Patents

Literature

33results about How to "Solve ecological and environmental problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

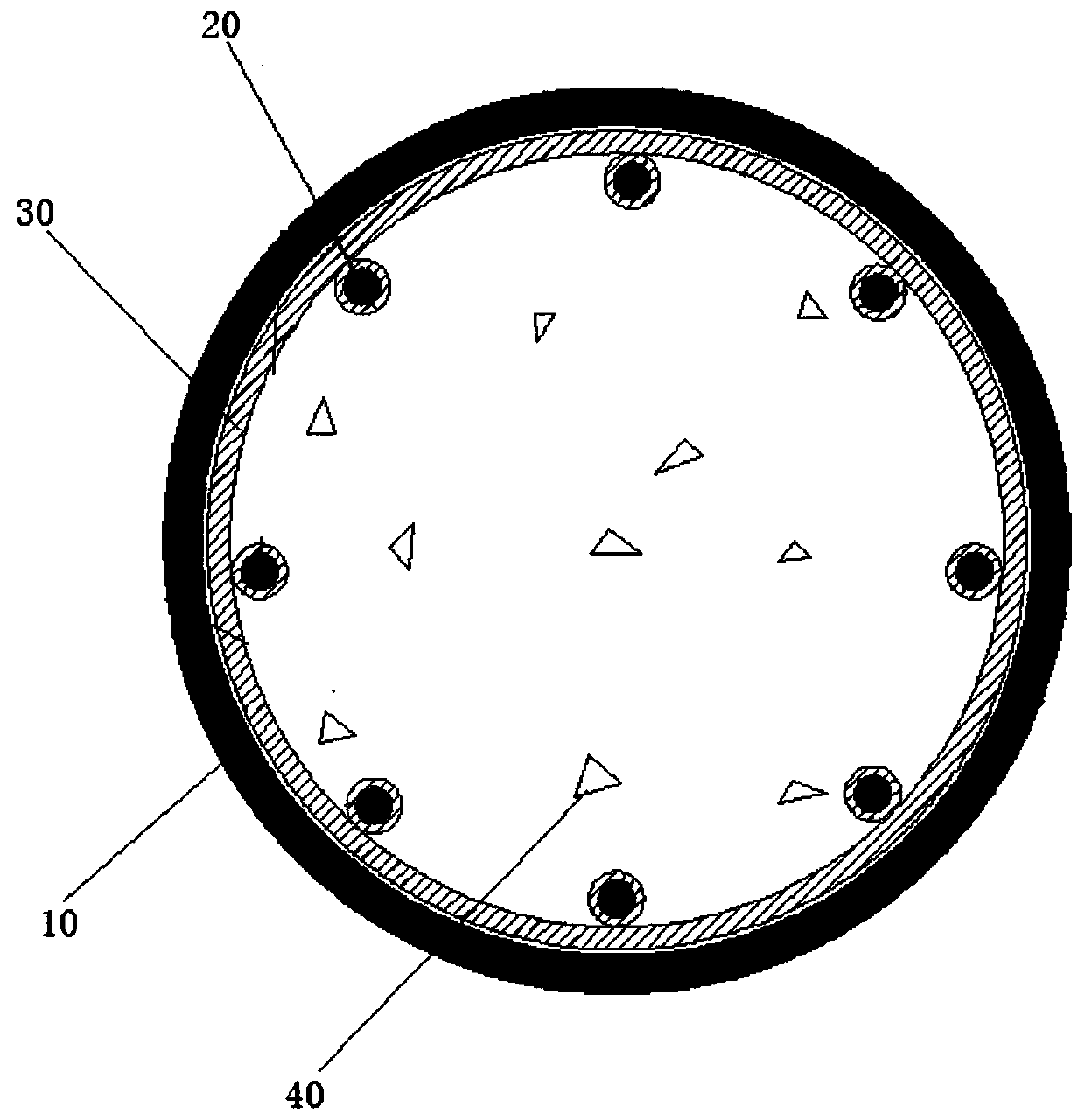

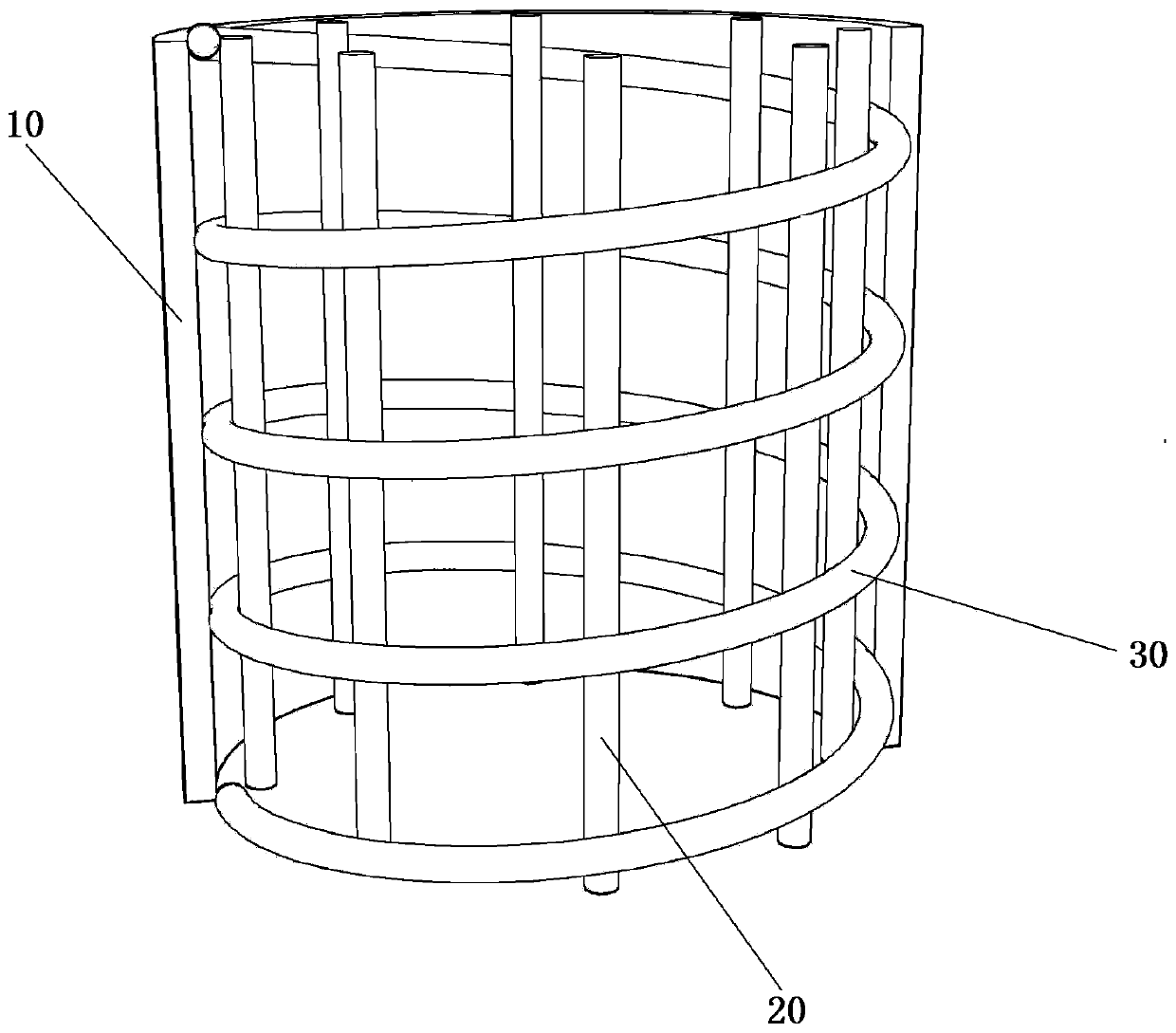

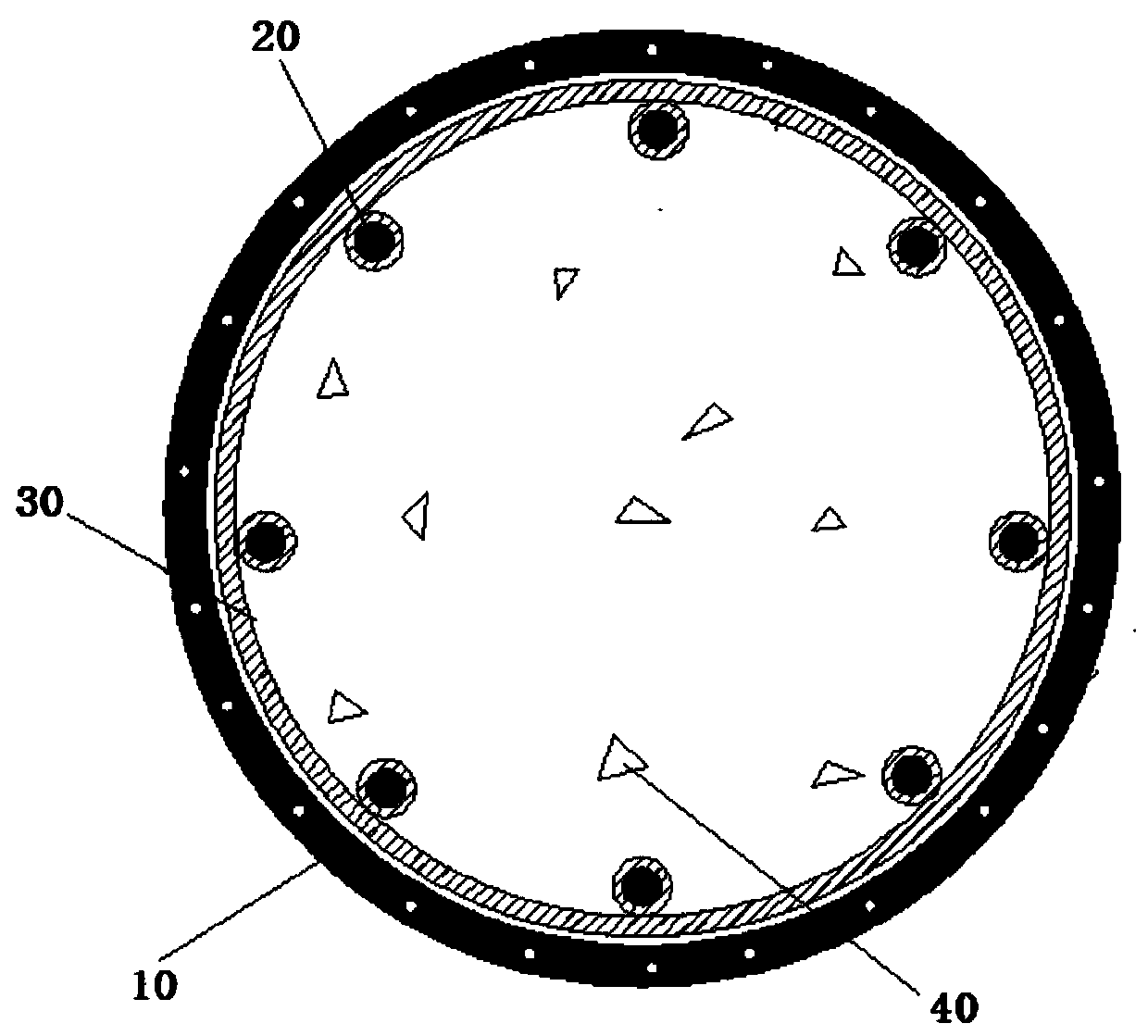

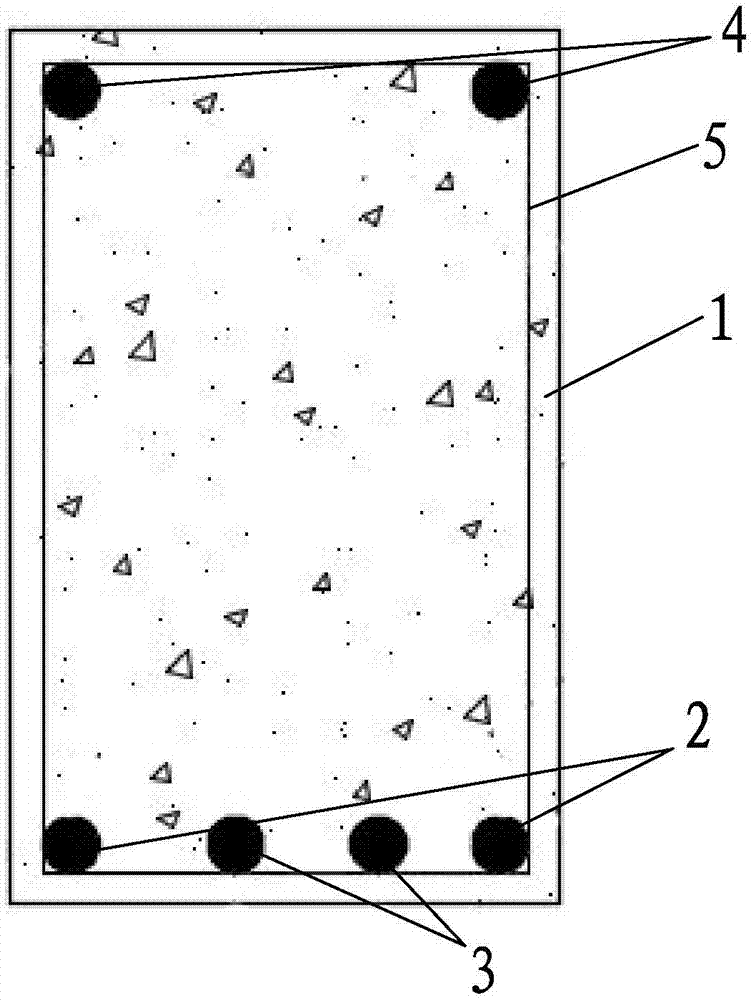

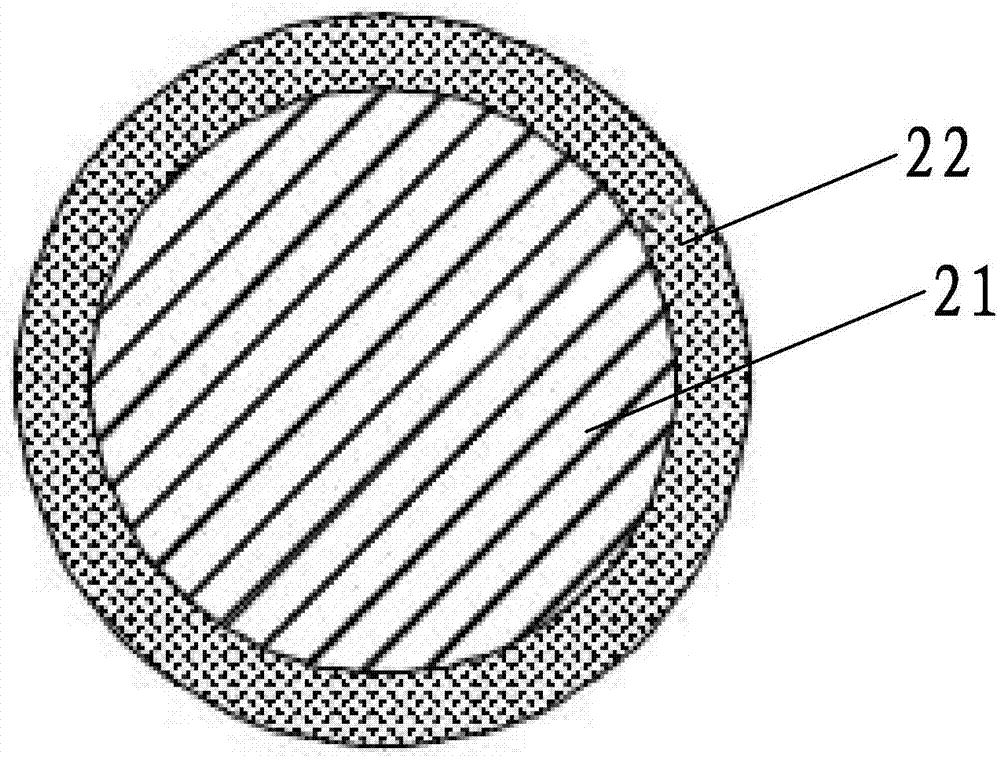

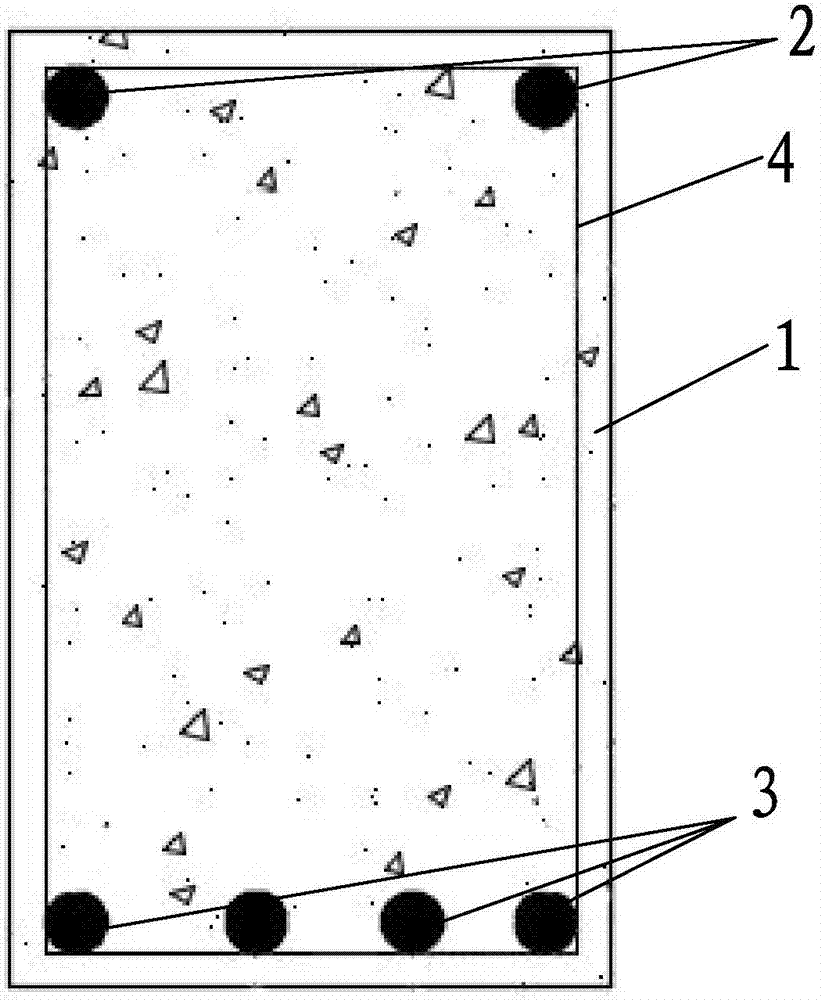

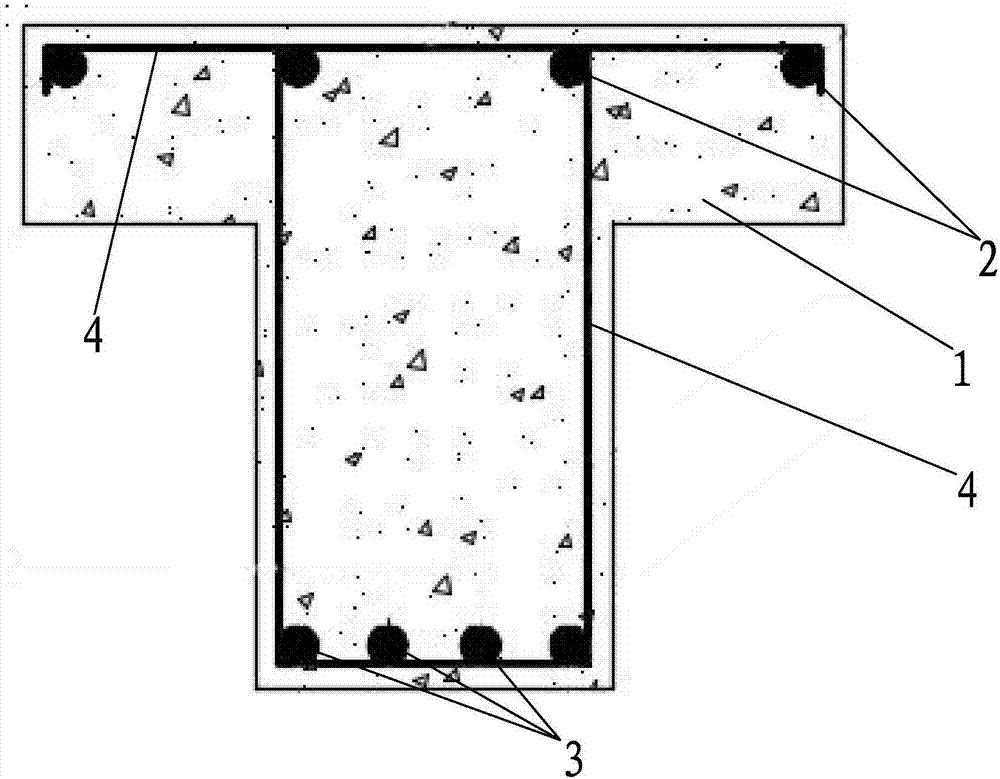

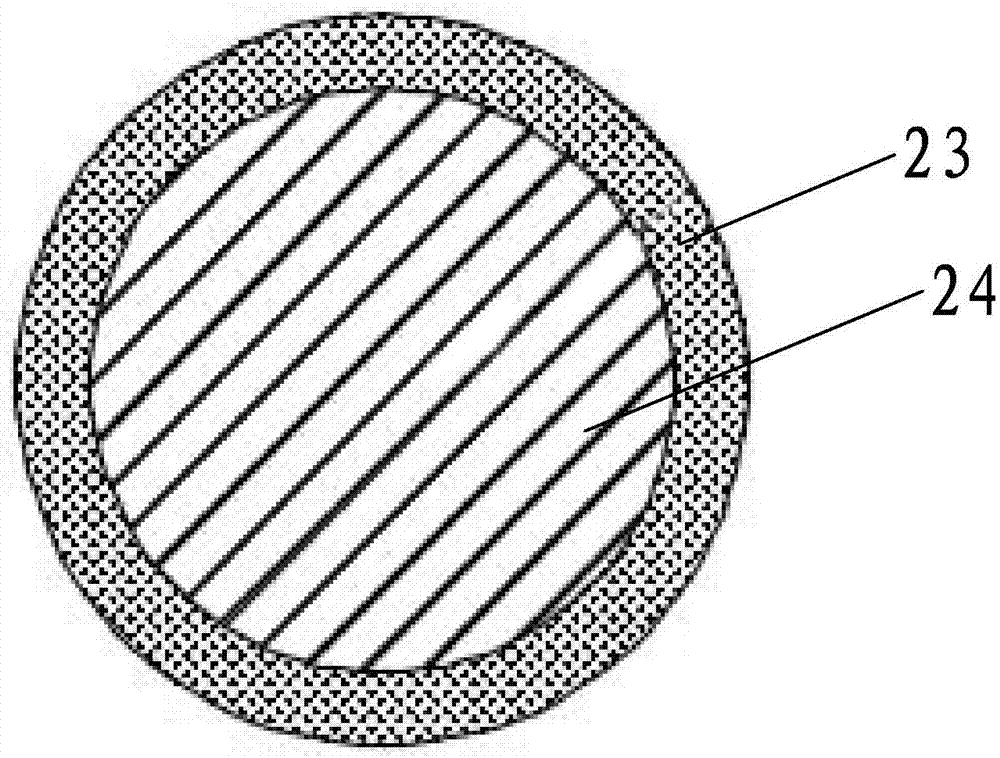

Seawater and sea sand concrete column

A seawater and sea sand concrete column comprises a polyethylene pipe and a plurality of FRP-steel composite reinforcements. The plurality of FRP-steel composite reinforcements are vertically arrangedin the polyethylene pipe, the plurality of FRP-steel composite reinforcements are arranged in the polyethylene pipe are evenly arranged in the circumferential direction in an equal-radian mode, FRP-steel composite stirrups are arranged outside the plurality of FRP-steel composite reinforcements, the polyethylene pipe is filled with concrete, and the concrete is composed of sea sand, seawater, cement and coarse aggregate. According to the invention, by adopting the polyethylene pipe on the outside and the FRP-steel composite reinforcements on the inside to constrain the concrete composed of the sea sand and seawater, the