Method for preparing waste carboxylbutyronitrile adhesive powder and PVC mixture

A technology of waste carboxylated nitrile rubber powder and waste carboxylated nitrile rubber, which is applied in the field of preparation of waste carboxylated nitrile rubber powder and PVC blends, can solve the problems of increased elongation at break and decreased tensile strength, and achieves Improved impact strength and elongation at break, low cost, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

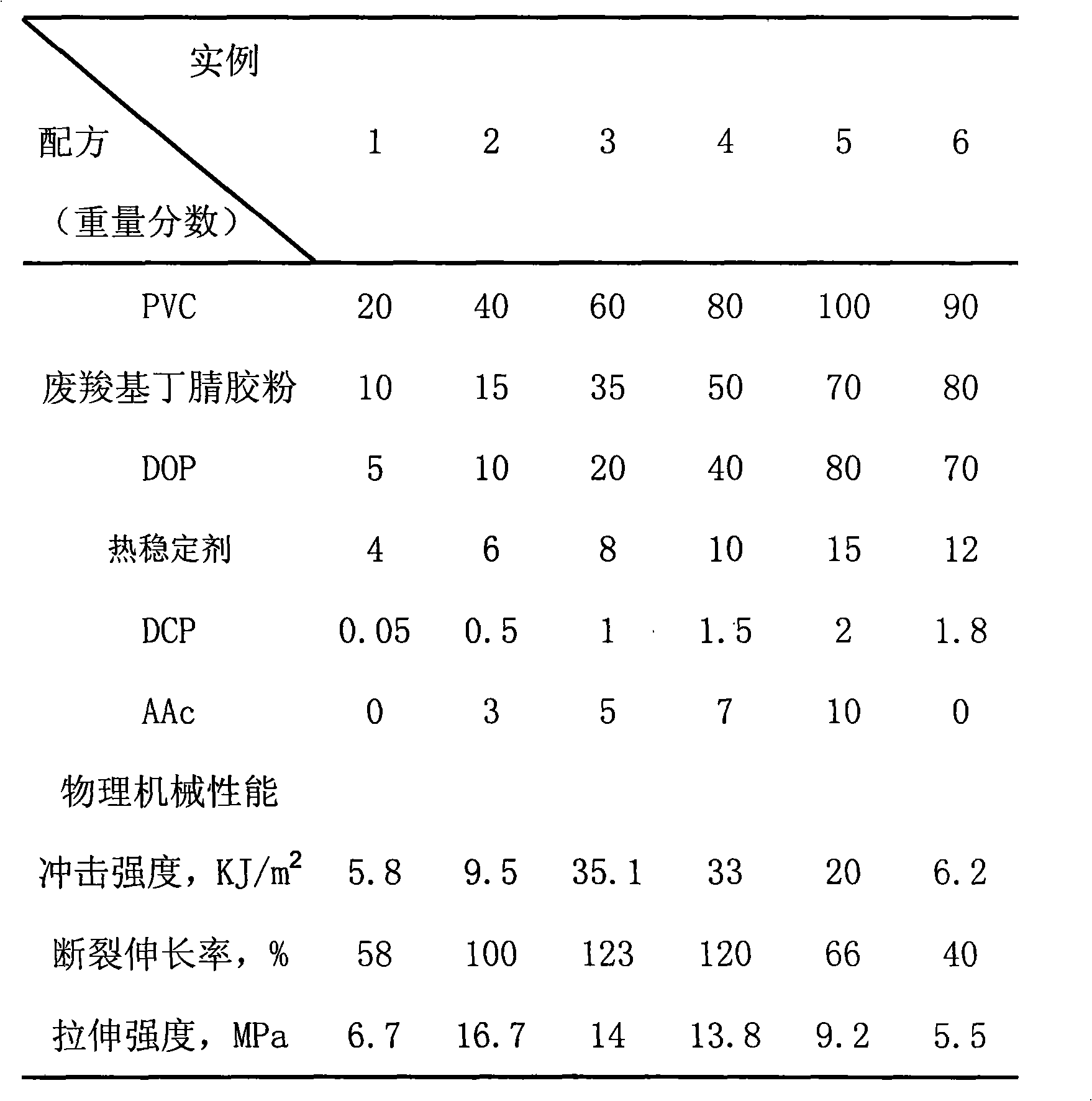

[0019] Put the mixture of plasticizer, heat stabilizer and PVC into a double-roller heat mixer and pre-plasticize at 90°C-120°C for 3-10min, then add initiator, modifier and crushed waste carboxybutylene in sequence Nitrile rubber powder is kneaded at 150°C-170°C for 5-15 minutes, then molded in a 15Mpa flat vulcanizer at 150°C-170°C for 5-15 minutes, and the test piece is quickly moved to a 15Mpa cold press for cooling After reaching room temperature, the mold is demoulded to obtain a waste carboxylated nitrile rubber powder / PVC blend. The component values of the above-mentioned plasticizer, heat stabilizer, PVC, initiator, modifier and waste carboxylated nitrile rubber powder are shown in Table 1. Wherein, plasticizer selects dioctyl phthalate (DOP) for use, heat stabilizer selects tribasic lead sulfate, barium stearate, calcium stearate, lead stearate (their mass ratio is 1:1 : 3: 1), the initiator is dicumyl peroxide (DCP), and the modifier is acrylic acid (AAc).

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com