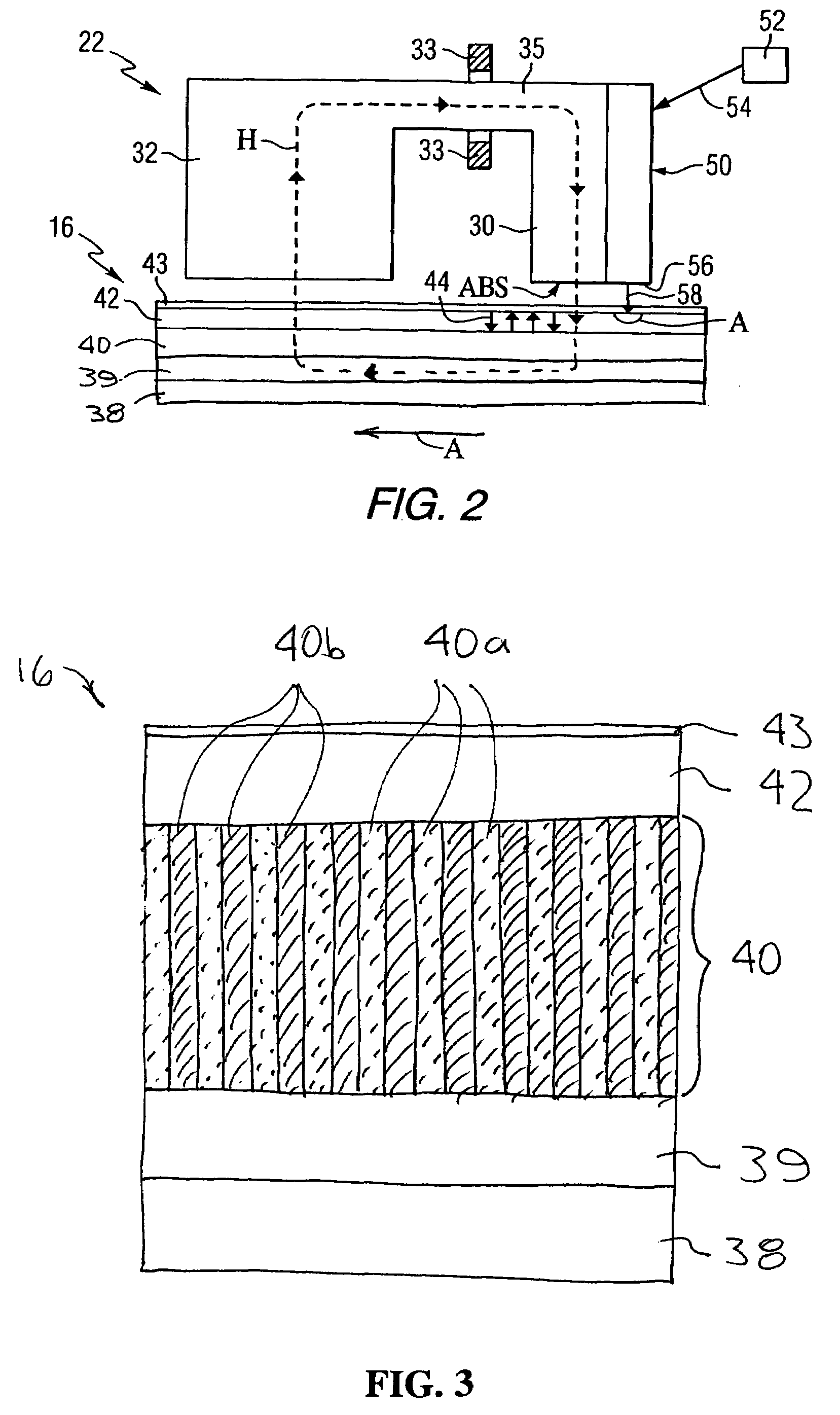

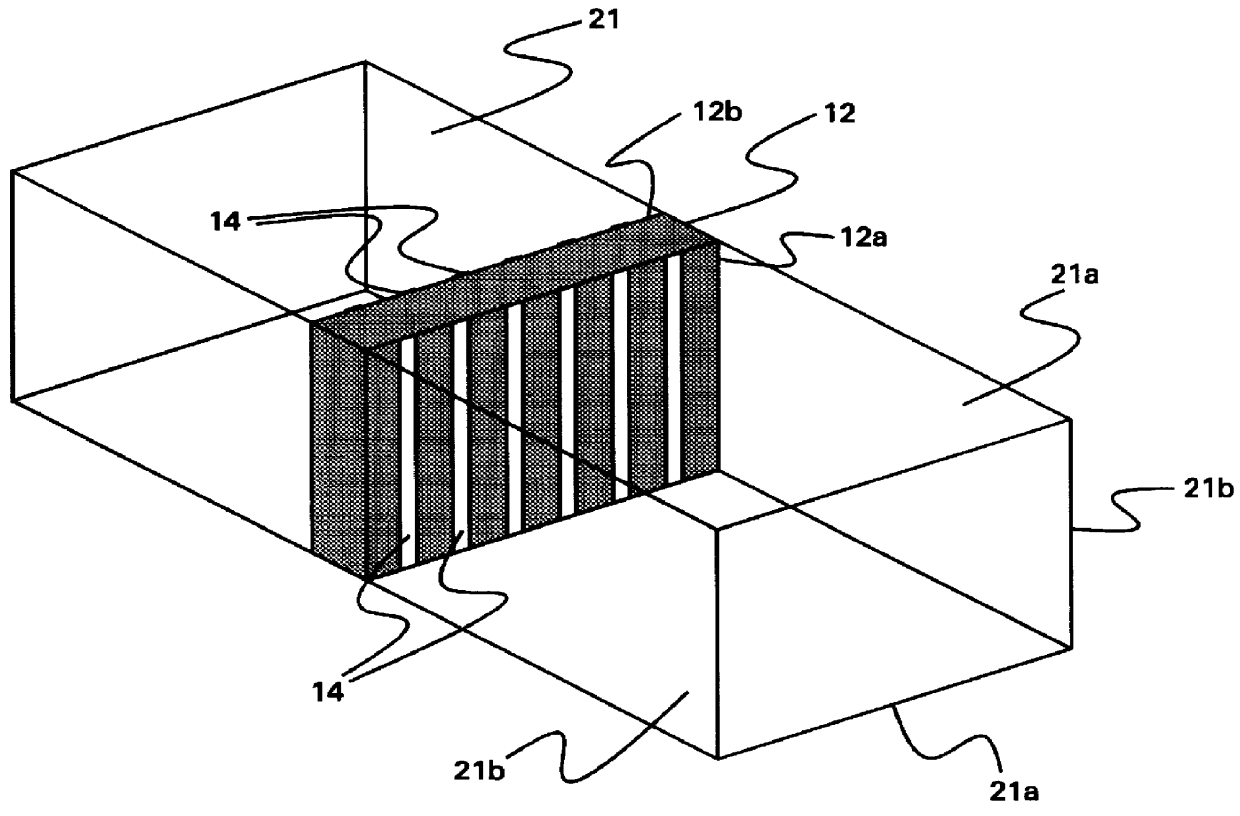

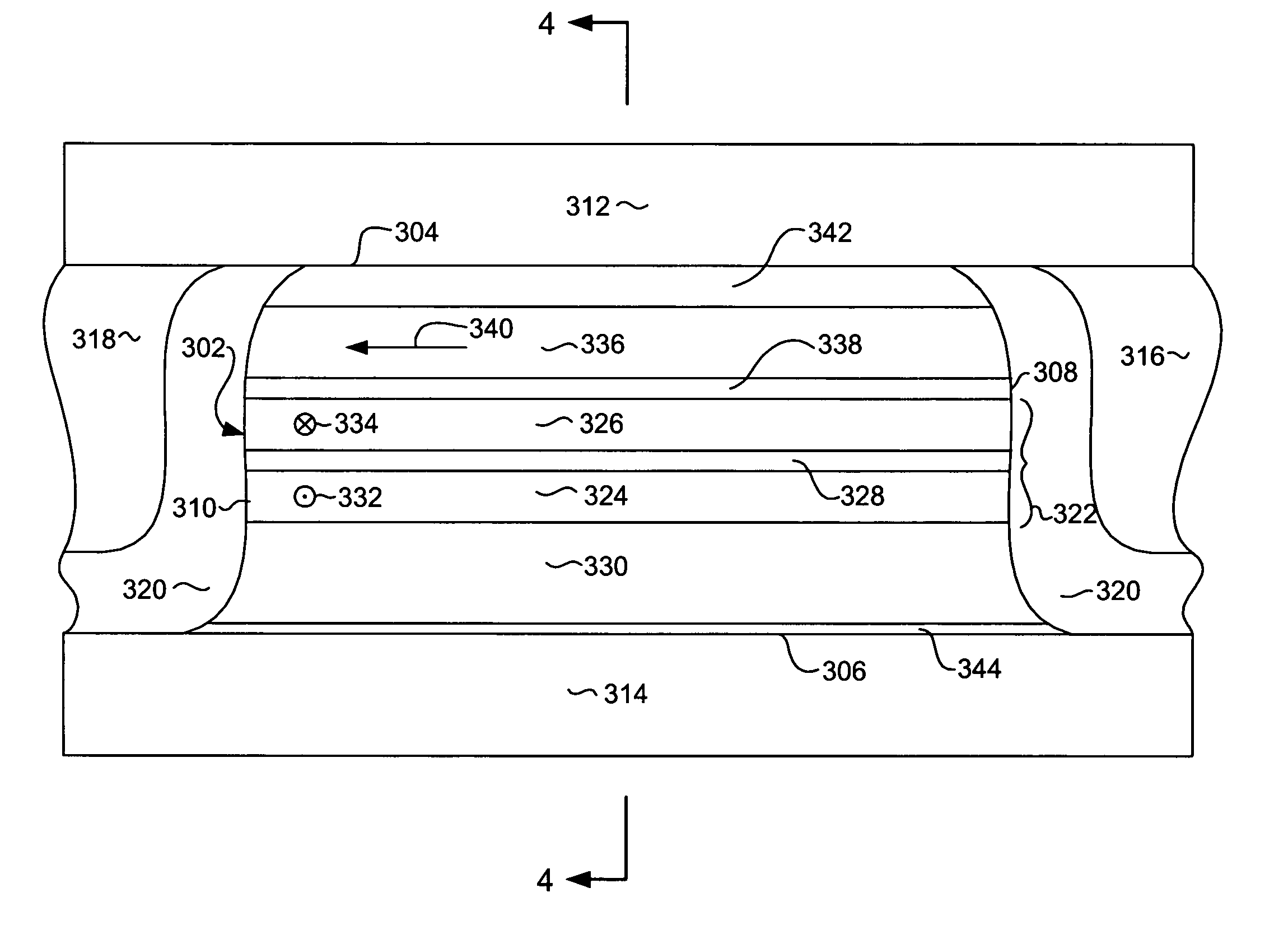

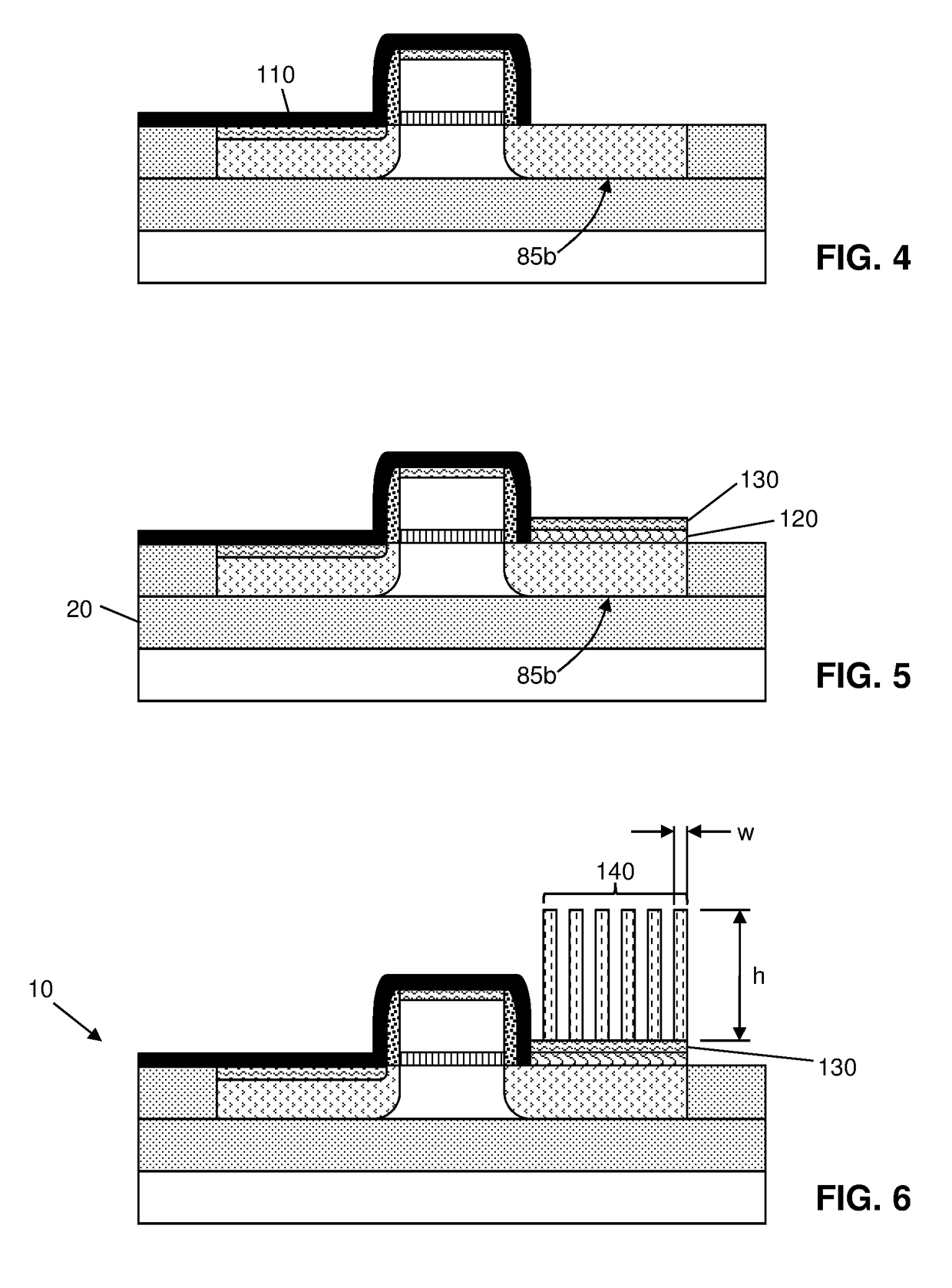

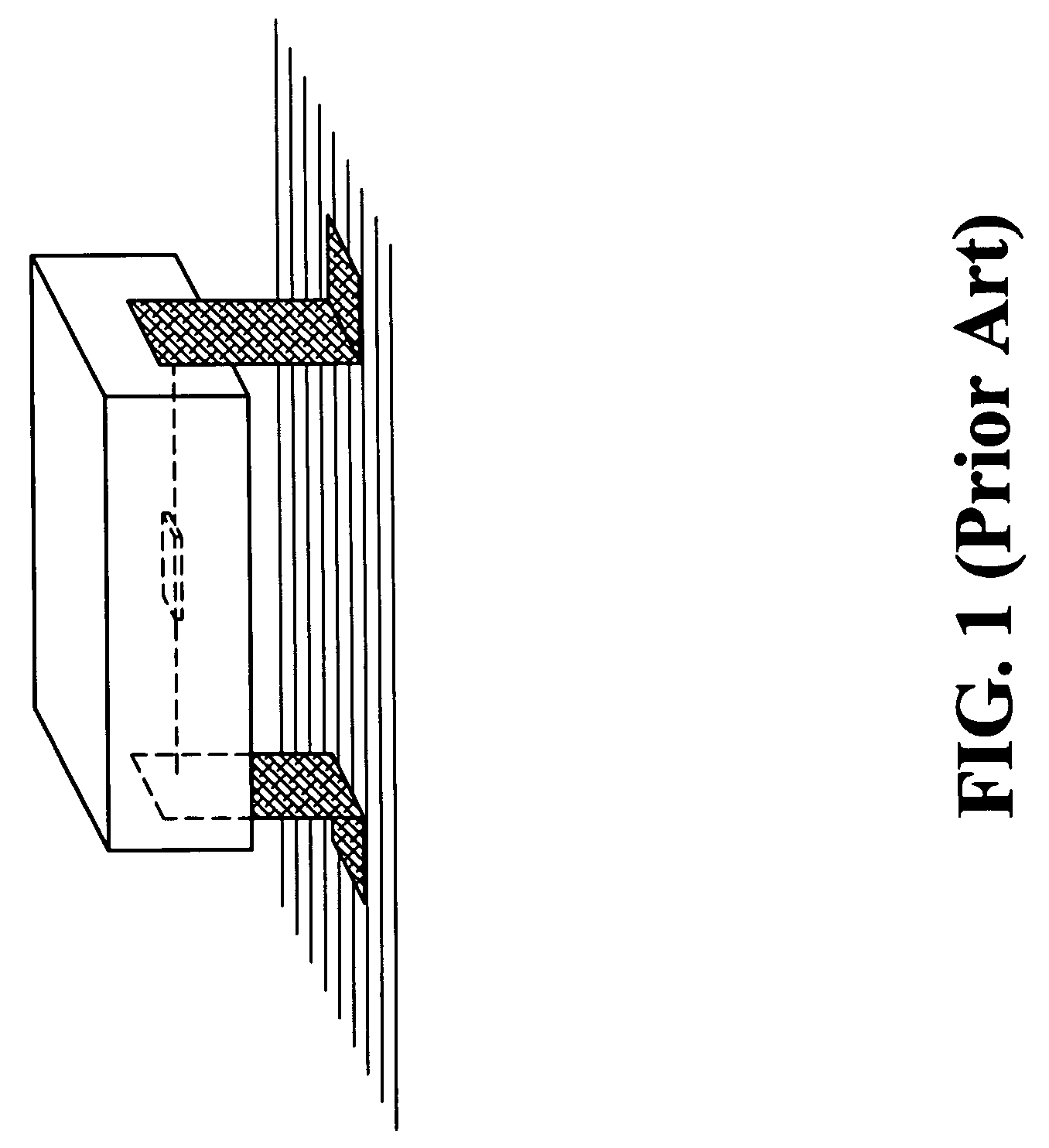

Patterned thin films and use of such films as thermal control layers in heat assisted magnetic recording media

ActiveUS20060154110A1Reduce heat transferImprove heat transfer performanceRecording by magnetic meansNanoinformaticsHeat-assisted magnetic recordingOptoelectronics

Patterned thin films comprise regions of relatively low thermal conductivity material separated by regions of relatively high thermal conductivity material. The low thermal conductivity regions may be provided in the form of cylinders or cuboids which are arranged in a continuous matrix of the high thermal conductivity material. The thin film may be used as thermal control layers in data recording media such as heat assisted magnetic recording media.

