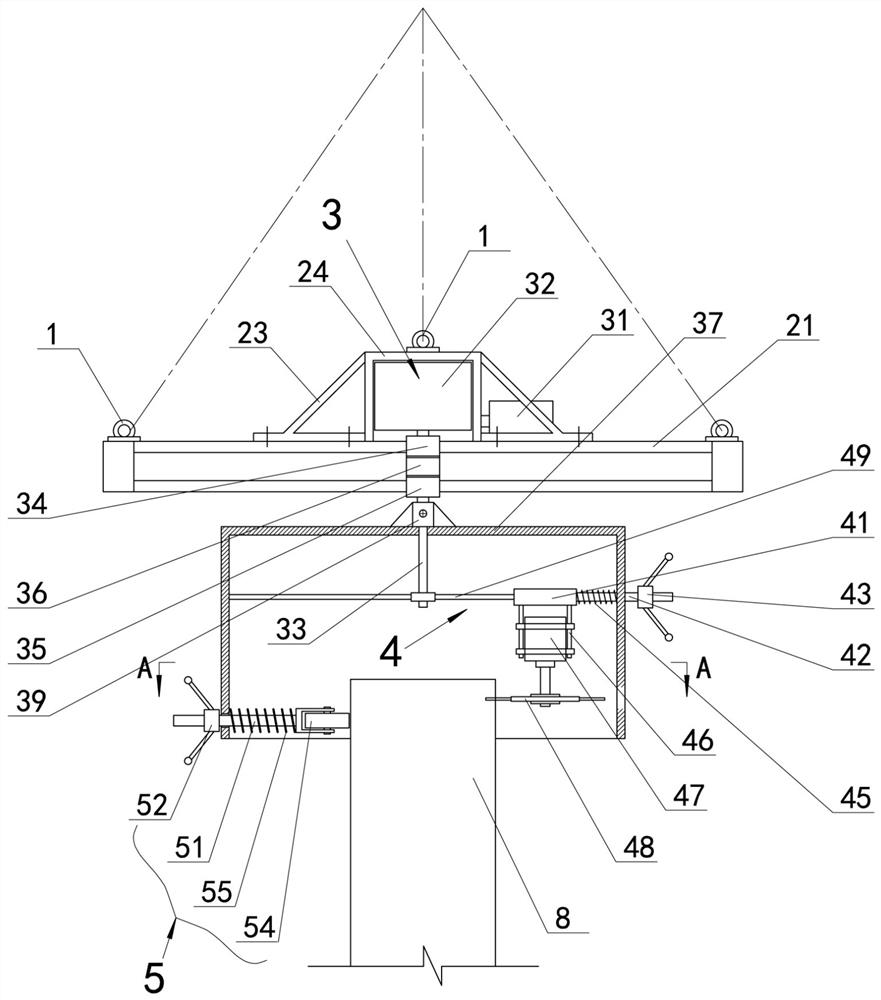

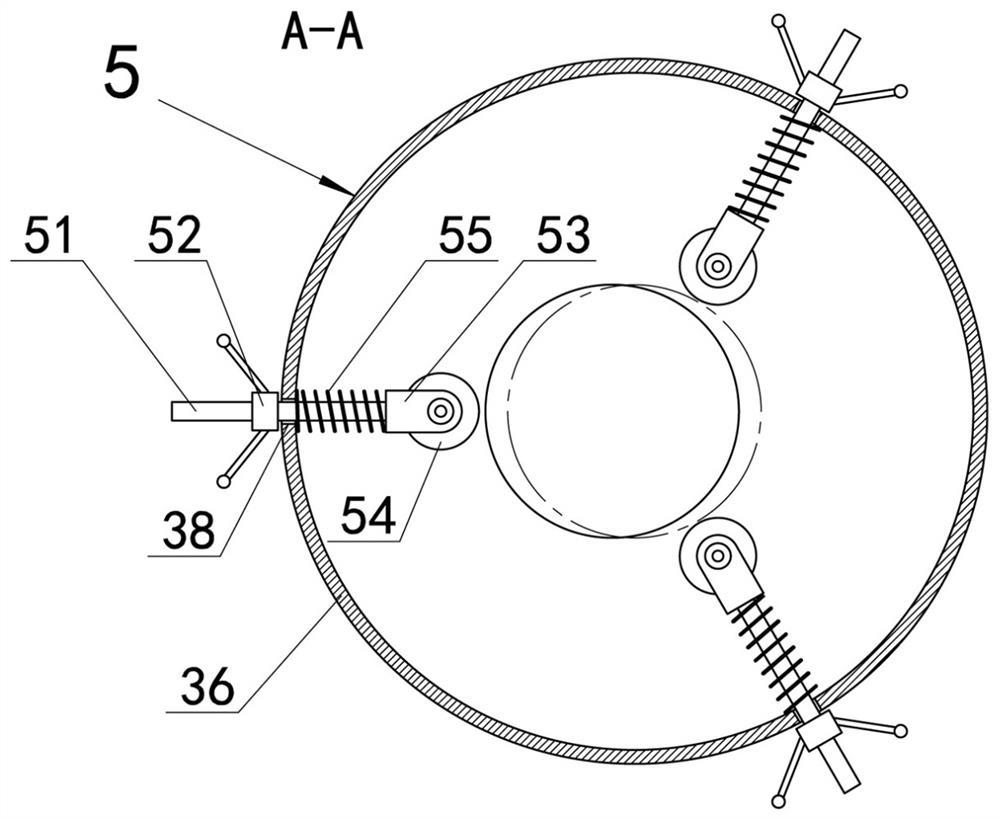

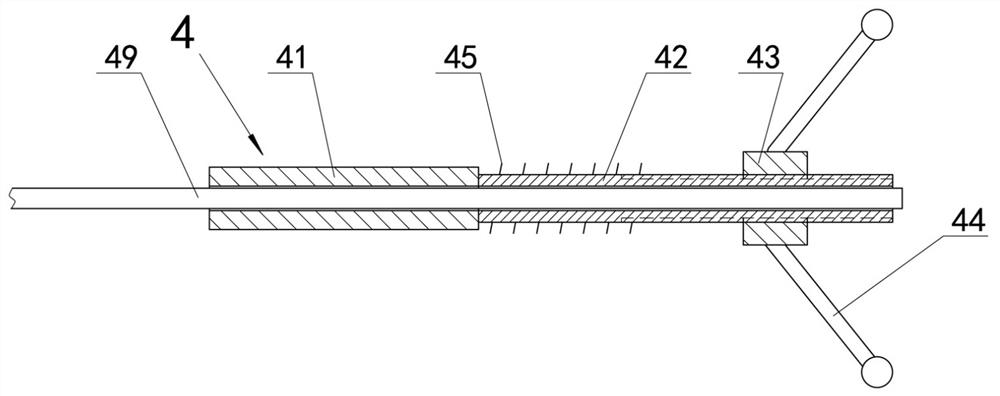

Lifting cast-in-place pile head cutting device

A cutting device and cast-in-place pile technology, which is applied in the direction of sheet pile walls, buildings, foundation structure engineering, etc., to achieve the effects of simple operation, smooth cutting section and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] When pouring cast-in-situ piles, the elevation of the top of the piles should be 0.5-1.0m higher than the design pile top elevation to ensure the concrete strength of the pile head, but the pile head part higher than the design elevation of the pile top must be chiseled off during the subsequent construction, that is, "Broken pile head". At present, the method of breaking the pile head is many times faster than the traditional manual pneumatic pick, but there are still problems of varying degrees in the existing pile breaking machines, mainly in the low construction efficiency and time-consuming stripping of the main reinforcement and acoustic pipe. It is longer and less efficient. When chiseling with a pneumatic pick, it is easy to cause damage to the steel bar and cause the steel bar to bend and deform, thereby reducing the tensile strength and weakening the connection between the pile body and the cap. After the pile head is removed, the pile top is uneven. , To a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com