bearing capacity of the concrete column is improved, ductility and anti-seismic capacity are improved, corrosion resistance is prominent, and therefore the section size ofthe column is reduced, the use area of a building is increased, and the bending resistance is good.

Owner:GUANGDONG UNIV OF TECH

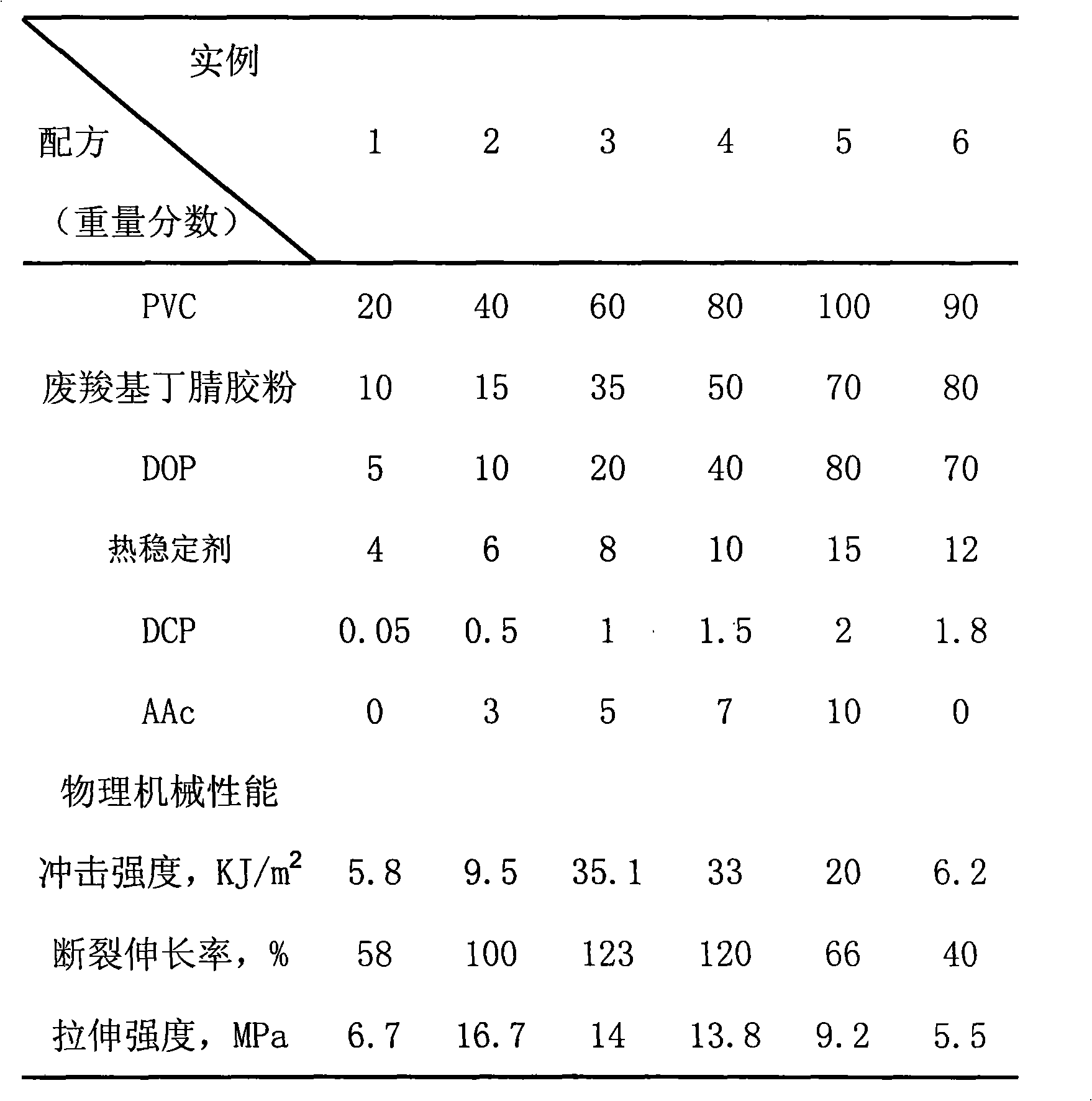

Method for preparing waste carboxylbutyronitrile adhesive powder and PVC mixture

The invention discloses a preparation method for waste carboxyl nitrile gelatine powder and PVC blend. The preparation method comprises the following steps that: plasticizer, heat stabilizer and PVC mixture are added in a double-roller feed mill to carry out preplasticizing, and then initiator, modifier and crushed waste carboxyl nitrile gelatine powder are added in turn to carry out milling; then, after stem pressing is completed inside a flat vulcanizing machine, a test block is quickly moved to a chilling press and demoulding is carried out after the test block is cooled down to room temperature, thereby obtaining the waste carboxyl nitrile gelatine powder / PVC blend. The blend not only has substantially increased impact strength and elongation at break, but also has a compact microstructure; moreover, the blend has wide application, simple manufacturing process, low cost and less environmental pollution.