Owner:SEAGATE TECH LLC

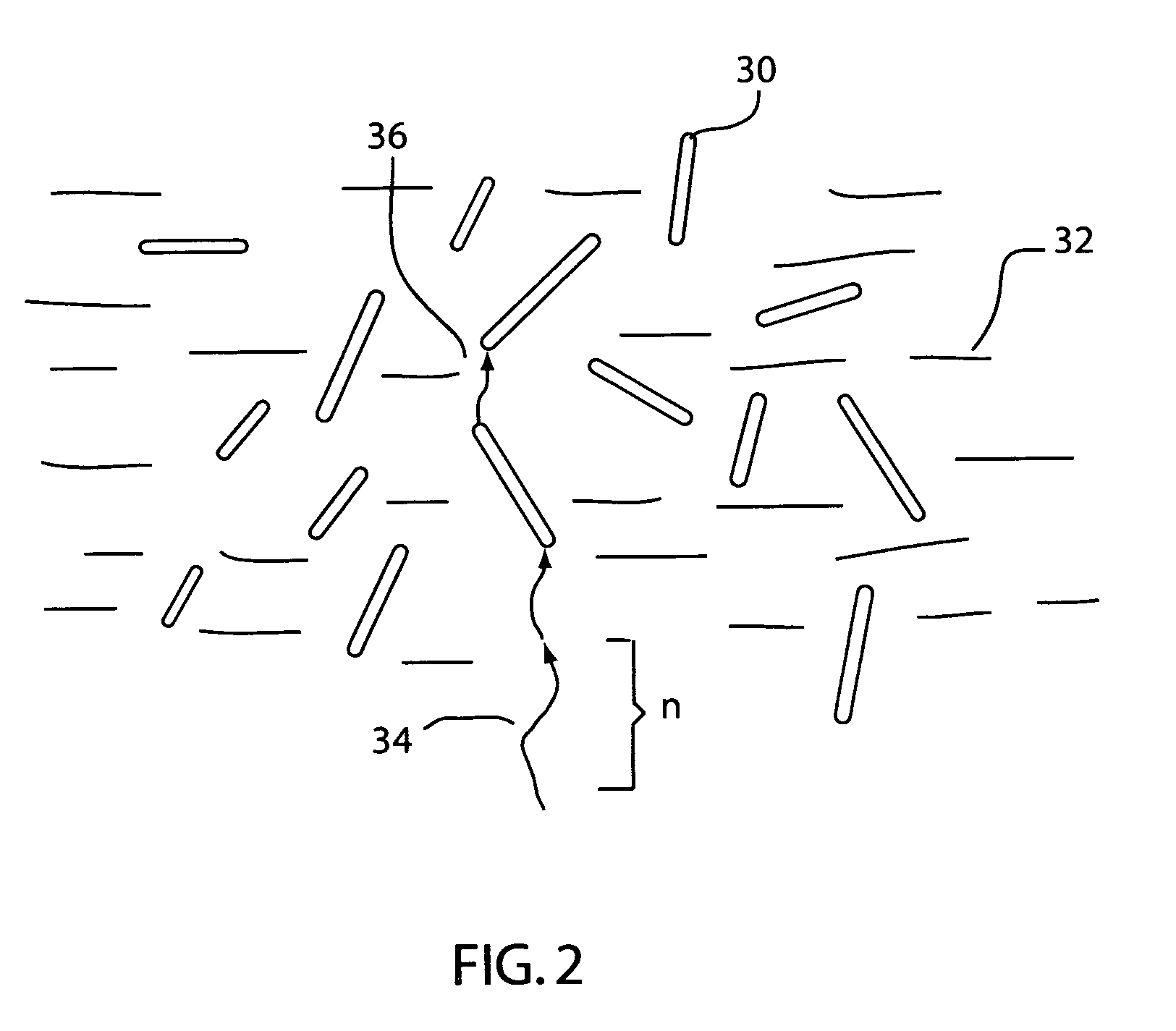

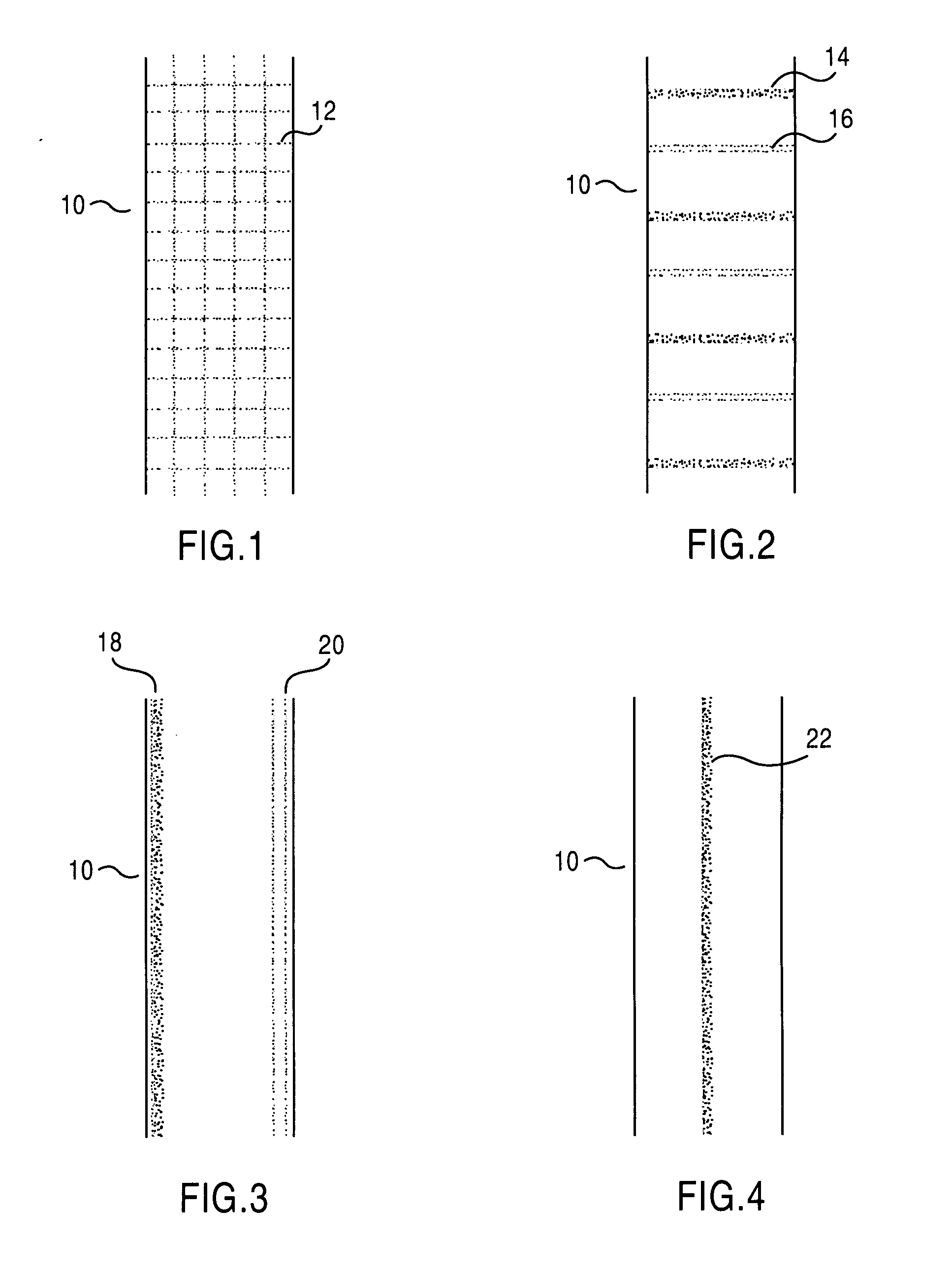

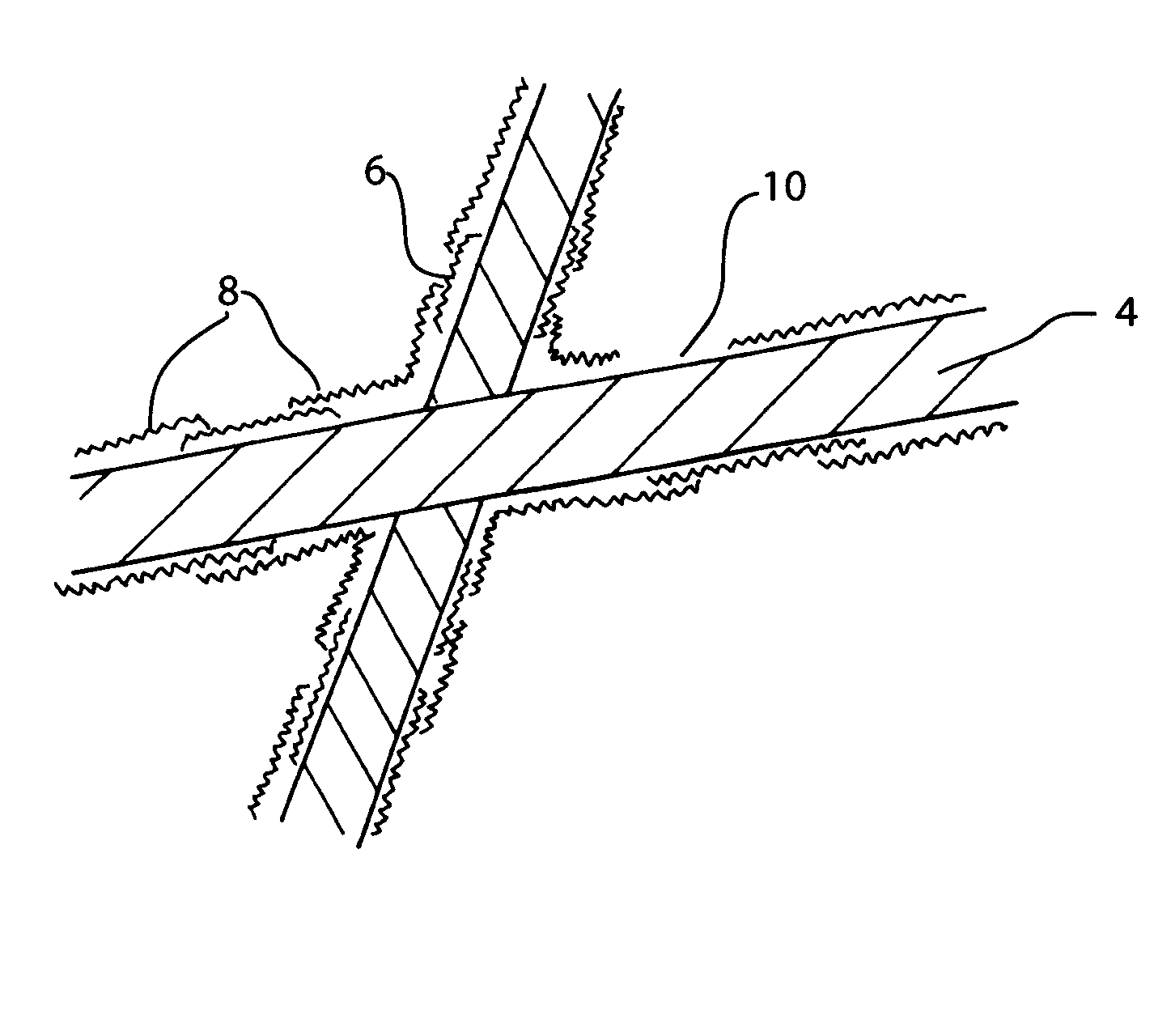

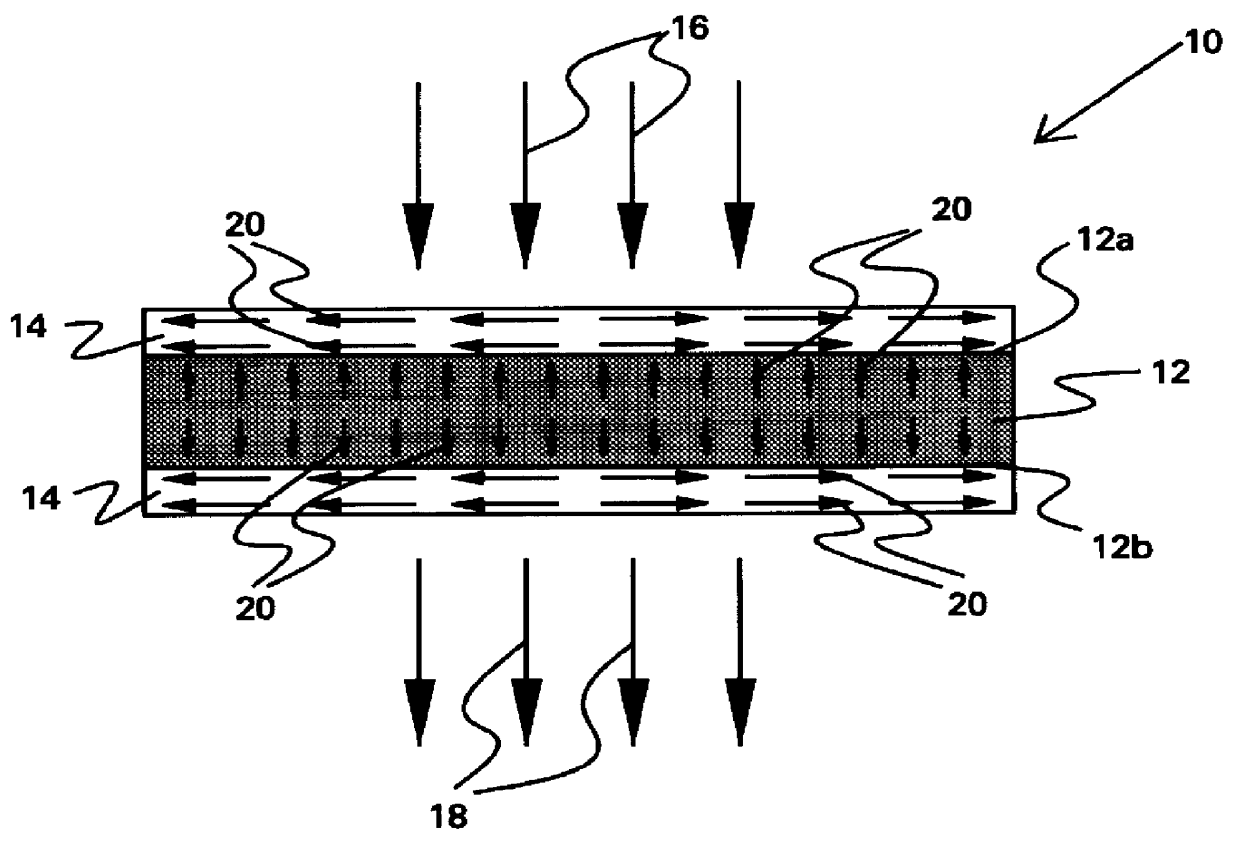

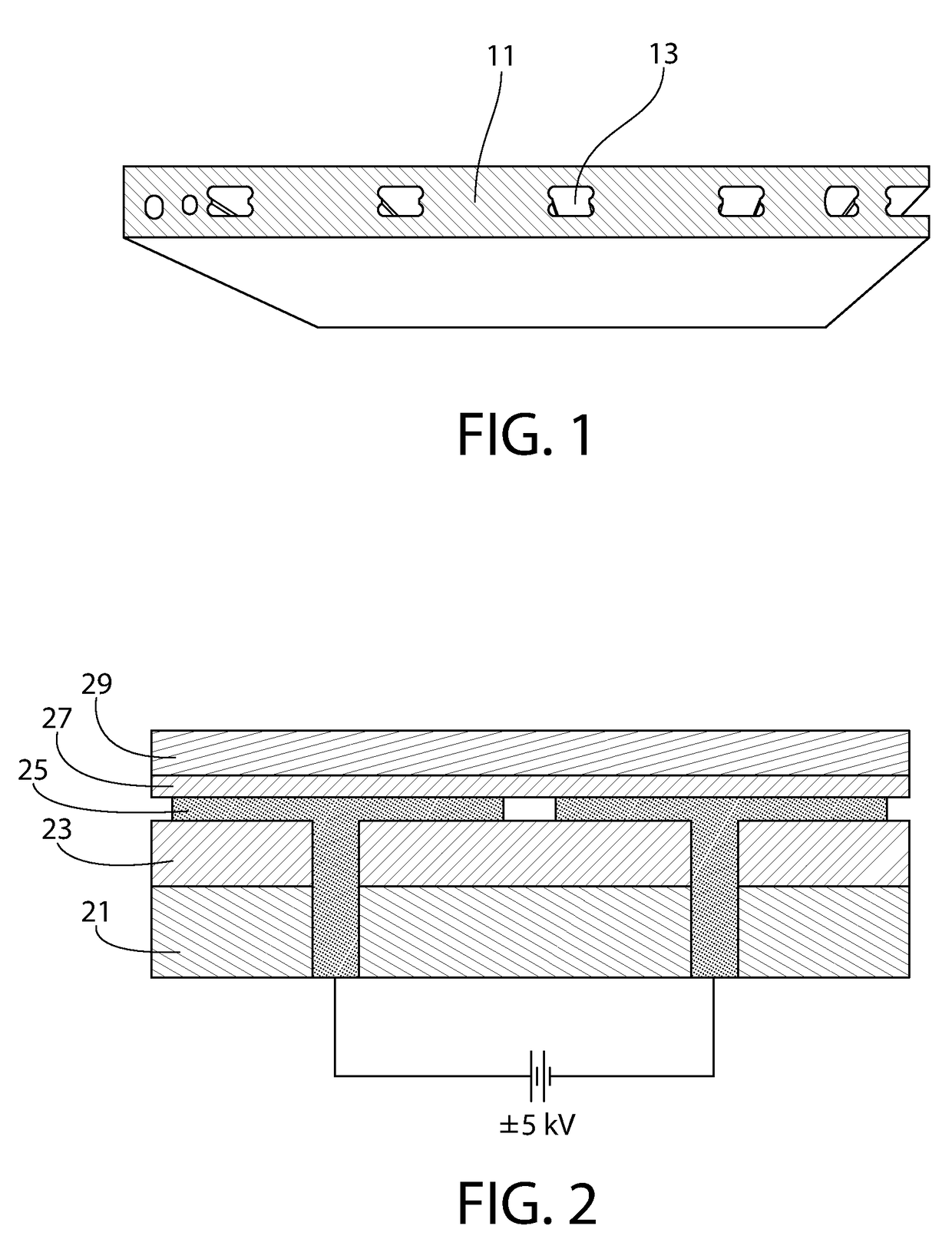

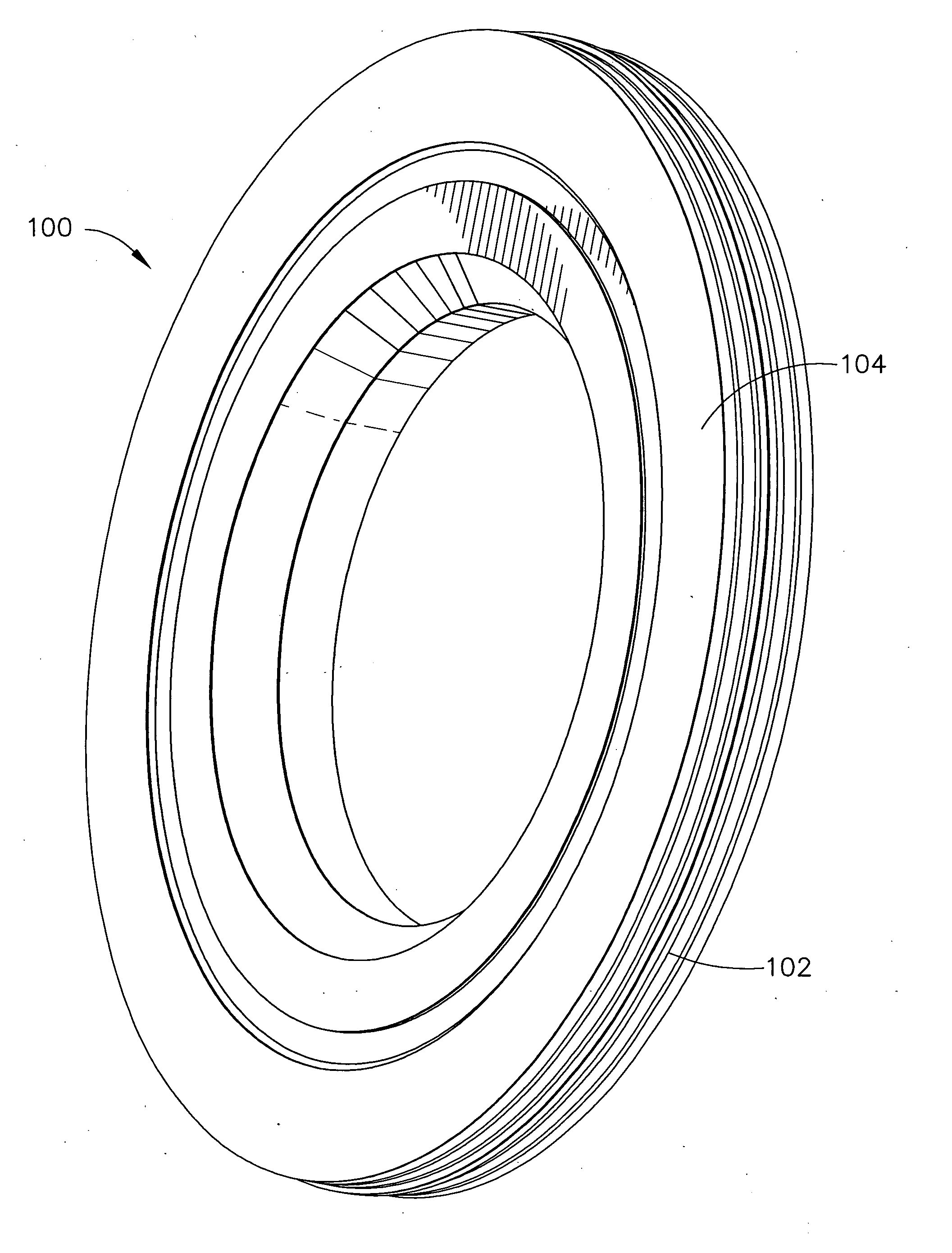

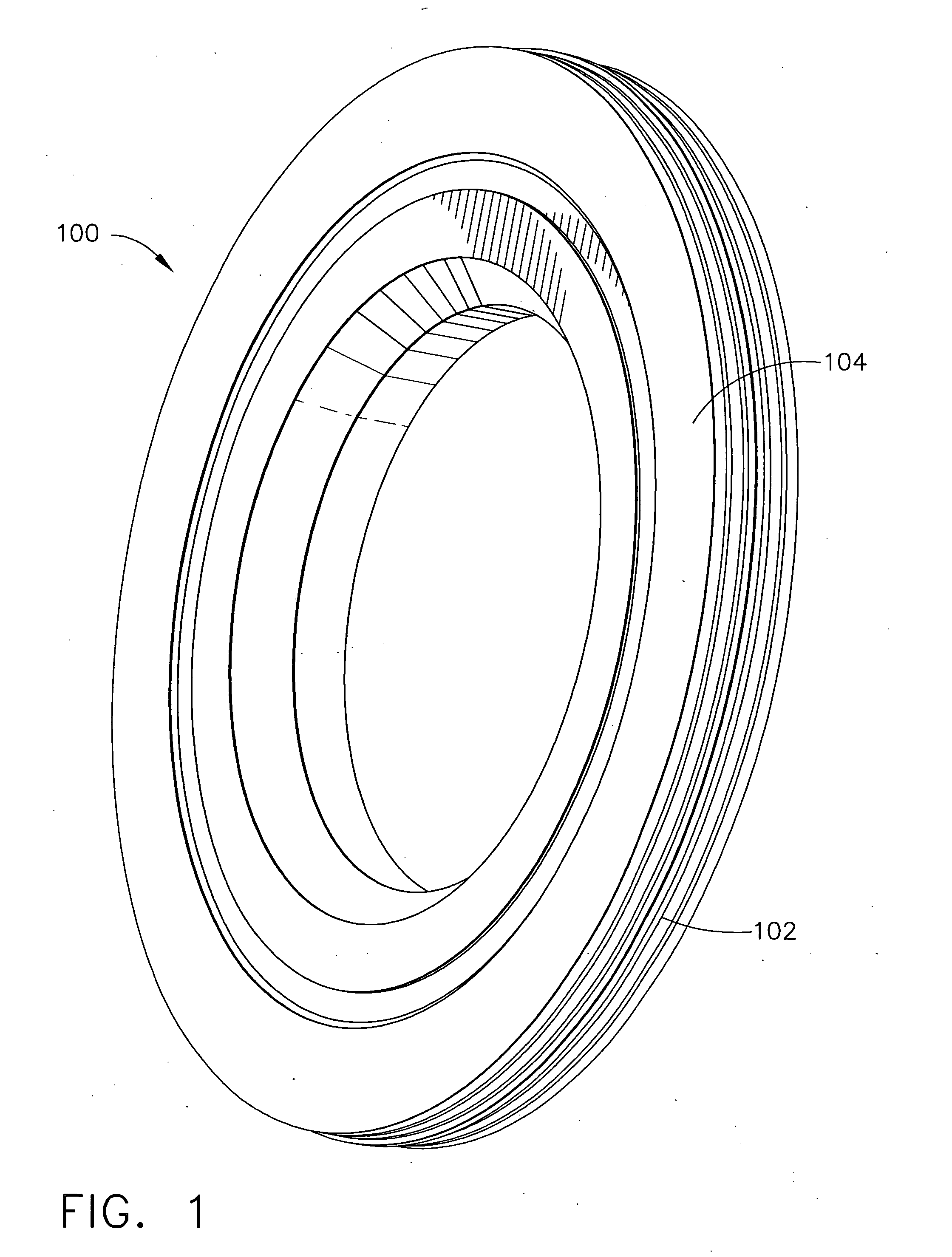

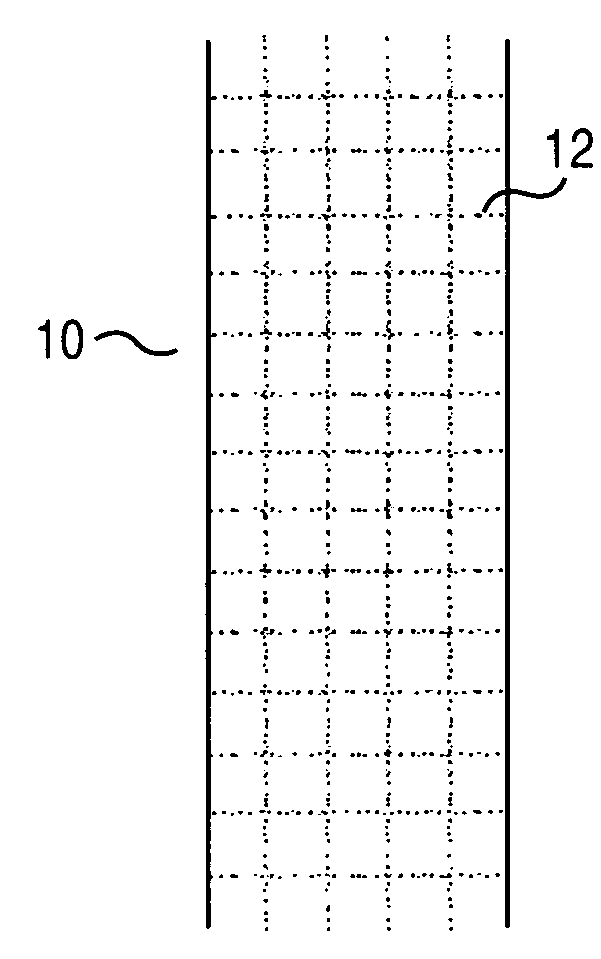

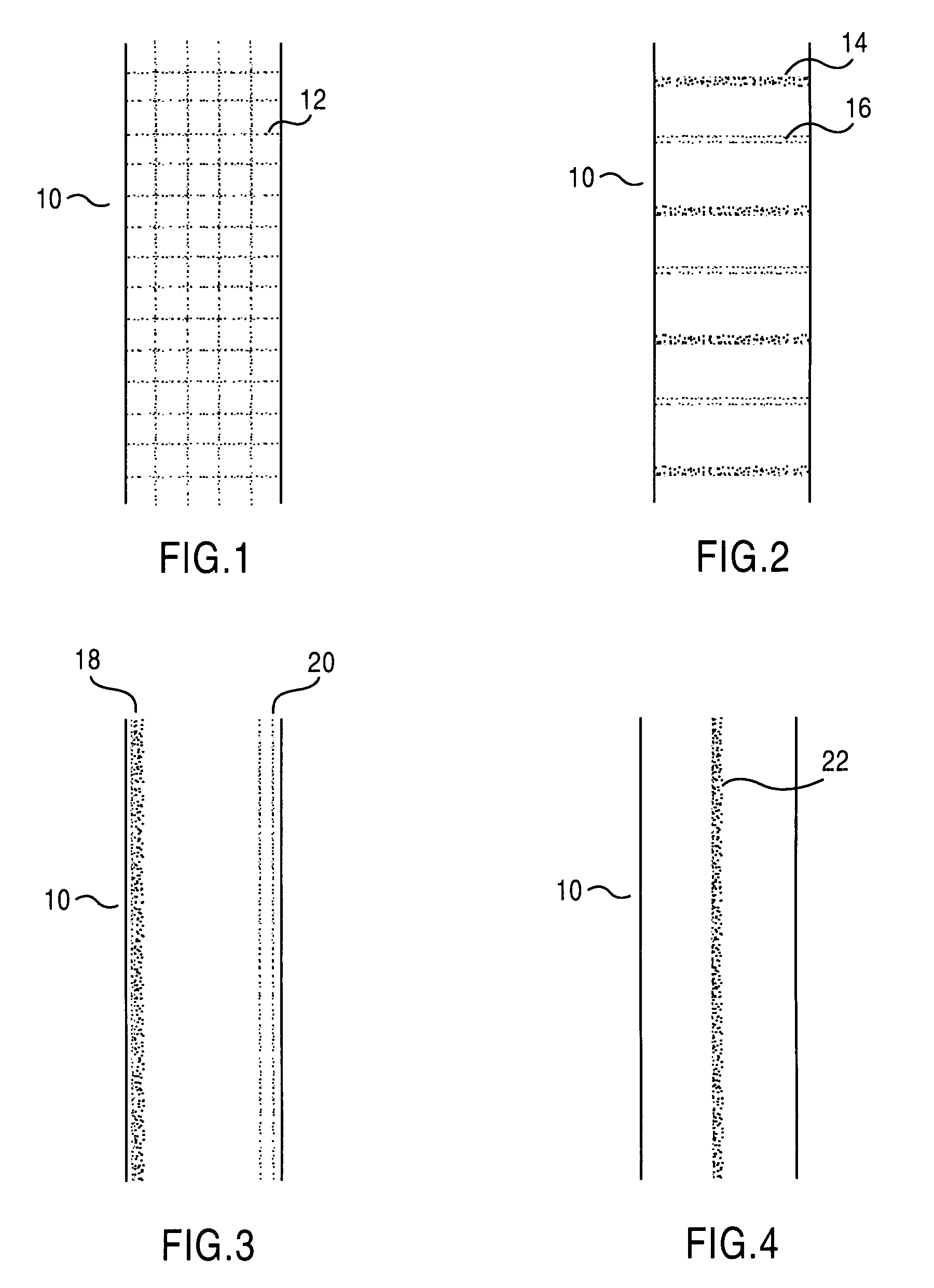

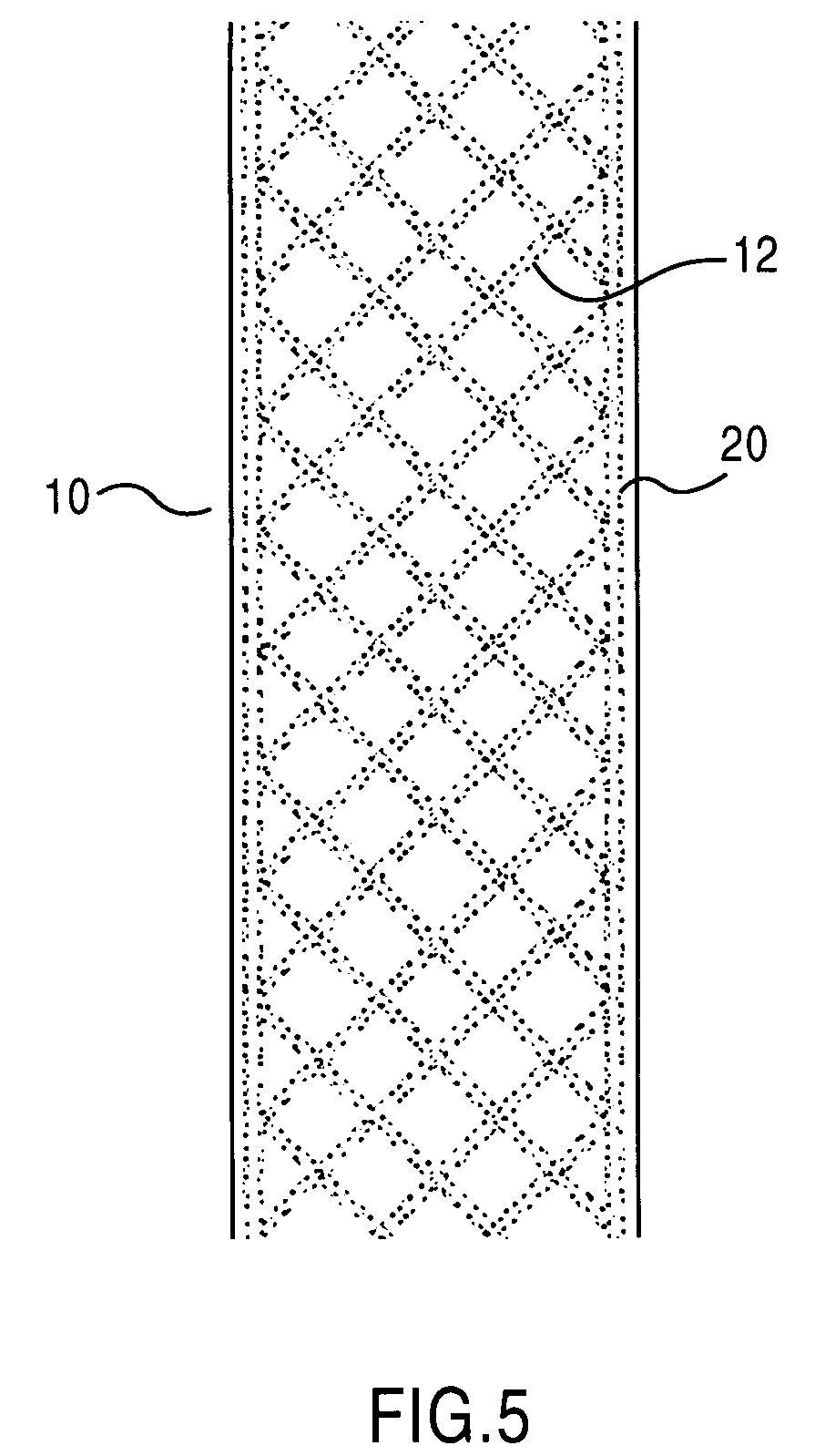

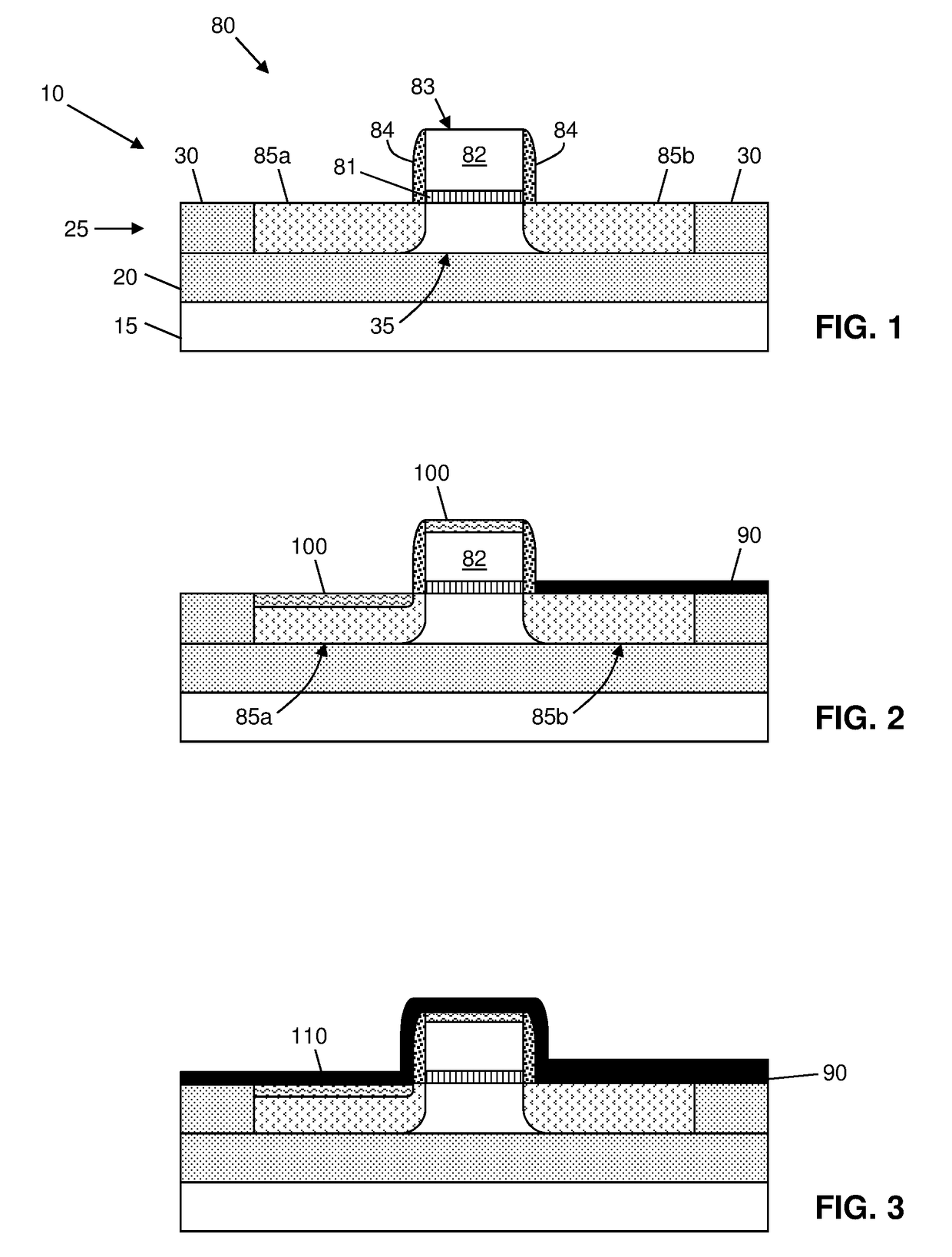

Patterning on surface with high thermal conductivity materials

ActiveUS20060234576A1Improve thermal conductivityHigh resistivityAdhesive articlesPaper/cardboardNanometreThermal transmittance

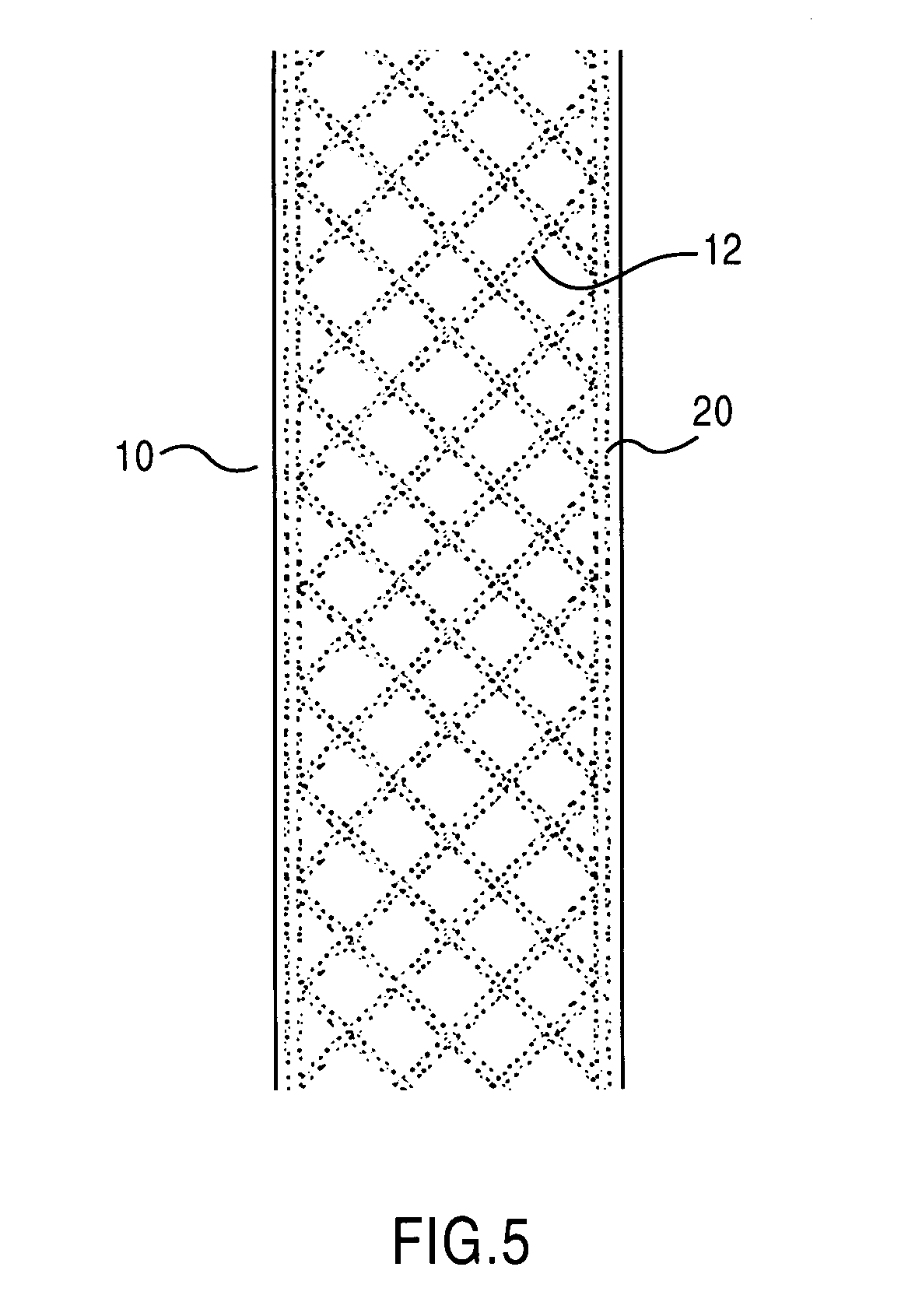

The present invention provides for high thermal conductivity paper that comprises a host matrix (10), and high thermal conductivity materials (12) added to a surface of the host matrix in a specific pattern (12). The high thermal conductivity materials are comprised of one or more of nanofillers, diamond like coatings directly on the host matrix, and diamond like coatings on the nanofillers. In particular embodiments the specific pattern comprises one or more of a grid, edging, banding centering and combinations thereof and the high thermal conductivity materials cover 15-55% of the surface of the host matrix. Multiple surfaces, including sub layers my have patterning.

Owner:SIEMENS ENERGY INC

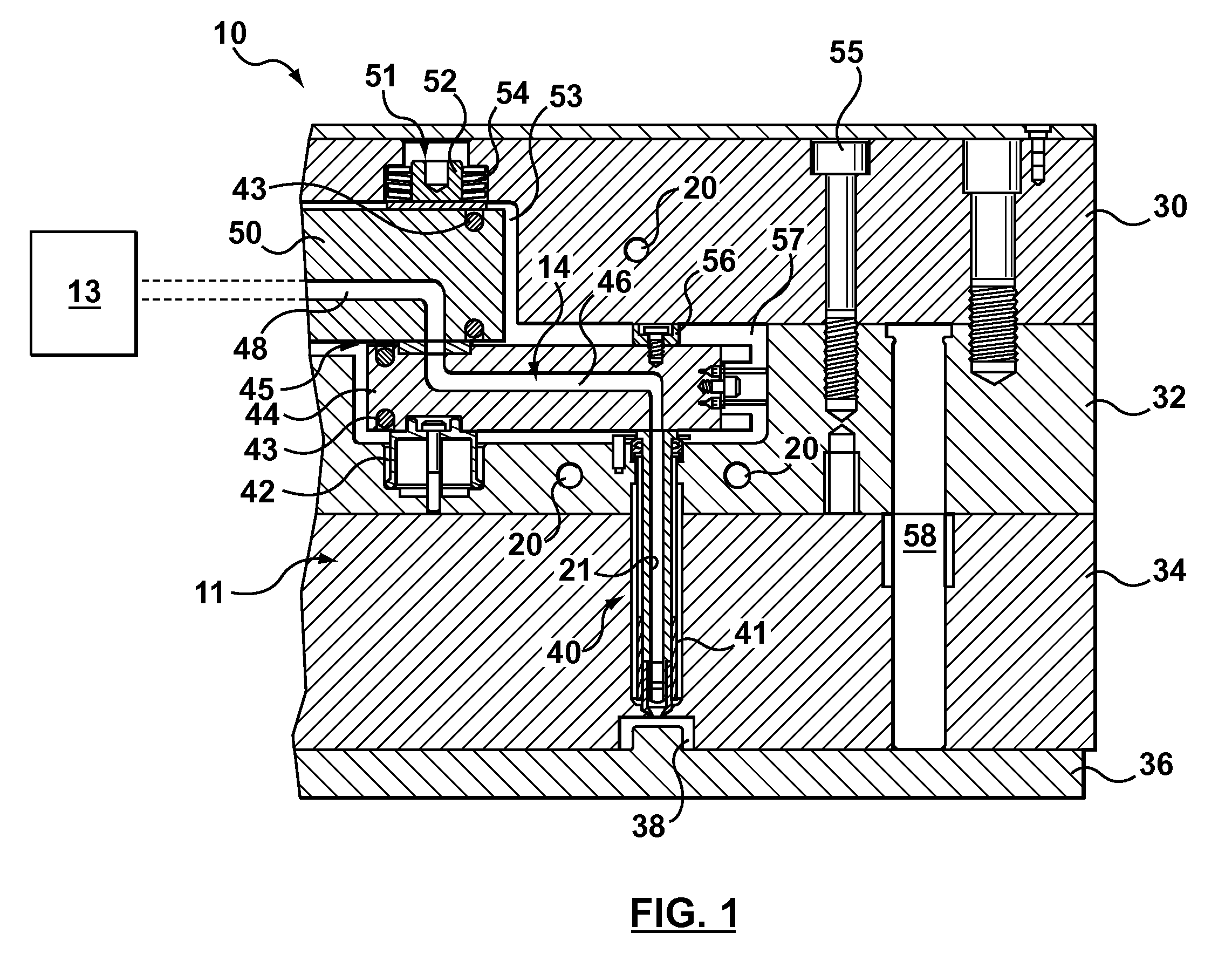

Integrated thermal management system

InactiveUS20150237762A1Lower operating temperatureEasy to operateHeat storage plantsSemiconductor/solid-state device detailsThermal management systemEngineering

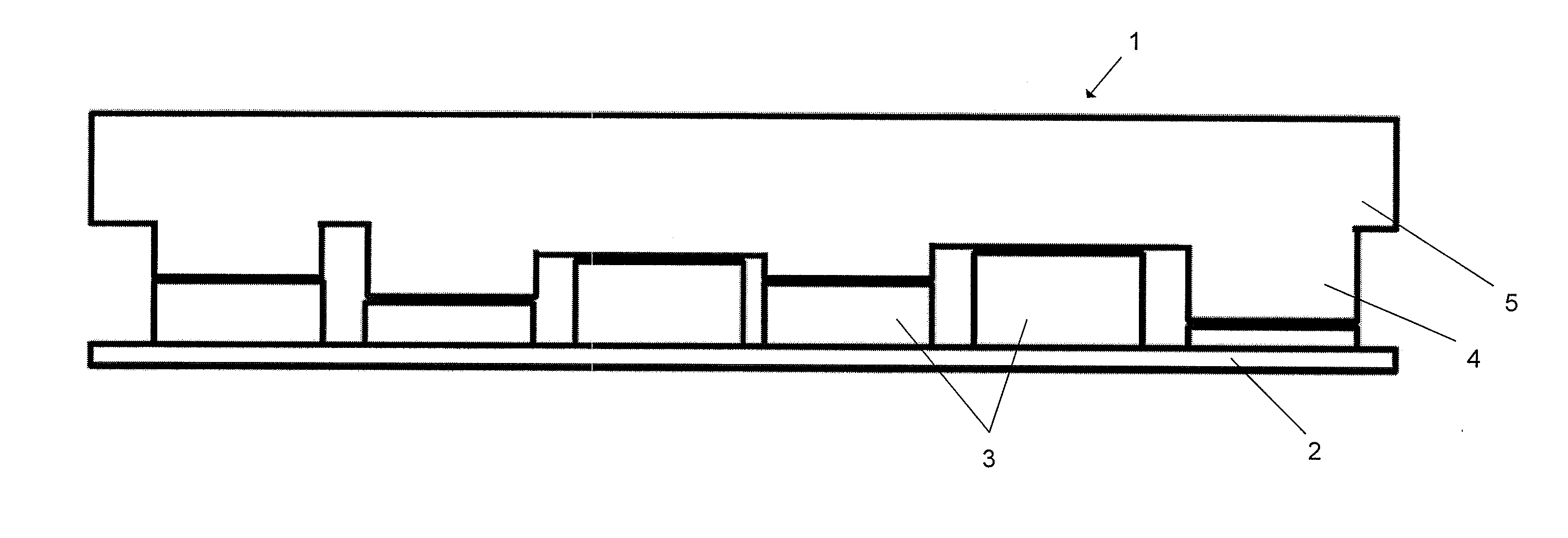

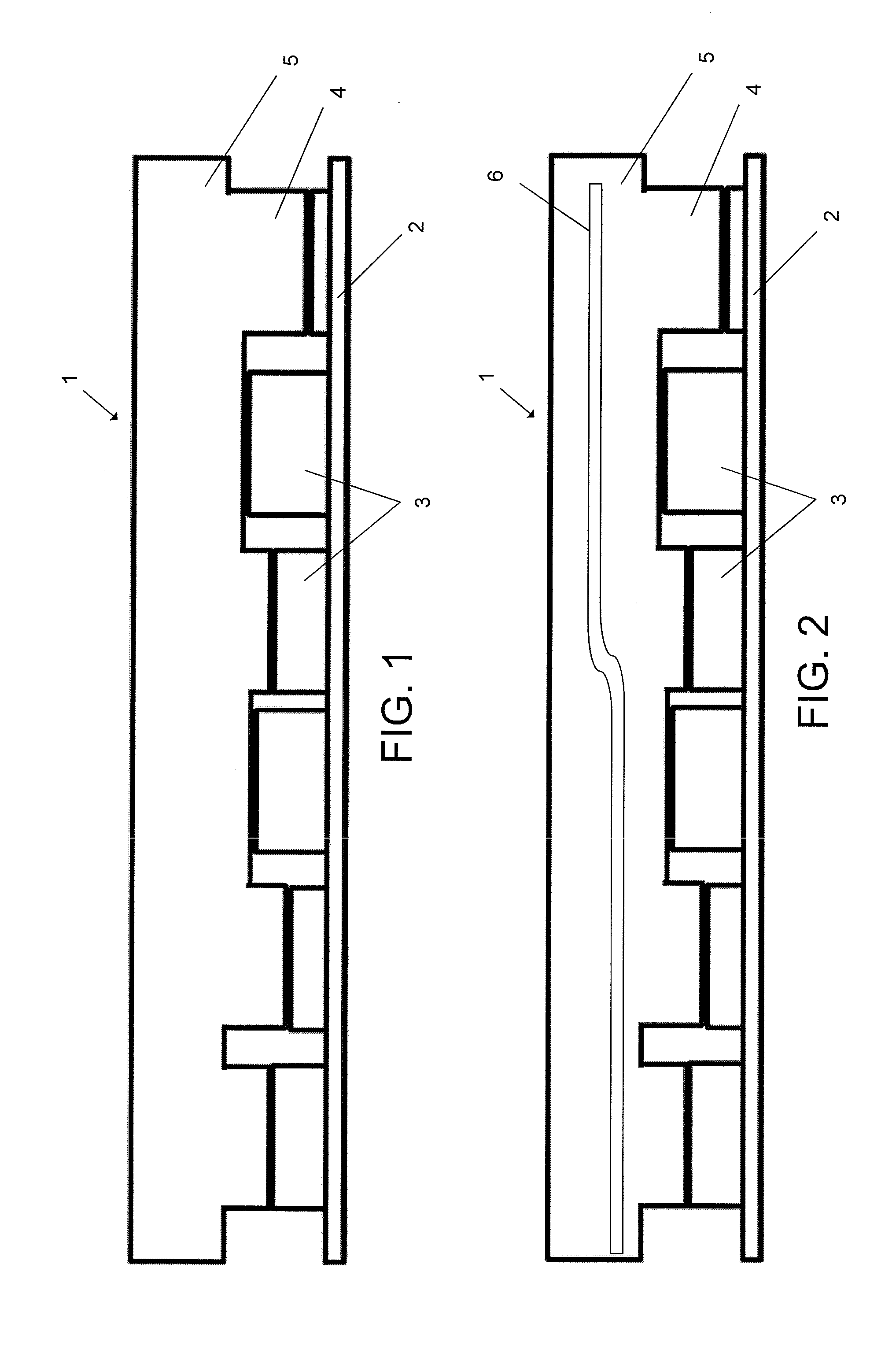

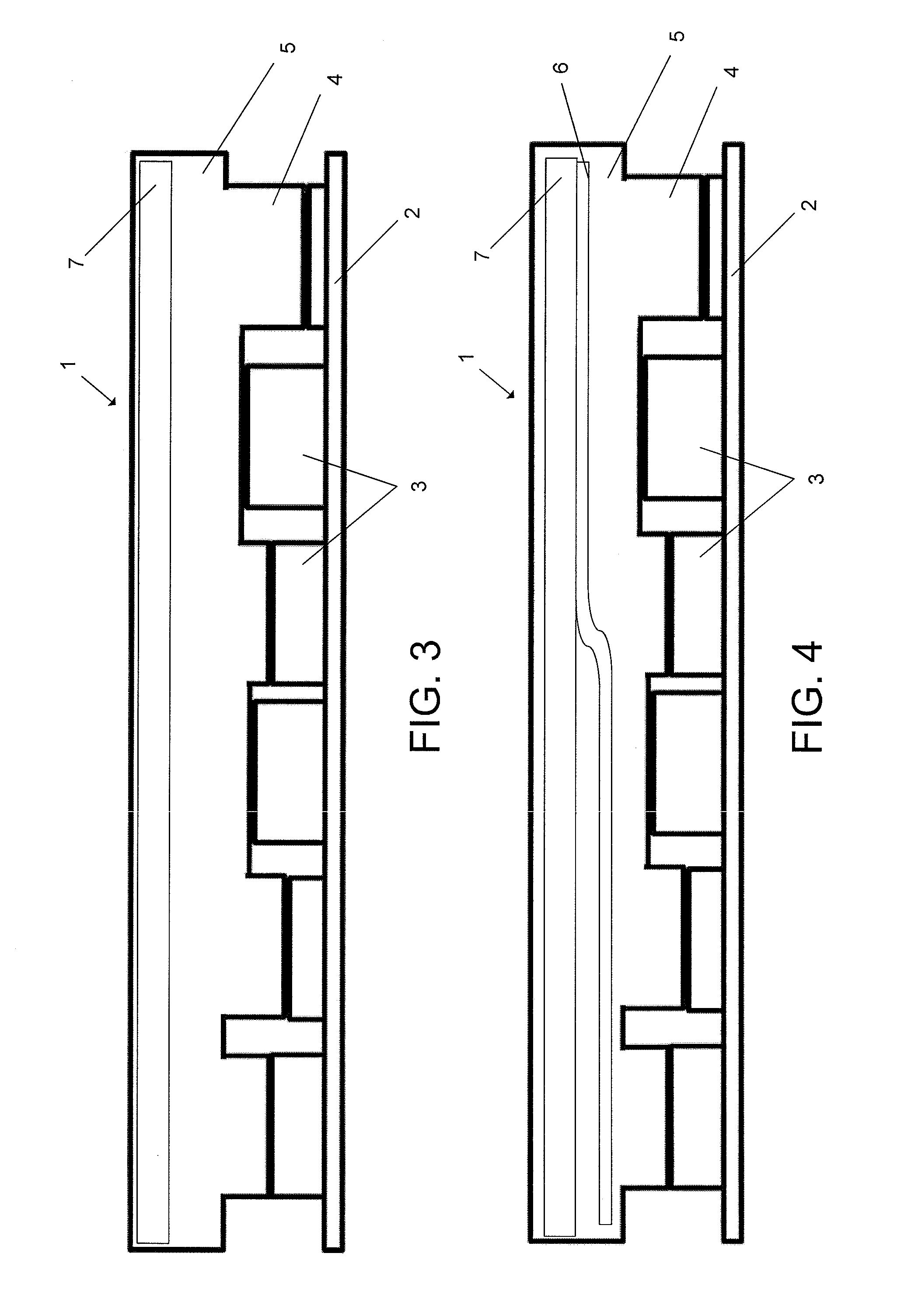

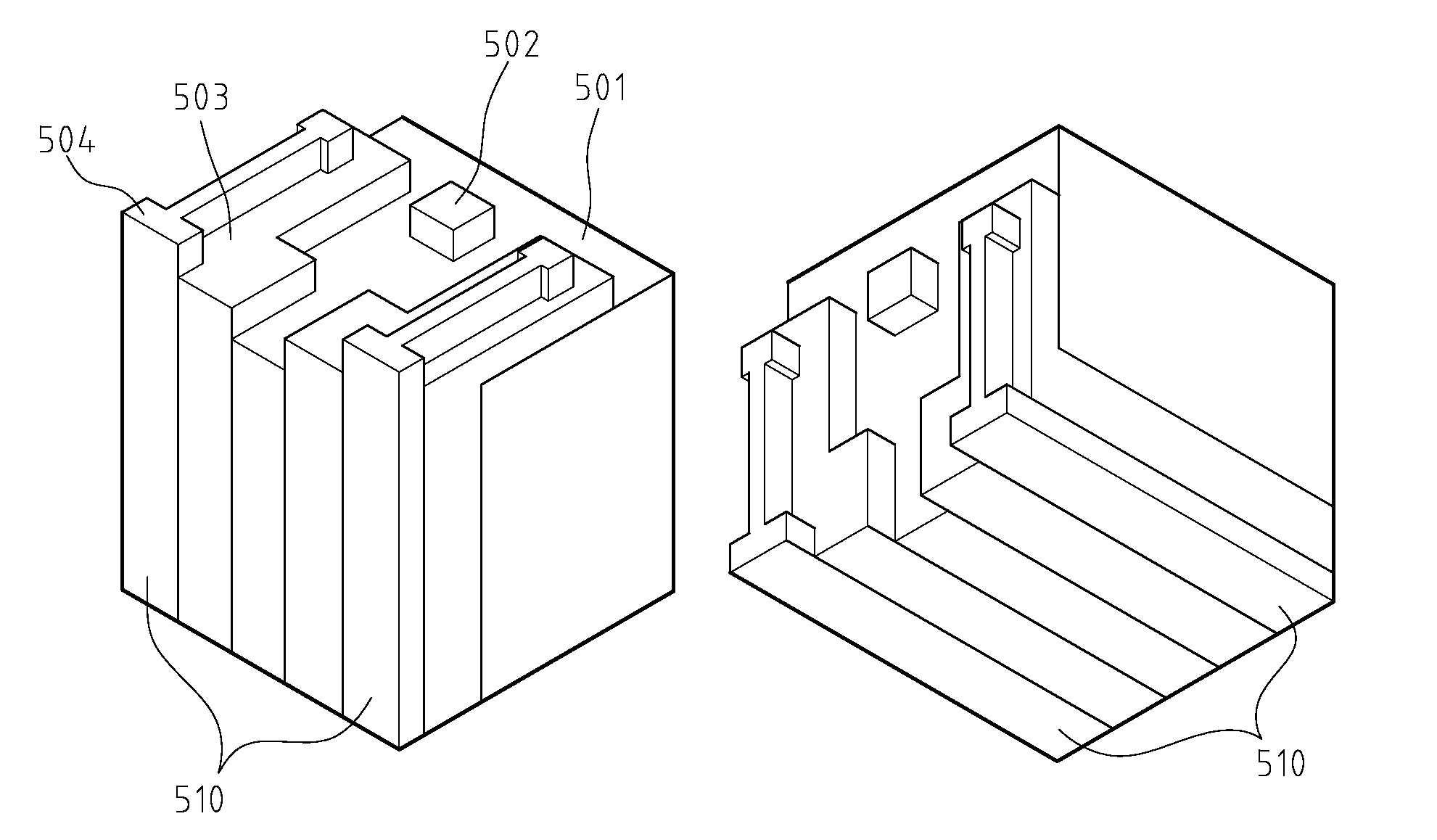

A thermal management system for a heat generating electrical component and a method of making such a thermal management system. Additive manufacturing is used to form at least a portion of the thermal management system as a unitary, monolithic structure. Such a structure maximizes heat transfer by reducing or eliminating thermal interfaces between the components of the thermal management system. The use of additive manufacturing also allows for the production of varying thermal management system geometries that are not possible with conventional methods.

Owner:RAYTHEON CO

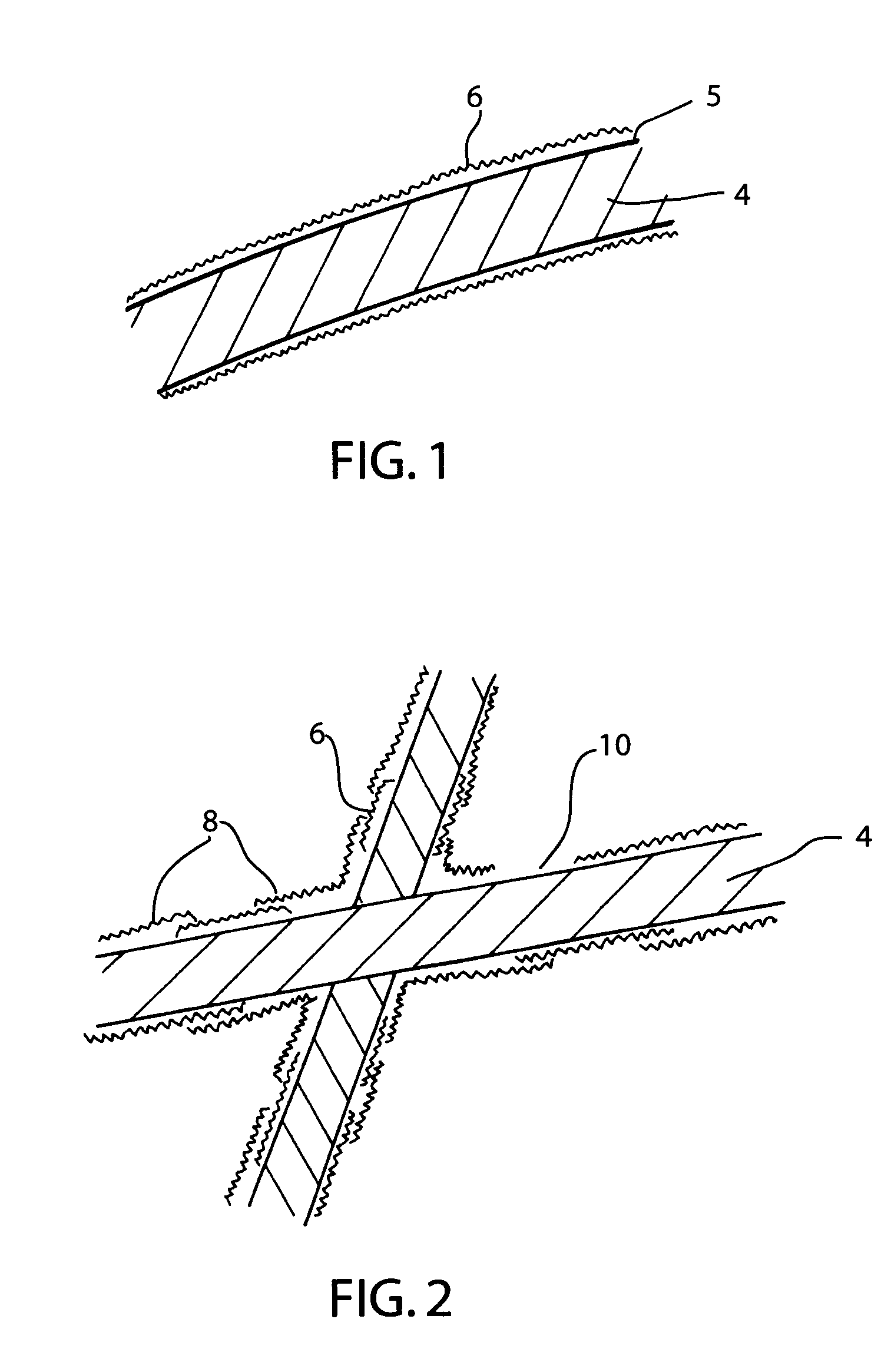

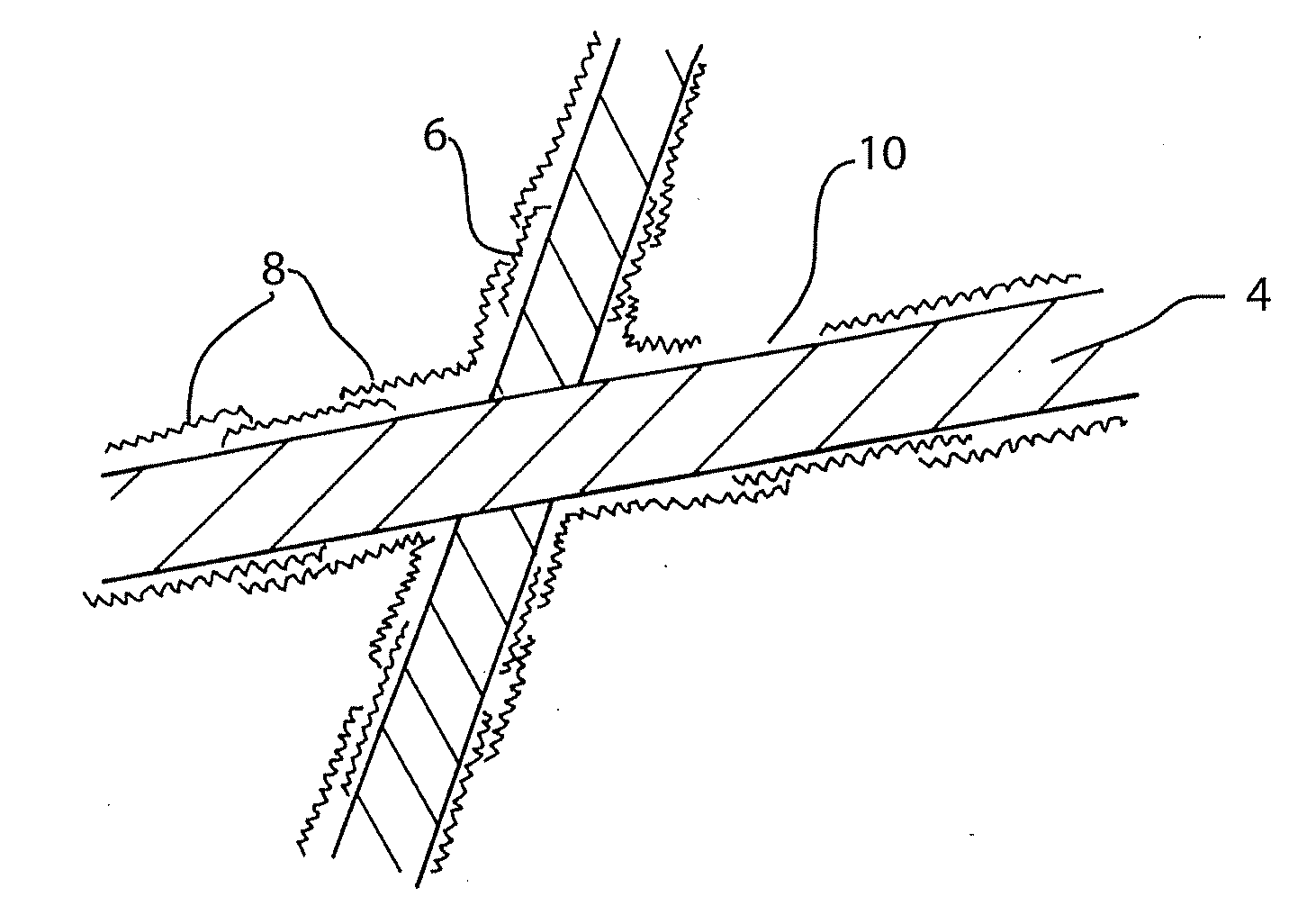

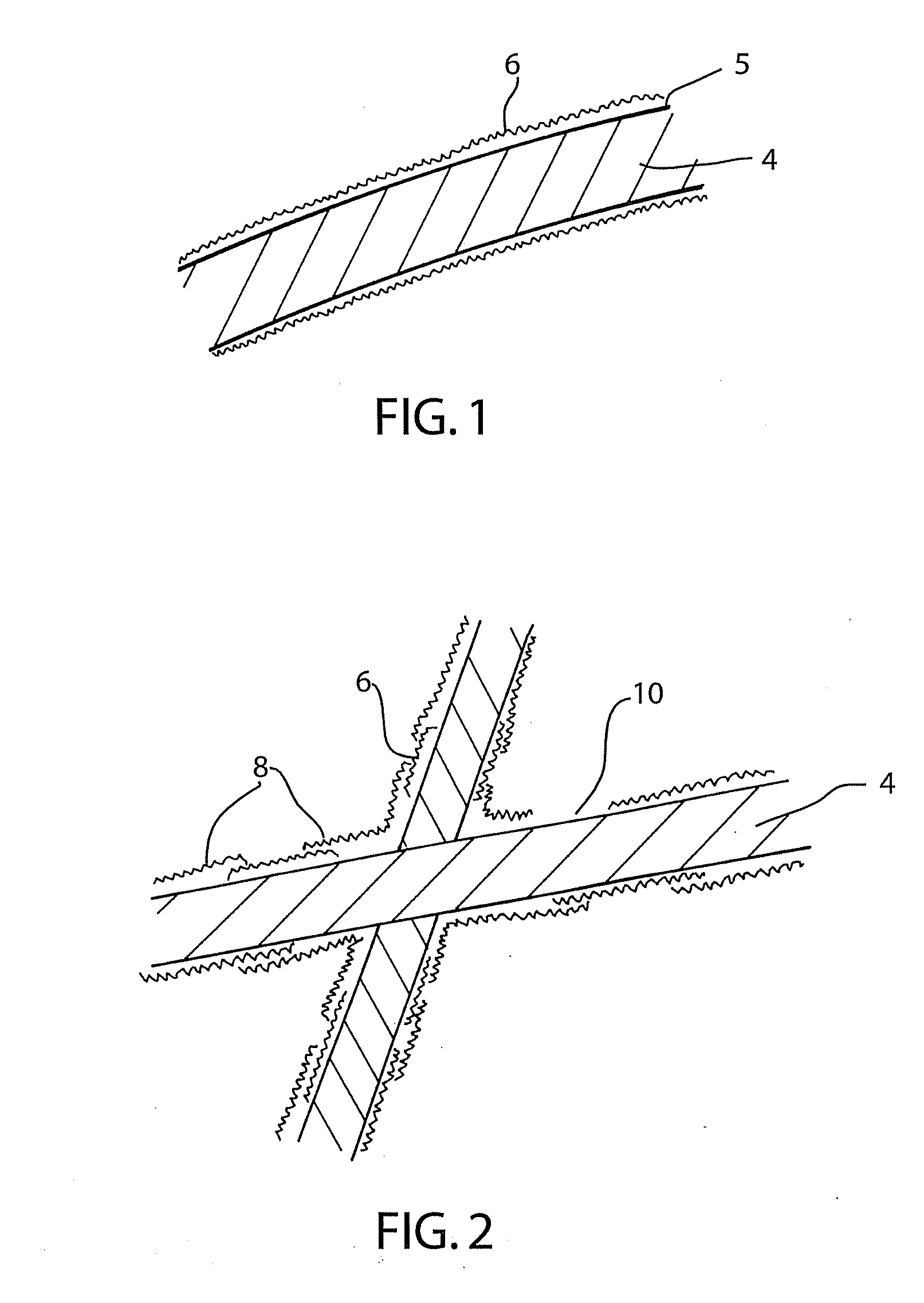

Fabrics with high thermal conductivity coatings

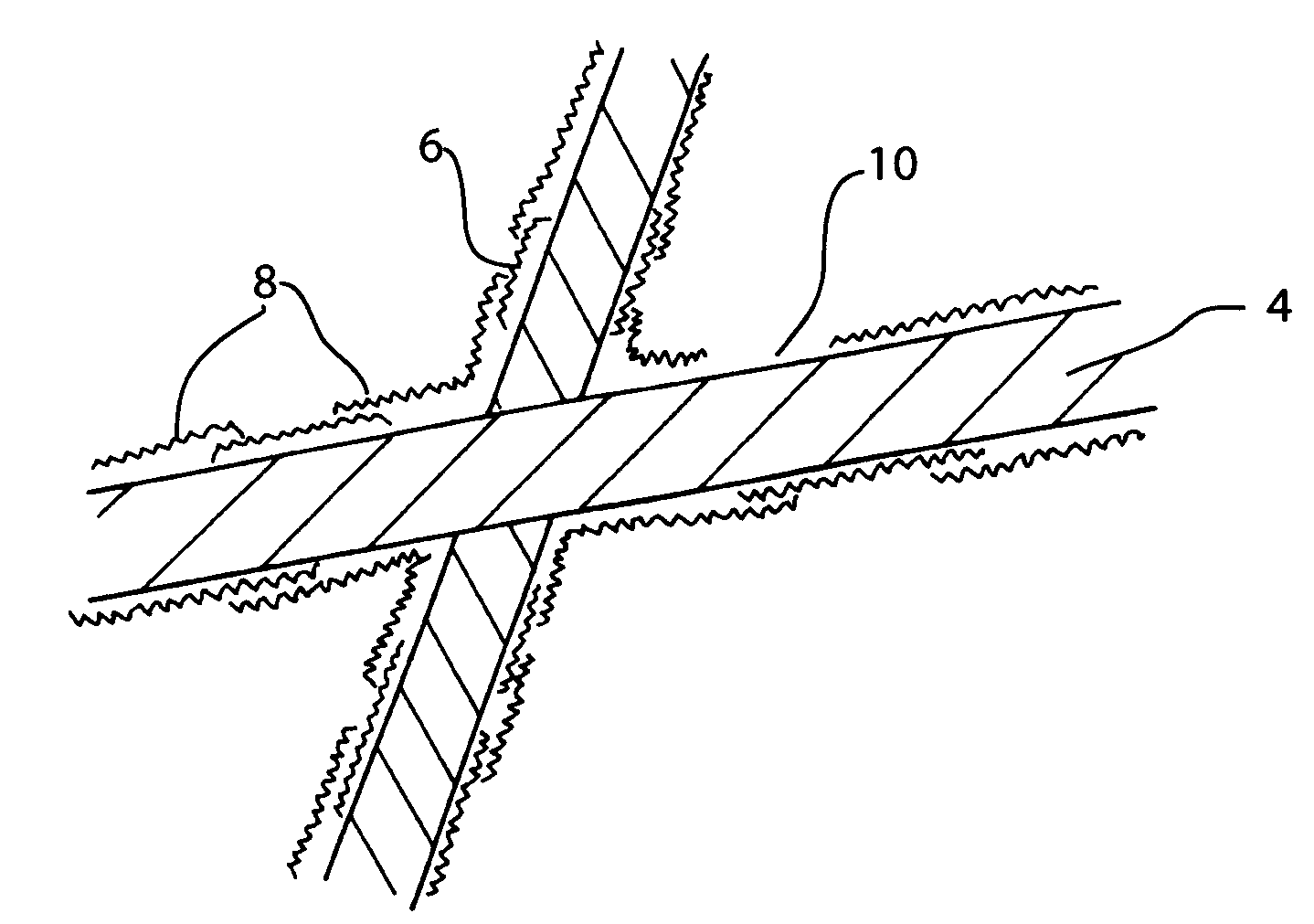

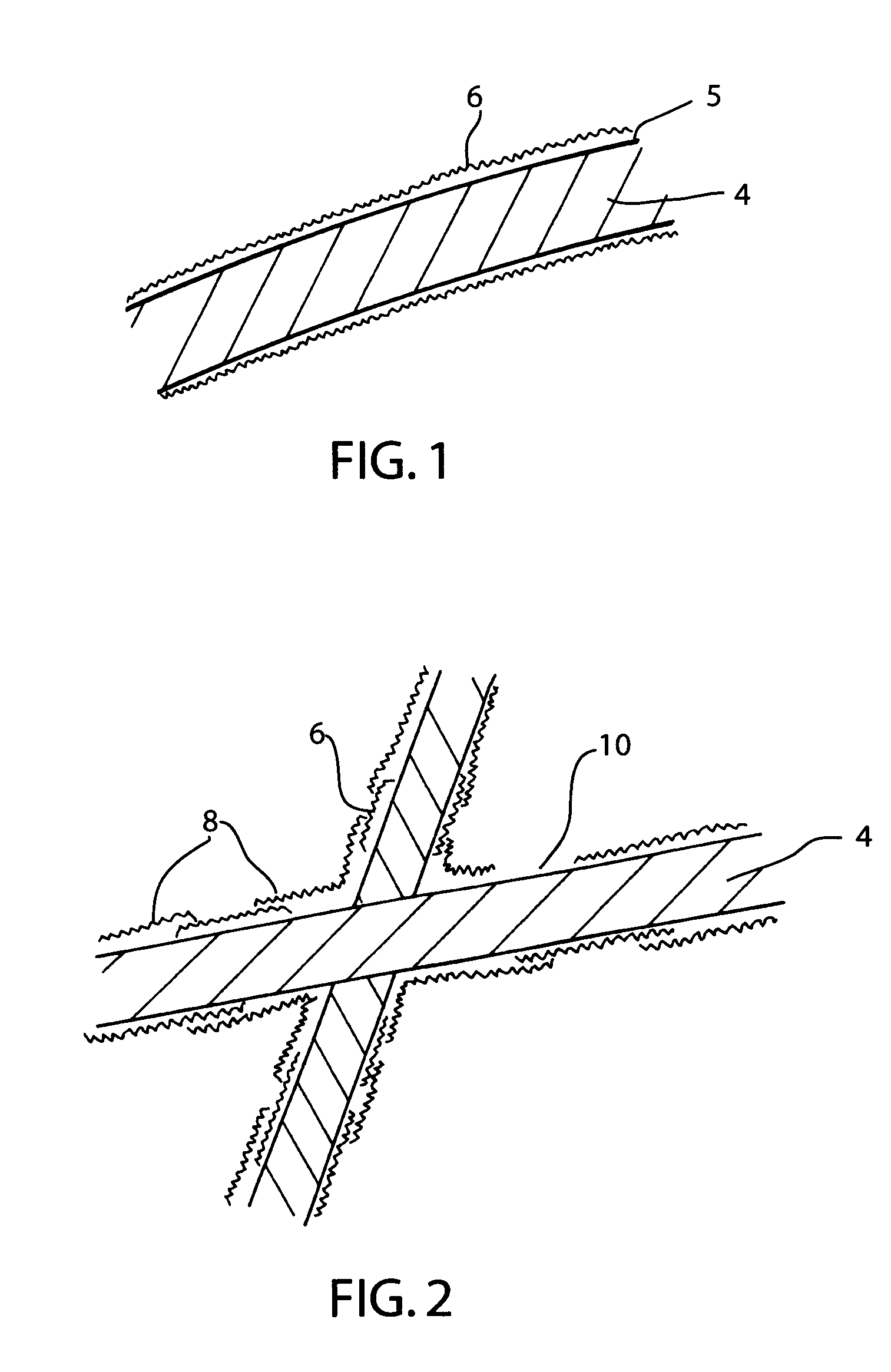

ActiveUS20050277350A1Improve thermal conductivityHigh thermal conductivity materialGlass/slag layered productsNatural mineral layered productsFiberCarbide

The present invention facilitates the thermal conductivity of fabrics by surface coating of the fabrics with high thermal conductivity materials 6. The fabrics may be surface coated when they are individual fibers or strands 4, bundles of strands, formed fabric or combinations therefore. A particular type of fibrous matrix used with the present invention is glass. Some fabrics may be a combination of more than one type of material, or may have different materials in alternating layers. HTC coatings of the present invention include diamond like coatings (DLC) and metal oxides, nitrides, carbides and mixed stoichiometric and non-stoichiometric combinations that can be applied to the host matrix.

Owner:SIEMENS ENERGY INC

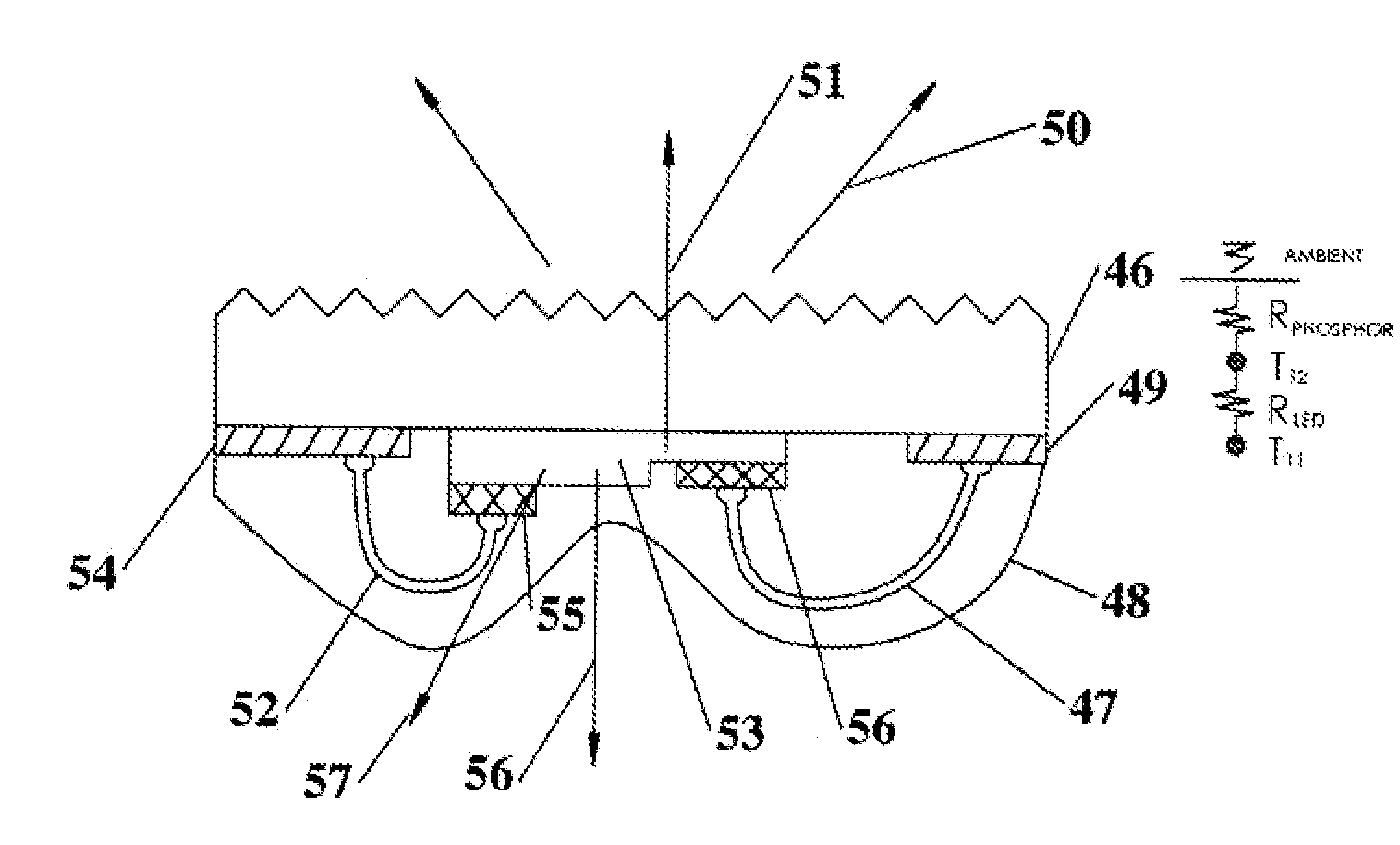

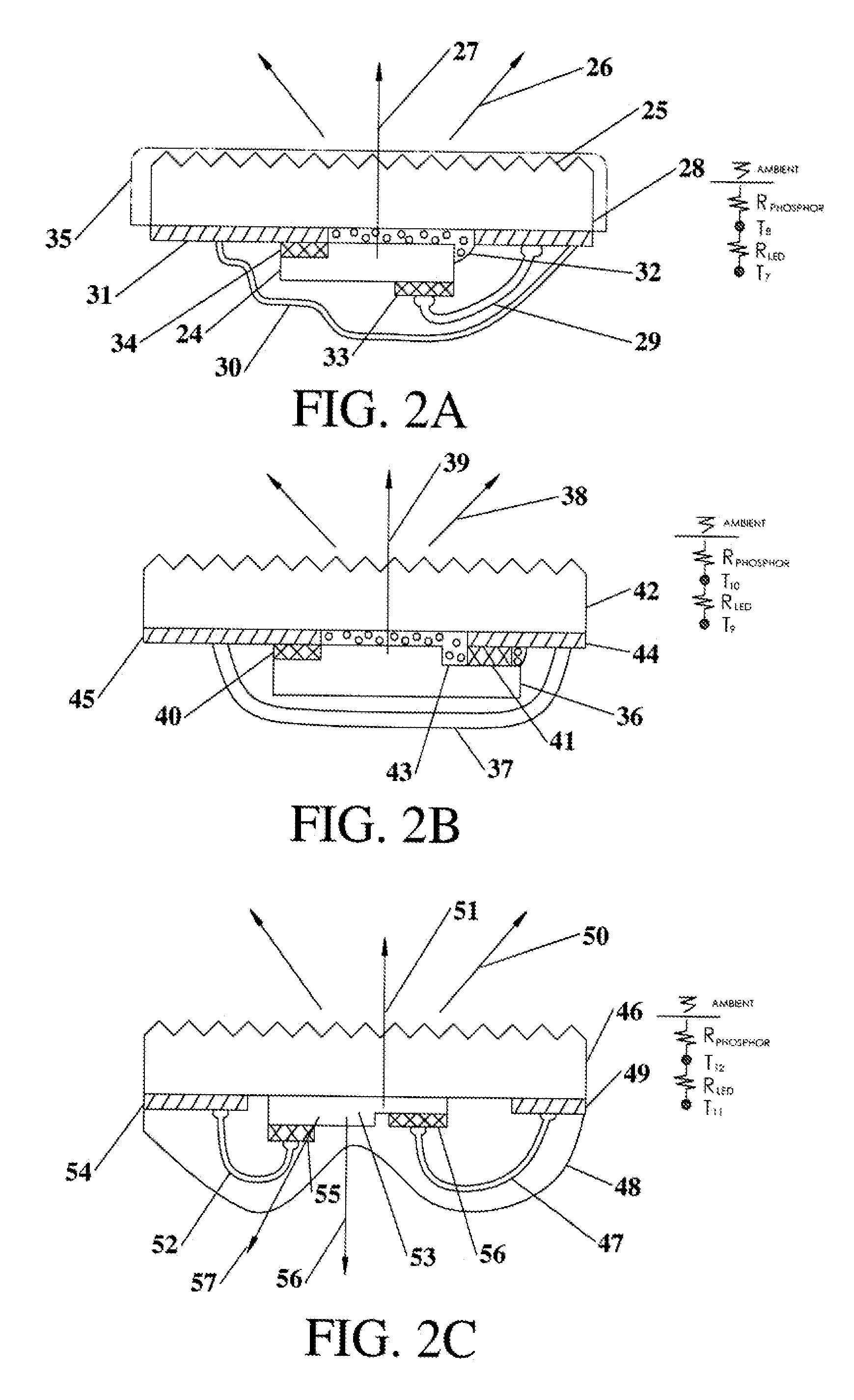

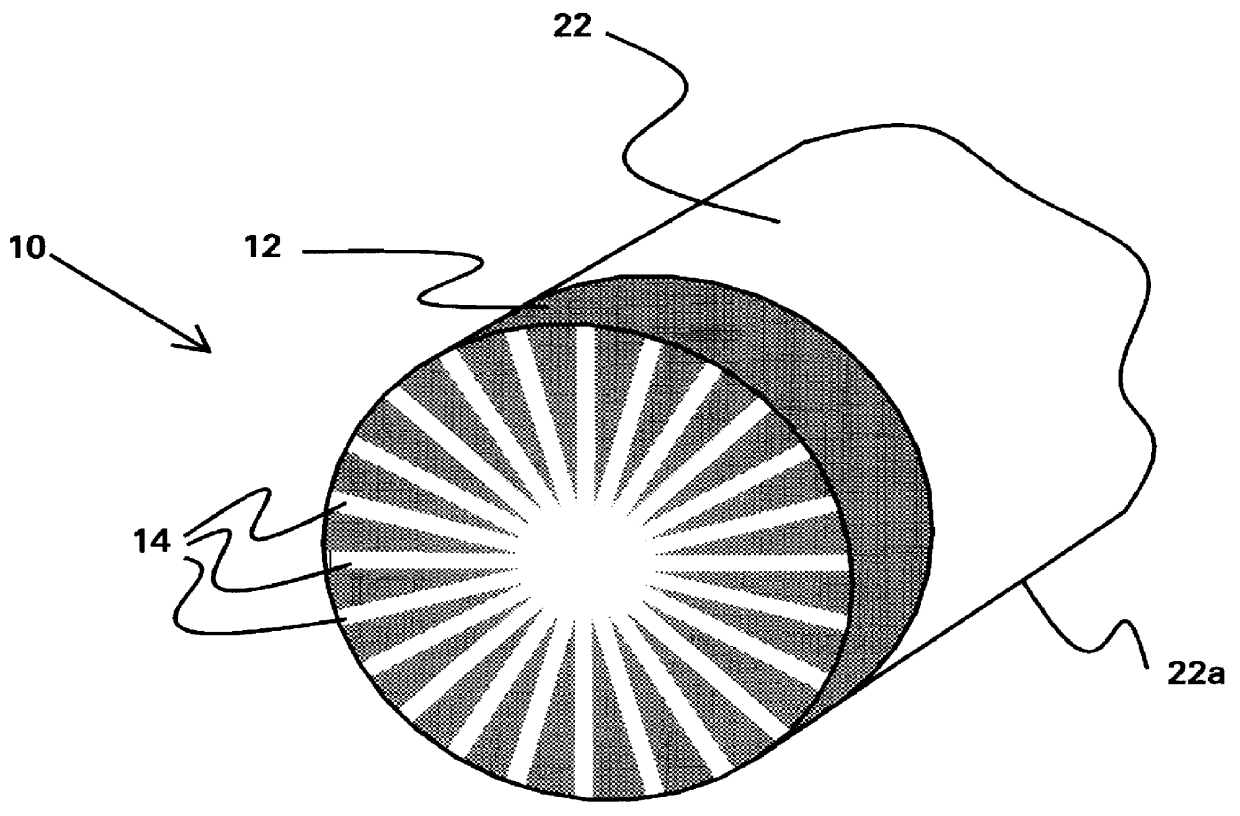

Solid state light sources with common luminescent and heat dissipating surfaces

ActiveUS20140042467A1Increase surface areaDissipate majorityElectric circuit arrangementsLighting heating/cooling arrangementsOptoelectronicsThermal contact

A solid state light source with LEDs in thermal contact to thermally conductive translucent elements where light emitted from the LEDs is directed to emerge from the heat dissipating surfaces of the elements. The thermally conductive translucent elements are arranged or combined with a reflector to form a light recycling cavity. The outside surfaces of the thermally conductive translucent elements forming the cavity become luminescent as the light emitted by the LEDs on the inside of the cavity is continually reflected and recycled until a very high percentage of the light emitted by the LEDs is eventually transmitted through and emitted uniformly and omnidirectionally. Simultaneously, the heat from the LEDs conducts through and to the luminescent outside surfaces of the elements of the cavity, which radiatively and convectively cool the light source thereby eliminating the need for bulky appended heat sinks.