Owner:SOUTH CHINA UNIV OF TECH

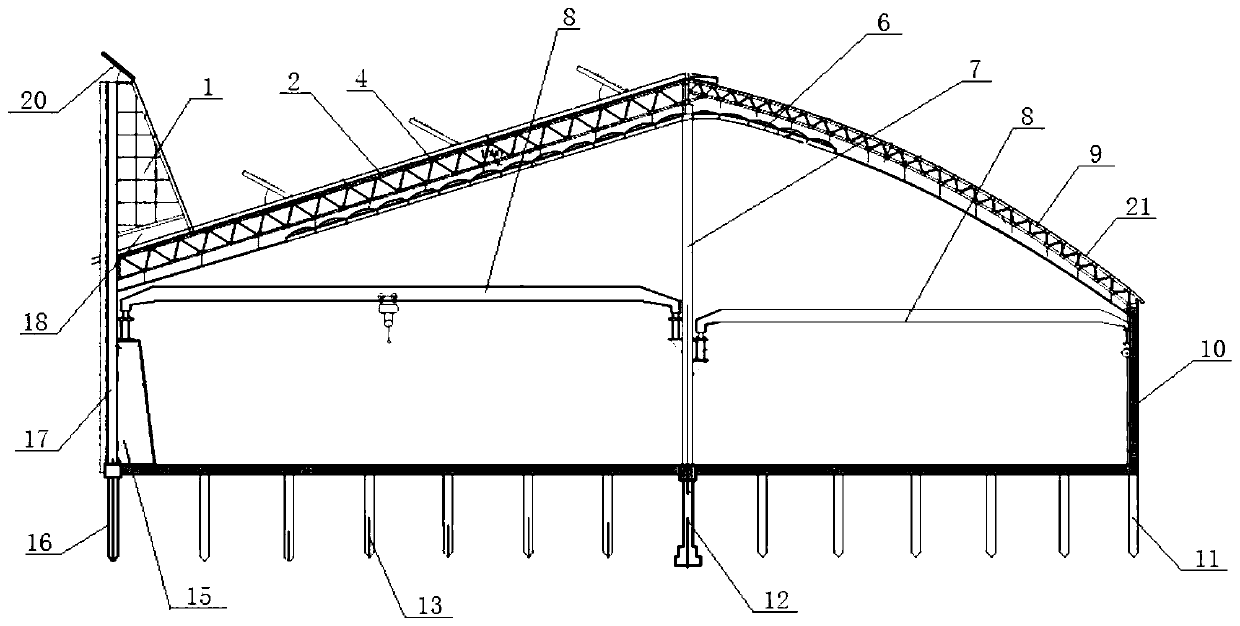

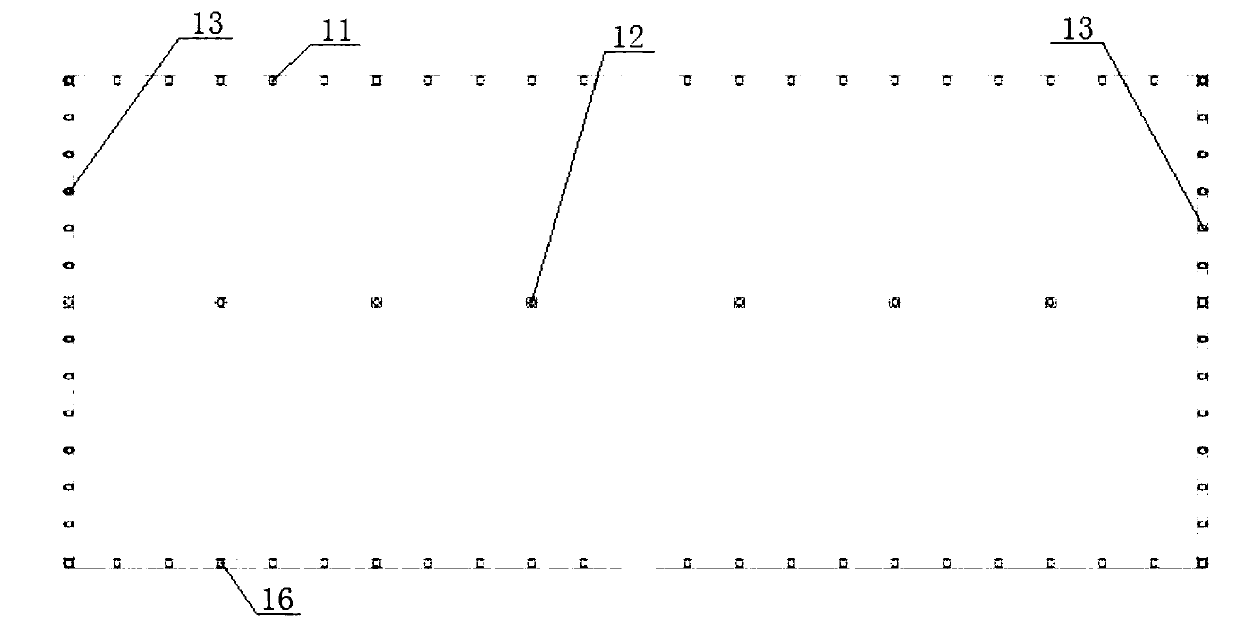

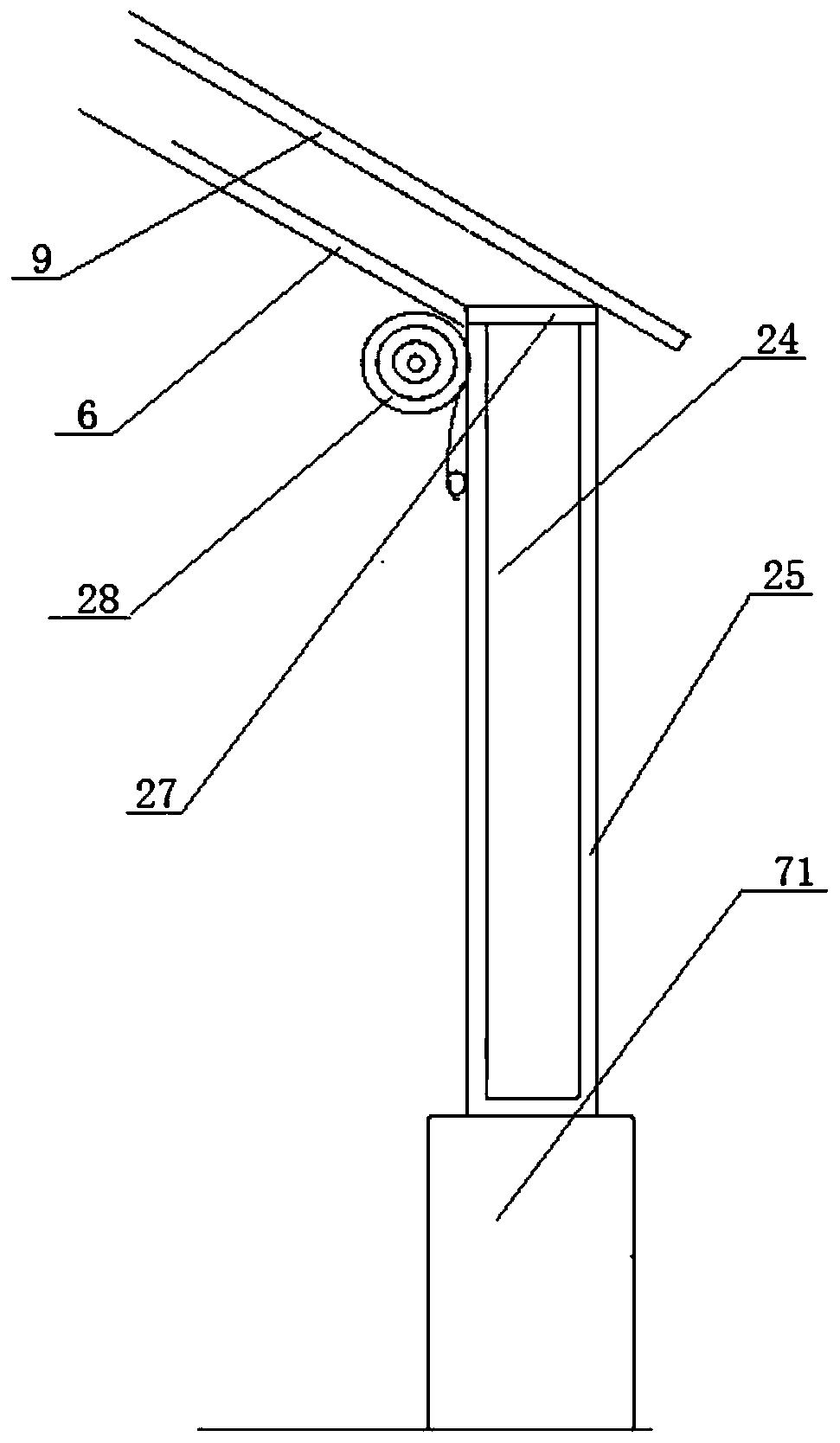

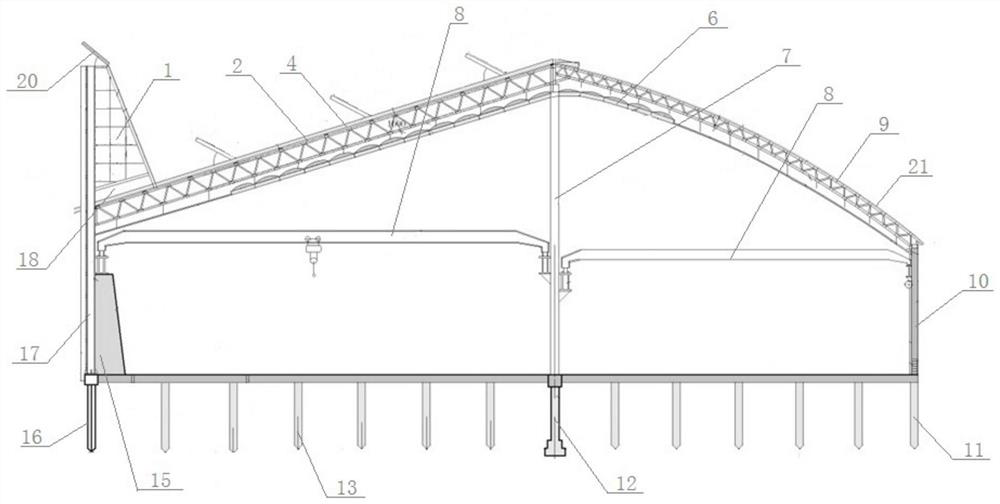

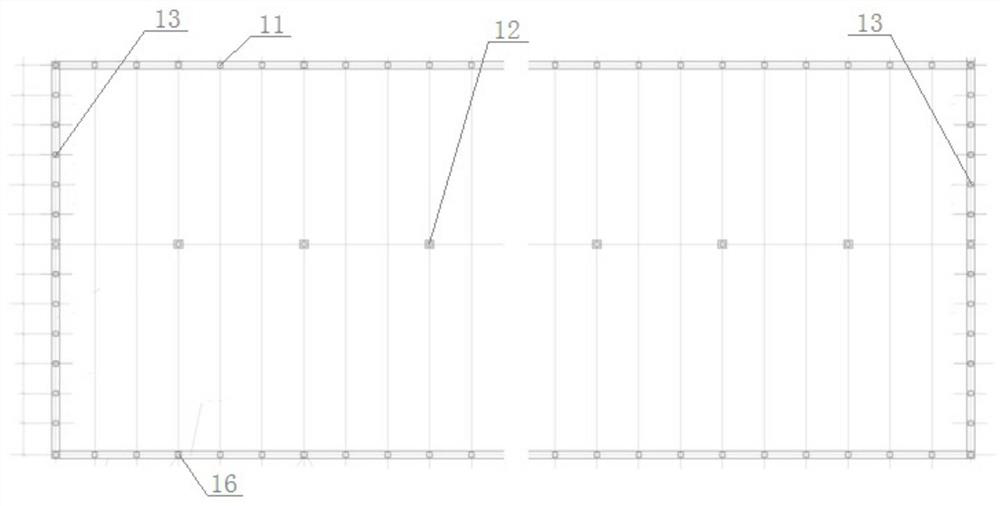

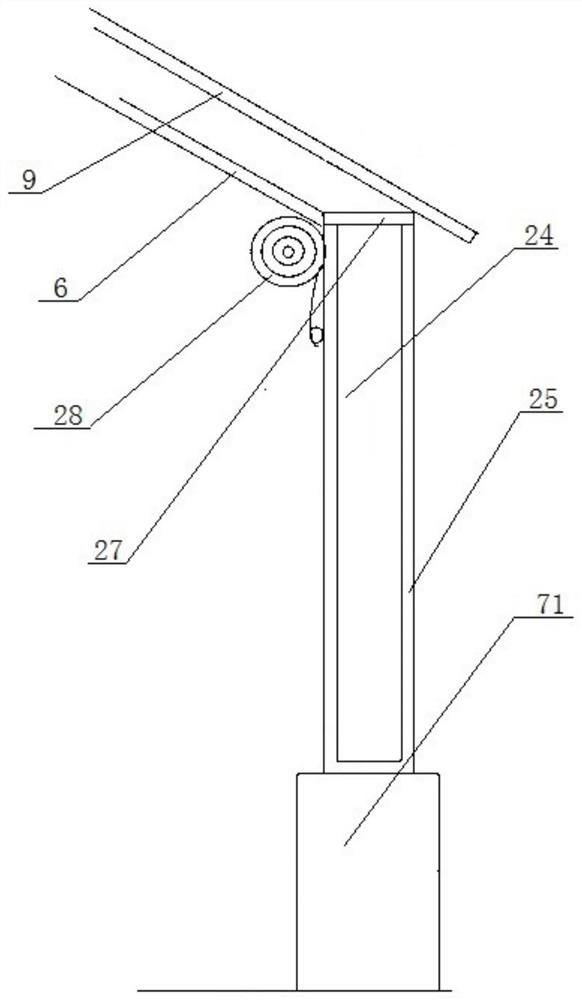

Energy-saving, environmental protection and ecological triune industrial plant stadium and key joint design method and construction method thereof

ActiveCN110185292AGood effect of capturing light energyAvoid Morning Cream EffectsSolar heating energyDucting arrangementsEngineeringRidge

The invention relates to an energy-saving, environmental protection and ecological triune industrial plant stadium and a key joint design method and a construction method thereof. The energy-saving, environmental protection and ecological triune industrial plant stadium is characterized by comprising a foundation, the lower end of the foundation extends into the ground, a front wall, a gable and arear wall are fixedly connected to the upper part of the foundation, a center pillar is arranged on and fixedly connected with the top surface of a fourth pile foundation of the foundation, a front roof is arranged on and fixedly connected with the top surface of the front wall, the gable and a ridge, a rear roof is arranged on and fixedly connected with the middle parts of the ridge, the gable and the rear wall; key joints include orientation positions and the height of the ridge of a lighting roof; the construction method comprises the steps that the foundation is built, then the gable, therear wall, the front wall, the rear roof and the front roof are built sequentially, and an energy cabin, an insulation layer, a heat storage wall, an energy storage and heat storage system, an air circulation system and a wind and light power generation system are installed in sequence.

Owner:吉林市东北生态农业发展有限责任公司

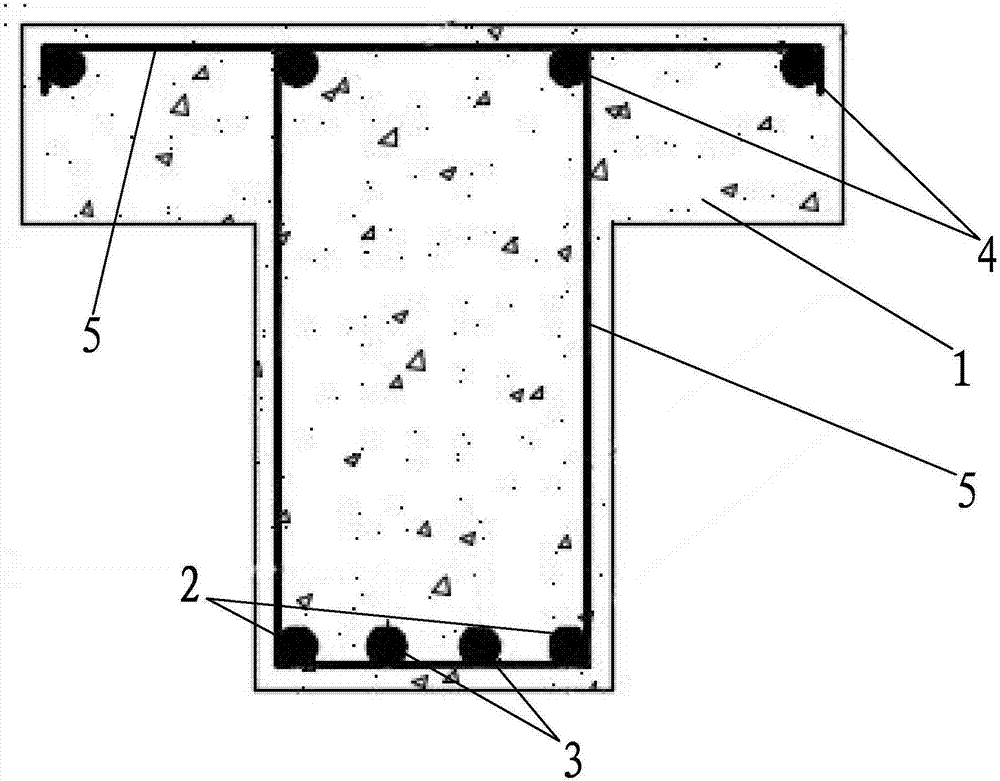

Sea sand concrete beam with mixed reinforcements of fiber reinforced plastics (FRP)-steel composite bars and FRP bars and construction method thereof

The invention discloses a sea sand concrete beam with mixed reinforcements of fiber reinforced plastics (FRP)-steel composite bars and FRP bars. The sea sand concrete beam comprises sea sand concrete, the FRP-steel composite bars, the FRP bars, erection bars and a plurality of stirrups, wherein the FRP-steel composite bars, the FRP bars, the erection bars and the stirrups are fixedly arranged in the sea sand concrete. The FRP-steel composite bars and the FRP bars are arranged at the lower end of the sea sand concrete, and the erection bars are arranged at the upper end of the sea sand concrete. The lengths of the FRP-steel composite bars and the FRP bars are arranged along the length of the sea sand concrete. The stirrups are evenly and fixedly connected to the outer surfaces of the FRP-steel composite bars, the FRP bars and the erection bars in a bound mode in the direction of the lengths of the FRP-steel composite bars and the erection bars. The FRP-steel composite bars comprise steel bars and FRP fiber cloth, wherein the outer surfaces of the steel bars are wrapped with the FRP fiber cloth. The FRP fiber cloth is bonded with the sea sand concrete. The invention further discloses a construction method of the sea sand concrete beam with the mixed reinforcements of the fiber reinforced plastics (FRP)-steel composite bars and the FRP bars. According to the sea sand concrete beam with the mixed reinforcements of the fiber reinforced plastics (FRP)-steel composite bars and the FRP bars and the construction method thereof, sea sand does not need to be subjected to desalting treatment, the strength is high, and the bearing property is good.