Owner:GOLDENEYE

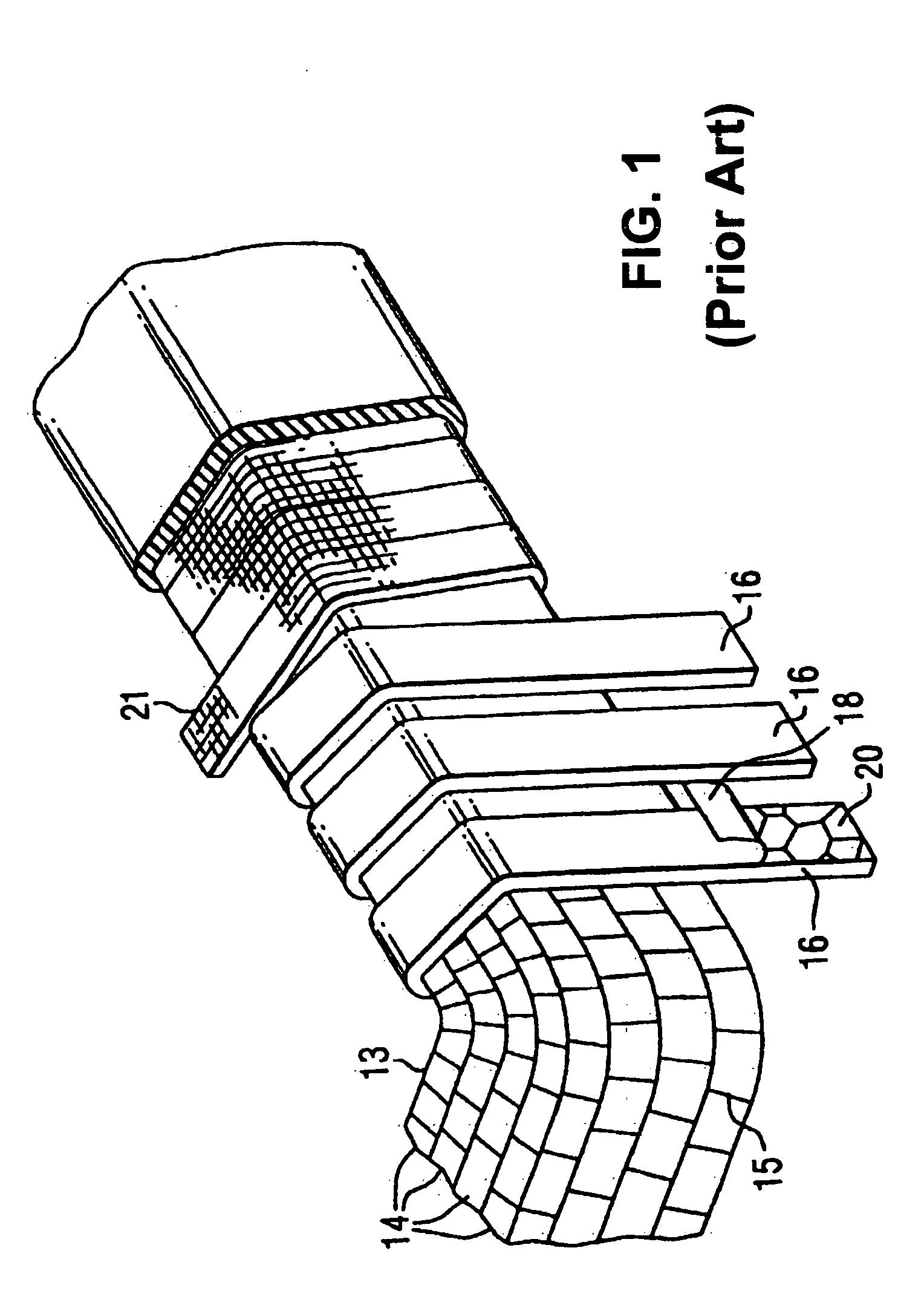

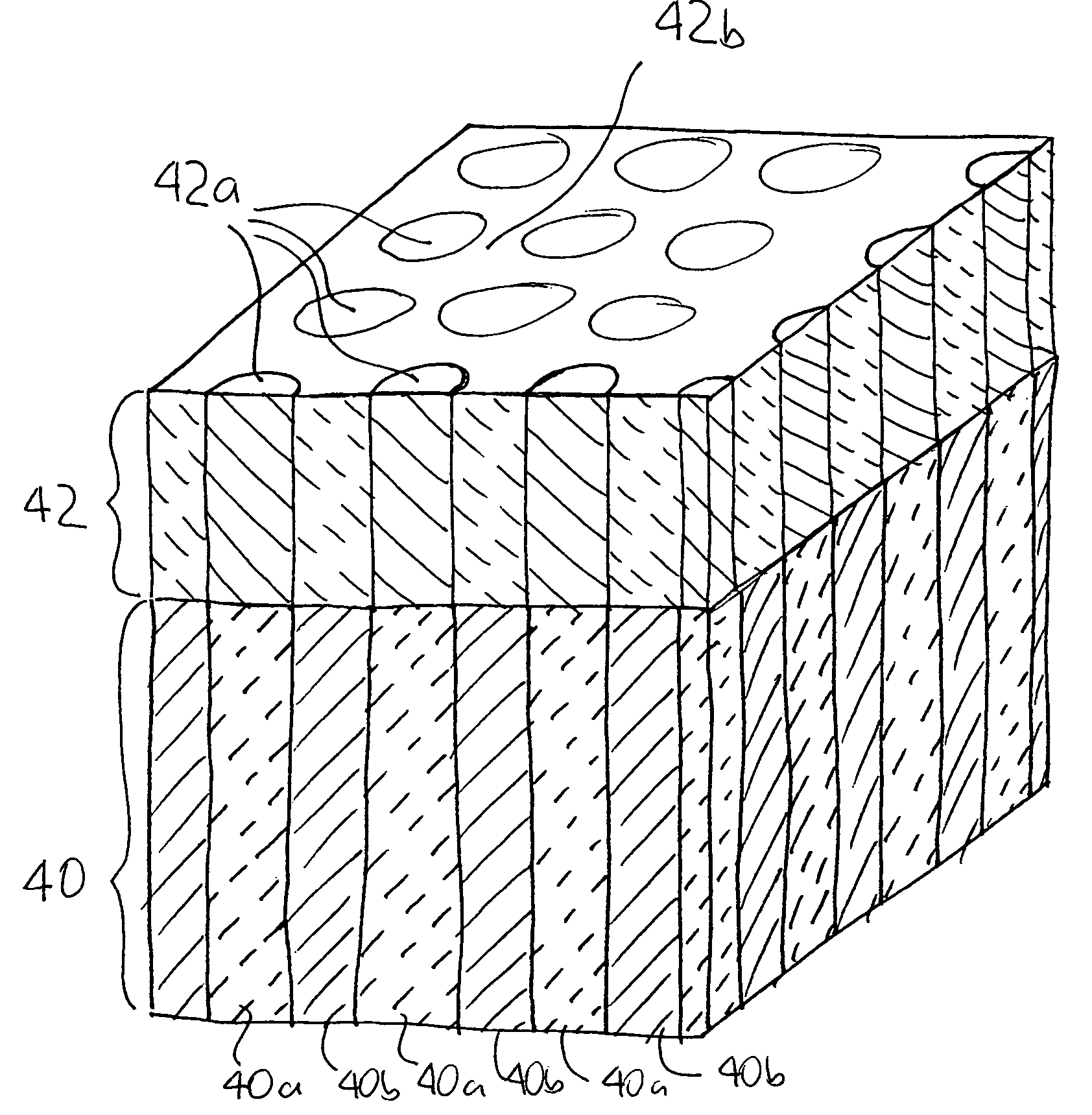

Patterned thin films and use of such films as thermal control layers in heat assisted magnetic recording media

ActiveUS7521137B2Reduce heat transferImprove heat transfer performanceRecording by magnetic meansPatterned record carriersHeat-assisted magnetic recordingOptoelectronics

Patterned thin films comprise regions of relatively low thermal conductivity material separated by regions of relatively high thermal conductivity material. The low thermal conductivity regions may be provided in the form of cylinders or cuboids which are arranged in a continuous matrix of the high thermal conductivity material. The thin film may be used as thermal control layers in data recording media such as heat assisted magnetic recording media.

Owner:SEAGATE TECH LLC

Modulated composite surfaces

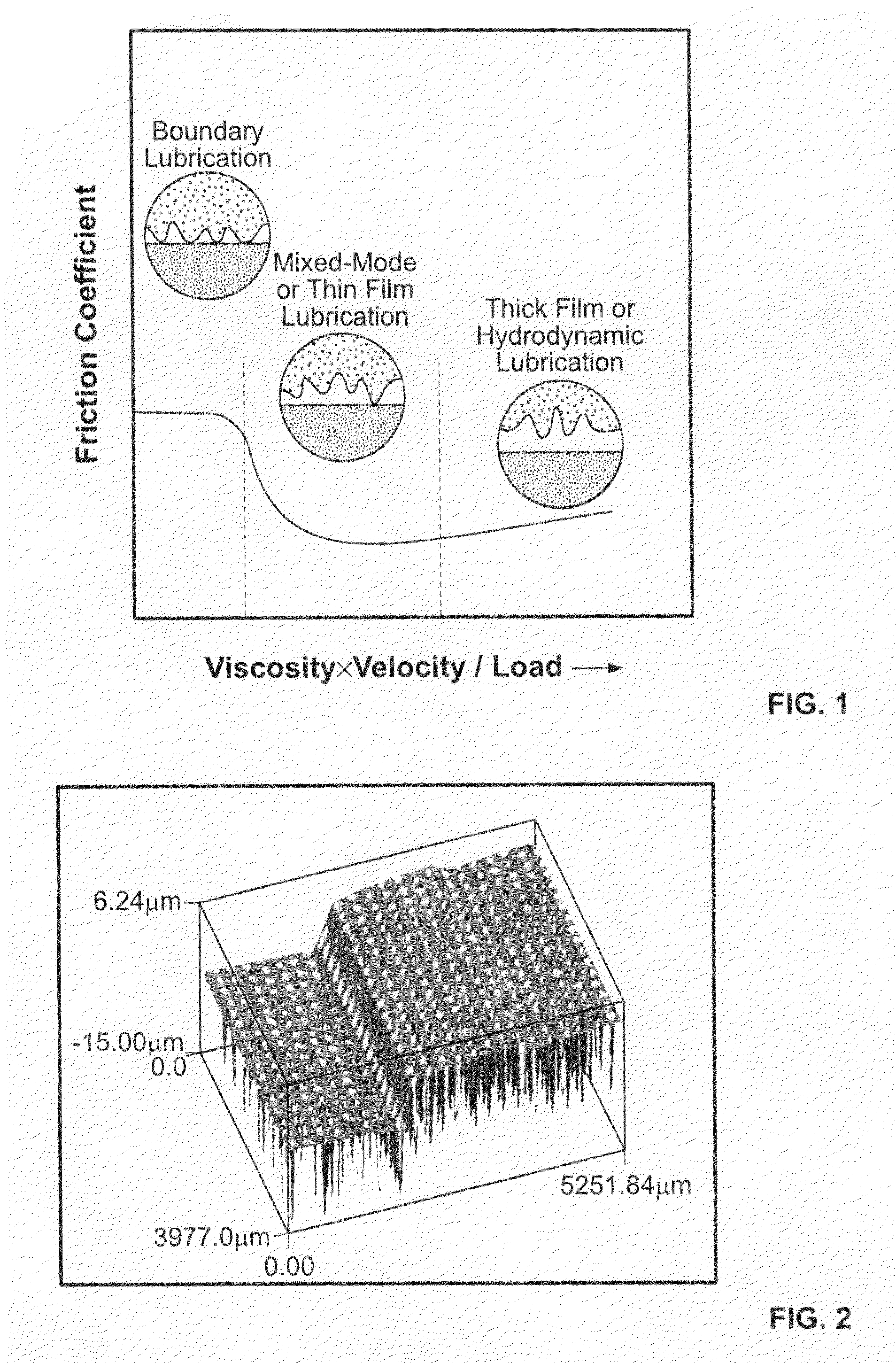

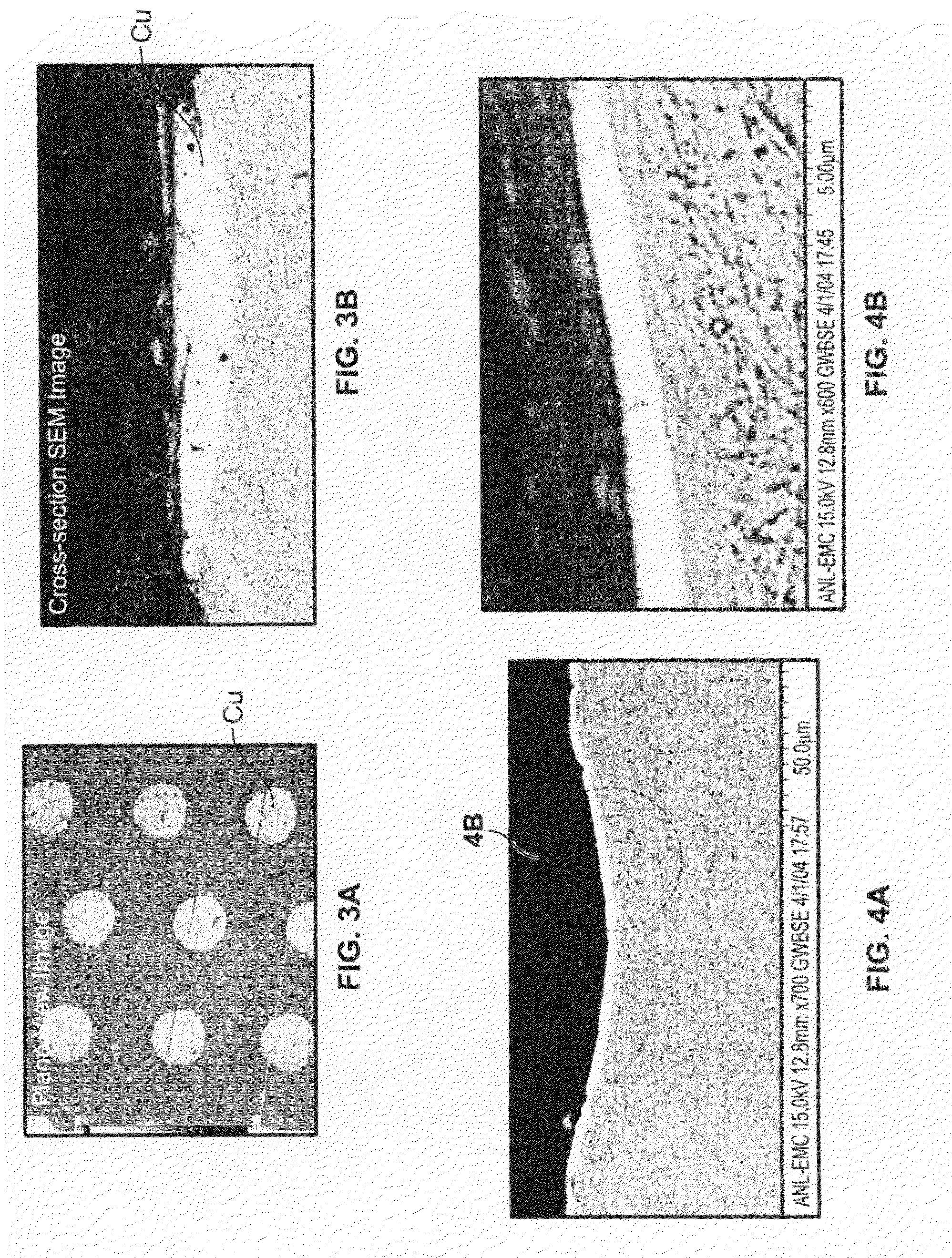

InactiveUS7846556B2Improve the immunityReduce frictionMaterial nanotechnologyDecorative surface effectsWear resistanceNanometre

Methods and compositions relating to the preparation of structurally and compositionally modulated composite surfaces that can potentially reduce friction and increase resistance to wear and scuffing in rolling, rotating and sliding bearing applications. Preparation of nano-to-micro size pores, holes, or dimples on a given solid surface and filling them with soft or hard coatings at desired thickness to achieve such properties.

Owner:UCHICAGO ARGONNE LLC

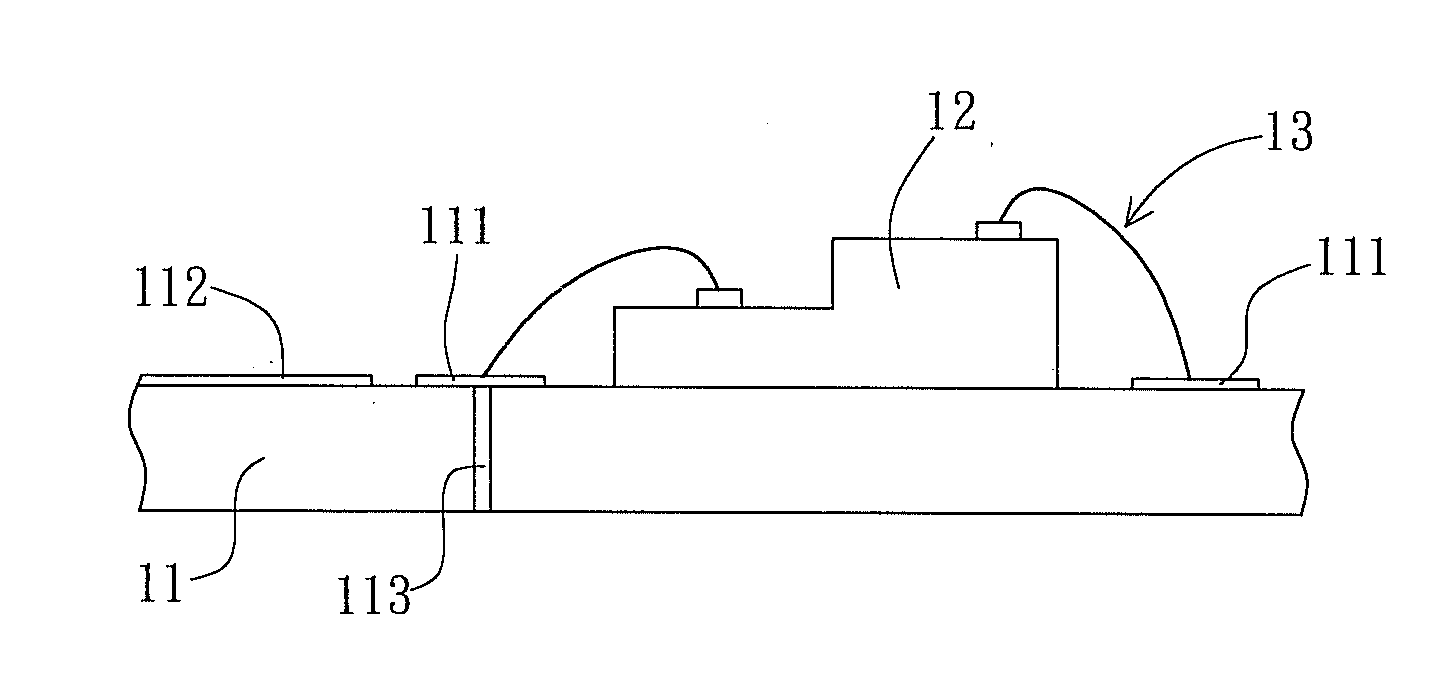

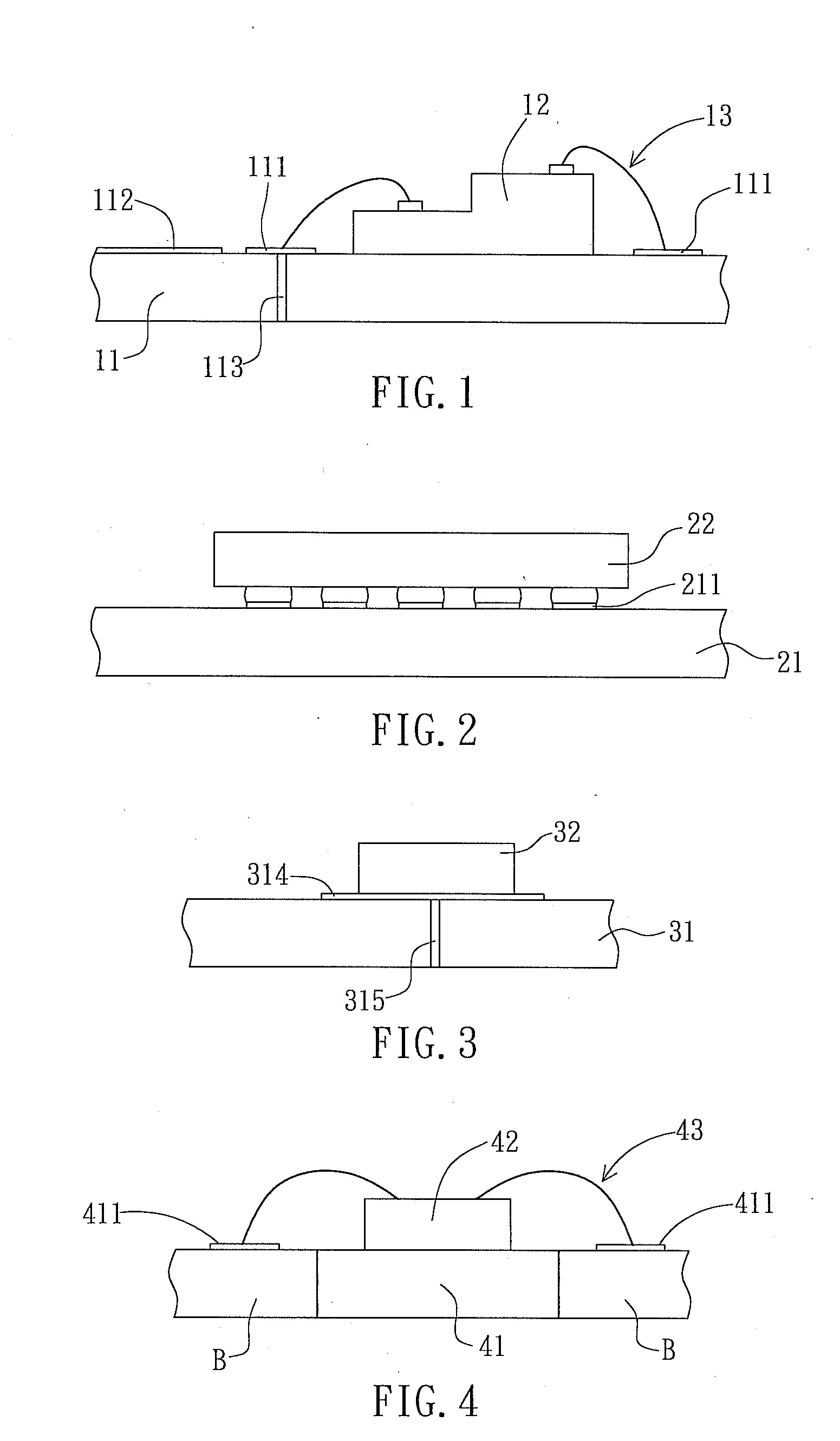

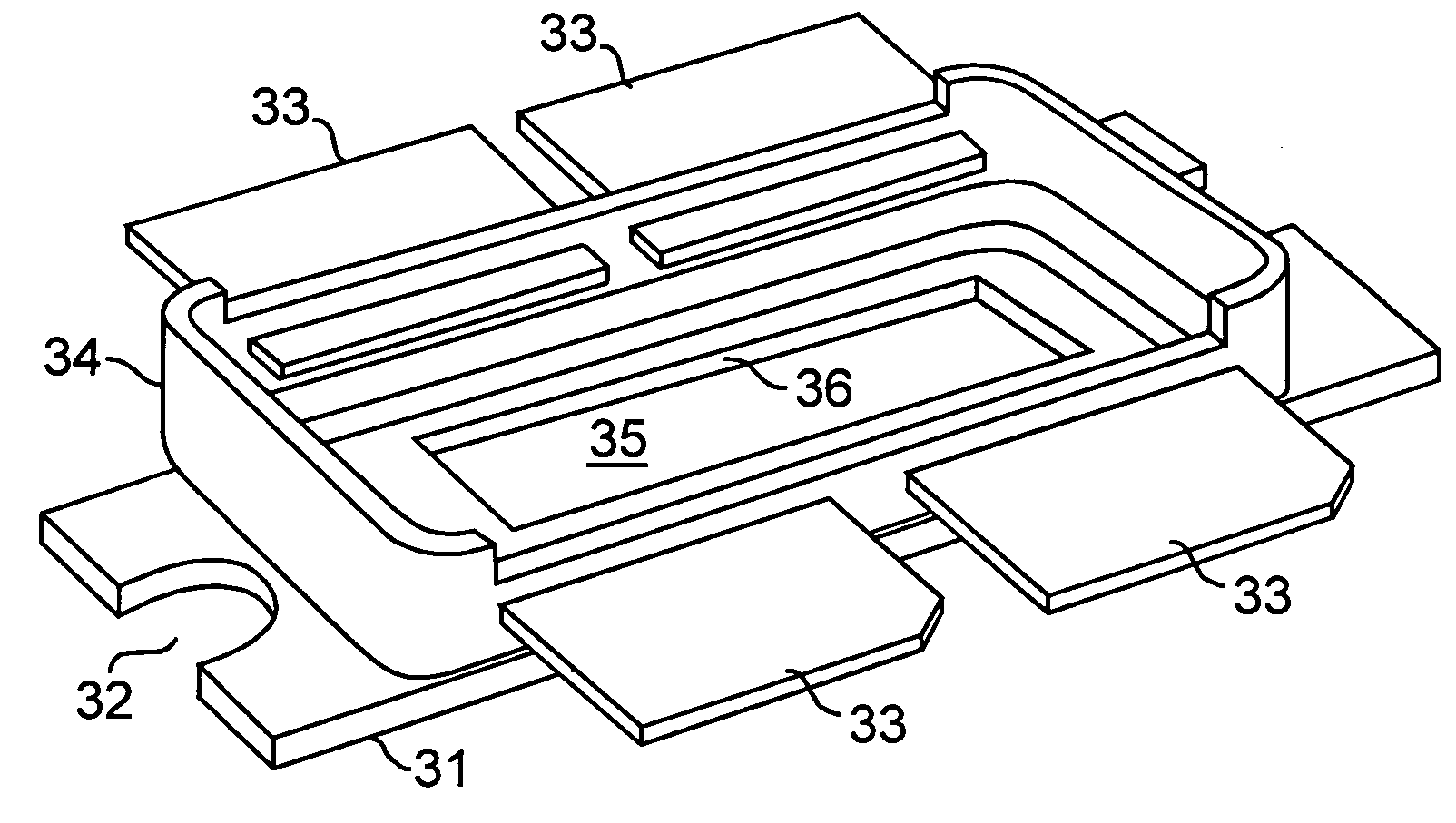

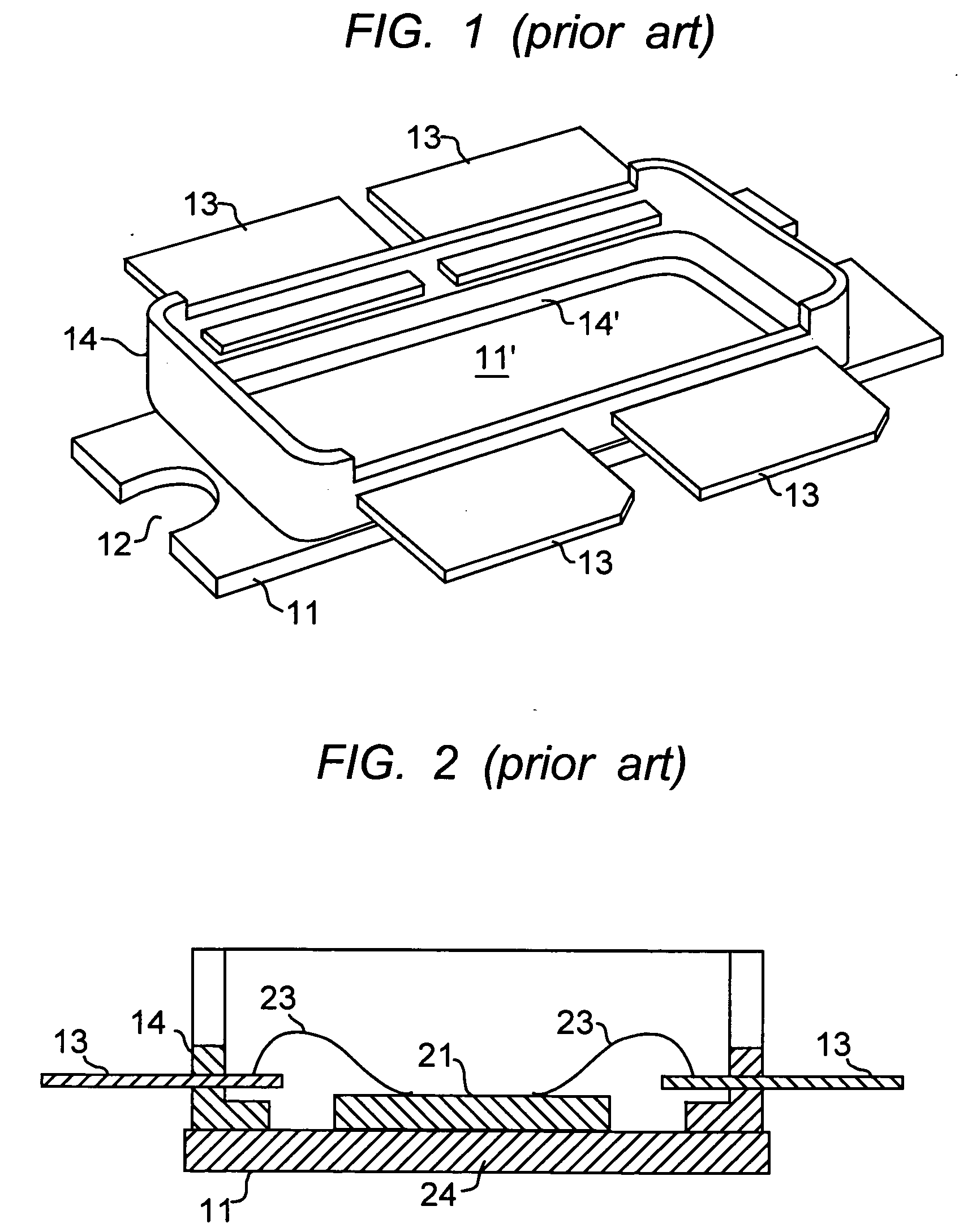

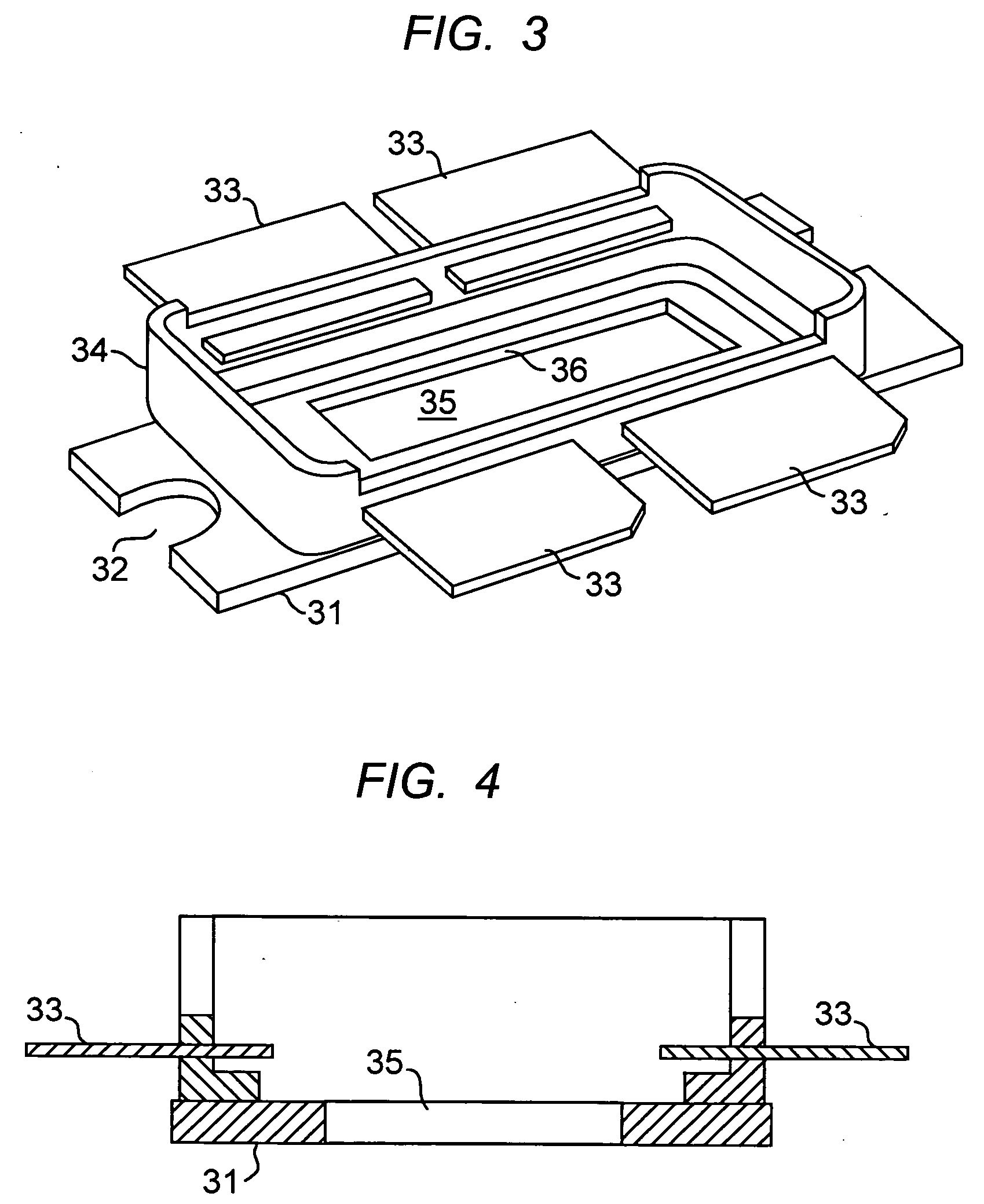

Co-fired ceramic module

InactiveUS20090091020A1Improve thermal conductivityImprove efficiencySemiconductor/solid-state device detailsPrinted circuit aspectsMetallurgyCo-fired ceramic

A co-fired ceramic module includes a ceramic substrate and at least one heat-emitting device. The ceramic substrate has at least one high thermal conductivity material. The heat-emitting device is disposed on the ceramic substrate. The substrate further includes a cavity and the heat-emitting device is disposed in the cavity.

Owner:DELTA ELECTRONICS INC

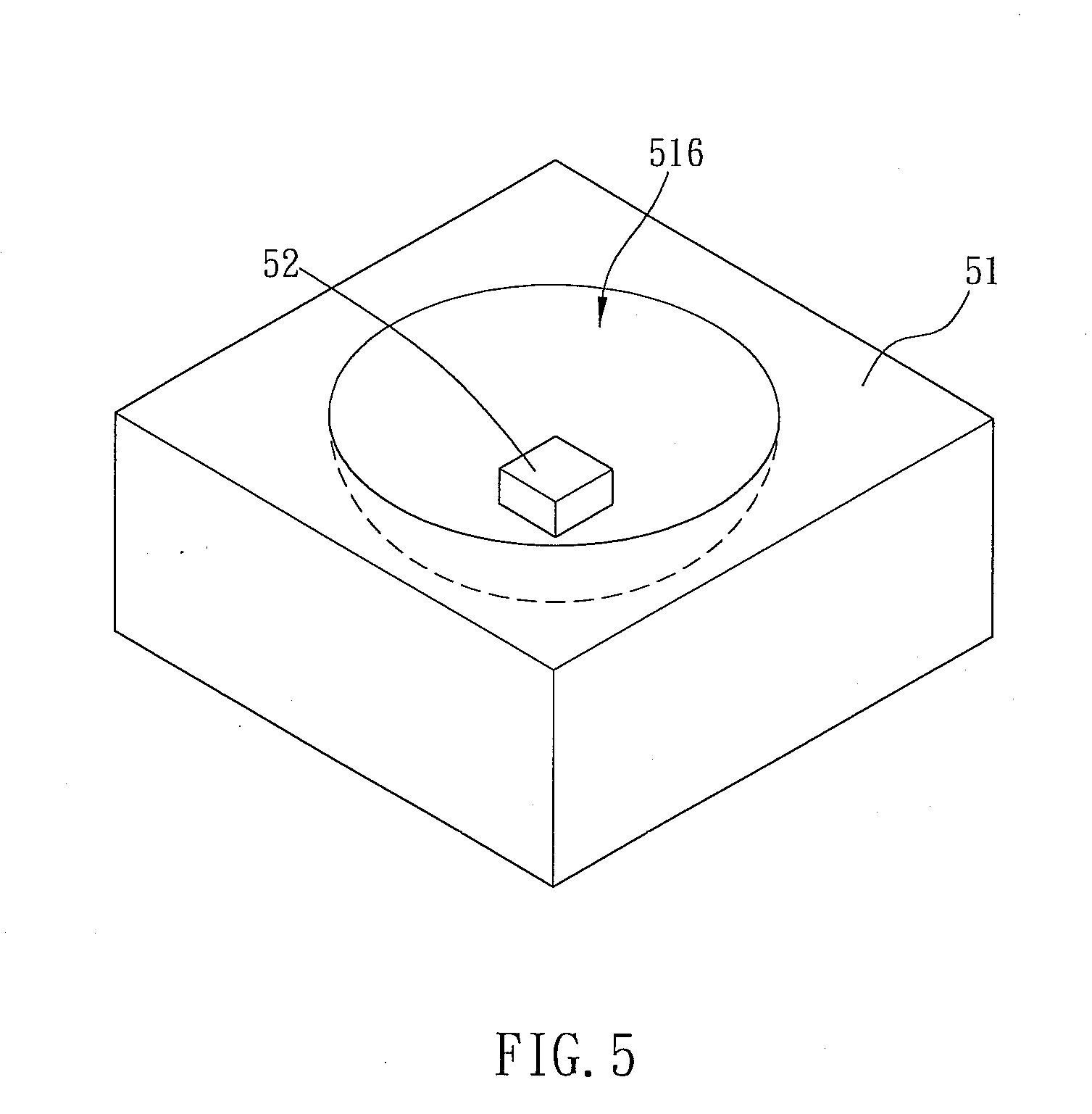

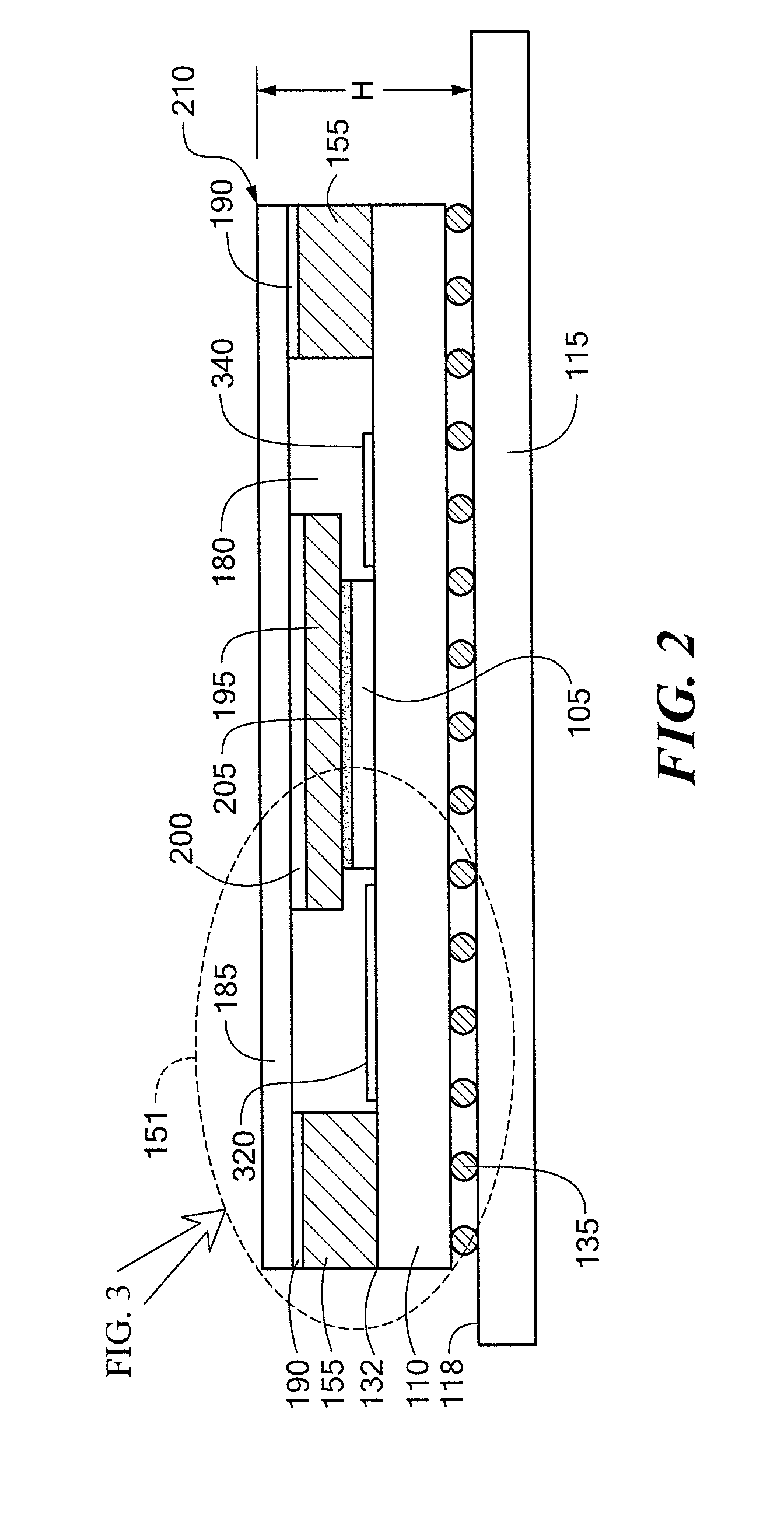

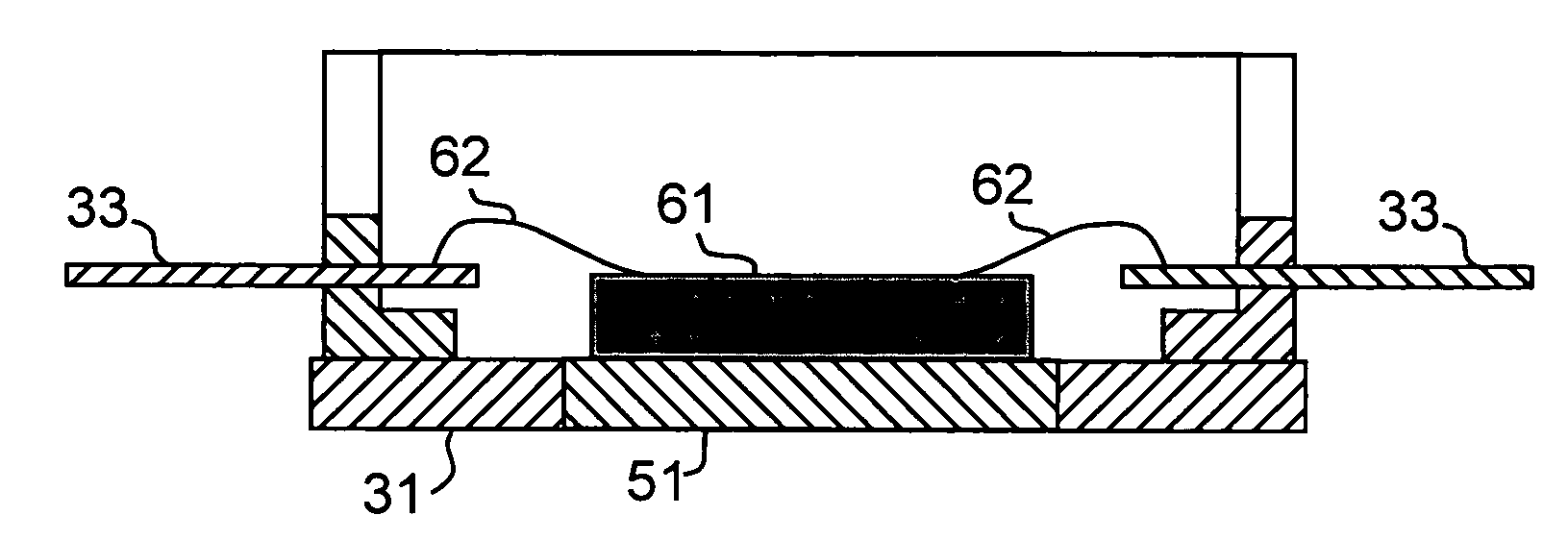

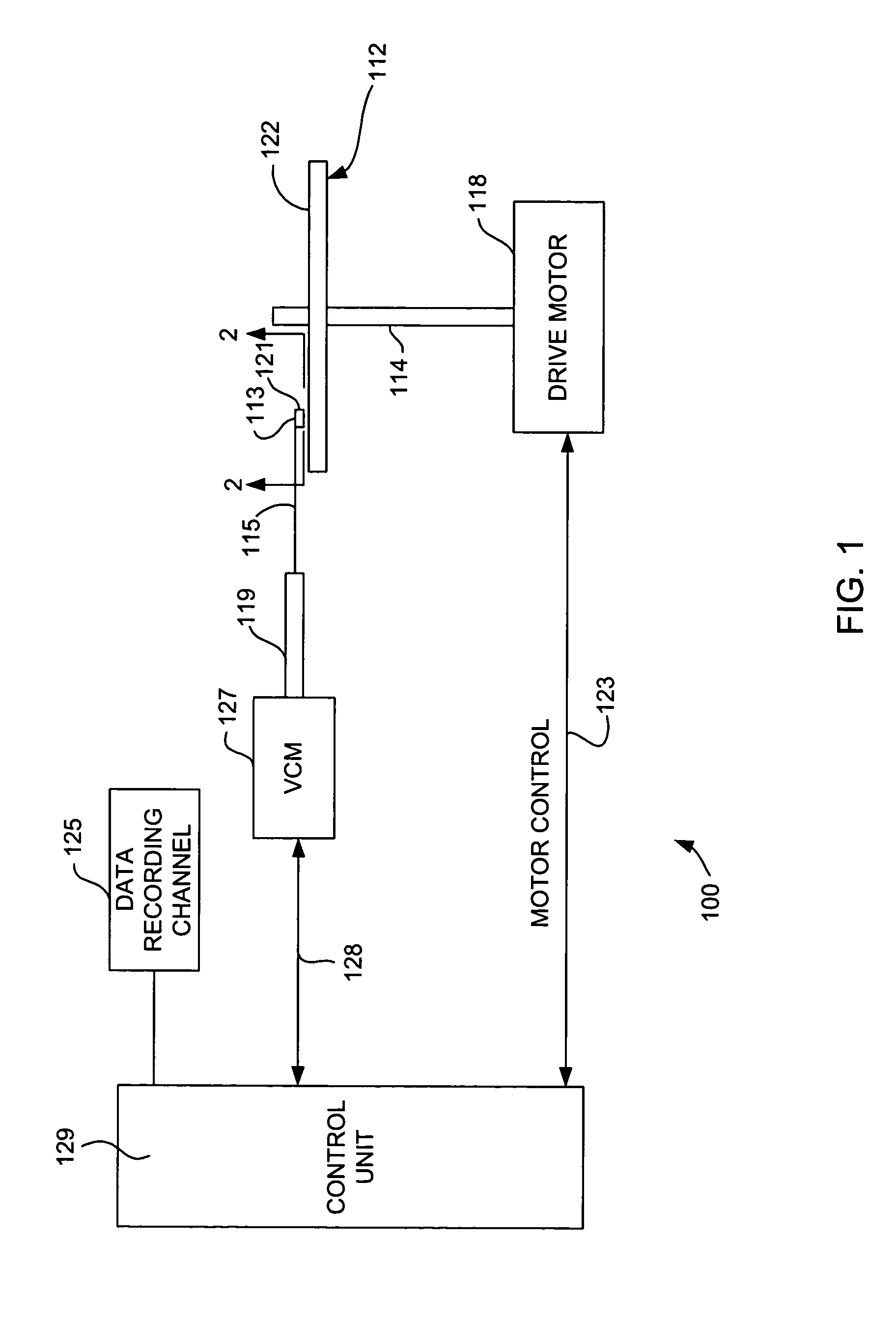

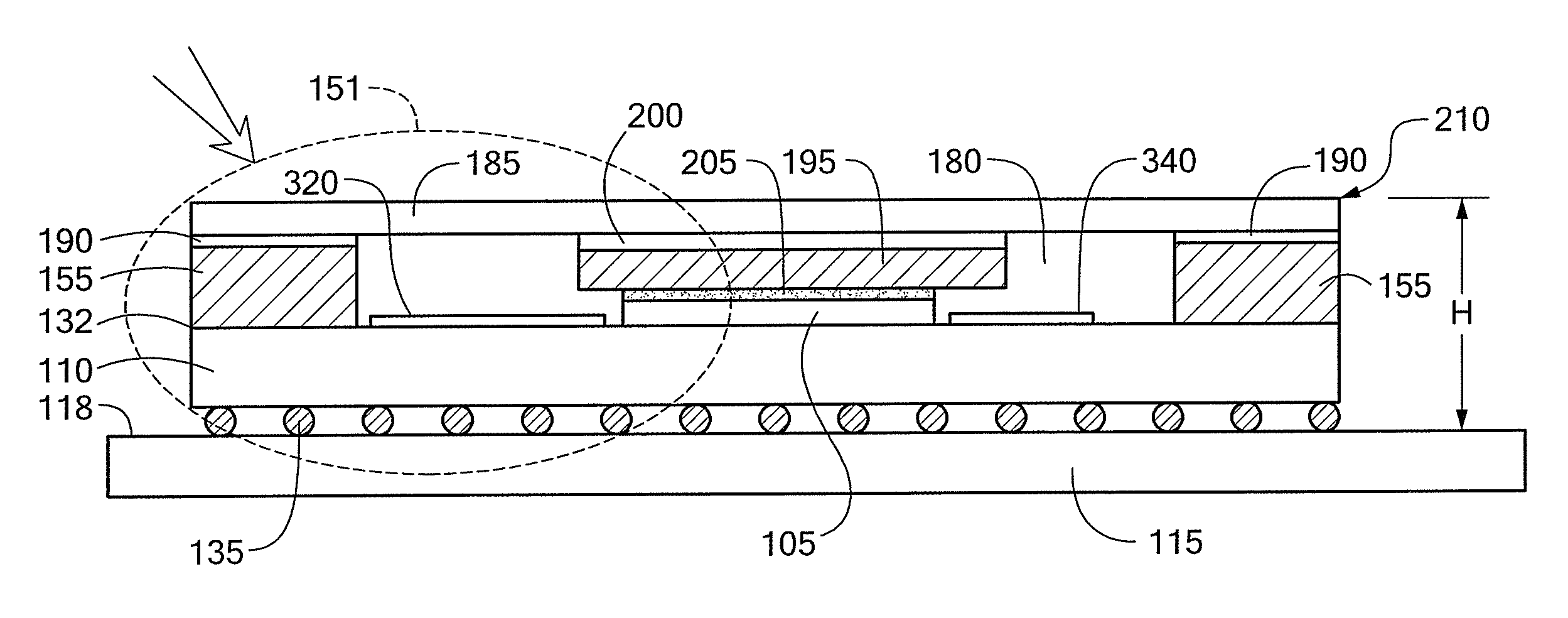

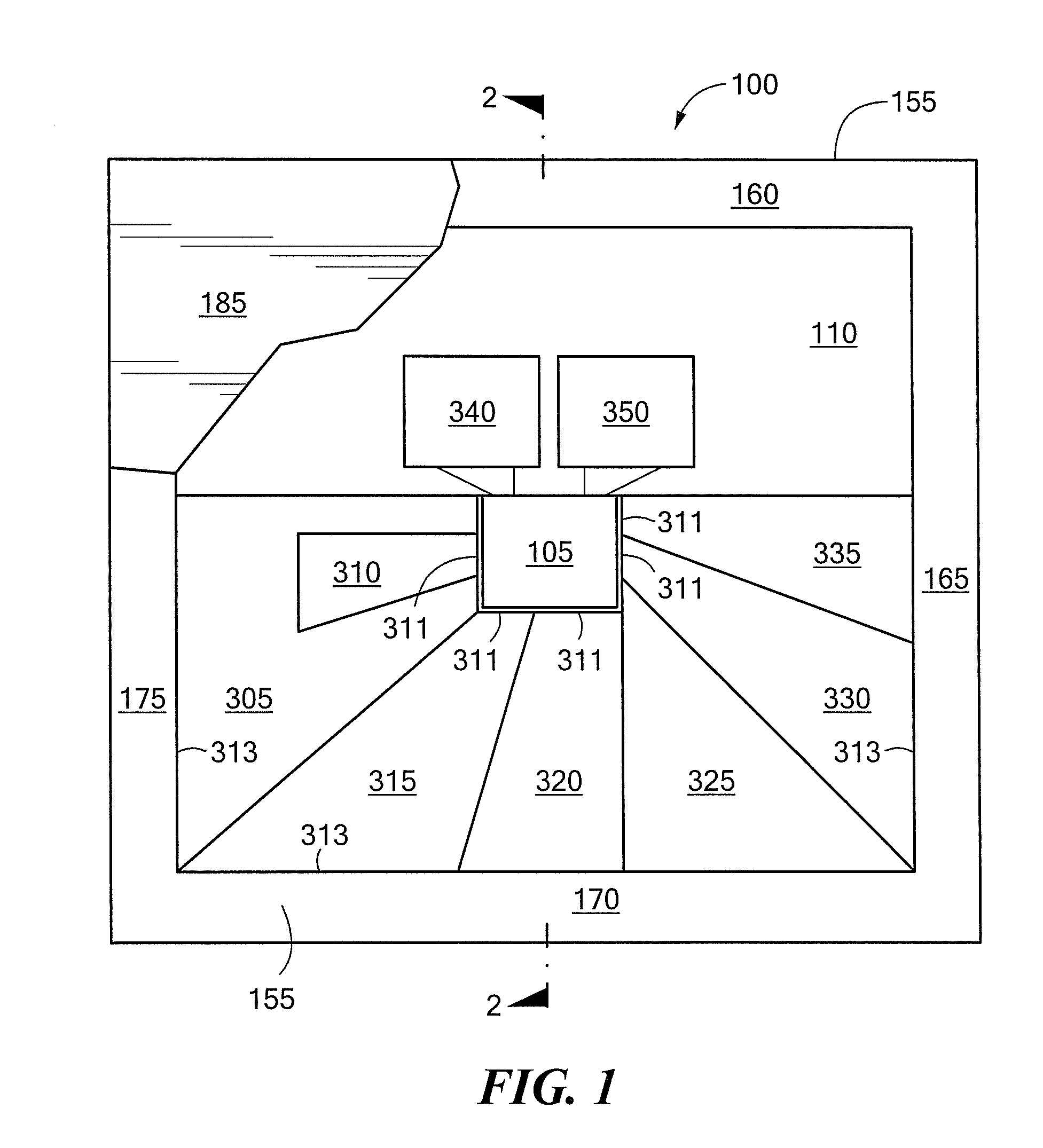

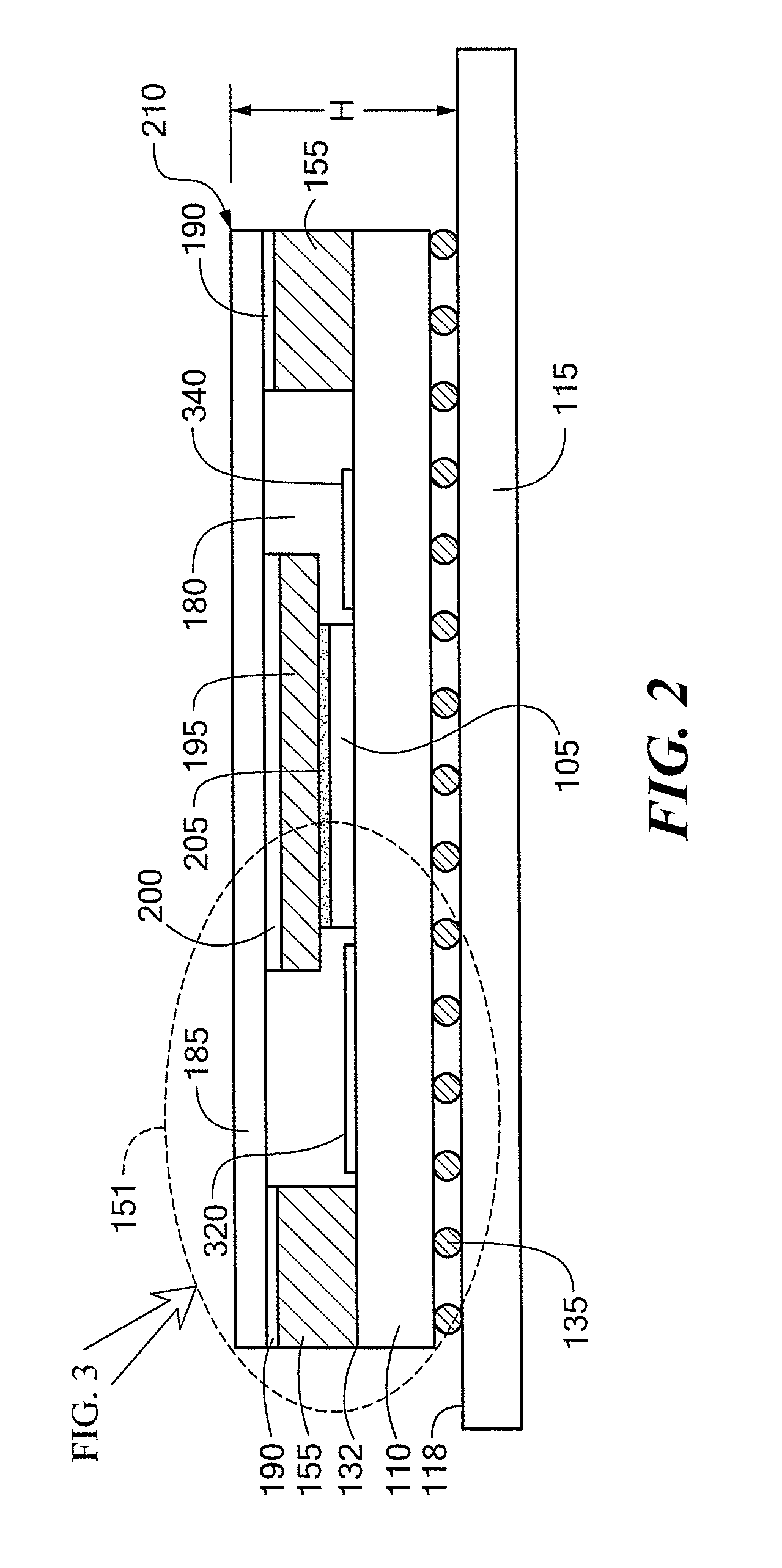

Low noise high thermal conductivity mixed signal package

ActiveUS20110018126A1Efficient thermal managementHigh thermal conductivity materialSemiconductor/solid-state device detailsSolid-state devicesLow noiseEngineering

An improved microelectronic assembly (100) and packaging method includes a device package for housing a semiconductor die or chip, (105), an array of passive electronic components (305-355) operating in cooperation with the flip chip semiconductor die (105) and housed inside the device package to decouple noise from input signals, and a heat spreader (195) disposed between a top surface of the semiconductor die (105) and a package cover (185). The semiconductor die (105) is configured as a flip chip die and the device package includes a package substrate (110) configured as a ball grid array. The improved microelectronic device (100) reduces parasitic inductance in electrical interconnections between the semiconductor die and an electrical system substrate (115) and reduces signal noise in mixed signal high frequency analog to digital converters operating at clock rates above 1 GHz.

Owner:RAYTHEON CO

Core for injection molding tools

InactiveUS20020003199A1High thermal conductivity materialFood shapingWelding apparatusShell moldingInjection moulding

Owner:CHECK JOHN M +1

Fabrics with high thermal conductivity coatings

InactiveUS20090238959A1Improve thermal conductivityHigh thermal conductivity materialSynthetic resin layered productsPrinted circuit aspectsFiberCarbide

The present invention facilitates the thermal conductivity of fabrics by surface coating of the fabrics with high thermal conductivity materials 6. The fabrics may be surface coated when they are individual fibers or strands 4, bundles of strands, formed fabric or combinations therefore. A particular type of fibrous matrix used with the present invention is glass. Some fabrics may be a combination of more than one type of material, or may have different materials in alternating layers. HTC coatings of the present invention include diamond like coatings (DLC) and metal oxides, nitrides, carbides and mixed stoichiometric and non-stoichiometric combinations that can be applied to the host matrix.

Owner:SIEMENS ENERGY INC

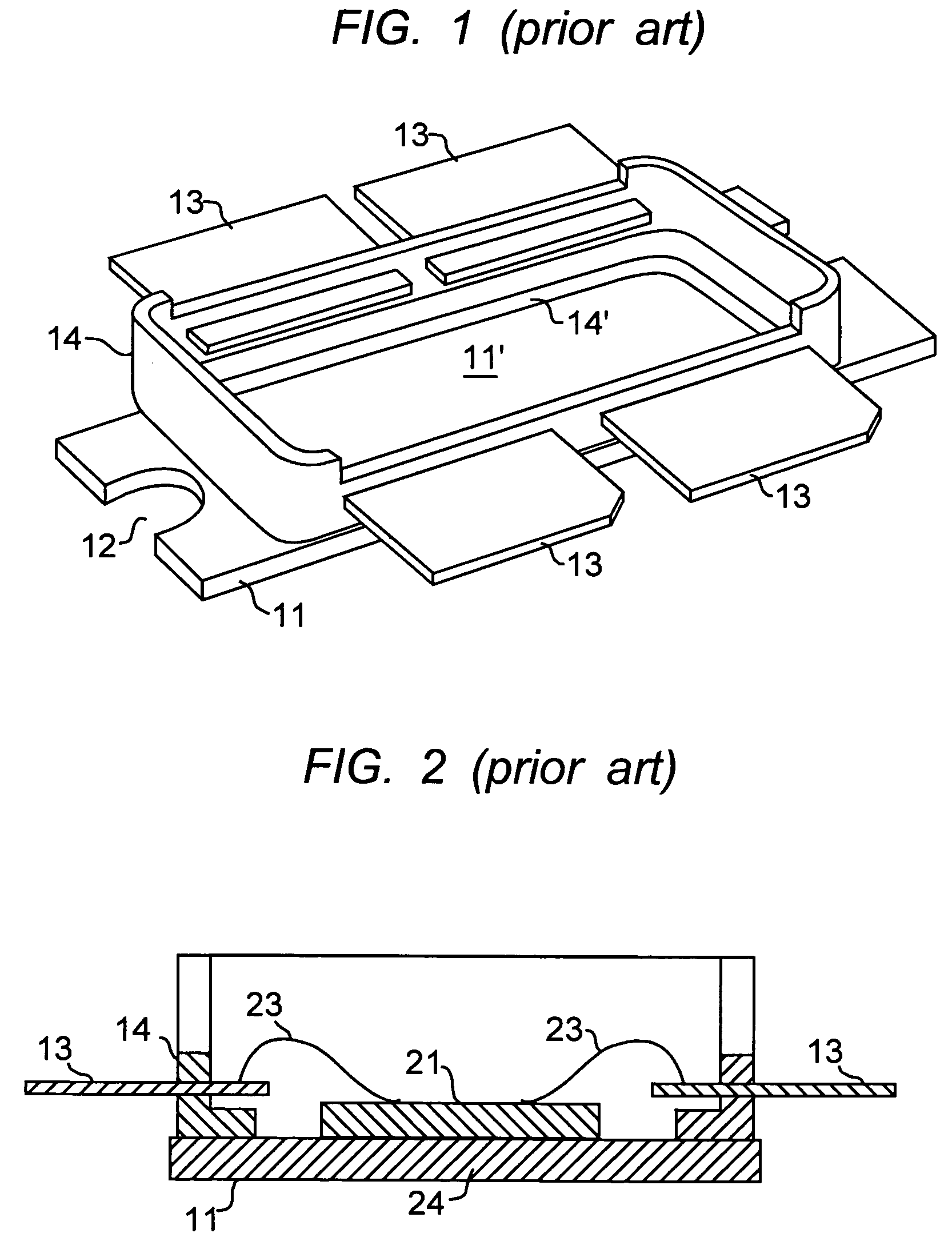

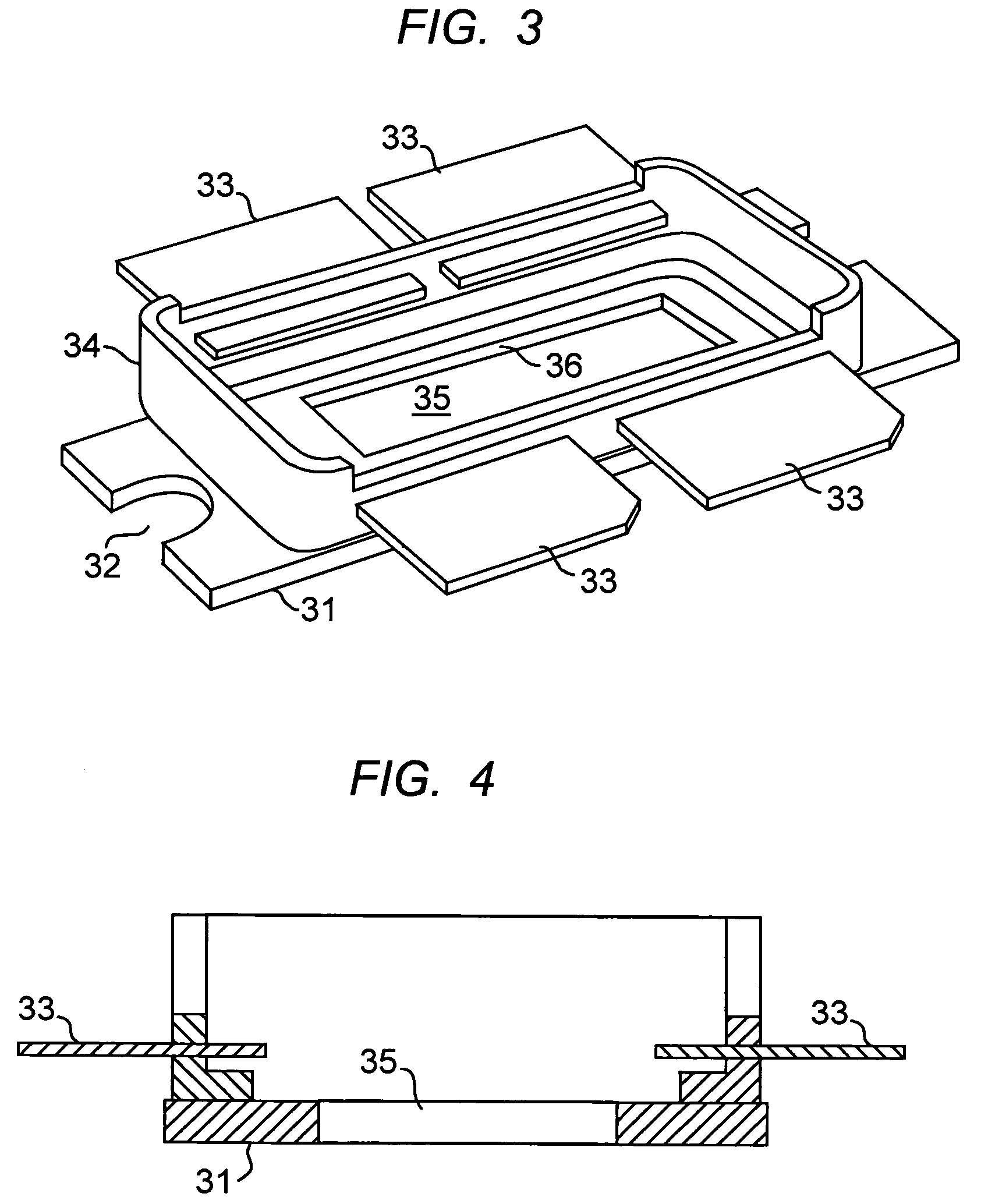

Leadframe designs for integrated circuit plastic packages

ActiveUS20060108670A1Effective coolingHigh strengthSemiconductor/solid-state device detailsSolid-state devicesPackage designEngineering

The specification describes a plastic cavity package design for high power transistor packages in which the leadframe is formed of a composite of materials. This allows the portions of the leadframe that require strength to be formed of a high strength material, e.g. steel, while the paddle portion of the leadframe is formed of a high thermal conductivity material, e.g. copper. This composite leadframe optimizes thermal and mechanical performance at low cost. In the preferred embodiment the leadframe is provided with a center cutout, where the die is attached. A copper insert is assembled in the cutout. The copper insert provides an effective heat sink, while the remainder of the leadframe provides the desired mechanical strength.

Owner:BELL SEMICON LLC

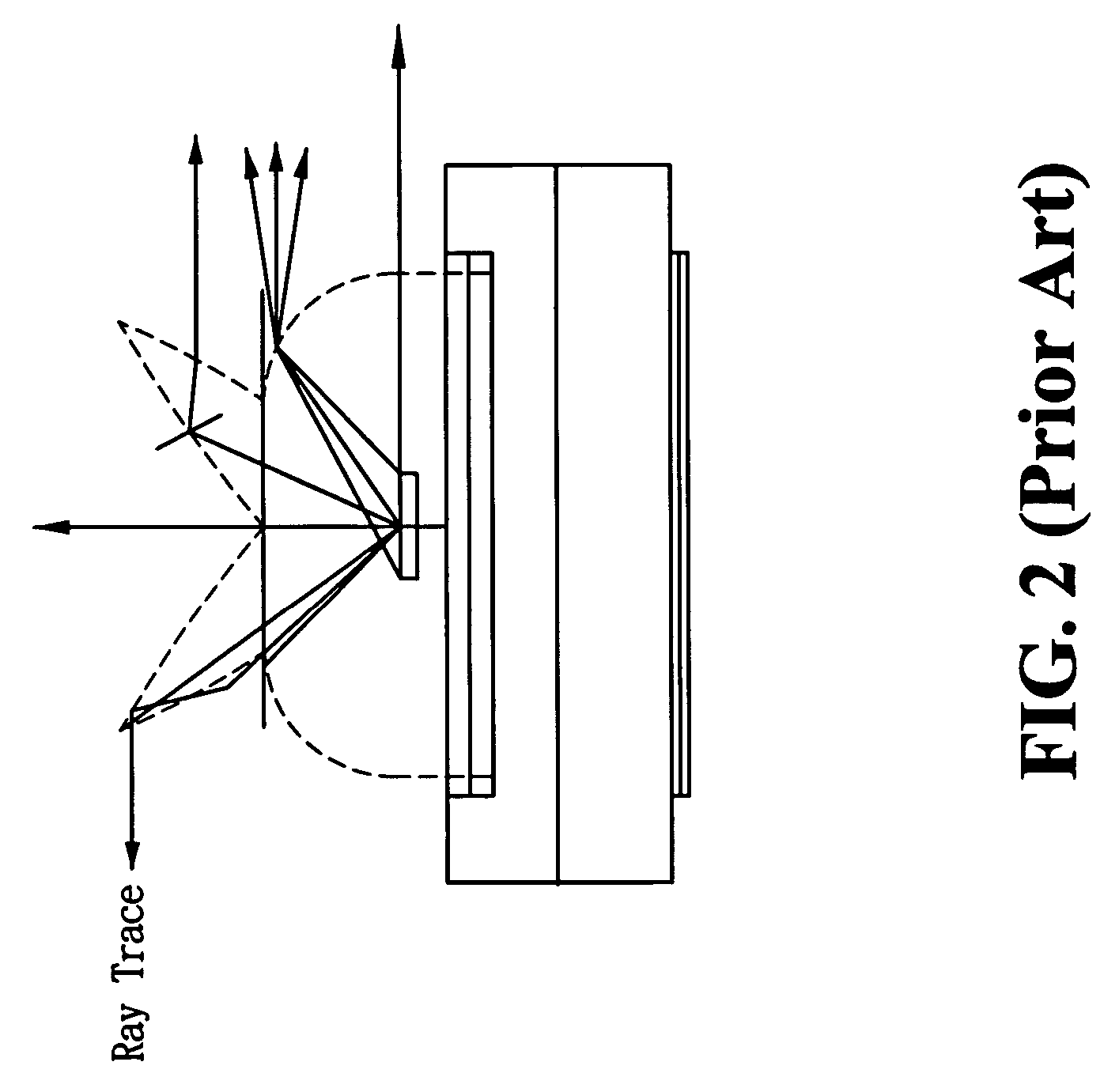

High average-power microwave window with high thermal conductivity dielectric strips

InactiveUS6118358AImprove effective thermal conductivityImprove thermal conductivityWaveguidesKlystronPolycrystalline diamond

A high average-power microwave window is provided whose thermal conductivity has been enhanced to enable it to transmit higher average RF power levels than conventional windows of the same size. Such a window is suitable for use with high-average power RF sources such as klystrons and magnetrons. The window comprises a ceramic substrate, typically a low-loss ceramic such as alumina or quartz, to which narrow strips of a high thermal conductivity material have been bonded. One such high thermal conductivity material is synthetic polycrystalline diamond, which can be bonded to the surface of a dielectric substrate using a high-temperature cement or can be directly deposited on the surface by a process such as chemical vapor deposition (CVD). High-purity alumina, a commonly-used material for high-power RF windows, has a thermal conductivity of 26.4 W / mx DEG C., while synthetic diamond has a thermal conductivity of 1000 W / mx DEG C., 2.6 times that of copper and 38 times that of alumina. The novel feature is the use of high thermal conductivity strips to increase the effective thermal conductivity of a microwave window by providing low-resistance paths by which heat can be extracted from the window, resulting in a significant increase in the window's power-handling capacity.