Owner:GUANGDONG UNIV OF TECH

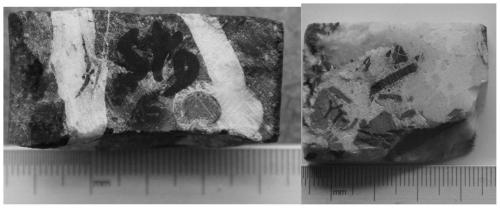

Copper slag-base low silicon iron tailing filling material and preparation technology thereof

InactiveCN105541255ASolve the technical problems that can only be prepared with high-silicon aggregatesSolve the whereabouts problemSolid waste managementMaterial resourcesWater reducer

The invention belongs to the field of filling cementing material preparation and particularly relates to a copper slag-base low silicon iron tailing filling material. The filling cementing material is prepared from 15-25wt% of copper slag materials, 3-8wt% of cement clinker, 0.3-0.8wt% of sodium hydroxide and 70-80wt% of low silicon iron tailings. The copper slag materials are prepared from 75-80wt% of copper slag, 3-6wt% of lime, 15-18wt% of gypsum and 0.3-0.8wt% of naphthalene water reducer. The filling cement material is prepared through the copper slag and the low silicon iron tailings, the local ecological environment problems and slag waste problems of mines are solved, and manpower and material resources can be greatly saved. The cost is low, the equipment investment is small, the filling effect is good, and the copper slag-base low silicon iron tailing filling material has wide application prospects in the fields of mine backfilling, building materials and others.

Owner:FUZHOU UNIV

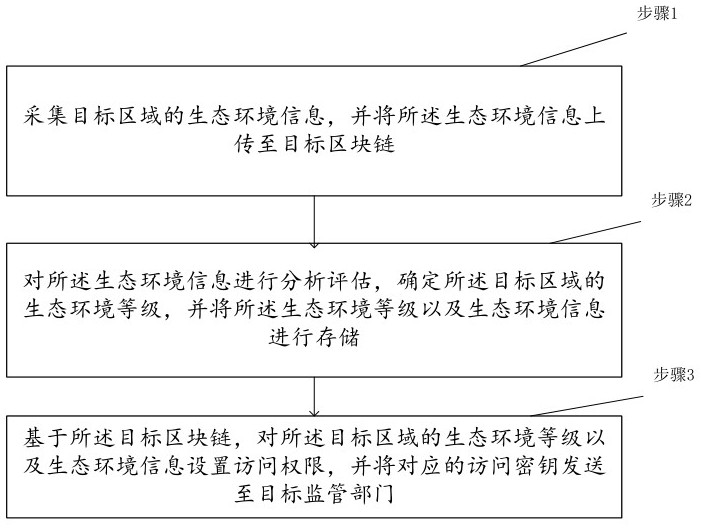

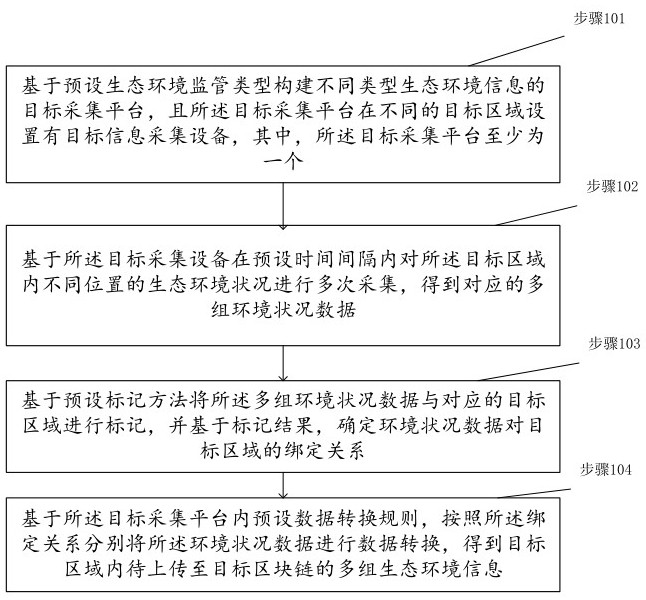

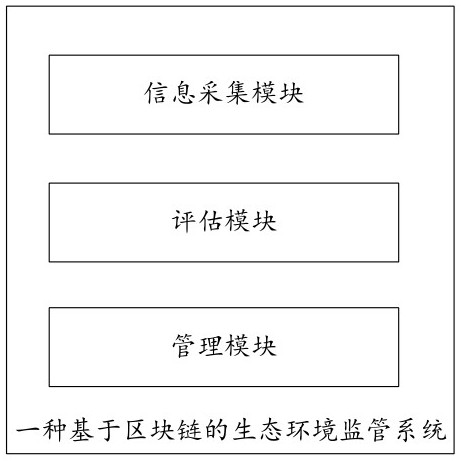

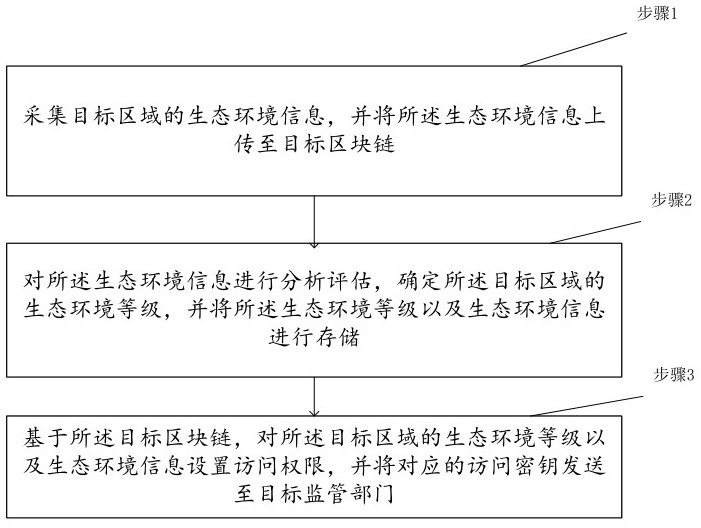

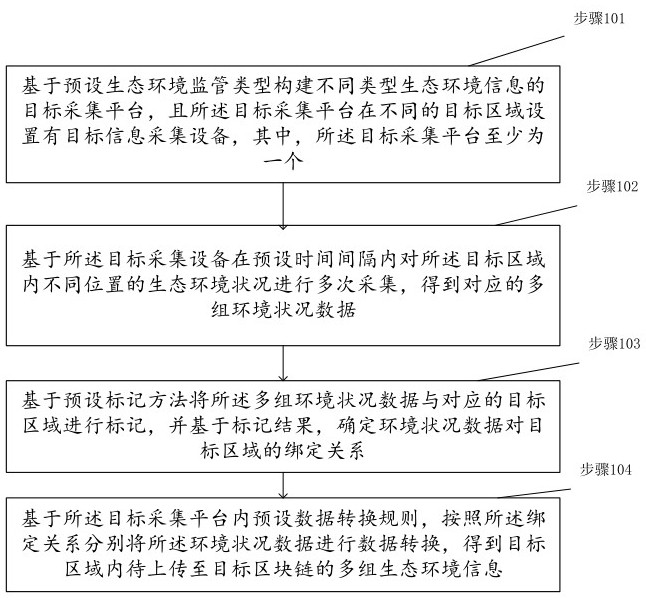

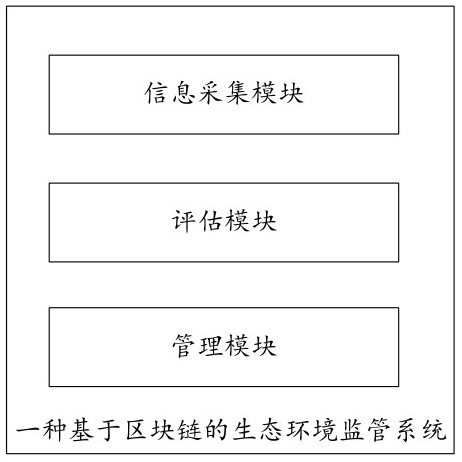

Blockchain-based ecological environment supervision method and system

ActiveCN113822781AImprove regulatory efficiencyImprove effectivenessResourcesEnvironmental resource managementEcological environment

The invention provides a blockchain-based ecological environment supervision method and system, and the method comprises the steps: collecting the ecological environment information of a target area, and uploading the ecological environment information to a target blockchain; analyzing and evaluating the ecological environment information, determining the ecological environment grade of the target area, and storing the ecological environment grade and the ecological environment information; and based on the target blockchain, setting an access permission for the ecological environment level and the ecological environment information of the target area, and sending a corresponding access key to a target supervision department. The ecological environment information of the target area is acquired in real time through the blockchain, the ecological environment of the target area is graded, and the ecological environment grade of the target area is sent to each supervision department through the blockchain, so that the environment supervision efficiency and the effectiveness of supervision measures are improved, and convenience is provided for solving the ecological environment problem.

Owner:河北硕权科技有限公司

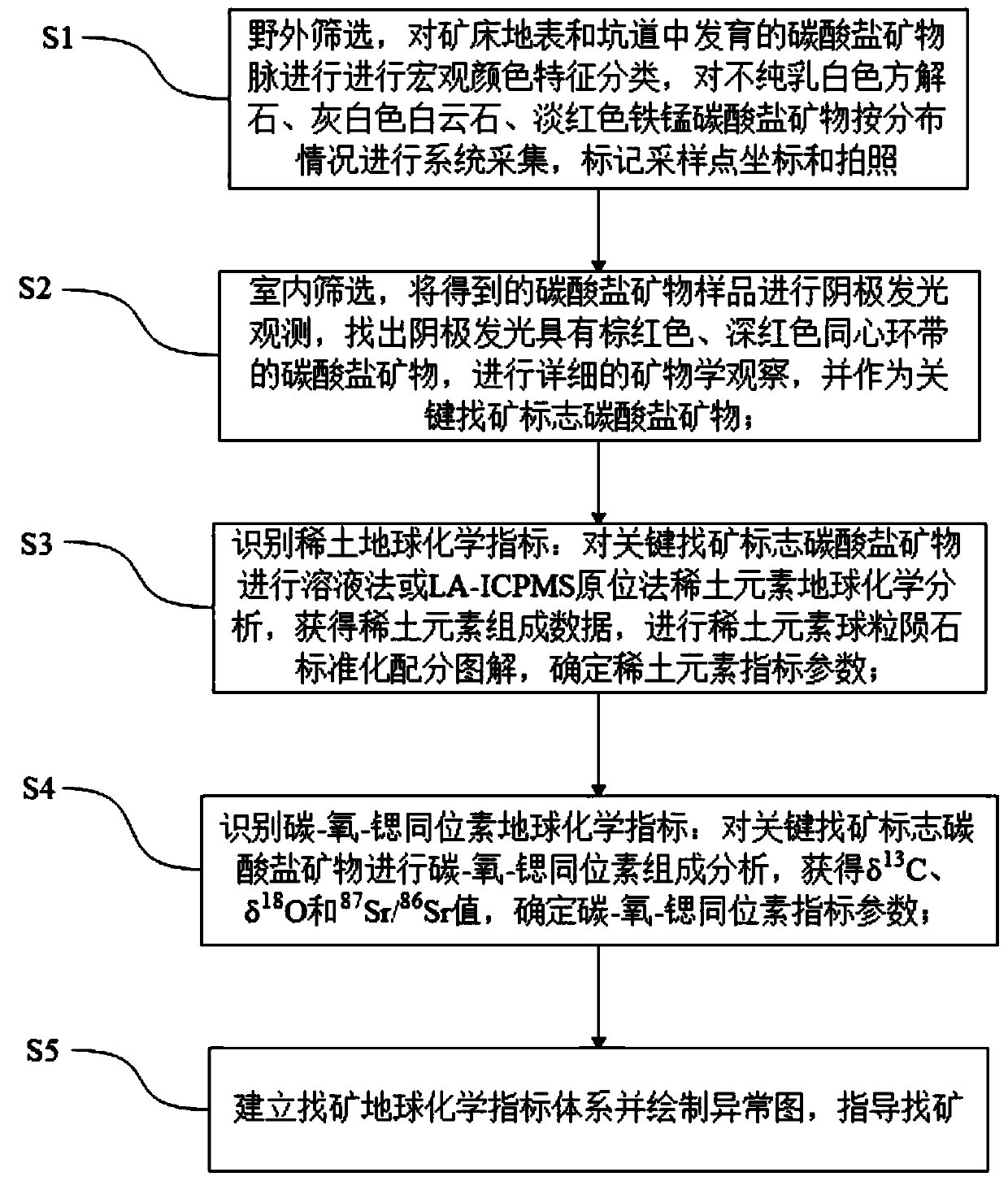

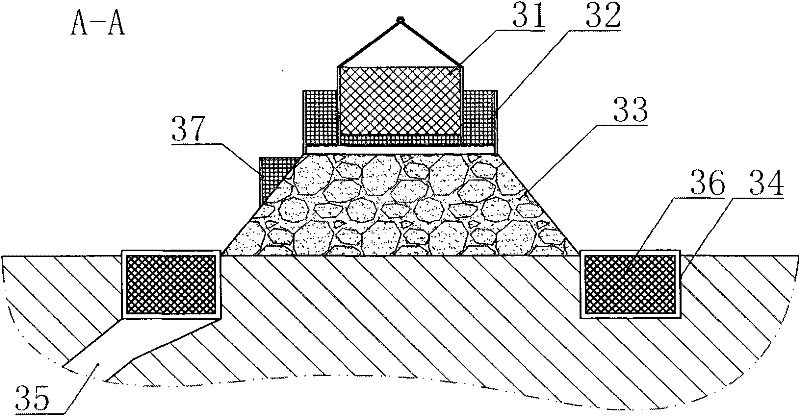

Ore prospecting method for carbonate rock type lead-zinc ore deposit

InactiveCN111189903AAchieving Potential EvaluationSolve ecological and environmental problemsMaterial analysis by electric/magnetic meansMetallogenyIsotope geochemistry

The invention discloses an ore prospecting method for a carbonate rock type lead-zinc deposit. The ore prospecting method comprises the steps of: field screening, indoor screening, rare earth geochemical index and carbon-oxygen isotope geochemical index recognition, ore prospecting geochemical index system establishment, abnormal graph drawing to guide ore prospecting and the like. The method canbe used for rapidly guiding prospecting prediction of carbonate rock type lead-zinc ore deposit to improve the prospecting efficiency, also can be used for judging the ore-forming fluid migration pathof the carbonate rock type lead-zinc deposit and indicating a prospecting direction, and has very high application and popularization value. According to the method, the problems of long period, highinvestment and high risk in the existing exploration technology are solved, the economical efficiency and high efficiency of carbonate rock type lead-zinc deposit potential evaluation and ore right decision are realized, meanwhile, the method is also one of the important ways for realizing green exploration, and the ecological environment problem possibly caused in the implementation process of the traditional exploration technology is solved.