Owner:CROUCH DAVID D

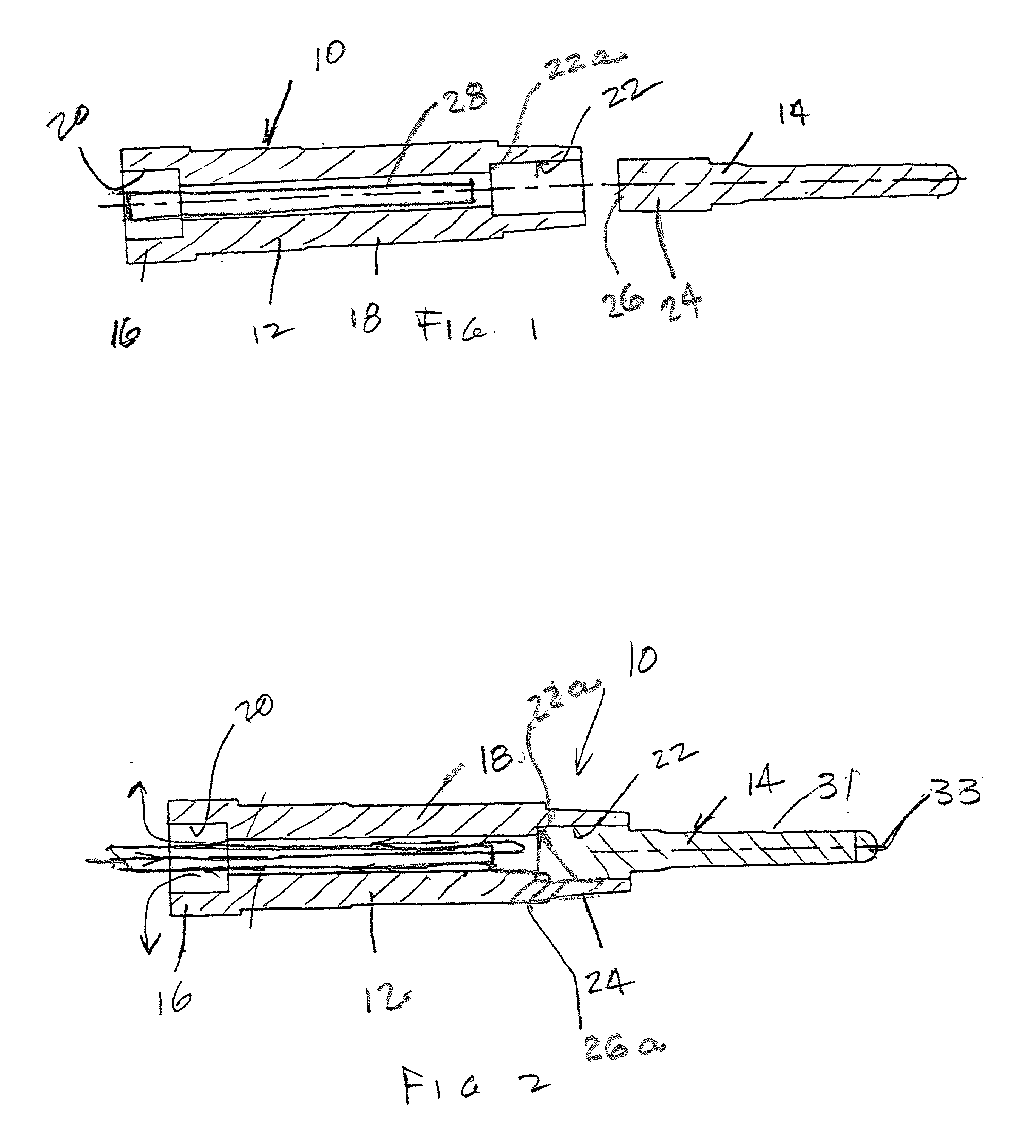

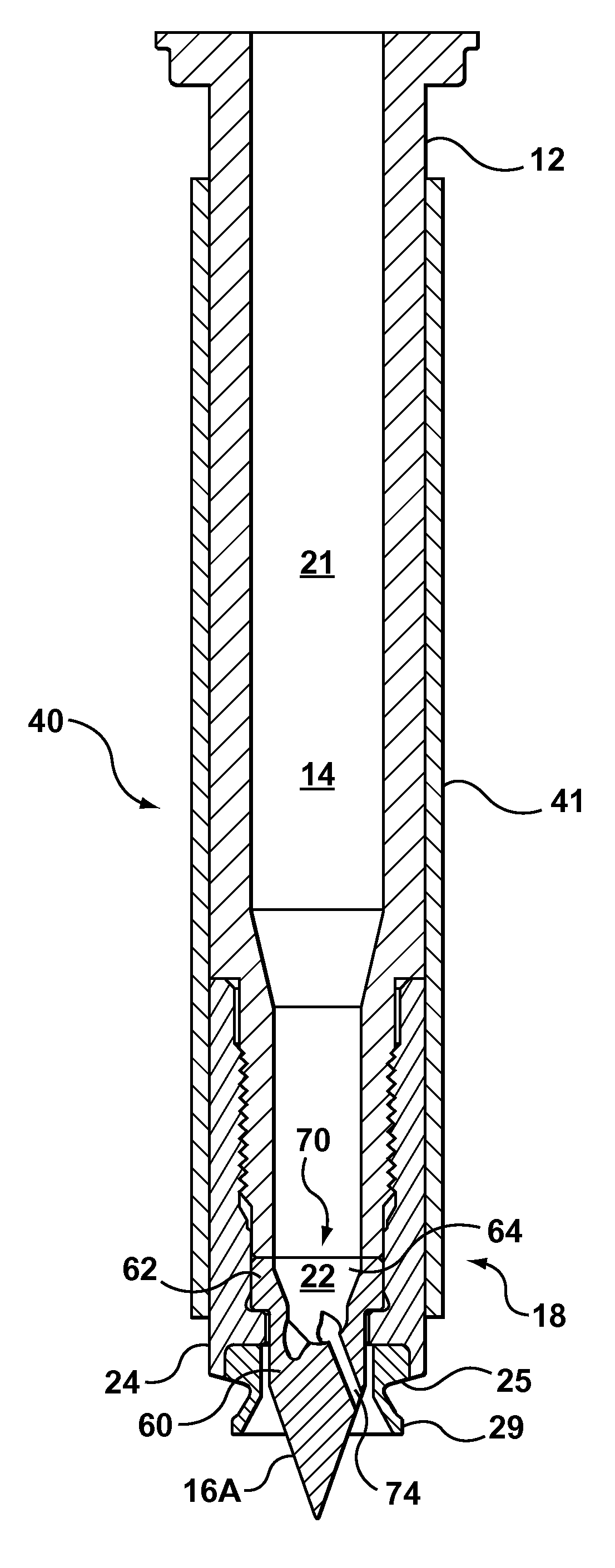

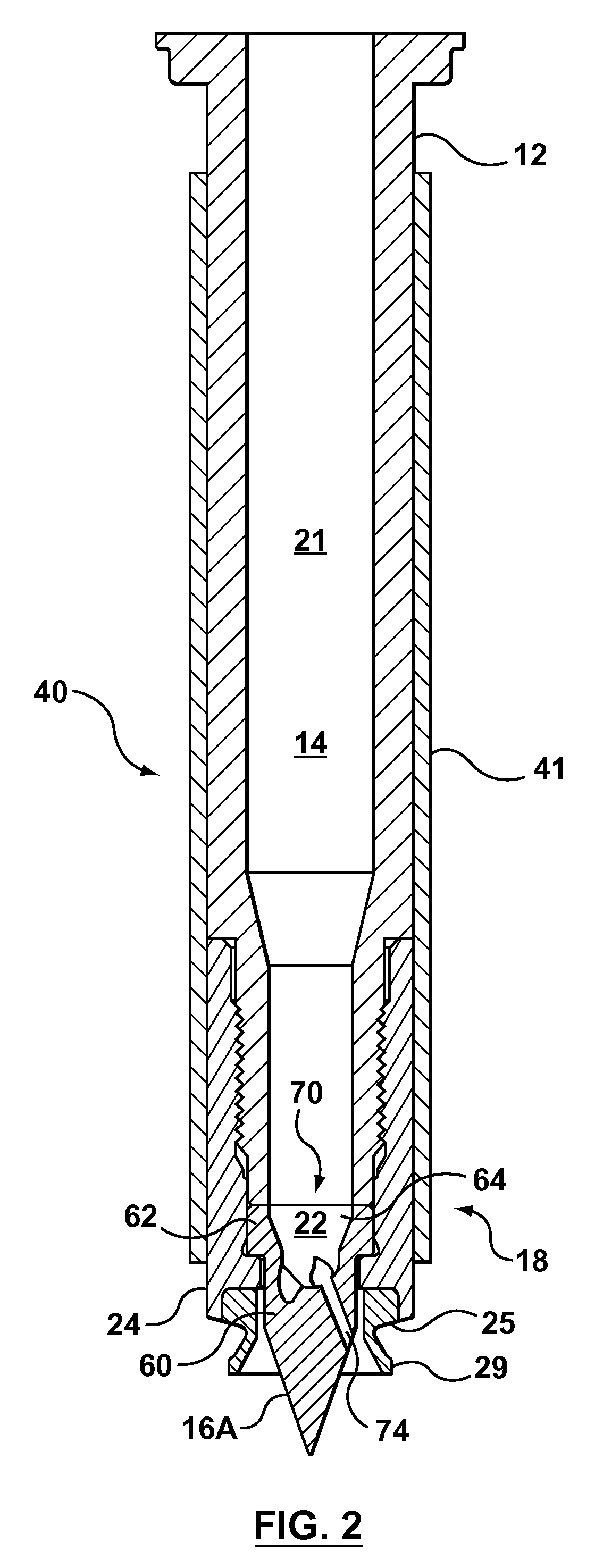

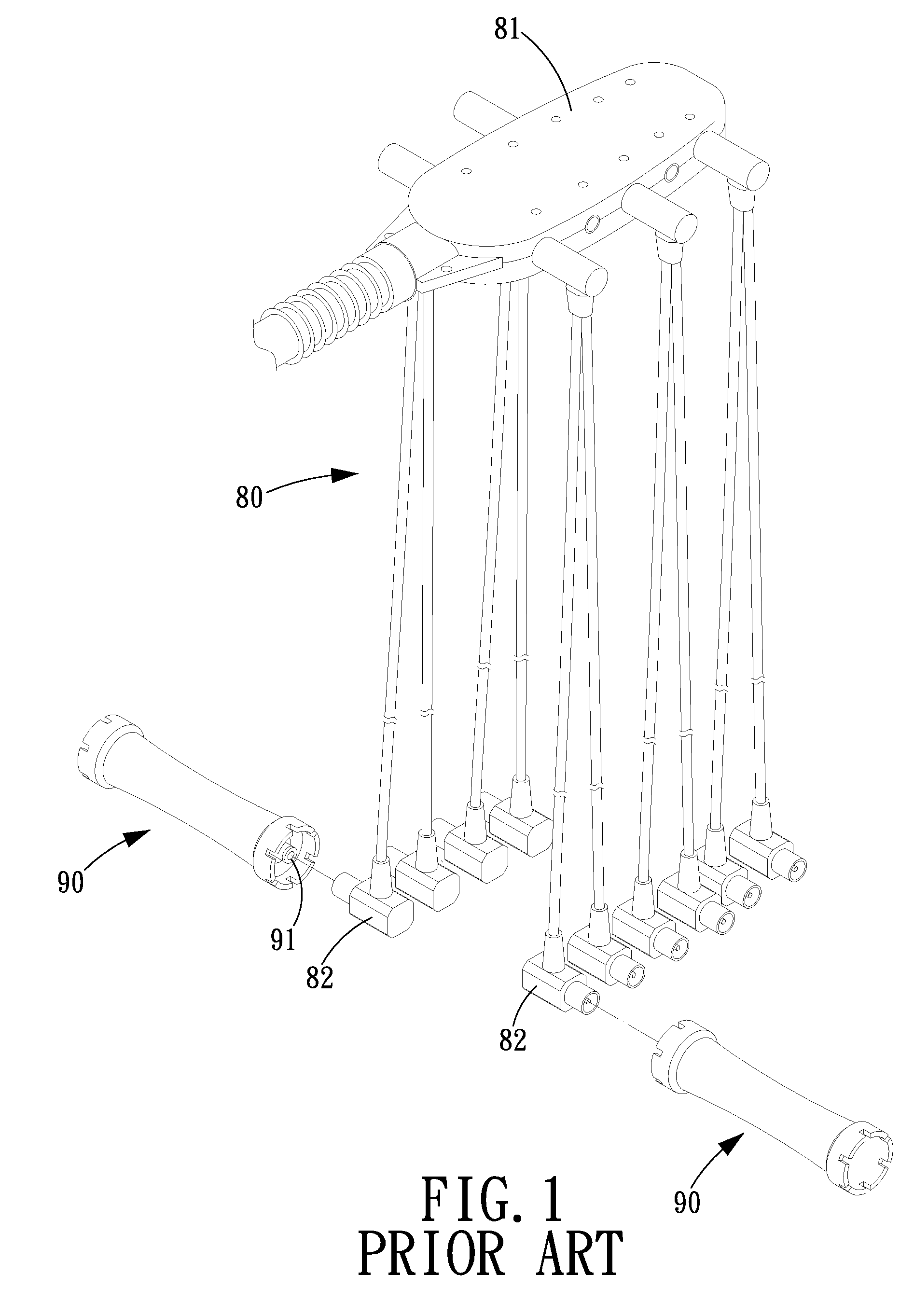

Injection Molding Nozzle Assembly with Composite Nozzle Tip

InactiveUS20080206391A1High thermal conductivity materialHigh strengthFurnace typesFood shapingThermal conductivityThermal transmittance

A nozzle assembly for an injection molding assembly has a nozzle housing having a melt channel extending therethrough, a nozzle tip, and a retainer that retains the nozzle tip against the nozzle housing. The nozzle tip is formed of a precipitation hardened, high thermal conductivity material and a precipitation hardened, high strength material, which are integrally joined together to form the body. The thermal conductivity of the high thermal conductivity material is greater than the thermal conductivity of the high strength material, and the strength of the high strength material is greater than the strength of the high thermal conductivity material. The high thermal conductivity material and the high strength material can be precipitation hardened together under the same precipitation hardening conditions to achieve increases in the value of at least one strength aspect of the high thermal conductivity material and the value of at least one strength aspect of the high strength material.

Owner:HUSKY INJECTION MOLDING SYST LTD

Leadframe designs for integrated circuit plastic packages

ActiveUS7221042B2Effective coolingHigh strengthSemiconductor/solid-state device detailsSolid-state devicesPackage designHigh intensity

Owner:BELL SEMICON LLC

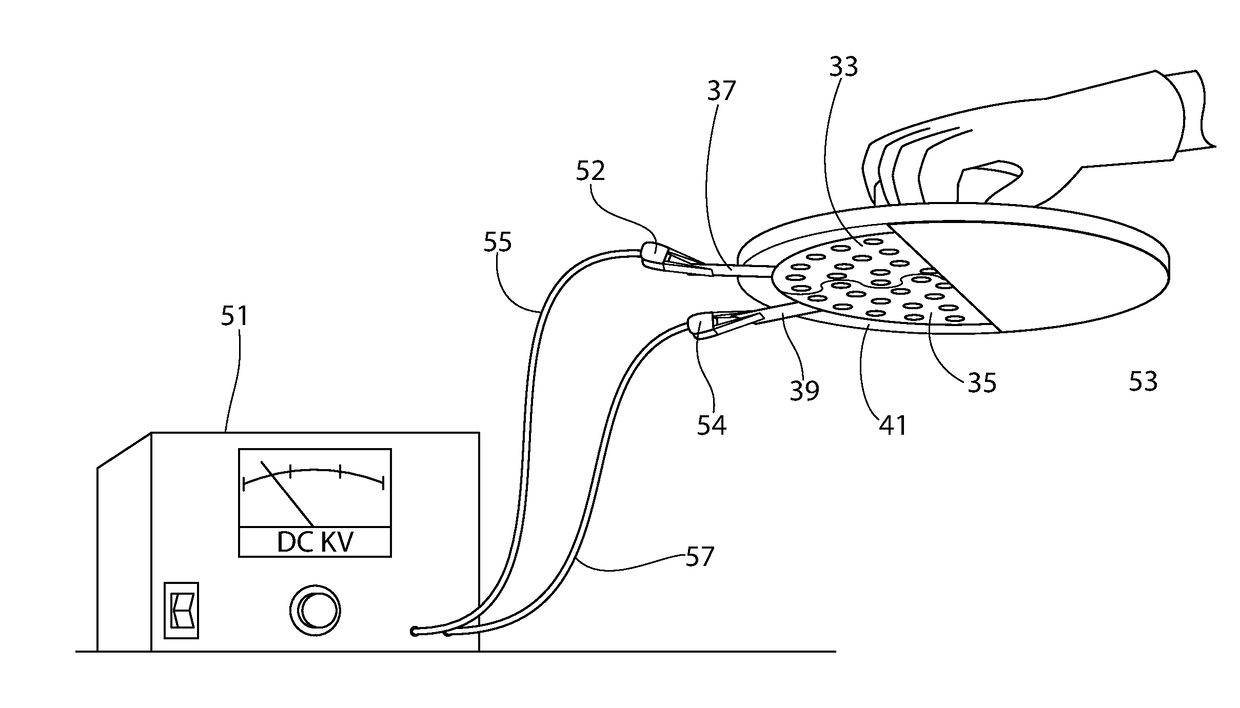

Film electrode for electrostatic chuck

ActiveUS20180047605A1High thermal conductivity materialHigh dielectric strengthVacuum evaporation coatingSputtering coatingThin sheetEngineering

A perforated film electrode for a pinned electrostatic chuck that lies below the top surface of the pins in the valleys or interstices between pins, below the elevation of the top surface of the pins, and is attached to the body of the chuck. In one embodiment, the perforated film electrode assembly features a thin film electrode sandwiched between thin sheets of electrically insulating material. The top, outer or exposed surface of the perforated film electrode assembly has a flatness that is maintained within 3 microns. That is, the distance or elevation between the tops of the pins and the top surface of the perforated film unit is maintained within plus or minus 3 microns. A tool for producing a uniform elevation of the top and bottom sheets or layers of electrically insulating material also is taught.

Owner:II VI DELAWARE INC

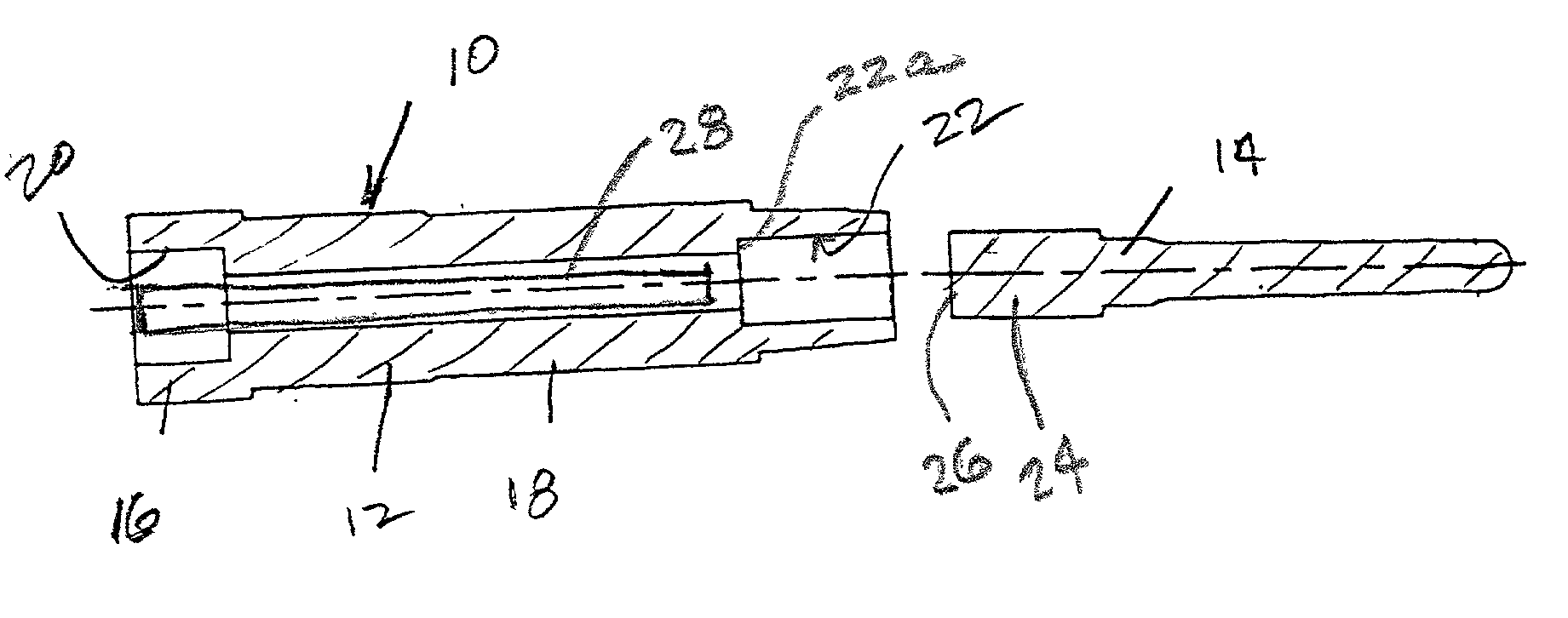

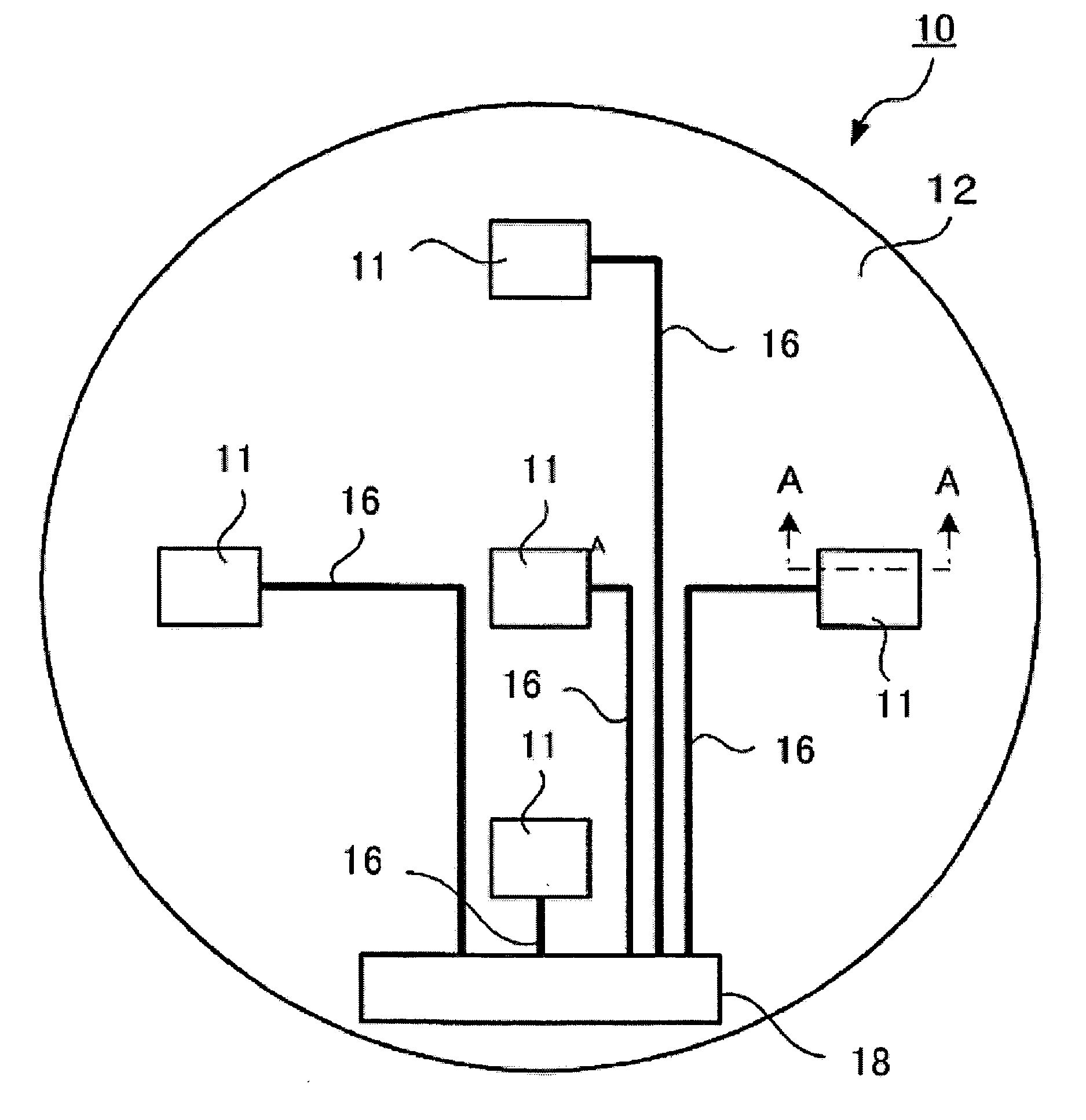

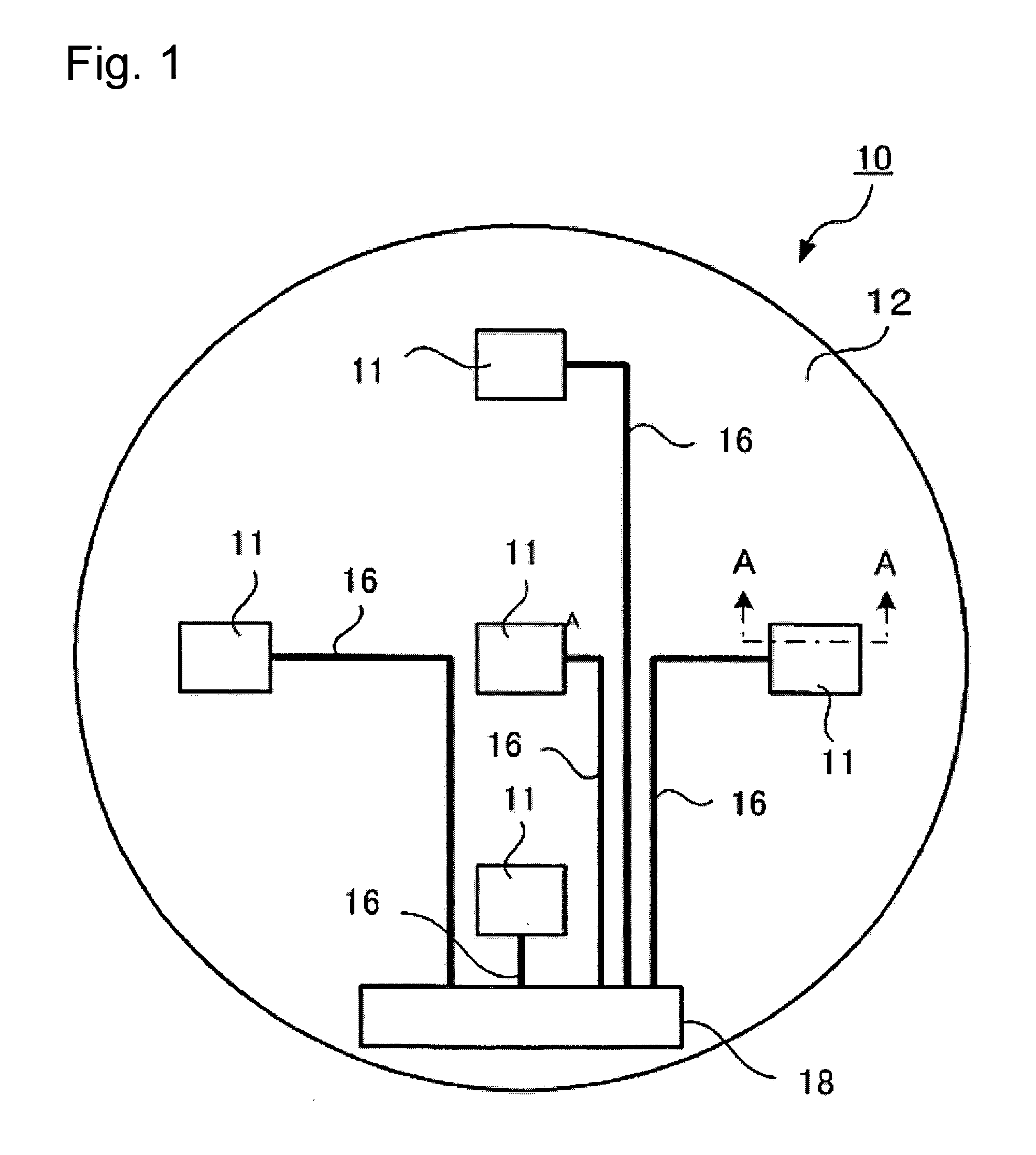

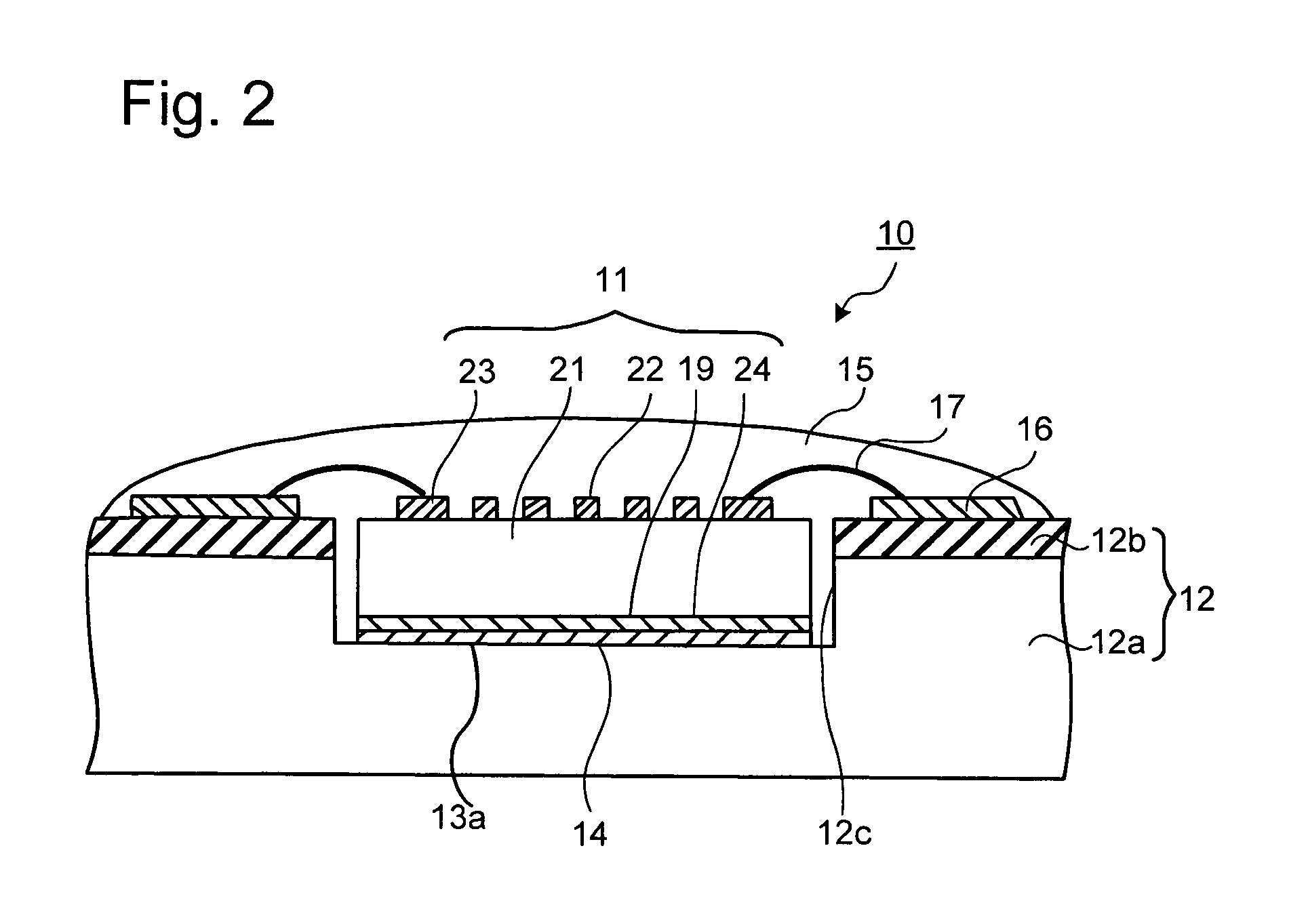

Wafer-Shaped Measuring Apparatus and Method for Manufacturing the Same

InactiveUS20090085031A1Convenient temperature measurementImprove the heating effectThermometer detailsSemiconductor/solid-state device detailsEngineeringContact layer

The present invention provides a temperature measuring apparatus with favorable temperature measuring performance and a method of manufacturing the same. A temperature measuring apparatus (10) provided with a temperature sensor (11) arranged on a bottom surface of a depressed section (12c) of a semiconductor wafer (12). The semiconductor wafer (12) and temperature sensor (11) are contacted together through a first contact layer (14) and second contact layer (24). The first and second contact layers (14) and (24) are formed from the same material, concretely a metal with high heat conductivity, and formed to provide virtually even thickness in surface direction. By such first and second contact layers (14) and (24), heat is conducted from the semiconductor wafer (12) to the temperature sensor (11) favorably. Therefore, the temperature measuring apparatus (10) has favorable temperature measuring performance.

Owner:TOKYO ELECTRON LTD

Fabrics with high thermal conductivity coatings

ActiveUS7553781B2Improve thermal conductivityHigh thermal conductivity materialGlass/slag layered productsNatural mineral layered productsFiberCarbide

The present invention facilitates the thermal conductivity of fabrics by surface coating of the fabrics with high thermal conductivity materials 6. The fabrics may be surface coated when they are individual fibers or strands 4, bundles of strands, formed fabric or combinations therefore. A particular type of fibrous matrix used with the present invention is glass. Some fabrics may be a combination of more than one type of material, or may have different materials in alternating layers. HTC coatings of the present invention include diamond like coatings (DLC) and metal oxides, nitrides, carbides and mixed stoichiometric and non-stoichiometric combinations that can be applied to the host matrix.

Owner:SIEMENS ENERGY INC

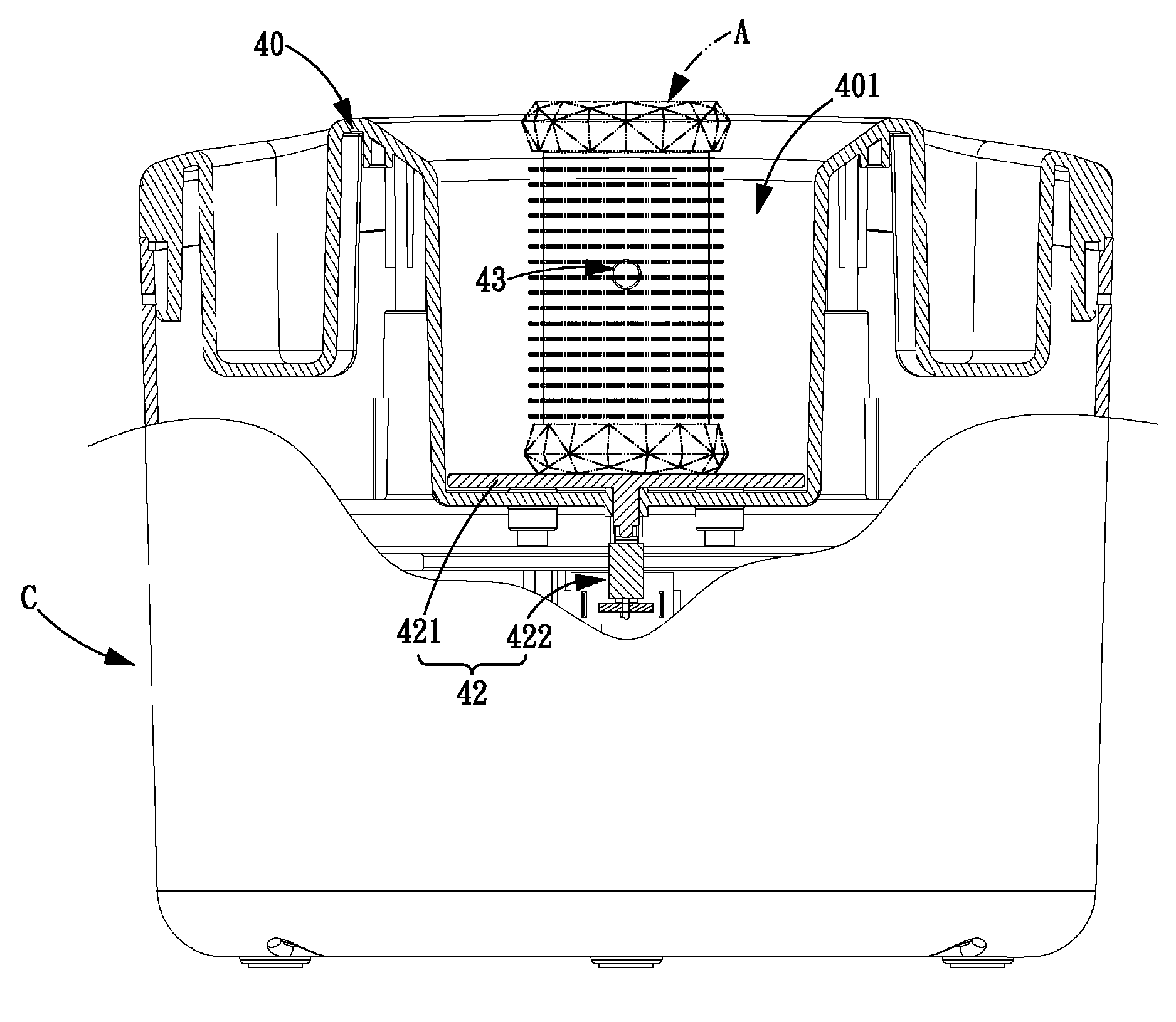

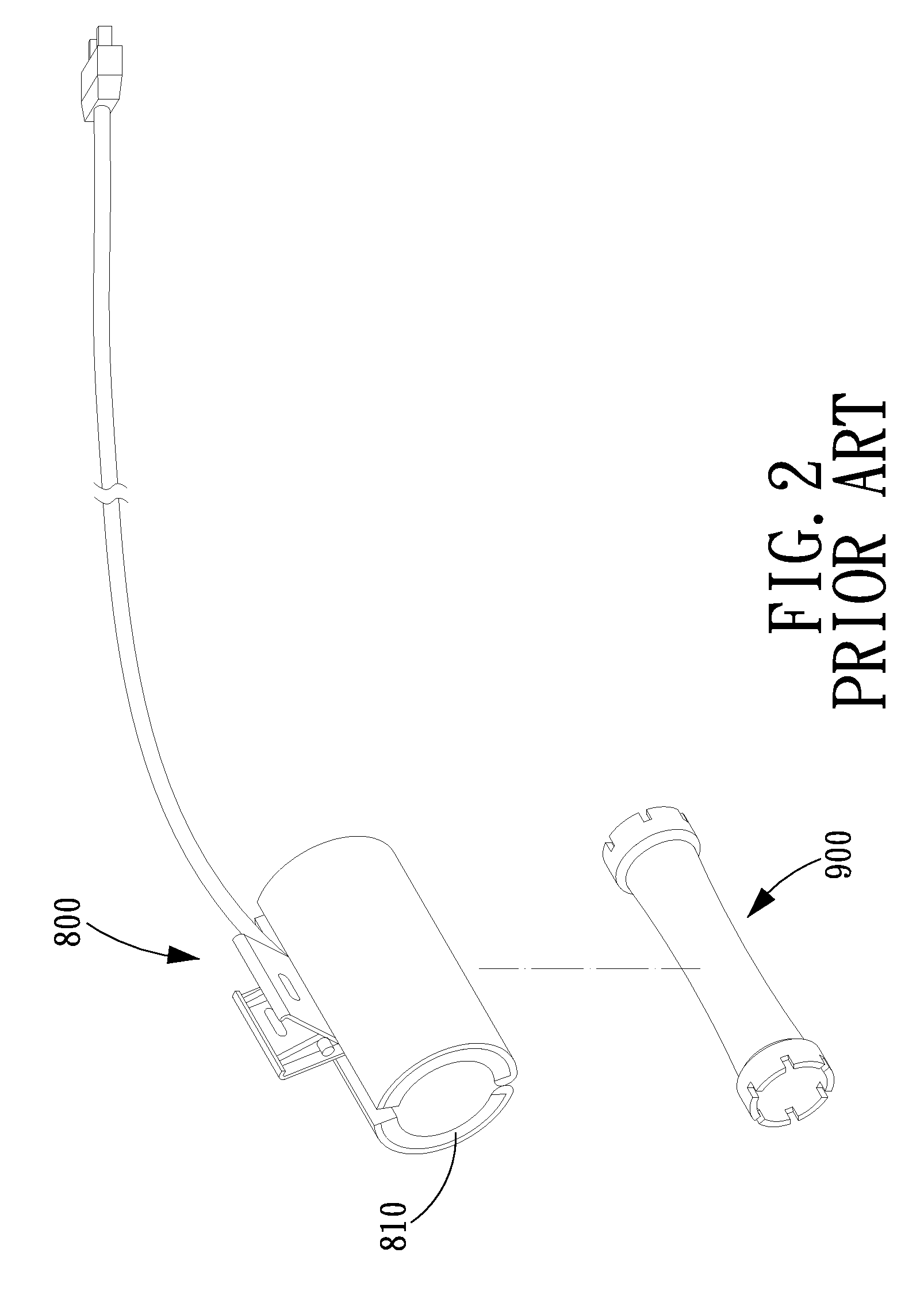

Hair styling heating apparatus

InactiveUS8912467B2Heating fastHigh thermal conductivity materialCurling-ironsCurling-tongsEngineeringElectromagnetic heating

A hair styler and its heating device which can heat the thermal storage piece inside the hair roller quickly to a desired temperature by electromagnetic heating. The thermal storage piece is made of high thermal conductivity material which absorbs heat quite quick and disposed inside the hair roller to prevent the hair from directly contacting the thermal storage piece during hair styling, consequently preventing the hair from being burned. Then a low thermal conductivity isolating layer retains the heat within the hair roller and enables the heat to be uniformly and constantly transmitted to the outer surface of the hair roller, providing an effect of low energy consumption and long-lasting heat. A temperature sensing piece is used to detect and indicate the temperature of the hair styler by using different colors, making it easier for the user to know the temperature of the hair styler.