Owner:YUNNAN UNIV

Hybrid FRP (Fiber Reinforced Plastics)-steel composite bar sea sand concrete beam

InactiveCN107217786AGood ductilityImprove comprehensive mechanical propertiesGirdersJoistsRebarBasalt fiber

The invention discloses a hybrid FRP (Fiber Reinforced Plastics)-steel composite bar sea sand concrete beam, which comprises sea sand concrete, and a plurality of upper composite bars, a plurality of lower composite bars and a plurality of hoops fixedly arranged in the sea sand concrete. The hoops are uniformly fixed and tied on the outer surfaces of the upper composite bars and the lower composite bars along length directions of the upper composite bars and the lower composite bars; the upper composite bars and the lower composite bars are respectively arranged on the upper end and the lower end of the bar sand concrete, and comprise reinforcing steel bars and FRP fiber cloth coating the outer surfaces of the reinforcing steel bars; the FRP fiber cloth of each upper composite bar is made of the same material or different materials; the FRP fiber cloth of the plurality of lower composite bars adopts at least two materials; the FRP fiber cloth is adhered with the sea sand concrete; the FRP fiber cloth of the lower composite bars comprises at least two of carbon fiber cloth, glass fiber cloth, basalt fiber cloth and aramid fiber cloth. The hybrid FRP-steel composite bar sea sand concrete beam provided by the invention has no need to desalt sea sand, and has good strength and a bearing performance.

Owner:GUANGDONG UNIV OF TECH

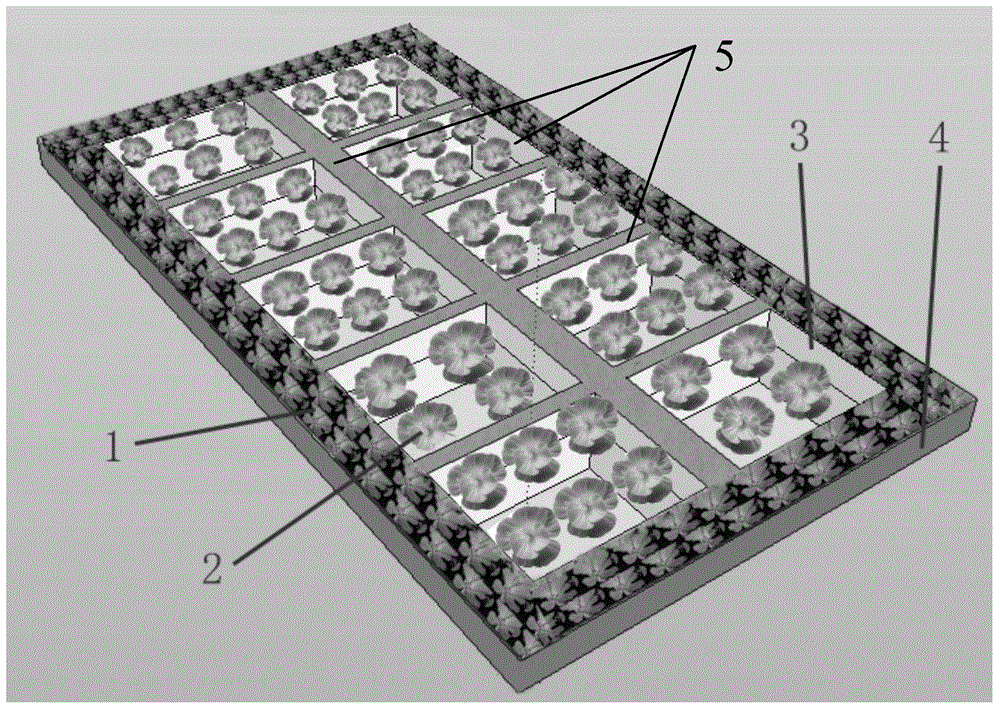

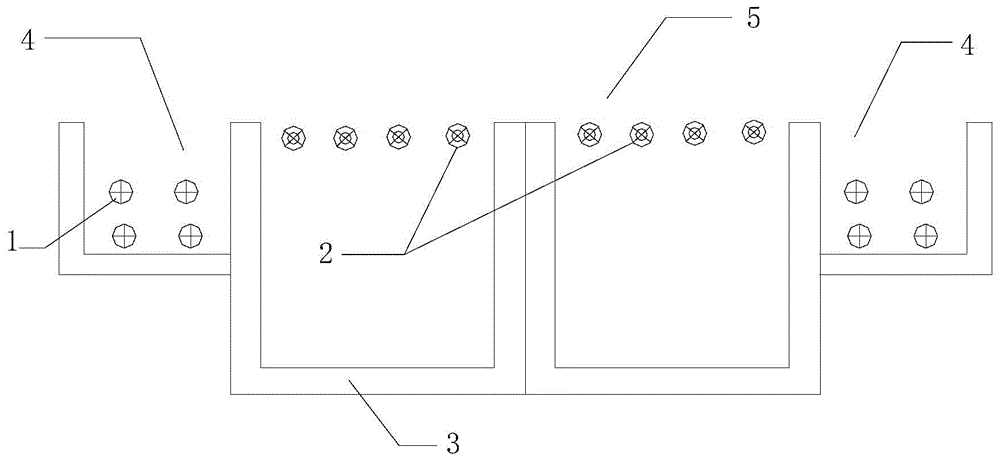

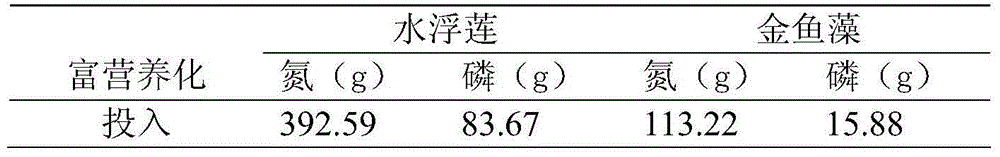

Method for governing eutrophication of fresh water net cage fish-farming area

InactiveCN104663389AReduce eutrophicationPlay a ornamental valueClimate change adaptationAgricultural fishingSocial benefitsEutrophication

The invention relates to the field of aquaculture and environment governing, in particular to a method for governing eutrophication of a fresh water net cage fish-farming area. The method includes the following steps of firstly, throwing water sinking aquatic plants in a peripheral net cage area with the initial throwing density smaller than or equal to 1.8 kg / m<2>, and throwing floating aquatic plants into the fish-farming net cage area with the initial throwing density smaller than or equal to 2.1 kg / m<2>; secondly, conduct harvesting when the density of the water sinking aquatic plants is larger than 4.8 kg / m<2> so that the density of the harvested water sinking aquatic plants can be smaller than or equal to 1.8 kg / m<2>, and conducting harvesting when the density of the floating aquatic plants is larger than 5.3 kg / m<2> so that the density of the harvested floating aquatic plants can be smaller than or equal to 2.1 kg / m<2>. The cultivation of the floating plants and the water sinking plants is combined with the net cage fish farming, the problem of the eutrophication of the fresh water net cage fish-framing area is quite obviously solved, and the method has the outstanding ecological benefits, social benefits and economic benefits.

Owner:SHANGHAI OCEAN UNIV +1

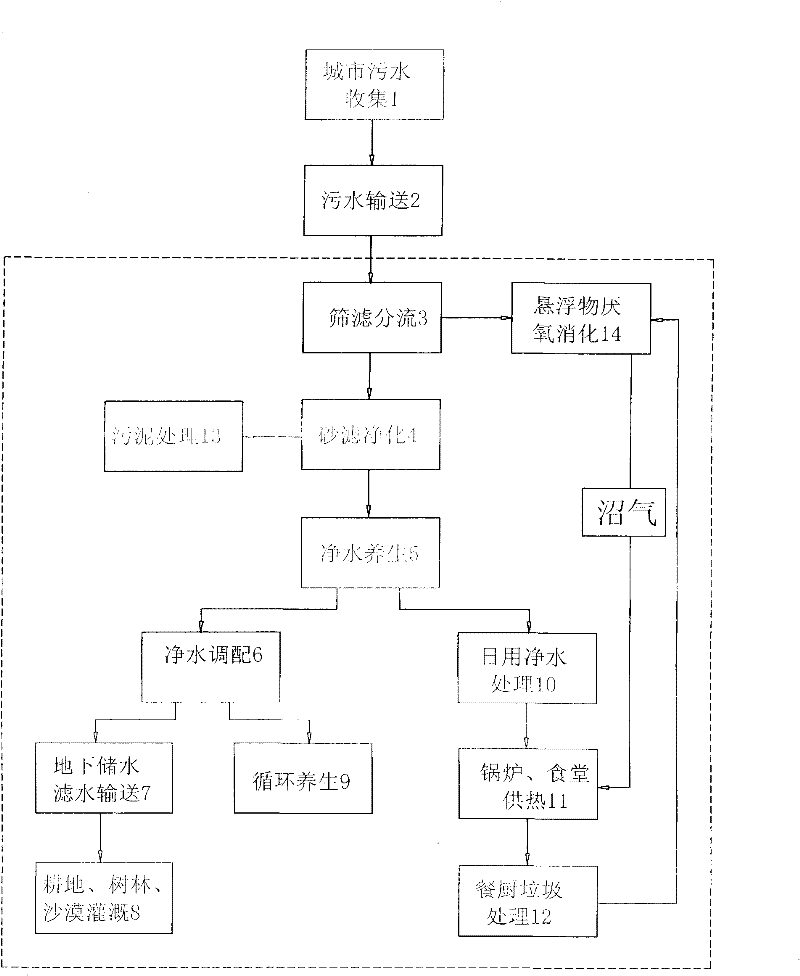

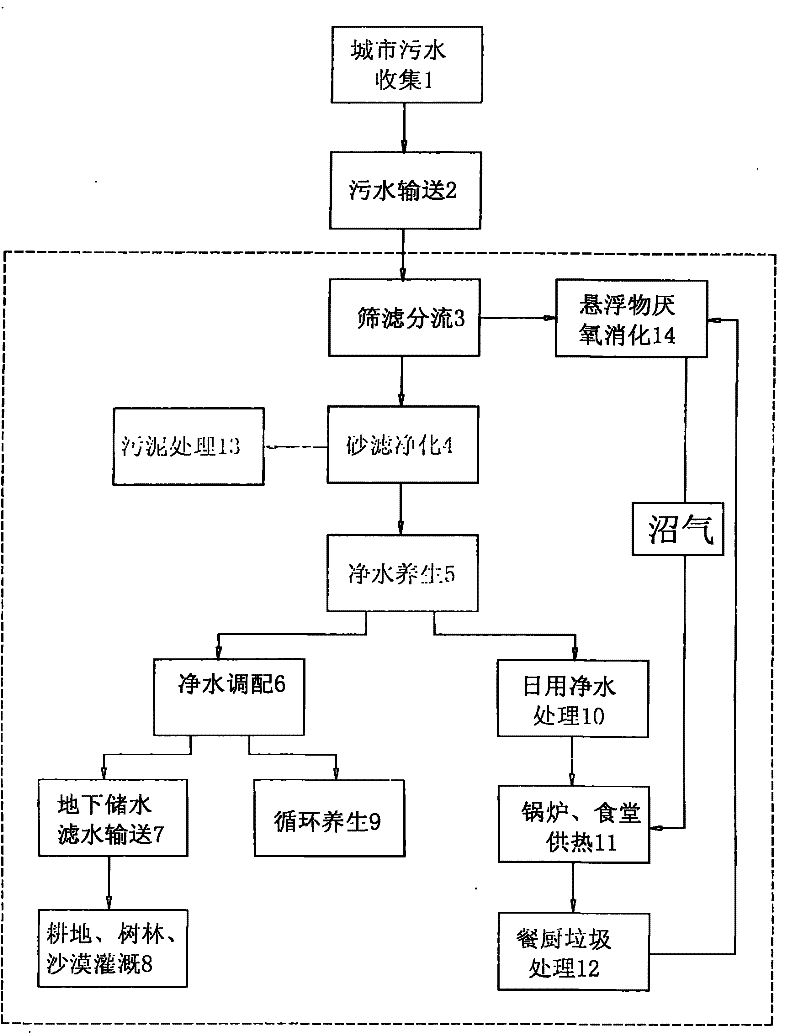

Method for treating desert by using municipal domestic sewage

InactiveCN102172192BSolve ecological and environmental problemsBio-organic fraction processingClimate change adaptationEcological environmentThirst

The invention provides a method for treating a desert by using municipal domestic sewage. The method is characterized by comprising the technological processes of collecting the municipal domestic sewage and conveying the municipal domestic sewage to an arid desertification region; screening, filtering and shunting to screen suspended matters and impurities with larger volumes; carrying out anaerobic digestion treatment on the screened, filtered and shunted suspended matters and impurities; sand-filtering and purifying the screened, filtered and shunted sewage; curing the purified pure water;and then conveying one part of the pure water to the desert, transformed farmlands or woodlands for irrigation via closed conduits, wherein the closed conduits are used as device for storage and further purification; and further purifying the other part of the pure water into domestic water. The method provided by the invention has the advantages that thirst deserts are treated by using the municipal domestic sewage to get vitality gain and the deserts are transformed to normal lands to be survival lands of human beings and all living beings. The two harm sources of the deserts and the domestic sewage in the world are transformed to green ecological systems benefiting humankind so that the ecological environment problem is effectively solved.

Owner:李君伟

Ore prospecting method for Carlin type gold deposit

InactiveCN111189785AResolution cycleHigh investmentMaterial analysis by electric/magnetic meansColor/spectral properties measurementsFluid migrationEcological environment

The invention discloses an ore prospecting method for a Carlin type gold deposit. The ore prospecting method comprises the steps of: field screening, indoor screening, rare earth geochemical index andcarbon-oxygen isotope geochemical index recognition, ore prospecting geochemical index system establishment, abnormal graph drawing to guide ore prospecting and the like. The method can be used for rapidly guiding Carlin-type gold deposit prospecting prediction, improves the prospecting efficiency, also can be used for judging the ore-forming fluid migration path of Carlin-type gold deposit and indicating a prospecting direction, has very high popularization and application value, solves the problems of long period, high investment and high risk of existing exploration technology, realizes the economical efficiency and high efficiency of Carlin-type gold deposit potential evaluation and ore right decision, is also one of important ways for realizing green exploration, and solves the ecological environment problem possibly caused in the traditional exploration technology implementation process.

Owner:YUNNAN UNIV

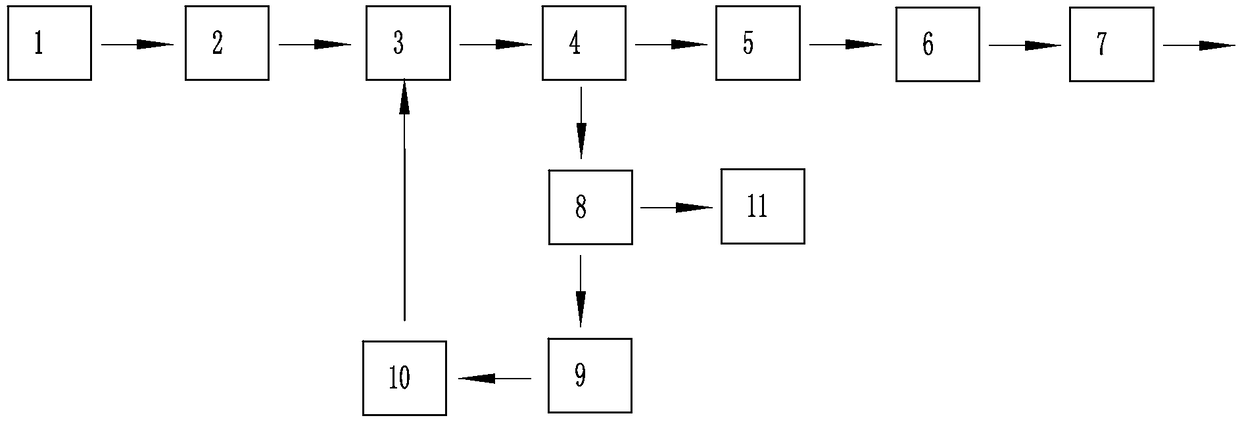

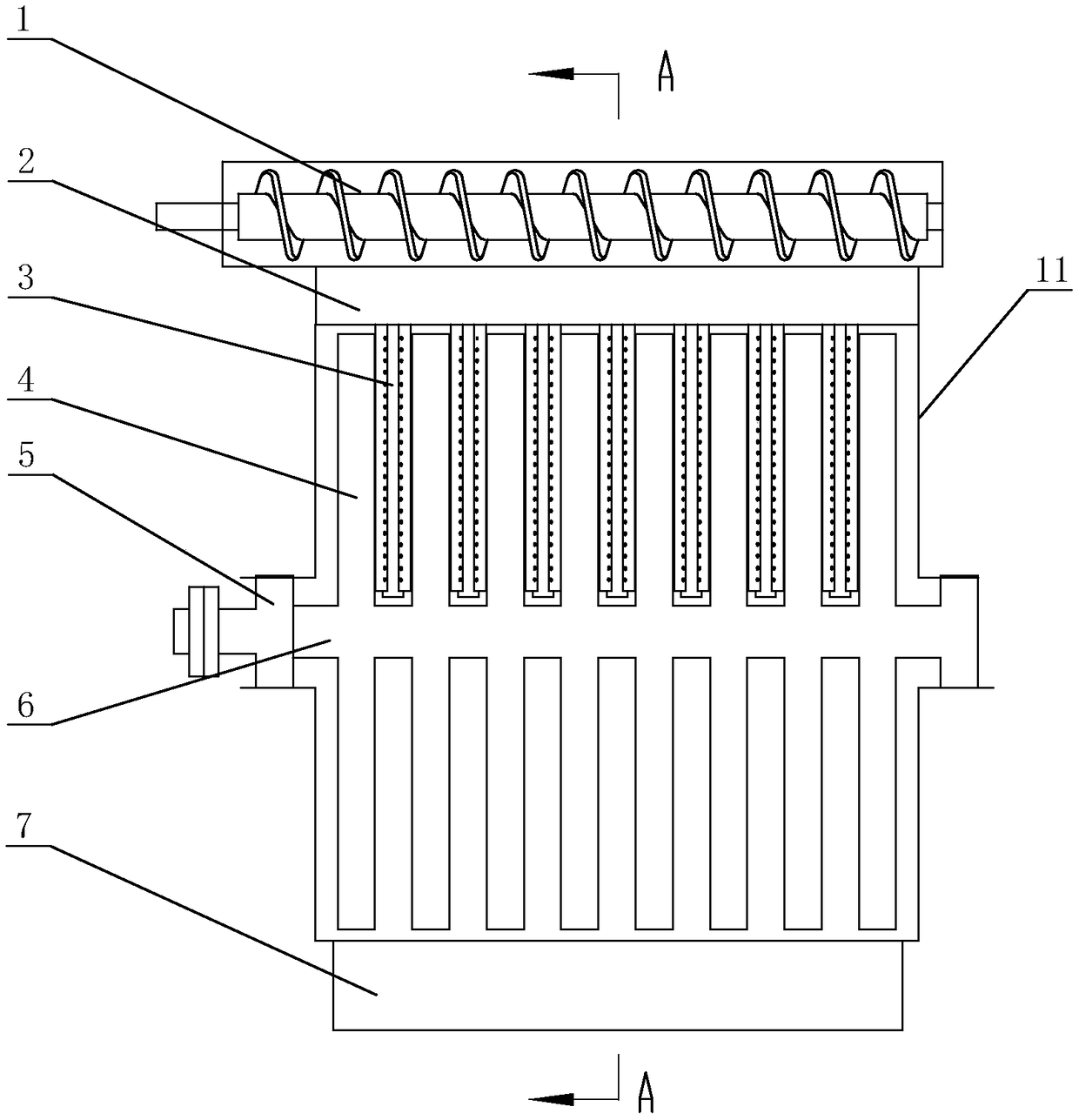

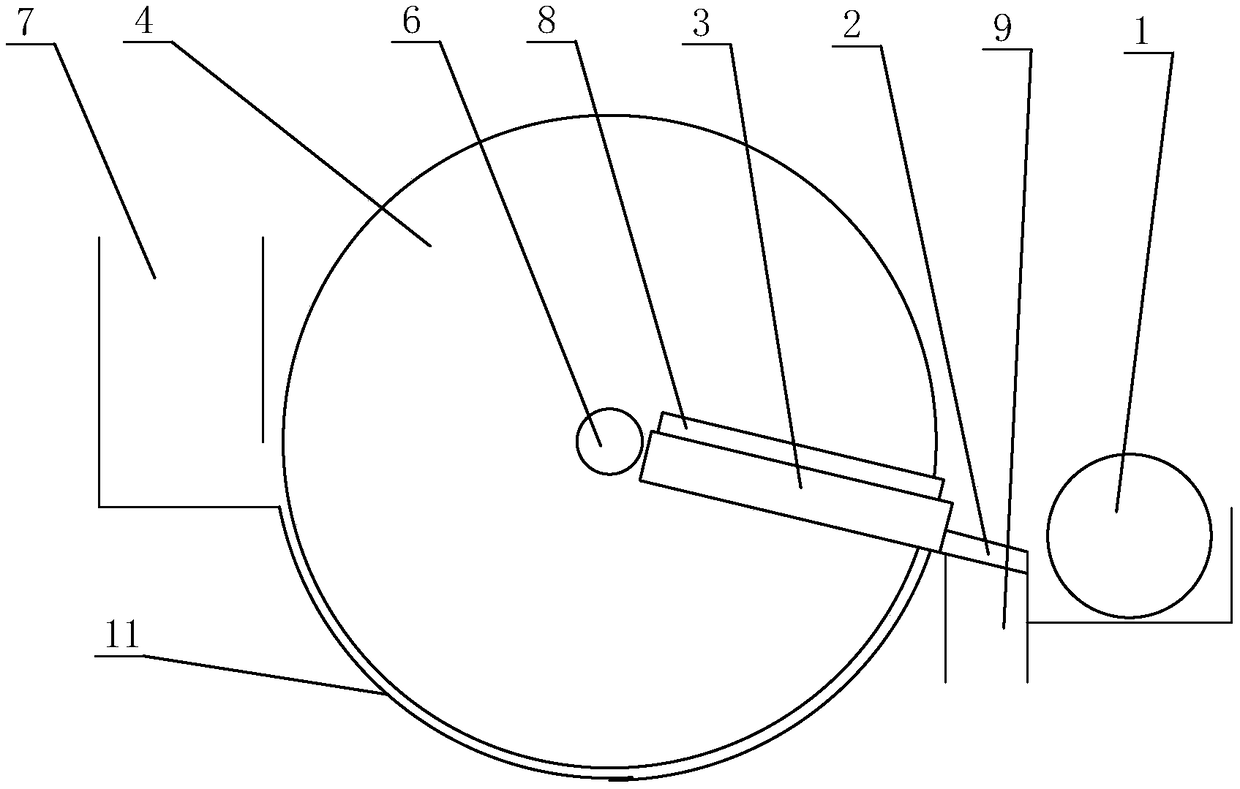

Super magnetic sewage purifying system and process

InactiveCN109231701AShort stayImprove processing efficiencyWater treatment parameter controlSludge treatment by de-watering/drying/thickeningActive carbonSmall footprint

The invention relates to a super magnetic sewage purifying system and process, and belongs to the field of sewage treatment. The super magnetic sewage purifying system comprises a coarse-fine screen 1, a primary settling tank 2, a stirring-mixing reactor 3, a super magnetic purifier 4, an MBR (Membrane Bioreactor) membrane filter 5, an active carbon abdsorber 6, a clean water pond 7, a dispersionreducer 8, a residual magnetism eliminator 9, a superparamagnetic doser 10 and a concentrated dehydrator 11. The super magnetic sewage purifying system has the advantages of simple process, high treatment efficiency, low investment, quick response, no constraint on geographic position, small influences of environment factors, ready availability of raw materials, small floor area and convenience inpractical application.

Owner:王腾

Method for treating desert by using municipal domestic sewage

InactiveCN102172192ASolve ecological and environmental problemsBio-organic fraction processingClimate change adaptationMunicipal sewageEcosystem

The invention provides a method for treating a desert by using municipal domestic sewage. The method is characterized by comprising the technological processes of collecting the municipal domestic sewage and conveying the municipal domestic sewage to an arid desertification region; screening, filtering and shunting to screen suspended matters and impurities with larger volumes; carrying out anaerobic digestion treatment on the screened, filtered and shunted suspended matters and impurities; sand-filtering and purifying the screened, filtered and shunted sewage; curing the purified pure water; and then conveying one part of the pure water to the desert, transformed farmlands or woodlands for irrigation via closed conduits, wherein the closed conduits are used as device for storage and further purification; and further purifying the other part of the pure water into domestic water. The method provided by the invention has the advantages that thirst deserts are treated by using the municipal domestic sewage to get vitality gain and the deserts are transformed to normal lands to be survival lands of human beings and all living beings. The two harm sources of the deserts and the domestic sewage in the world are transformed to green ecological systems benefiting humankind so that the ecological environment problem is effectively solved.

Owner:李君伟

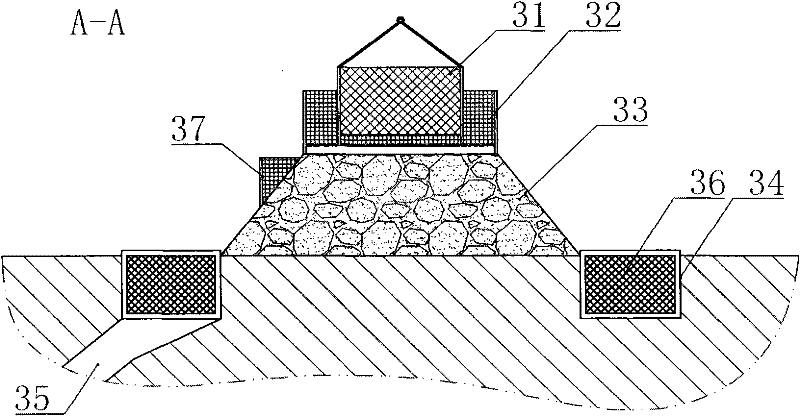

Method for manufacturing autoclaved bricks by utilizing contaminated acid sludge

InactiveCN102775113BSolve ecological and environmental problemsWide variety of sourcesBrickPortland cement

The invention discloses a method for manufacturing autoclaved bricks by utilizing contaminated acid sludge. The method comprises the steps of: I. drying: collecting and drying contaminated acid sludge; II. ball-milling: placing the dried contaminated acid sludge in a ball mill, adding a grinding additive and a chemical excitant to carry out ball milling; III. stirring: adding the ball-milled materials in a stirrer for stirring; IV. wheel milling: conveying the stirred materials in a wheel mill, adding ordinary Portland cement and adding water for wheel milling; V. compressing moulding: loading the wheel-milled materials in a standard brick mould, and placing a compression testing machine for pressure maintaining and then demoulding to obtain brick blanks; VI. static curing: placing the stamping formed brick blanks into a cement standard curing chamber for static curing; and VII. autoclaved curing: placing the brick blanks subjected to static curing into an autoclaved kettle, introducing vapor, carrying out high-temperature constant-pressure autoclaved curing, naturally cooling and taking out of the kettle to obtain the autoclaved bricks. The method solves the problem that the acid sludge pollutes biological environment and achieves the effect of changing wastes into valuables.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

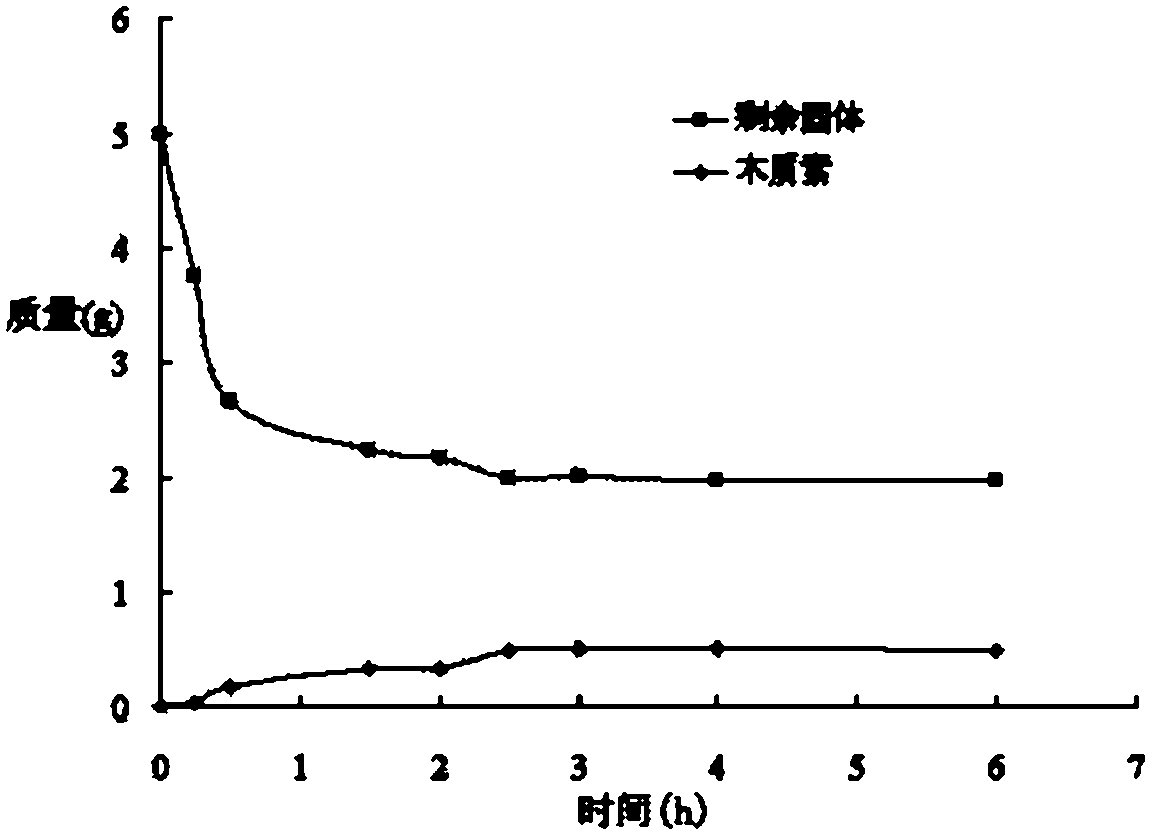

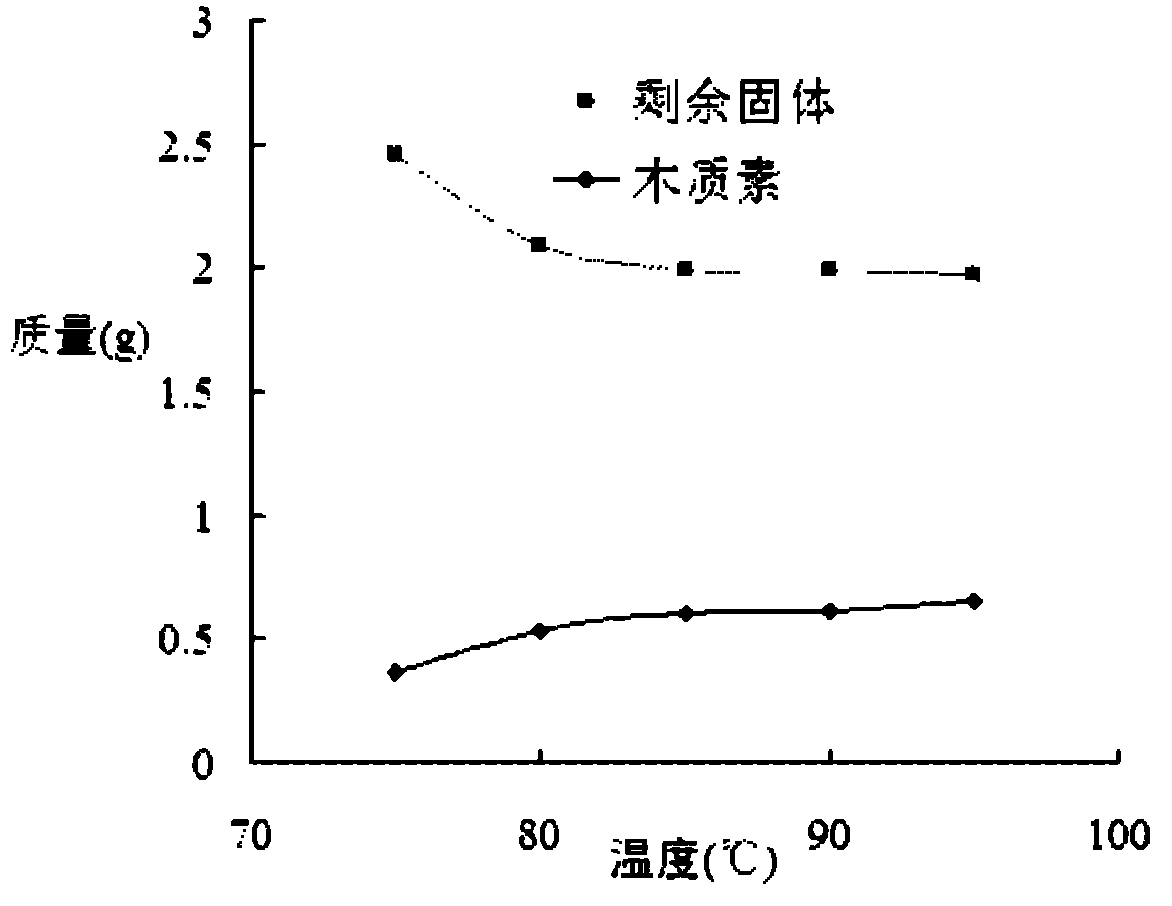

Method of preparing organic fertilizer and making paper from beanstalk fiber

InactiveCN104649734ASolve drought and water shortageSolving Nutrient DepletionPulping with acid salts/anhydridesOrganic fertilisersFiberPapermaking