Owner:MANICA TAIWAN

Use of powder metal sintering/diffusion bonding to enable applying silicon carbide or rhenium alloys to face seal rotors

InactiveUS20050175840A1Improve thermal conductivityHigh stressEngine sealsBearing componentsRheniumPowder mixture

A method for making aerospace face seal rotors reinforced by rhenium metal, alloy, or composite in combination with silicon carbide or other ceramic. The resulting rotor also is disclosed. Ceramic grains, preferably silicon carbide (SiC), are mixed with powdered metallic (PM) binder that may be based on a refractory metal, preferably rhenium. The mixture is applied to a rotor substrate. The combined ceramic-metal powder mixture is heated to sintering temperature under pressure to enable fusion of the ceramic in the resulting metal-based substrate. A load may then be applied under an elevated temperature. The resulting coated rotor can exhibit high hot hardness, increased durability and / or high hot wear resistance, as well as high thermal conductivity.

Owner:HONEYWELL INT INC

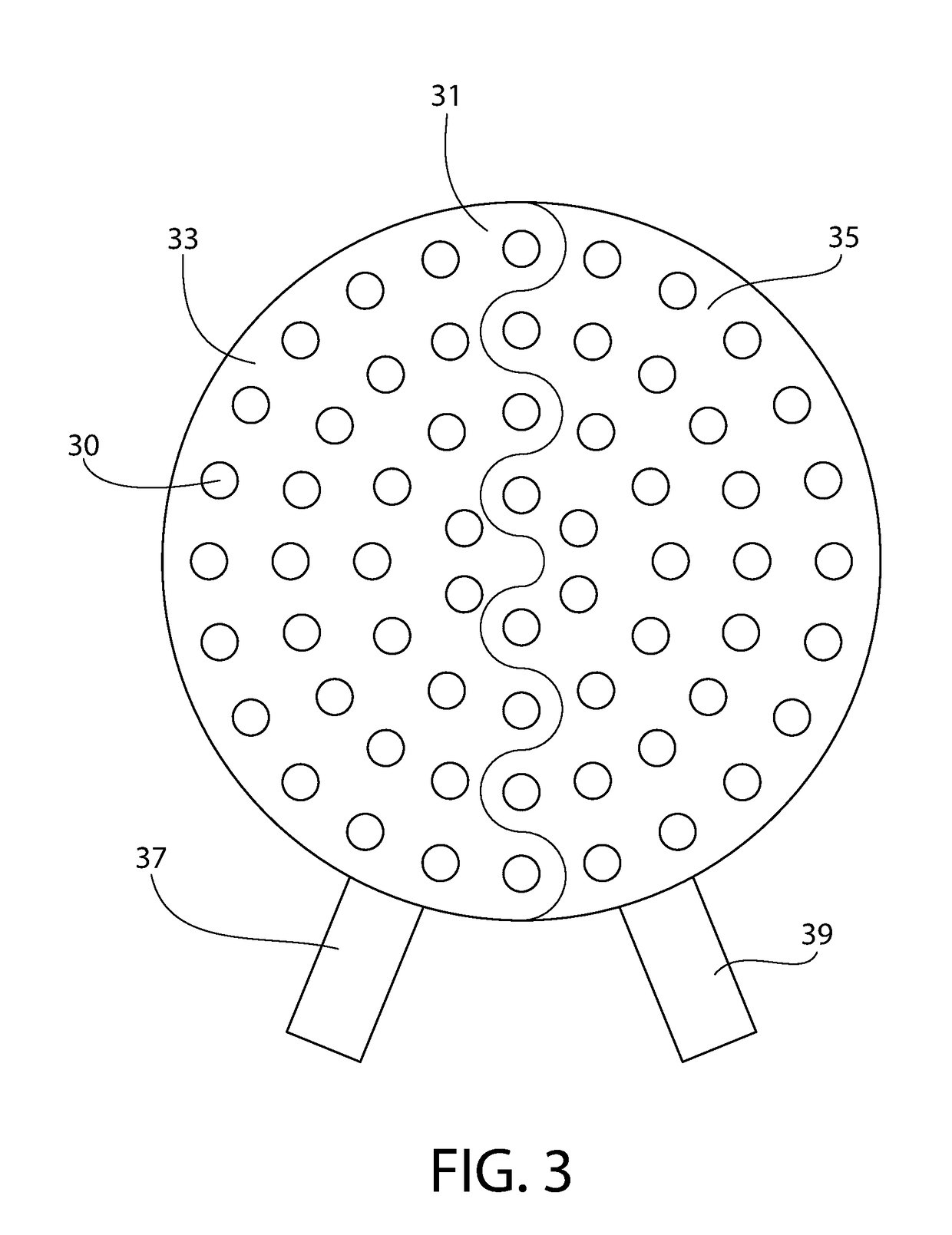

Patterning on surface with high thermal conductivity materials

ActiveUS7651963B2Maximize the effectMore placementAdhesive articlesPaper/cardboardNanometreThermal transmittance

The present invention provides for high thermal conductivity paper that comprises a host matrix (10), and high thermal conductivity materials (12) added to a surface of the host matrix in a specific pattern (12). The high thermal conductivity materials are comprised of one or more of nanofillers, diamond like coatings directly on the host matrix, and diamond like coatings on the nanofillers. In particular embodiments the specific pattern comprises one or more of a grid, edging, banding centering and combinations thereof and the high thermal conductivity materials cover 15-55% of the surface of the host matrix. Multiple surfaces, including sub layers may have patterning.

Owner:SIEMENS ENERGY INC

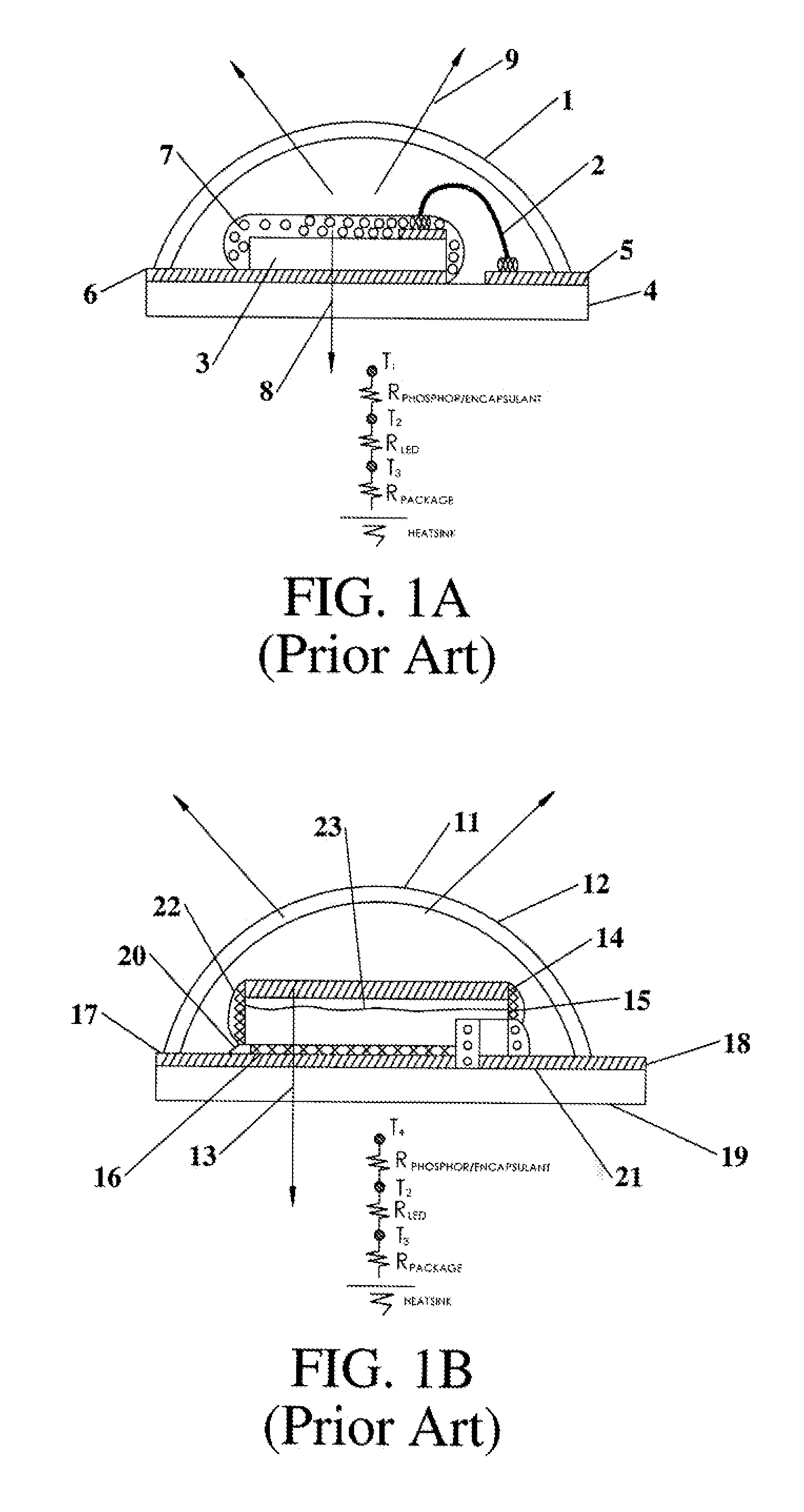

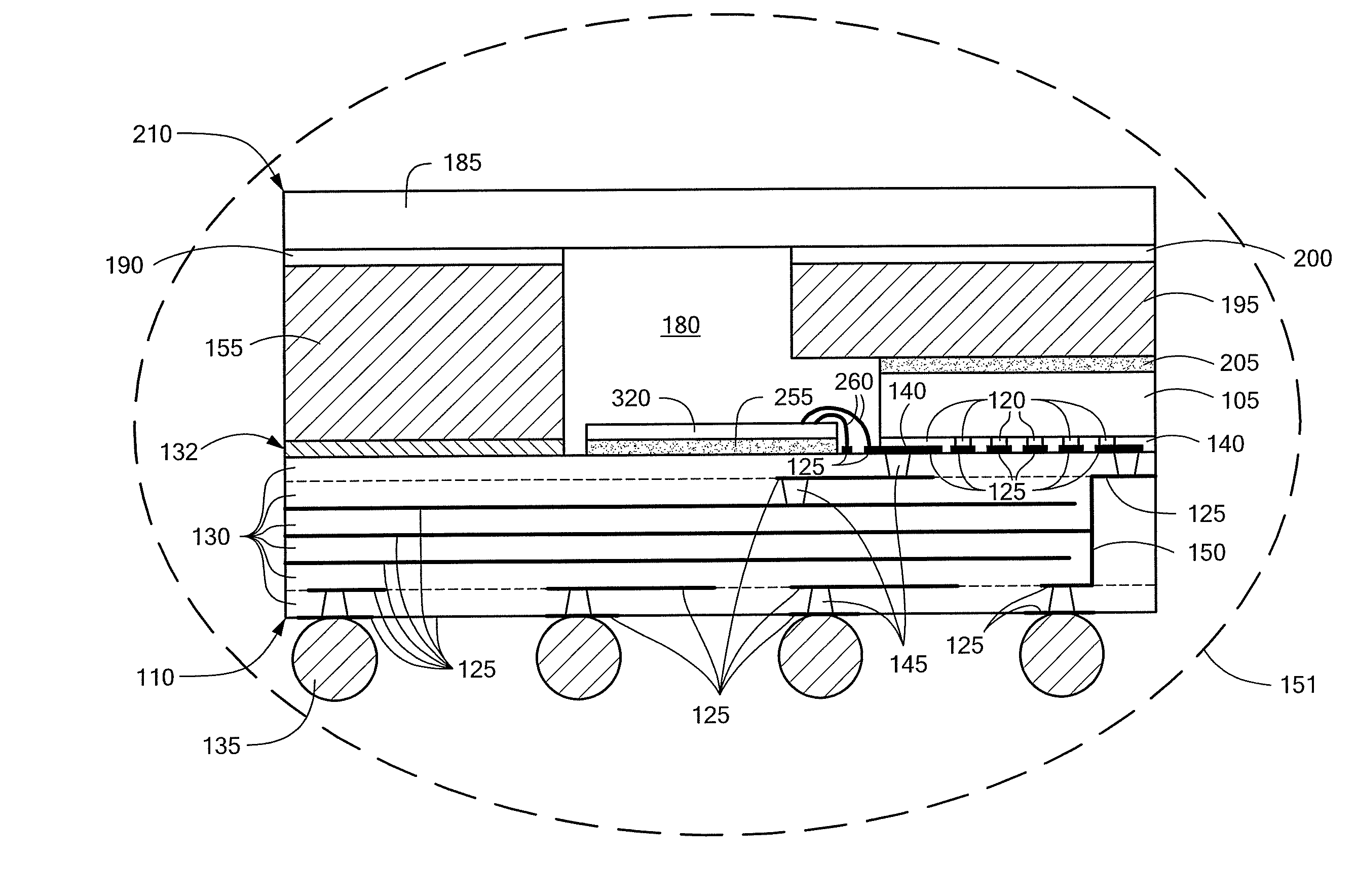

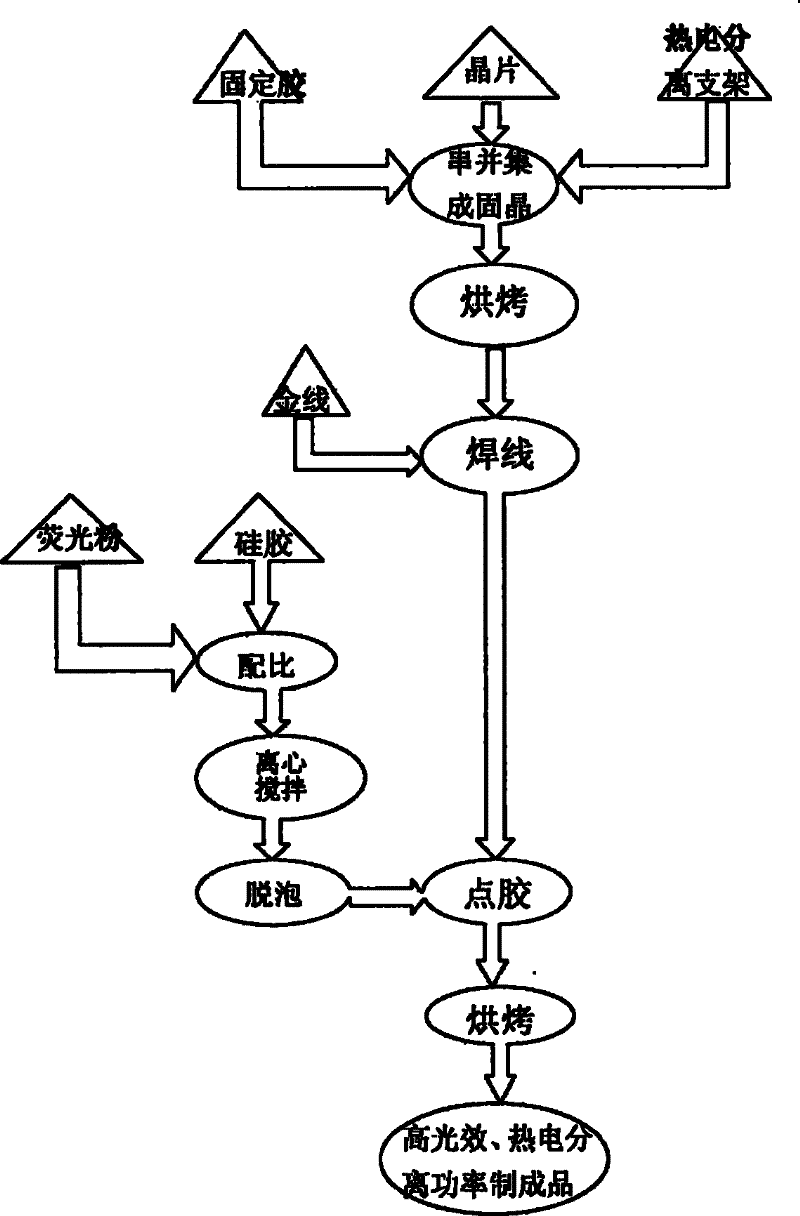

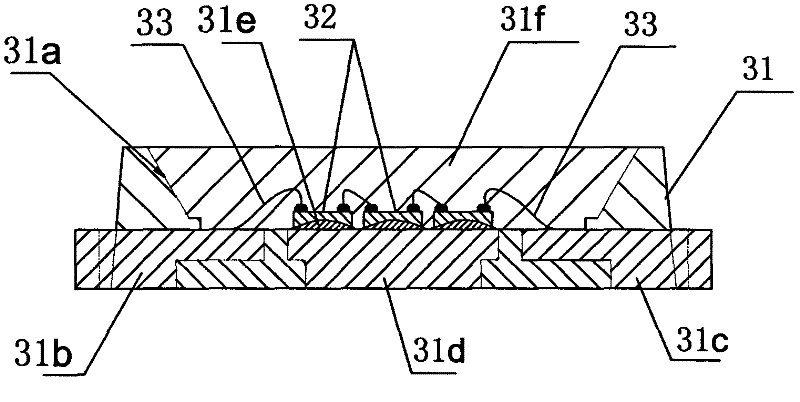

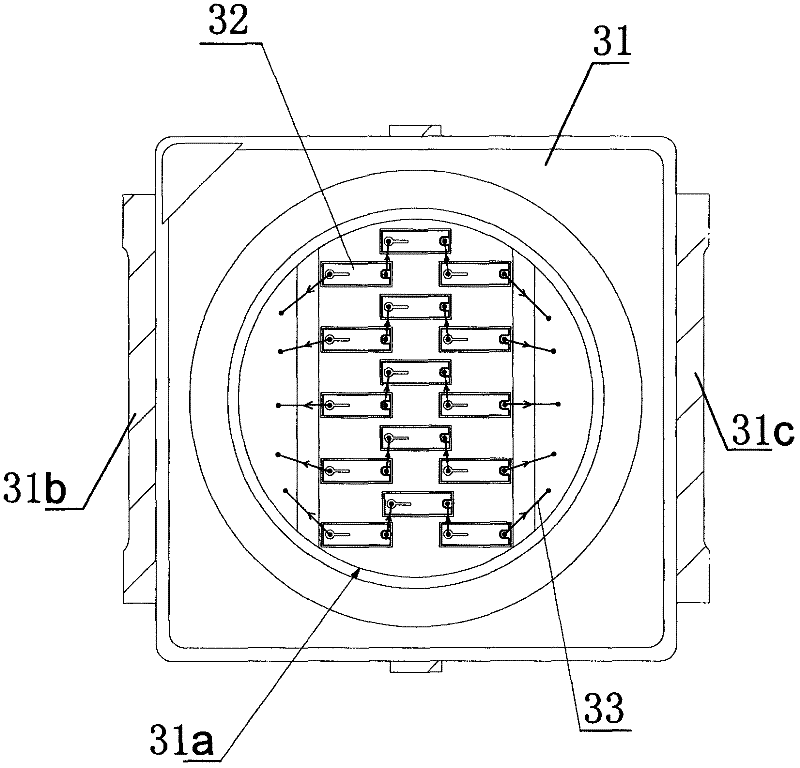

Highly integrated high light efficiency thermoelectric separation power type light emitting diode (LED) and encapsulating method thereof

InactiveCN102646673ASolve the problem of generally low light efficiencyHigh light efficiencySolid-state devicesSemiconductor devicesElectricityHeat conducting

The invention discloses a highly integrated high light efficiency thermoelectric separation power type light emitting diode (LED). The LED comprises a paster type bracket, an LED chip and gold threads, wherein a concave cup is formed on the upper surface of the bracket, electric conducting channels which are independently communicated into two sides of the concave cup are arranged at left and right sides of the bracket, the bottom surface of the bracket is provided with a heat conducting channel of which the middle part is communicated to the middle part of the concave cup, the LED chip is stuck with the heat conducting channel through heat conducting insulation paste, two poles of the LED chip are respectively electrically connected with the electric conducting channel through the gold threads, and a fluorescent colloid which is formed by mixing silica gel and fluorescent powder is filled and sealed in the concave cup. Because of the design of thermoelectric separation, heat dissipated when the LED chip works can be independently conducted to a heat dissipating pillar in time, and the impacts of heat on the reliability of second spot welding and the service life of the chip are reduced. With the design of polycrystal serial and parallel integration and thermoelectric separation, the LED disclosed by the invention has the technical effects of high light efficiency, independent heat and electric channels, simple structure, good heat dissipation effect and the like.

Owner:OUTRACE TECH

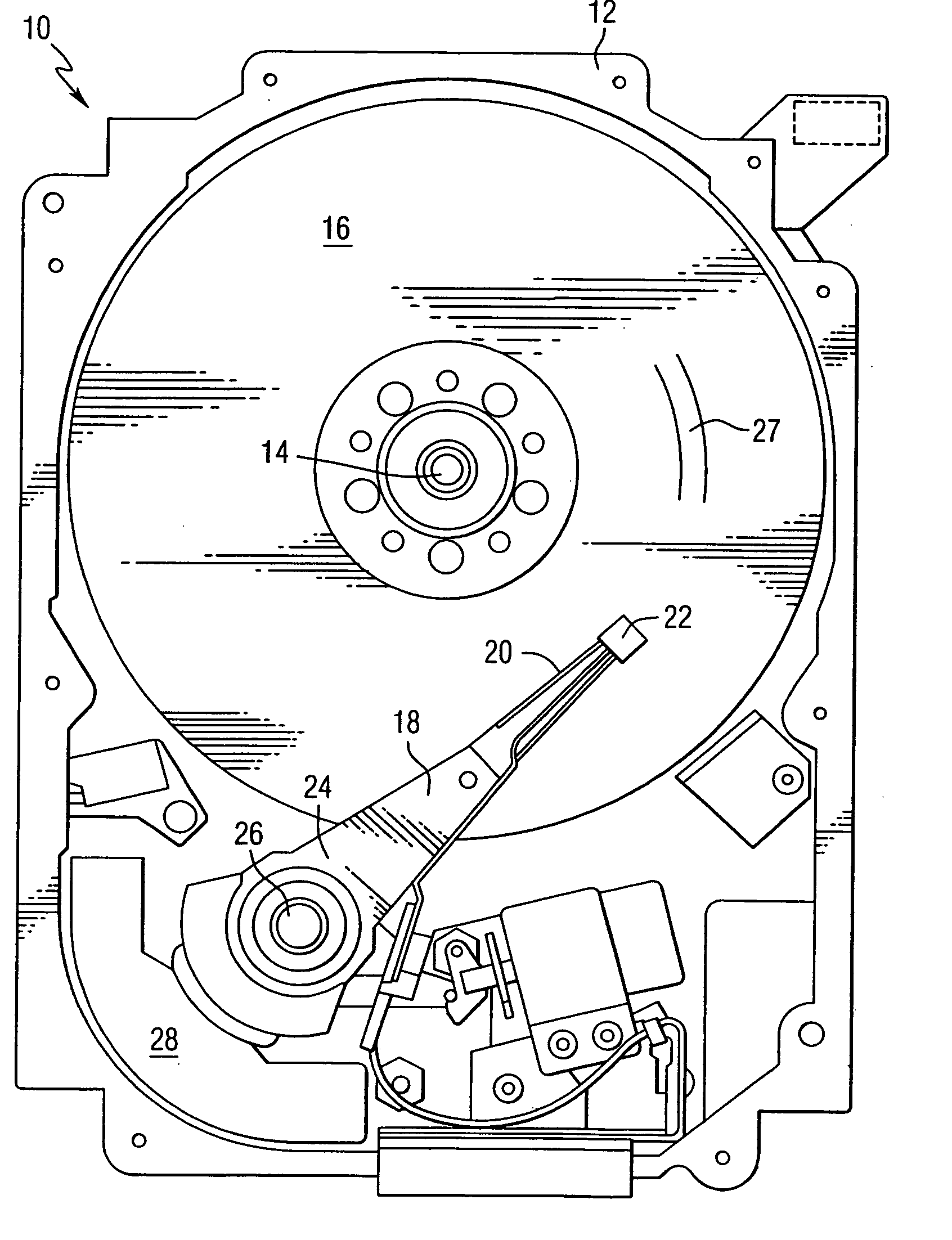

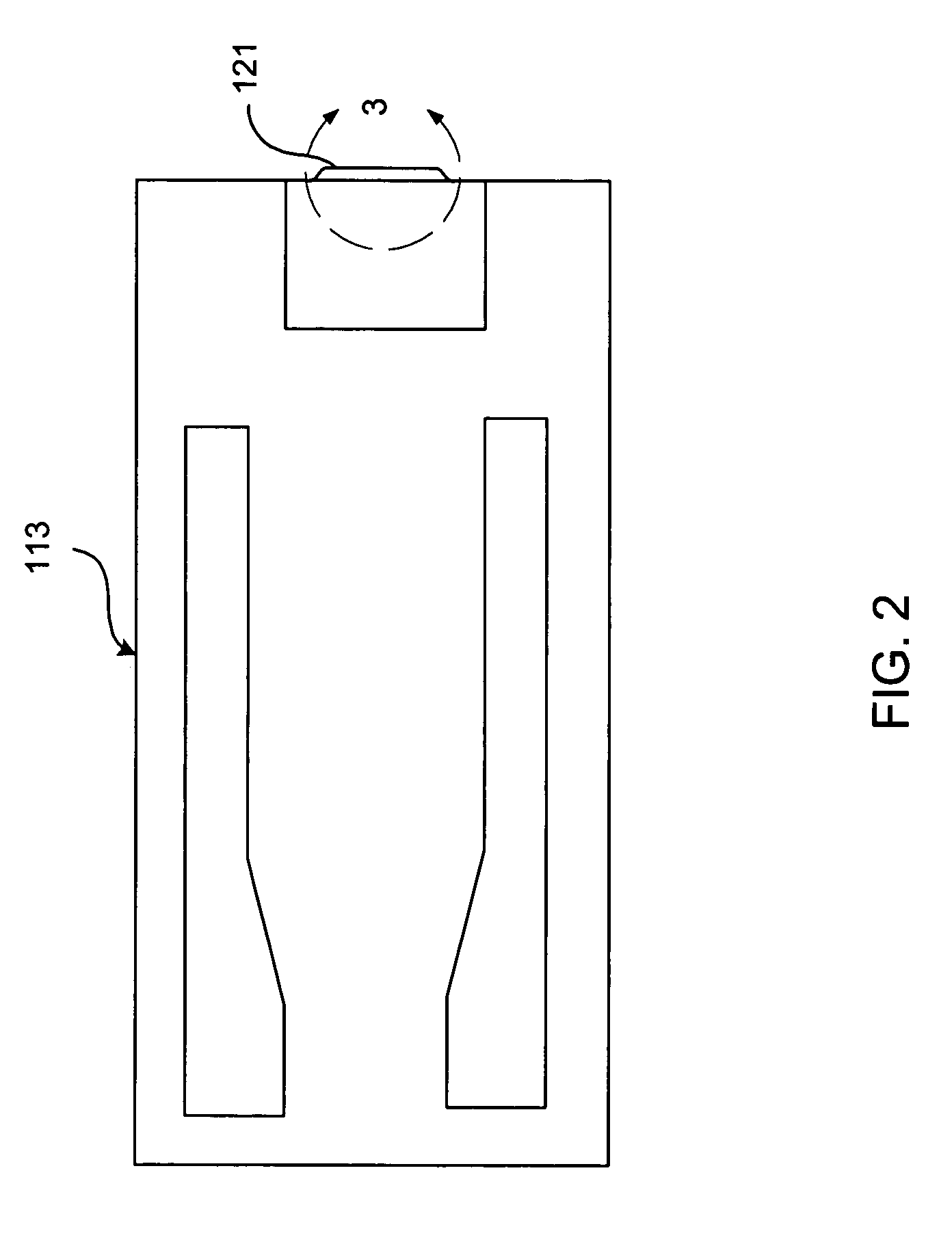

Heat sink and high thermal stability structure for CPP sensor

InactiveUS7209329B2Fast heat conductionHigh thermal conductivity materialNanoinformaticsHeads using thin filmsElectricityEngineering

A currently perpendicular to plane (CPP) sensor having a heat sink structure disposed beyond the stripe height of the sensor. The heat sink is preferably in thermal contact with one of the shields / leads of the sensor while being electrically insulated from the other shield / lead.