A method of preparing an organic fertilizer and making paper from beanstalk fibers. The invention aims to produce an environment-friendly multifunctional sand-fixing and soil-retaining organic fertilizer with co-production of paper, wherein no pollutant is discharged during the production process. The method includes following steps: (1) cutting beanstalk into short sections and putting the short beanstalk sections in a steam-boiling reaction pot; (2) mixing ammonium bicarbonate, potassium acetate and calcium oxide according to proportions and adding the mixture into a liquid storage pot; (3) adding hot water at about 80 DEG C with stirring for about 45 min and adding the stirred mixture into the steam-boiling reaction pot to mix the mixture with the steam-boiling reaction pot; (4) feeding steam, performing a steam-boiling reaction under a high-temperature and high-pressure condition for about 2.5 h to obtain a brown slurry mixture; (5) with a triple-way pulp extruding machine, performing a filter-pressing process to separate the brown slurry mixture to obtain paper pulp and a black liquid, wherein the paper pulp is used for blanching and papermaking and the black liquid is used for prepared the organic fertilizer through solidification; (6) during the solidification for preparing the organic fertilizer, concentrating the black liquid into a concentrated black liquid through an external-flow free falling film plate-type evaporator; and (7) feeding the concentrated black liquid into a spray drying column to dry and solidify the concentrated black liquid into powder.

Owner:凌海东

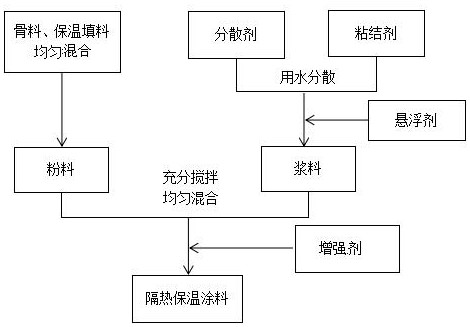

Preparation method of diatomite tailing thermal insulation coating

PendingCN113512309APollution controlRealize high value utilizationFireproof paintsSocial benefitsEcological environment

A preparation method of a diatomite tailing thermal insulation coating relates to a tailing high-value utilization method, and comprises the following preparation processes of: uniformly dispersing a dispersant and an inorganic binder in water, adding a suspending agent, adding the solution into diatomite tailings, an auxiliary aggregate, a thermal insulation filler and a reinforcing agent which are proportioned and mixing well, adding water and mixing to obtain paste and / or slurry, and packaging the paste and / or slurry to obtain the diatomite tailing thermal insulation coating. The invention provides a method for effectively treating diatomite tailings, and a new technical scheme is provided for treating diatomite tailings. According to the invention, the tailings are fully utilized, so that the ecological environment problem caused by tailings heap can be overcome, the tailings are turned into wealth, meanwhile, direct economic benefits can be brought, and the social benefits are significant.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

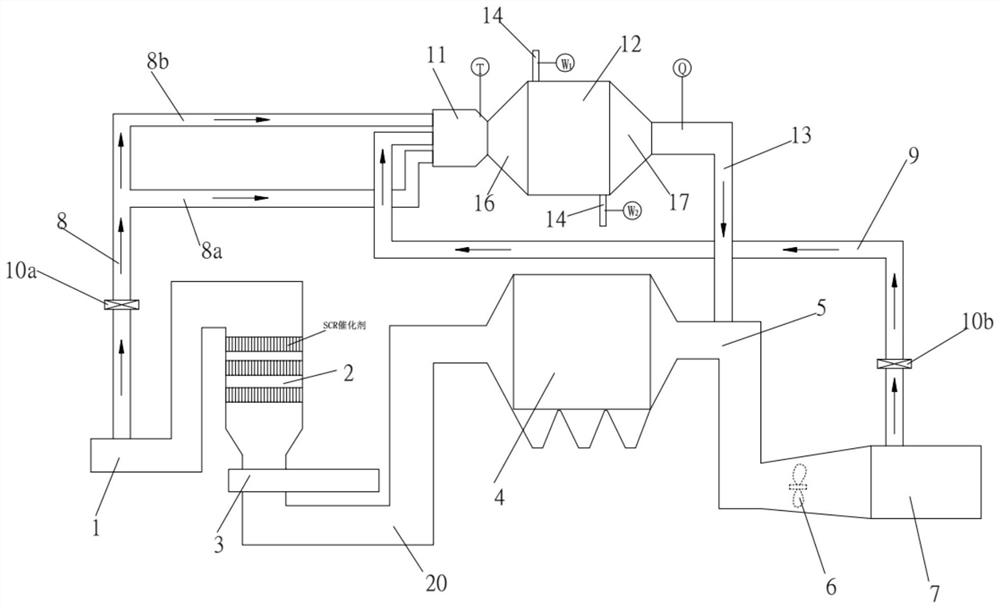

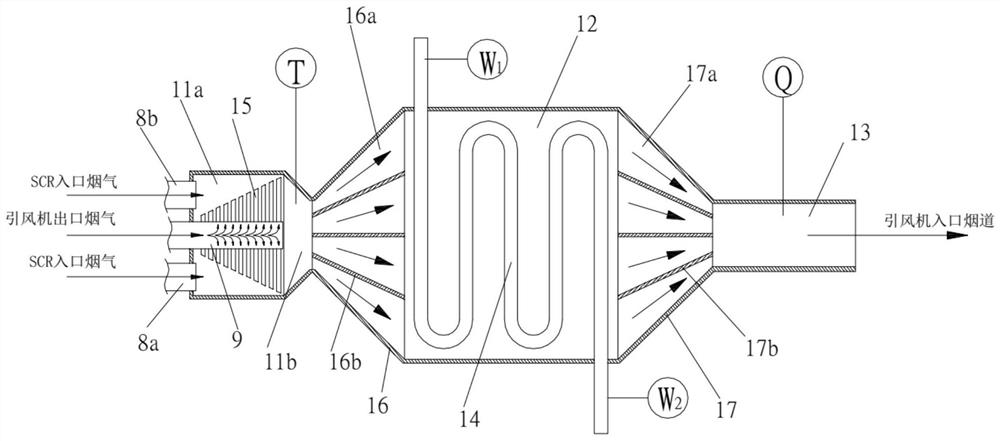

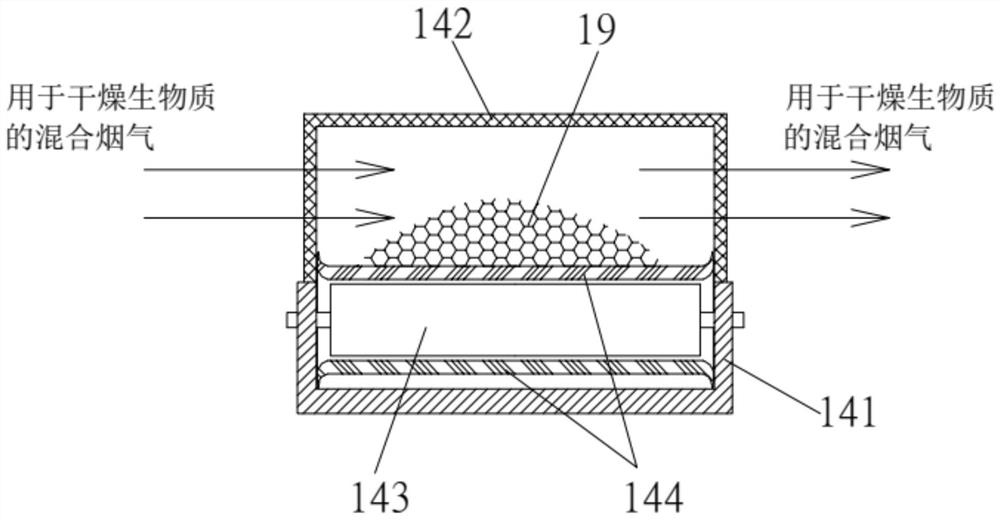

Pulverized coal boiler direct-fired biomass drying system and drying method

ActiveCN112902627AEffective control of oxygen contentProne to spontaneous combustionRecuperative heat exchangersDrying gas arrangementsThermodynamicsCombustor

The invention relates to a pulverized coal boiler direct-fired biomass drying system and drying method. According to the technical scheme, the pulverized coal fired boiler direct-fired biomass drying system comprises an SCR inlet flue, an SCR reactor, an SCR outlet flue, an induced draft fan inlet flue and an induced draft fan outlet flue which are sequentially connected. The pulverized coal boiler direct-fired biomass drying system further comprises a conveying belt used for conveying biomass into an inlet of a coal mill to be smashed and a drying system used for drying the biomass on the conveying belt, the conveying belt conveys the dried biomass into the coal mill to be ground, the dried biomass and pulverized coal are conveyed into a boiler together to be subjected to suspension combustion, the fibrous structure of the dried biomass is changed, the changed biomass can be ground by an existing coal mill, the grinding characteristic of biomass fuel is close to that of raw coal after the drying process, the biomass fuel can be ground to be fine enough, and after the biomass is ground into powder, through a powder pipe and a combustor of an existing coal pulverizing system, mixed suspension combustion can be achieved, and the large-proportion mixing problem of direct combustion of the biomass on a pulverized coal furnace is solved.

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD +1

Flue gas desulfurization agent and method for flue gas desulfurization

ActiveCN104001412BHigh removal rateReduce desulfurization costDispersed particle separationRed mudFlue gas

The invention discloses a flue gas desulfurization agent and a flue gas desulfurization method thereof. Expressed by weight percentage, the flue gas desulfurizer is composed of 10-80% of red mud, 5-50% of aluminum ash, 5-70% of fly ash and 5-30% of waste carbon powder. First, weigh various raw materials according to the composition ratio of raw materials, mix them evenly, and obtain a mixed material; press the mixed material into a prism, and a gas channel is provided in the middle of the prism; the prism is assembled in the desulfurization equipment, and the desulfurization equipment is connected to the flue gas pipeline. The flue gas generated in the flue gas pipeline is passed into the desulfurization equipment to fully contact with the desulfurizer for desulfurization; after measurement, the desulfurized gas meets the national emission standards and is discharged. The invention utilizes the respective characteristics of red mud, fly ash, aluminum ash and waste carbon powder, and mixes them as a desulfurizing agent, which can effectively remove sulfur dioxide in flue gas, and the desulfurization rate reaches over 90%. The invention treats waste with waste, has low desulfurization cost, high sulfur dioxide removal rate, and is beneficial to industrial scale-up.

Owner:湖南中大冶金设计有限公司

Combined production method for environment-friendly type multifunctional sand-fixation soil-retention organic fertilizer and paper

InactiveCN101215210BHas a bonding effectPrevent evaporationMagnesium fertilisersSewage/sludge fertilisersSulfite saltBleach

Disclosed is a joint production process of environment-friendly and multifunctional organic fertilizers which is used for sand consolidation and soil protection and paper making. The purpose of the invention is using ryegrass of agricultural waste to produce environment-friendly and multifunctional organic fertilizers which is used for sand consolidation and soil protection and in joint production of paper making, and no pollution discharges in the production process. The method of the invention comprises that cutting ryegrass into pipe nipples to fill in a stewing retort, adding ammonium hydrogen carbonate, sodium sulfite, potassium sulphate and magnesia into a liquid storage tank after mixing pro rata, adding hot water with a temperature of about 60 DEC G in the liquid storage tank to stir for about 30 minutes, pouring the mixture into the stewing retort to mix with pipe nipples of ryegrass, inletting steam, stewing and reacting in the condition of high temperature and high pressurefor about 2.5 hours to prepare a mixed bag of brown serosity, adopting a tertiary press master to press, filter and separate the mixed bag of brown serosity into paper pulp and black liquor, wherein the paper pulp is applied to bleach to make paper, and the black liquor is applied to cure fertilizer making. Adopting evaporator with outflow freely dropping lamina membranacea to concentrate the black liquor into concentrated black liquor, and then sending the concentrated black liquor into a spray drying tower to be dried and cured into powder.