Owner:WESTERN DIGITAL TECH INC

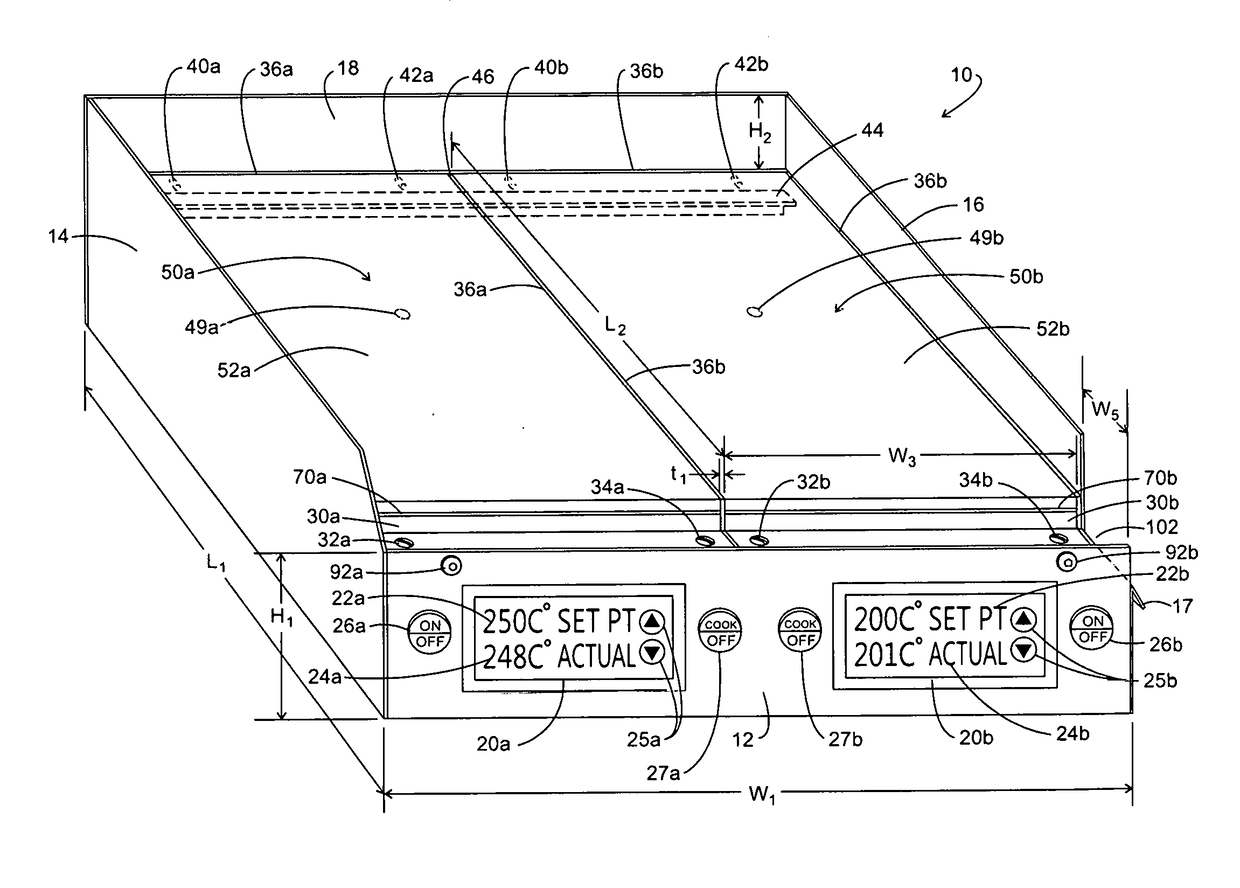

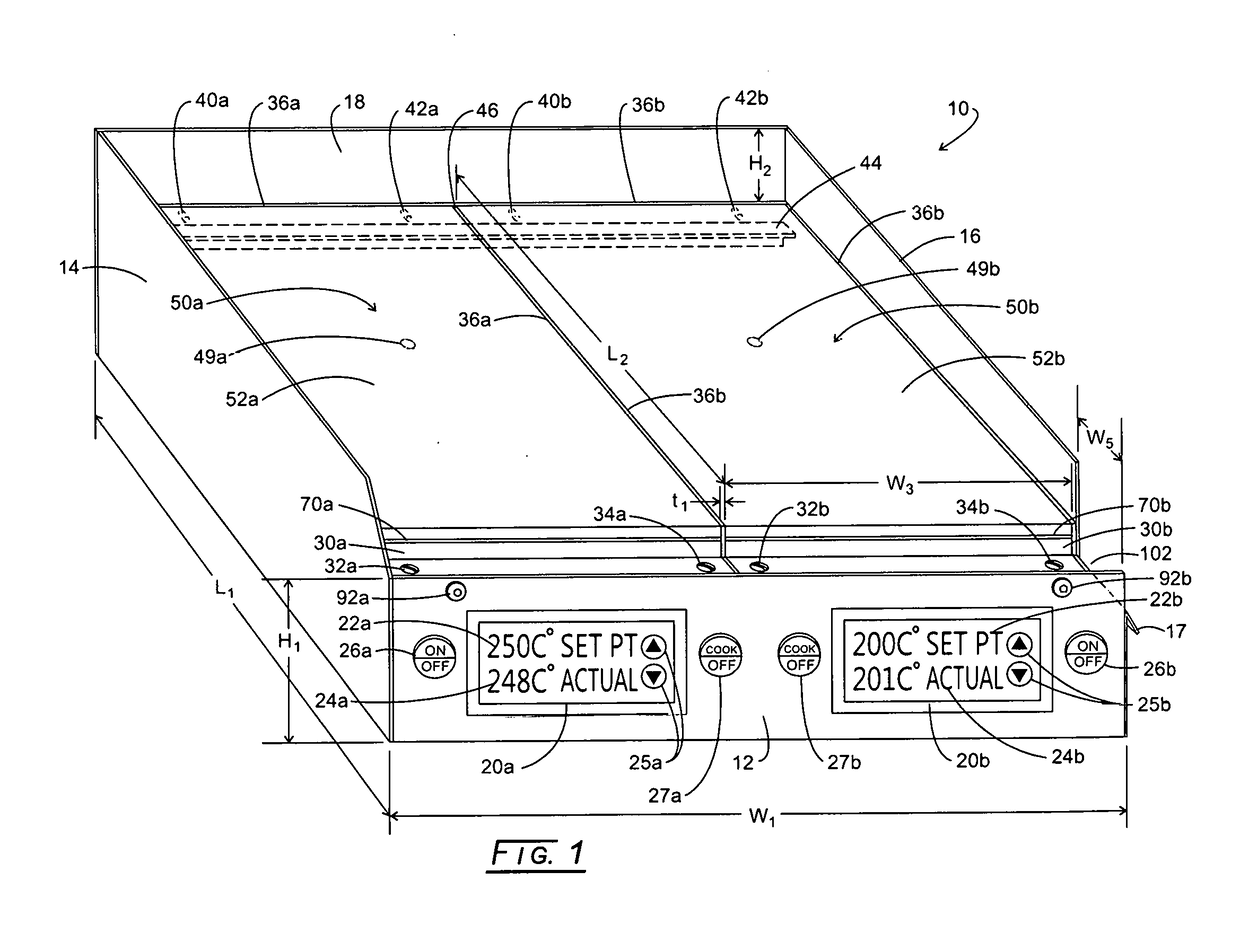

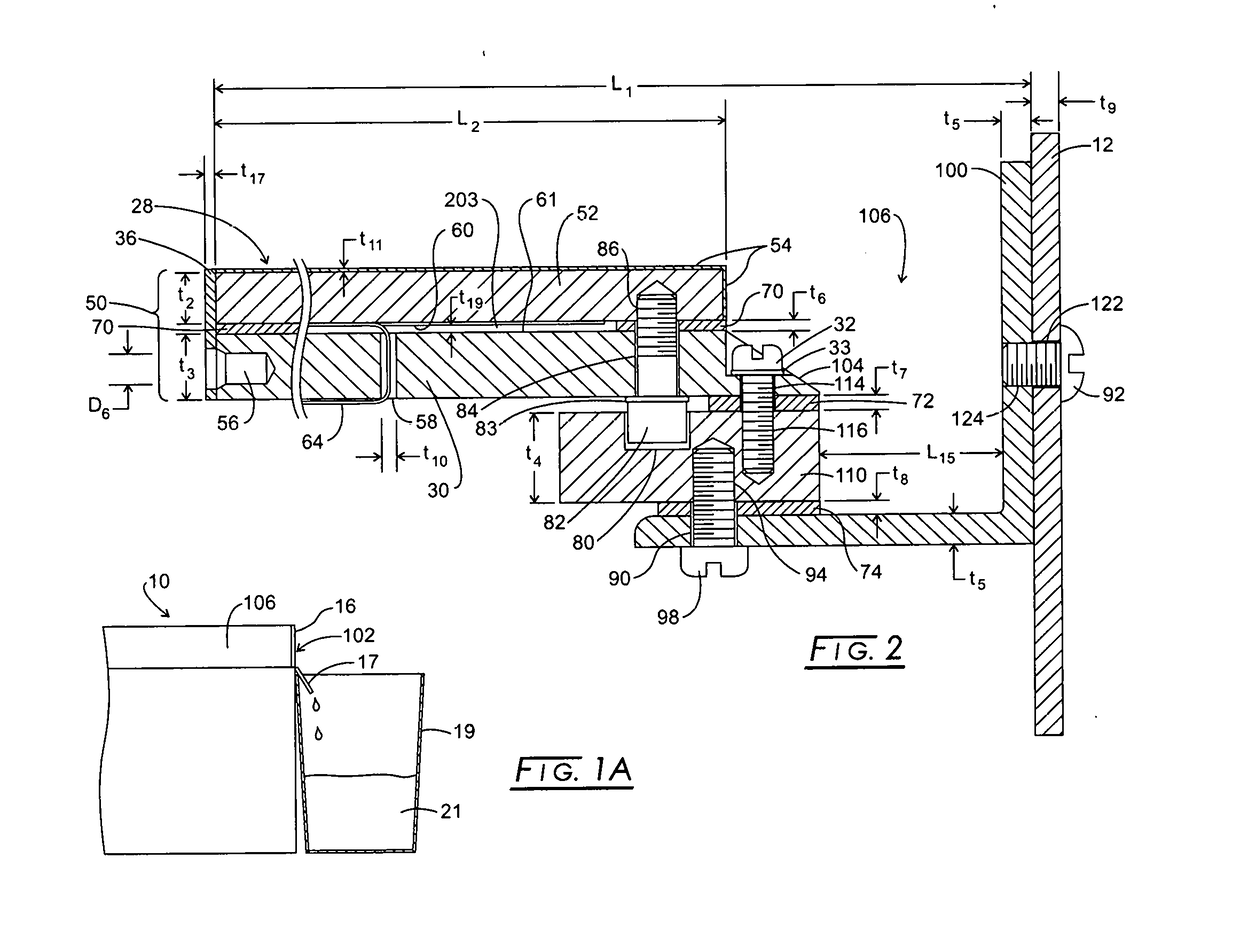

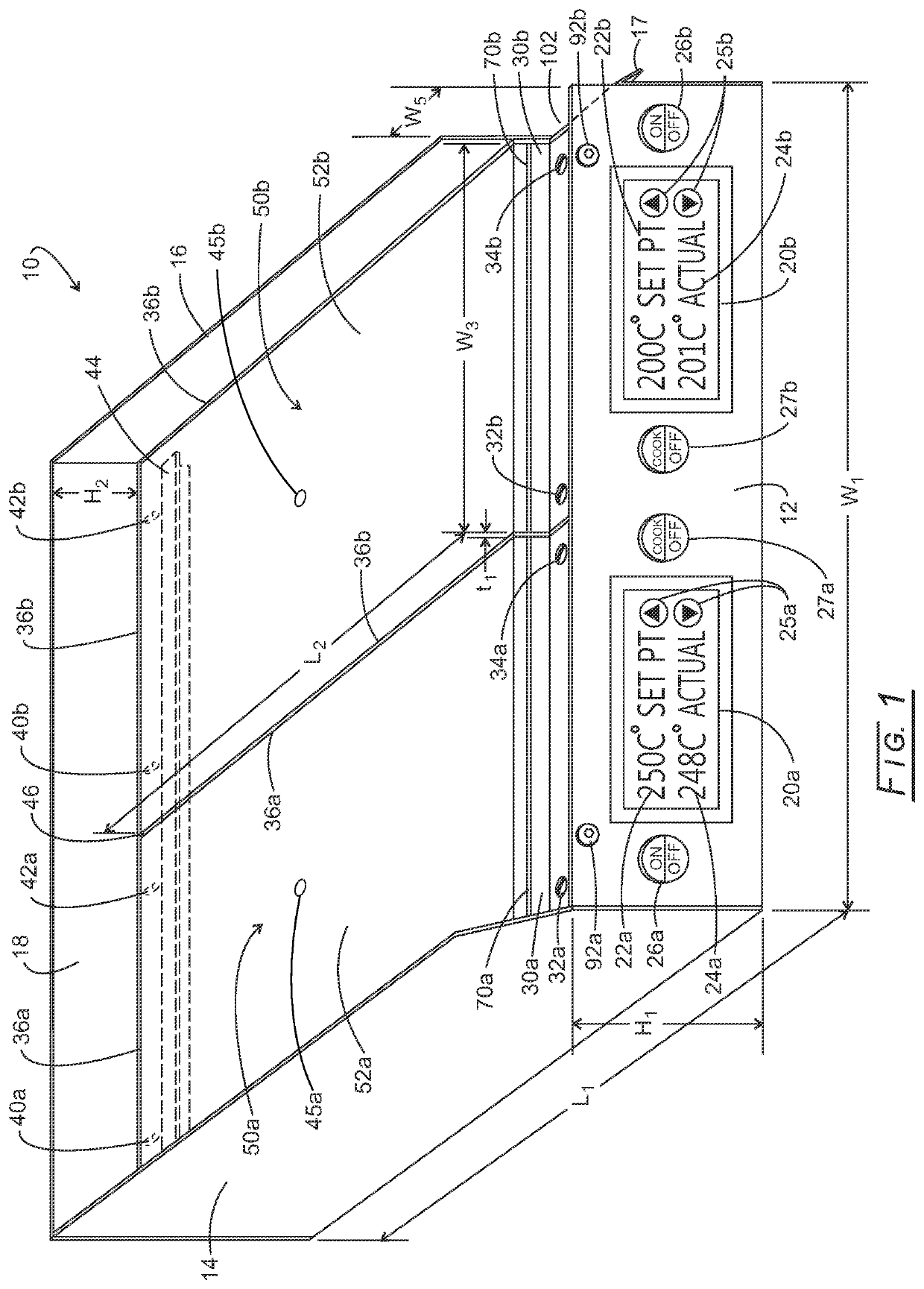

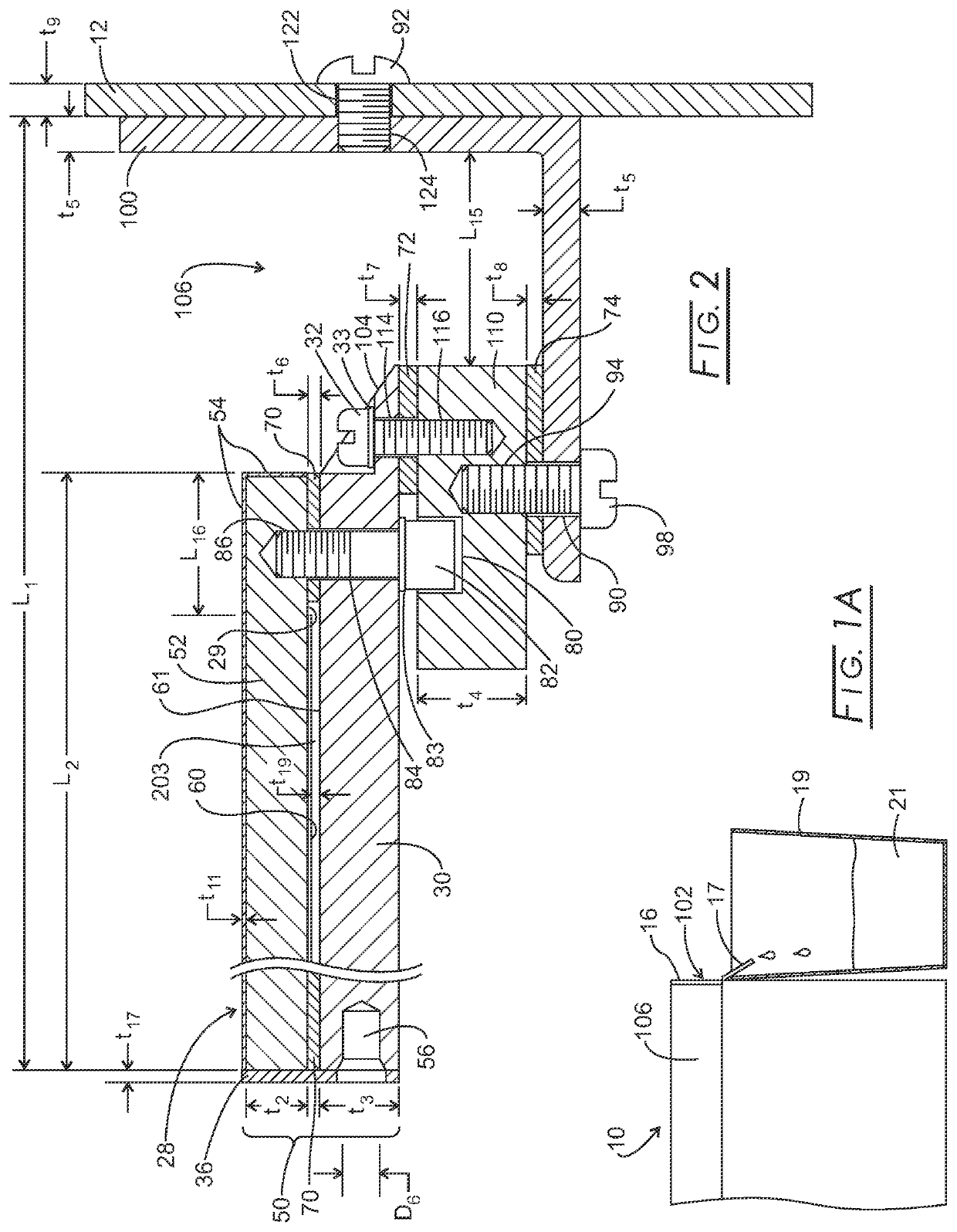

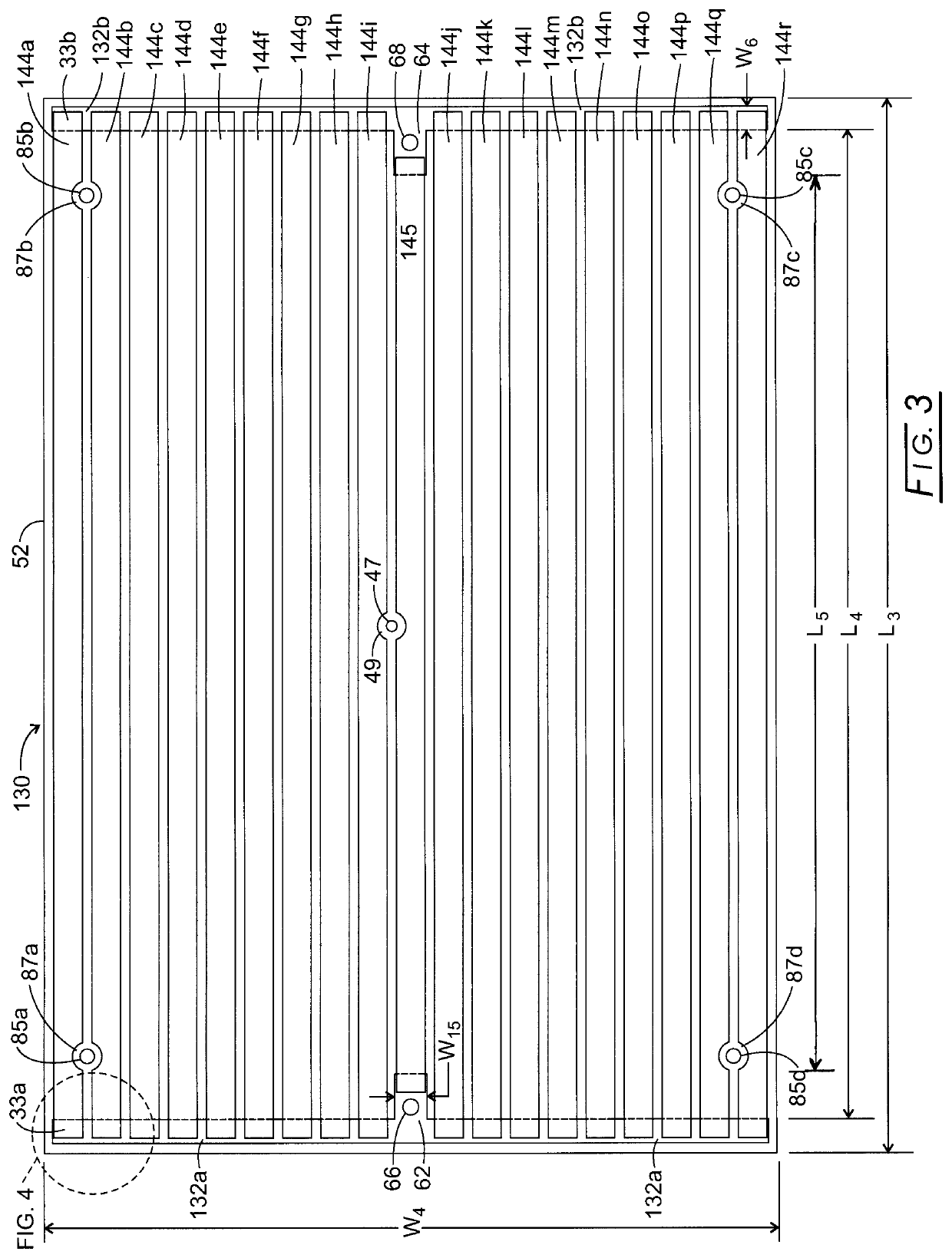

Isothermal Cooking Plate Apparatus, System, and Method of Manufacture and Use

ActiveUS20180328591A1Improve thermal conductivityHigh hardnessDomestic stoves or rangesLighting and heating apparatusElectrical connectionEngineering

An isothermal cooking plate assembly is formed from a first plate of high thermal conductivity material having a back surface and an oppositely disposed top cooking surface. One or more heater circuit assemblies are disposed on the first plate back surface for forming a composite having a back surface. A controller is in electrical connection with the heater circuit assemblies for controlling temperature of the first plate of high thermal conductivity material. The first plate can be aluminum Type 1100 or aluminum Type 6061. The first plate can be a laminate formed from a clad bottom metal layer and clad top cooking surface metal layer, where the clad layers formed from the same material and having about the same thickness. The clad material can be austenitic stainless steel. A second plate of low thermal conductivity material can be attached to the composite back surface of first plate.

Owner:EGGERS & ASSOC LLC

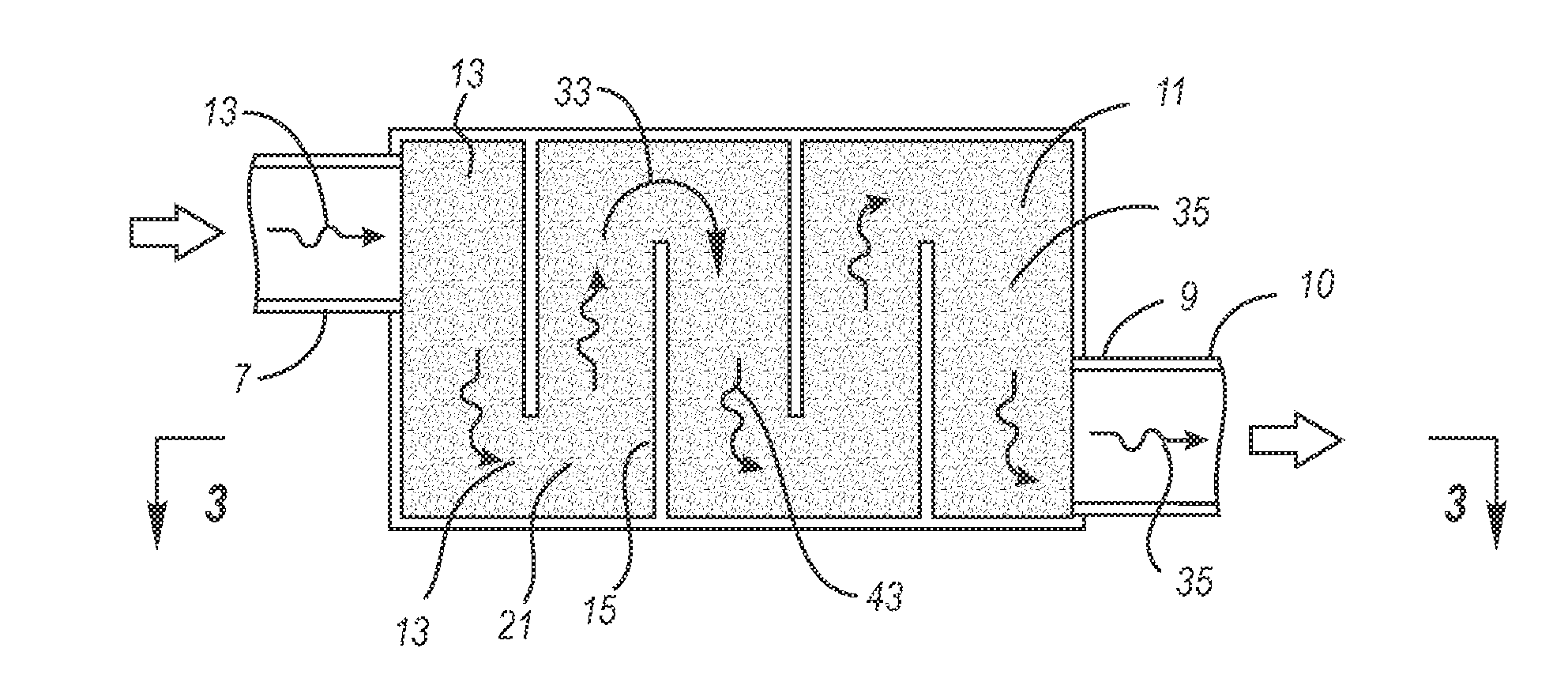

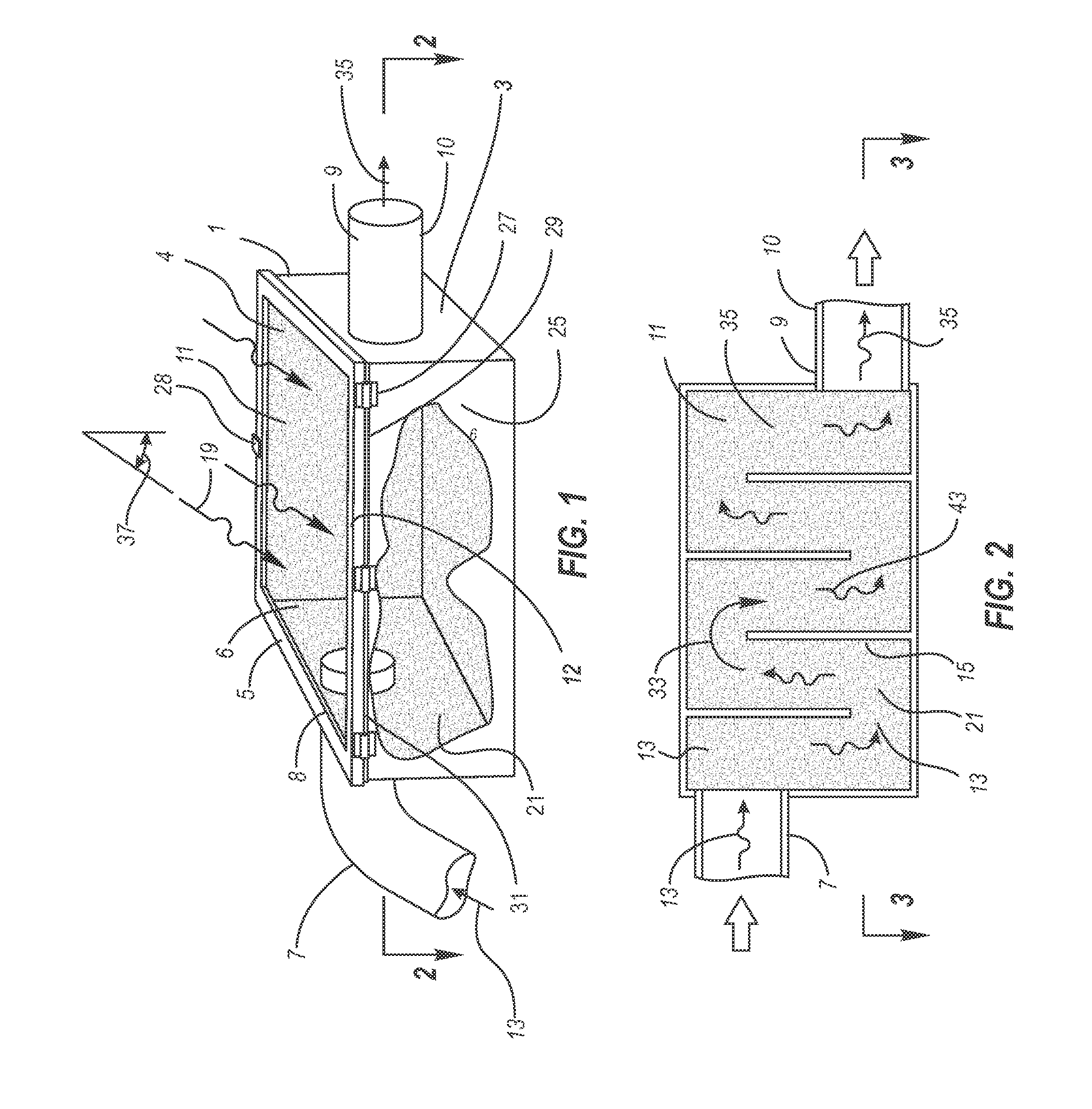

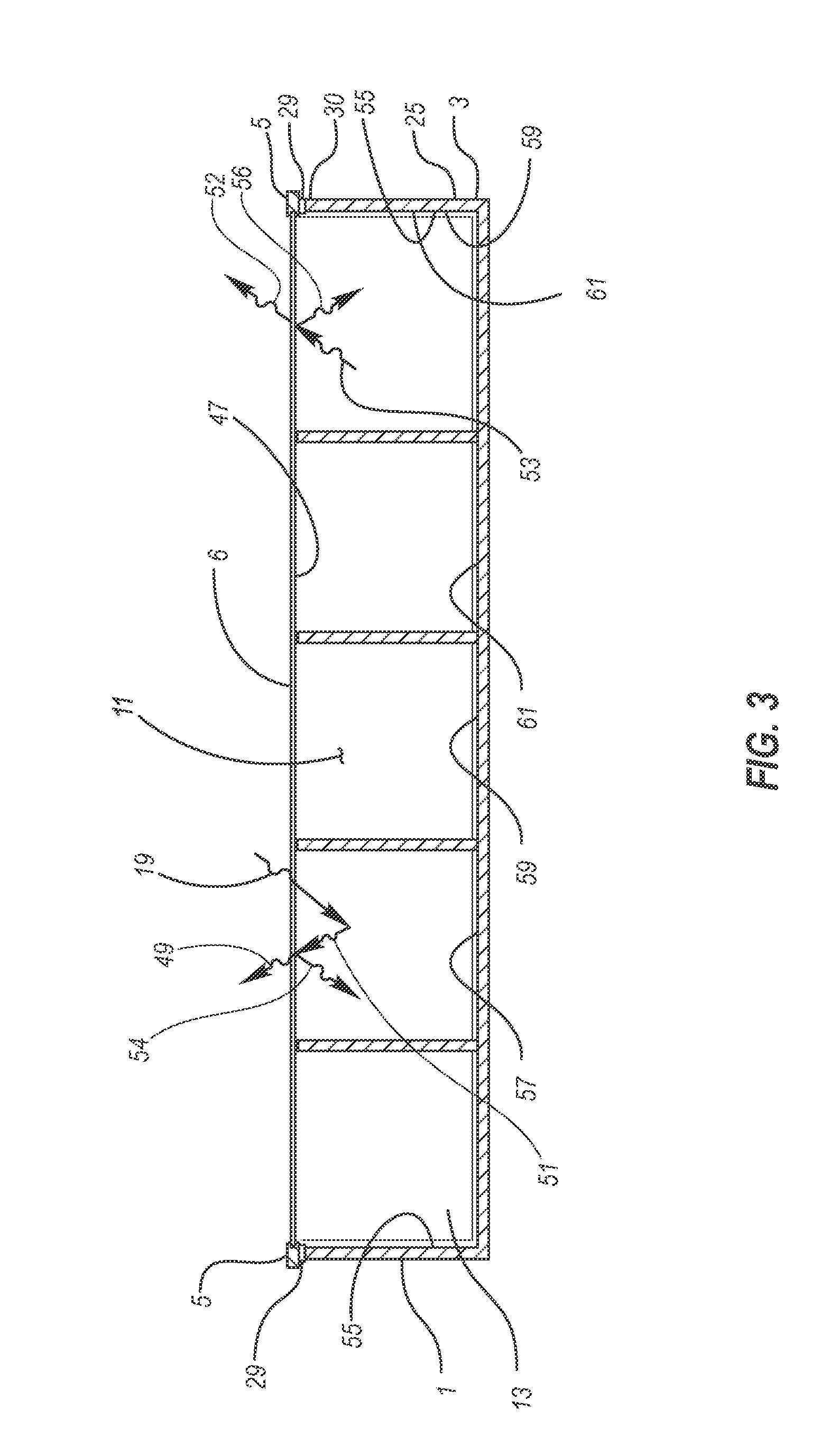

Solar receiver with direct absorption media irradiation

InactiveUS20150219364A1Reduce short-circuitingImprove transmittanceSolar heating energySolar heat devicesTelecommunicationsEngineering

A solar receiver having a receiver vessel with a receiver chamber, a receiver cover with a receiver window, a receiver fluid inlet, a receiver fluid outlet, and an absorption media matrix in the receiver chamber. In operation of the solar receiver, incident solar radiation is transmitted through the receiver window to the absorption media matrix. Receiver fluid is circulated through the receiver chamber and the absorption media matrix. Heat is transferred from the absorption media matrix to the receiver fluid.

Owner:JOHNSON NELDON P

Low noise high thermal conductivity mixed signal package

ActiveUS20120015485A1Reduces parasitic inductanceEliminates parasitic inductanceSemiconductor/solid-state device detailsSolid-state devicesLow noiseEngineering

An improved microelectronic assembly (100) and packaging method includes a device package for housing a semiconductor die or chip, (105), an array of passive electronic components (305-355) operating in cooperation with the flip chip semiconductor die (105) and housed inside the device package to decouple noise from input signals, and a heat spreader (195) disposed between a top surface of the semiconductor die (105) and a package cover (185). The semiconductor die (105) is configured as a flip chip die and the device package includes a package substrate (110) configured as a ball grid array. The improved microelectronic device (100) reduces parasitic inductance in electrical interconnections between the semiconductor die and an electrical system substrate (115) and reduces signal noise in mixed signal high frequency analog to digital converters operating at clock rates above 1 GHz.

Owner:RAYTHEON CO

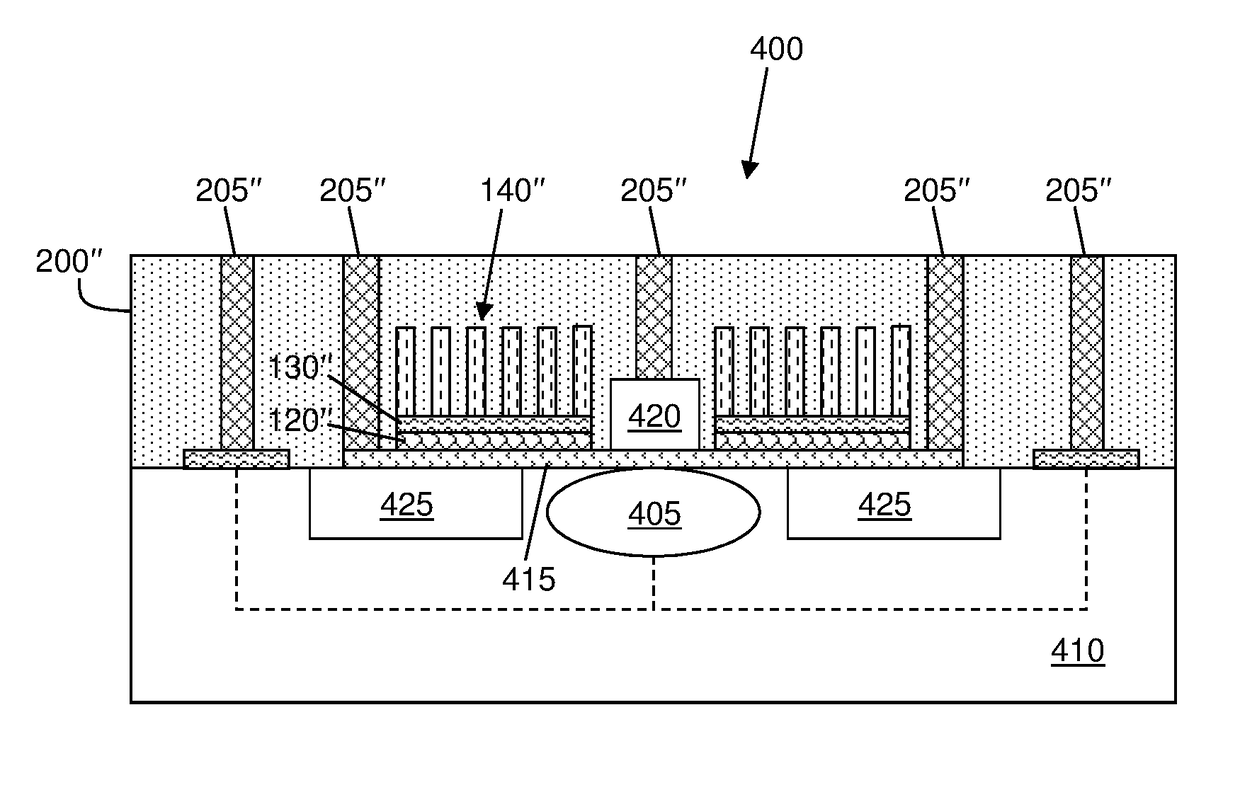

Integrated circuit heat dissipation using nanostructures

ActiveUS10109553B2High thermal conductivity materialSemiconductor/solid-state device detailsNanoinformaticsNanowireIsolation layer

An approach for heat dissipation in integrated circuit devices is provided. A method includes forming an isolation layer on an electrically conductive feature of an integrated circuit device. The method also includes forming an electrically conductive layer on the isolation layer. The method additionally includes forming a plurality of nanowire structures on a surface of the electrically conductive layer.

Owner:IBM CORP

Isotherm Cooking Plate Apparatus, System, and Method of Manufacture

PendingUS20210227634A1High thermal conductivity materialHigh hardnessRoasters/grillsHeating element materialsElectrical connectionAustenite

An isothermal cooking plate assembly is formed from a first plate of high thermal conductivity material having a back surface and an oppositely disposed top cooking surface. One or more heater circuit assemblies are disposed on the first plate back surface for forming a composite having a back surface. A controller is in electrical connection with the heater circuit assemblies for controlling temperature of the first plate of high thermal conductivity material. The first plate can be Aluminum Type 1100 or Aluminum Type 6061. The first plate can be a laminate formed from a clad bottom metal layer and clad top cooking surface metal layer, where the clad layers formed from the same material and having about the same thickness. The clad material can be austenitic stainless steel. A second plate of low thermal conductivity material can be attached to the composite back surface of first plate.

Owner:EGGERS & ASSOC LLC

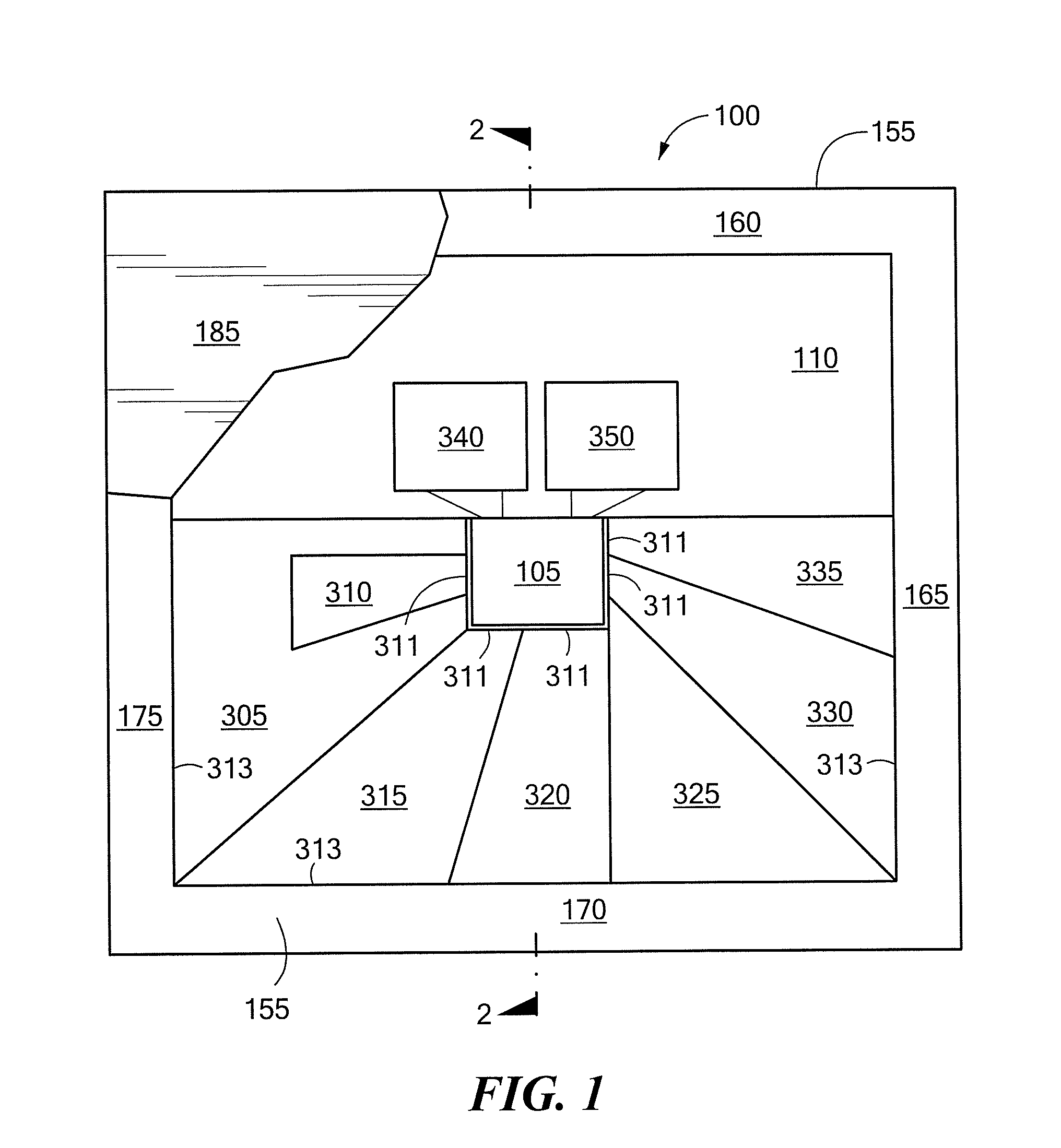

Packaging of SMD light emitting diodes

InactiveUS7339196B2Improve rendering capabilitiesExcellent characteristicsSolid-state devicesSemiconductor devicesComputer moduleEngineering

An SMD LED package with superior thermal dissipation capability is provided. The SMD LED package comprises a supporting block with circuit patterns and at least one LED attached to the supporting block. Wherein, circuit patterns of holes / vias, insulating layers, and conducting traces / pads are formed on and in the supporting block. The SMD LED packages can be further assembled to form a light module that allows emitted lights to travel in parallel with the mounting surface. The SMD manufacturing process is a mature production process and thus easy for mass production. Single or plural LED chips are mounted on a thermal conducting block that is disposed with patterns of conducting traces / pads and isolating dielectric layers. The side emitting characteristics of the present invention offers the advantage of reflecting and mixing the emitted lights to meet the desired chromaticity.

Owner:IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com