Owner:何秀院

A kind of industrial workshop venue and its construction method

ActiveCN110185292BGood effect of capturing light energyAvoid Morning Cream EffectsSolar heating energyDucting arrangementsInsulation layerThermal insulation

Owner:吉林市东北生态农业发展有限责任公司

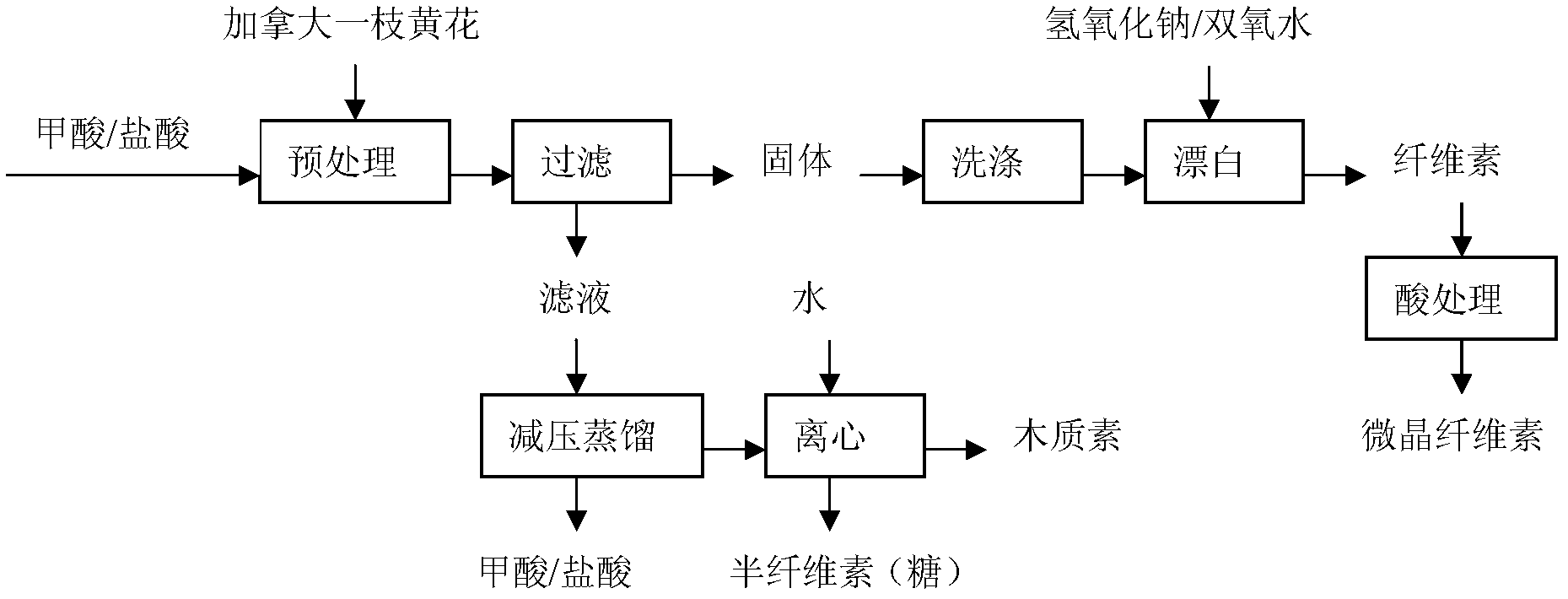

Preparation method of nanoscale solidago canadensis L. microcrystalline cellulose

InactiveCN102585017BNo pollution in the processIn line with the concept of biorefineryPaper material treatmentEcological environmentFiltration

The invention relates to a preparation method of nanoscale solidago canadensis L. microcrystalline cellulose, which includes: (1) smashing stalks of solidago canadensis L., being placed in a reaction vessel, adding formic acid and hydrochloric acid, stirring, and reacting at the temperature of 85 DEG C; and then performing suction filtration to obtain solid; (2) adding appropriate amount of sodium hydroxide solution in the solid, then adding hydrogen dioxide solution, performing suction filtration on obtained slurry after reaction is finished, washing the slurry by using distilled water to neutral, and drying obtained solid to obtain alpha-cellulose; and (3) putting the alpha-cellulose in the reaction vessel, adding sulfuric acid, stirring and reacting at the temperature of 100 DEG C, performing suction filtration after cooling, and finally washing, drying and grinding obtained solid to obtain the nanoscale solidago canadensis L. microcrystalline cellulose. The nanoscale solidago canadensis L. microcrystalline cellulose is simple in preparation method, high in resource recycling rate and small in pollution, and the preparation method is an effective measure to treat the solidago canadensis L. and can solve actual ecological environment problems.

Owner:DONGHUA UNIV

A blockchain-based ecological environment supervision method and system

ActiveCN113822781BImprove regulatory efficiencyImprove effectivenessResourcesRegulatory authorityEnvironmental resource management

The present invention provides a block chain-based ecological environment supervision method and system, the method comprising: collecting the ecological environment information of the target area, and uploading the ecological environment information to the target block chain; Carry out analysis and evaluation, determine the ecological environment level of the target area, and store the ecological environment level and ecological environment information; based on the target block chain, set the ecological environment level and ecological environment information of the target area access rights, and send the corresponding access key to the target regulatory authority. The ecological environment information of the target area is obtained in real time through the blockchain, and the ecological environment of the target area is rated. At the same time, the ecological environment level of the target area is sent to various regulatory departments through the blockchain, which improves the efficiency of environmental supervision and regulatory measures. The effectiveness provides convenience for solving ecological and environmental problems.

Owner:河北硕权科技有限公司

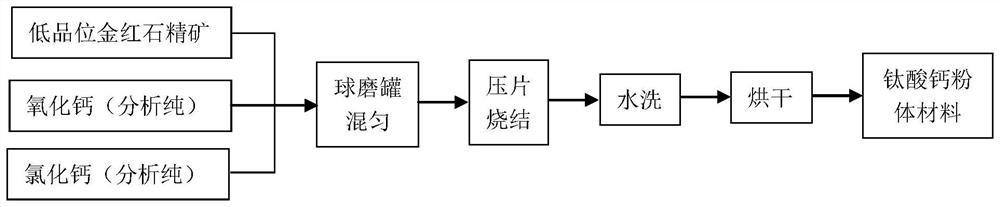

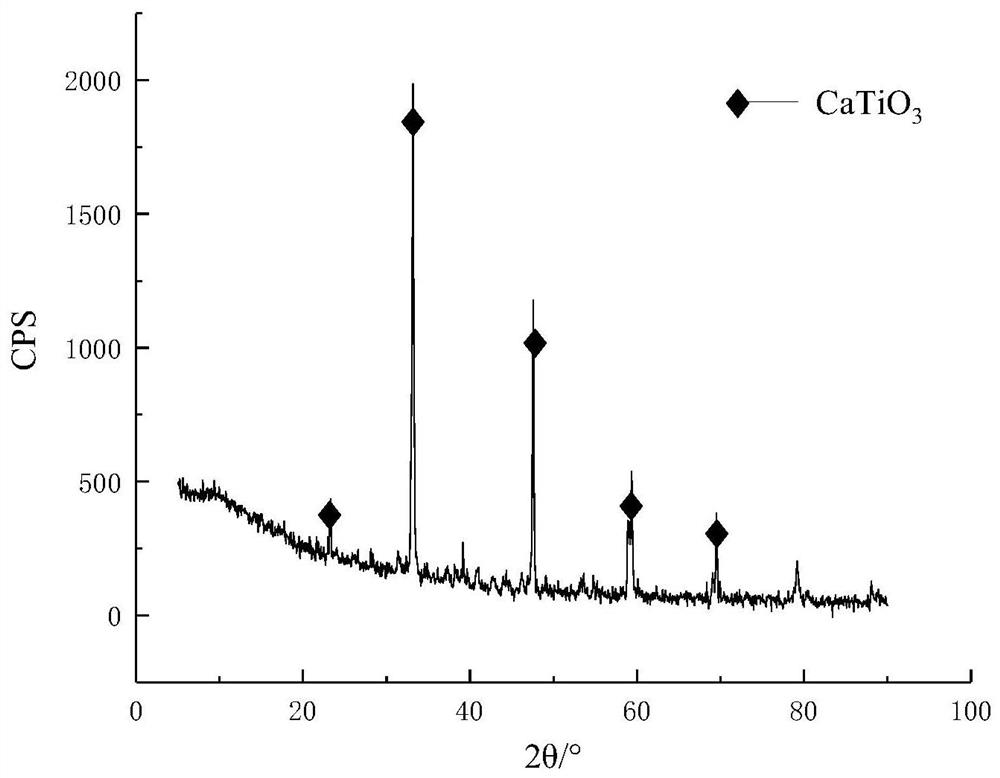

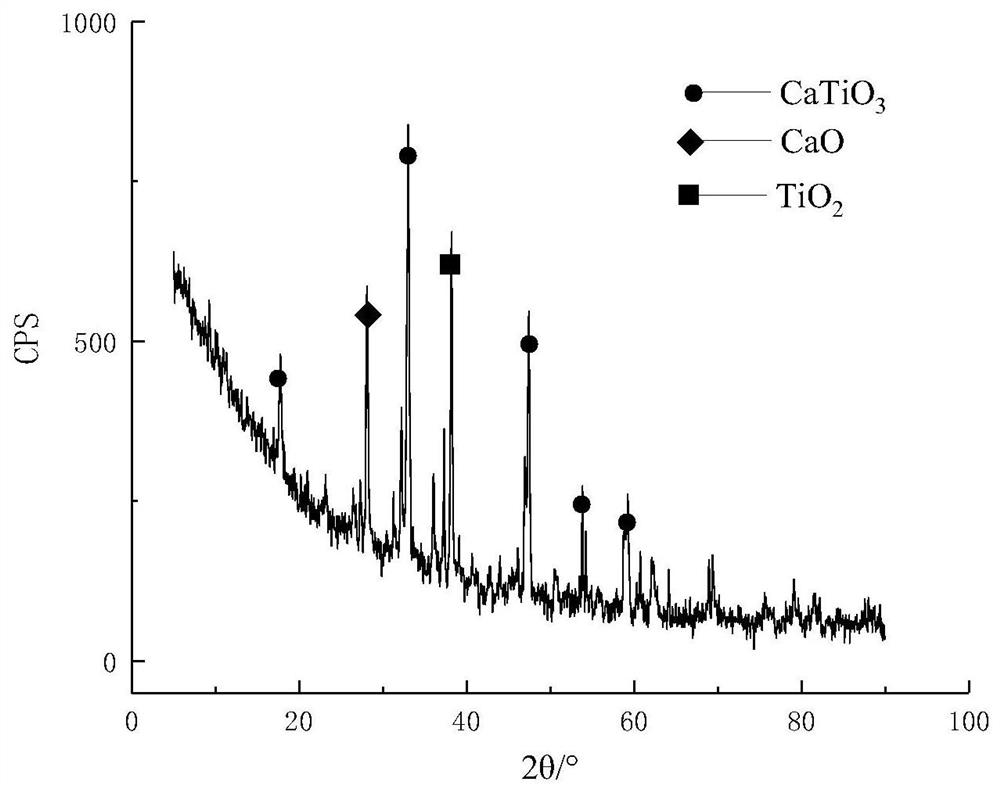

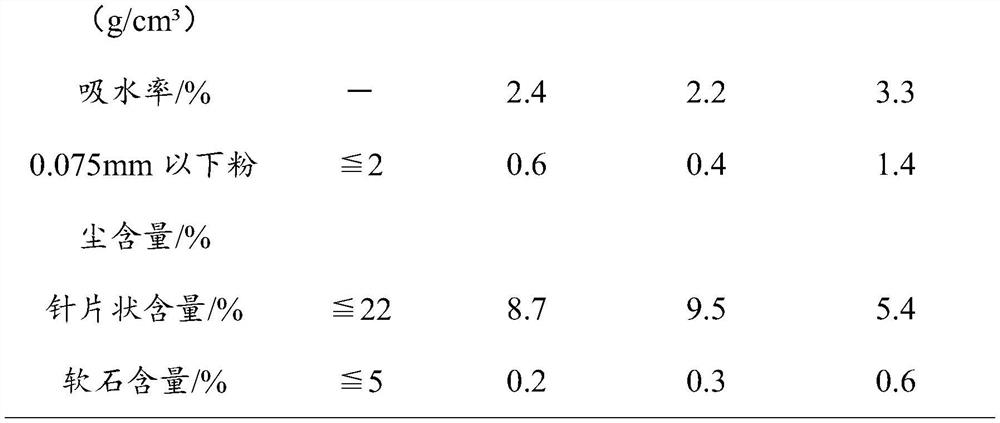

A method for preparing calcium titanate adsorption material by using low-grade rutile concentrate

ActiveCN113522224BMaximize utilizationWide variety of sourcesOther chemical processesWater contaminantsSilicic acidTitanic acid

The invention discloses a method for preparing calcium titanate adsorption material by using low-grade rutile concentrate. The method prepares a calcium titanate adsorption material with a stable crystal structure and excellent stability. Low-grade rutile has a wide range of sources and low price, and can comprehensively utilize the resources of titanium dioxide, turn waste into treasure, and solve the problem of ecological environment pollution. At the same time, using calcium chloride and potassium silicate as the molten salt reaction medium can effectively reduce the temperature of the reaction system and save costs. The high value-added products produced can effectively remove heavy metal ions in sewage, and have broad application prospects in the field of sewage treatment, with good economic, environmental and social benefits.

Owner:SHANGLUO UNIV

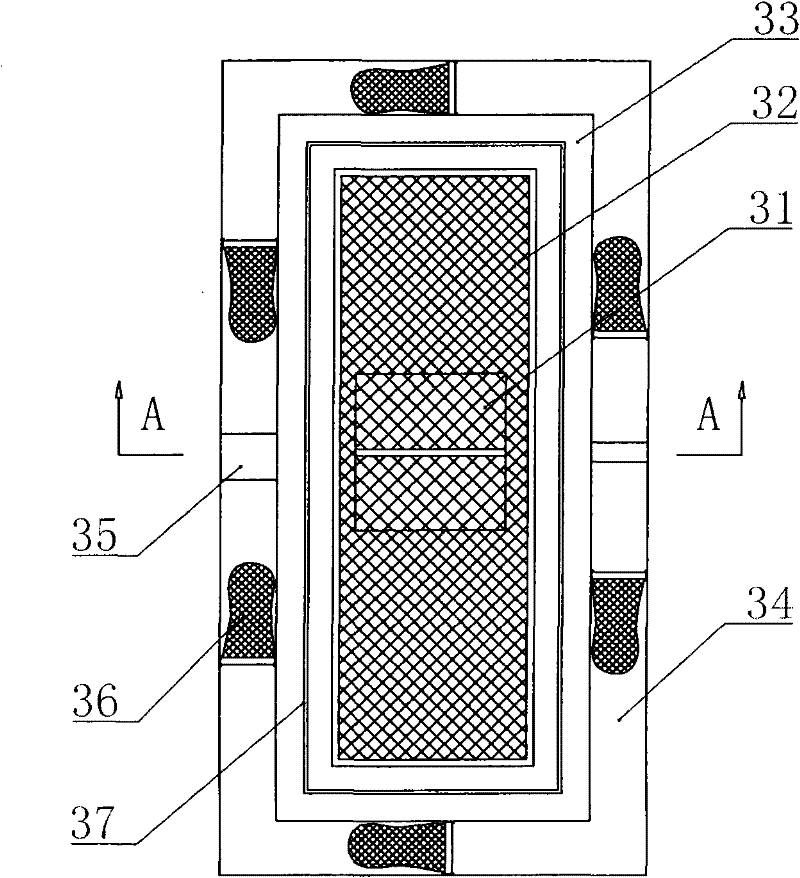

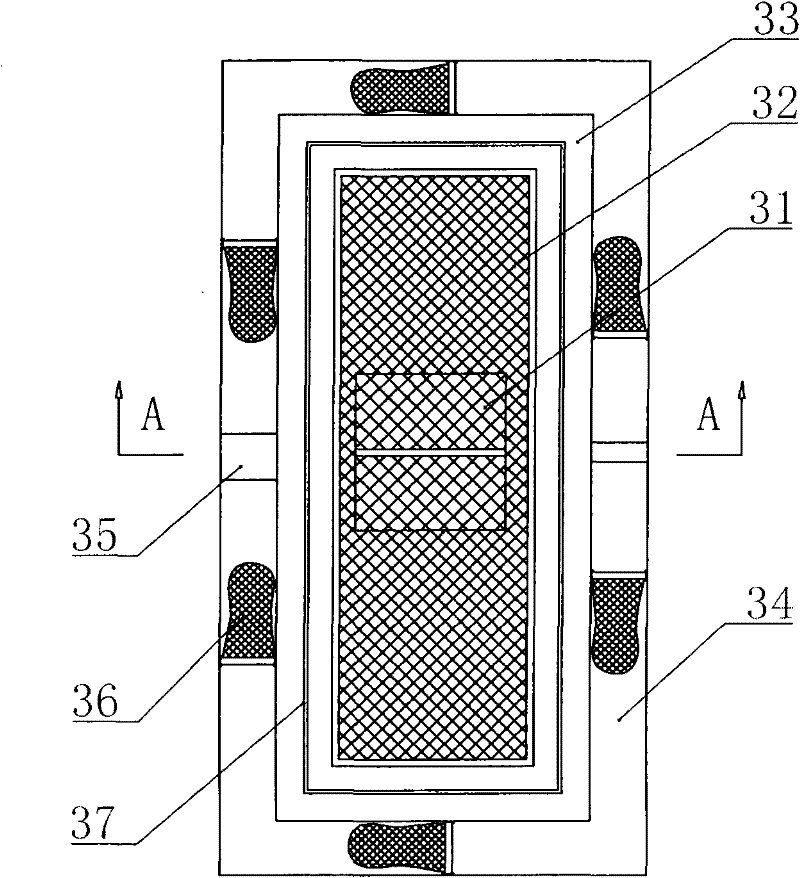

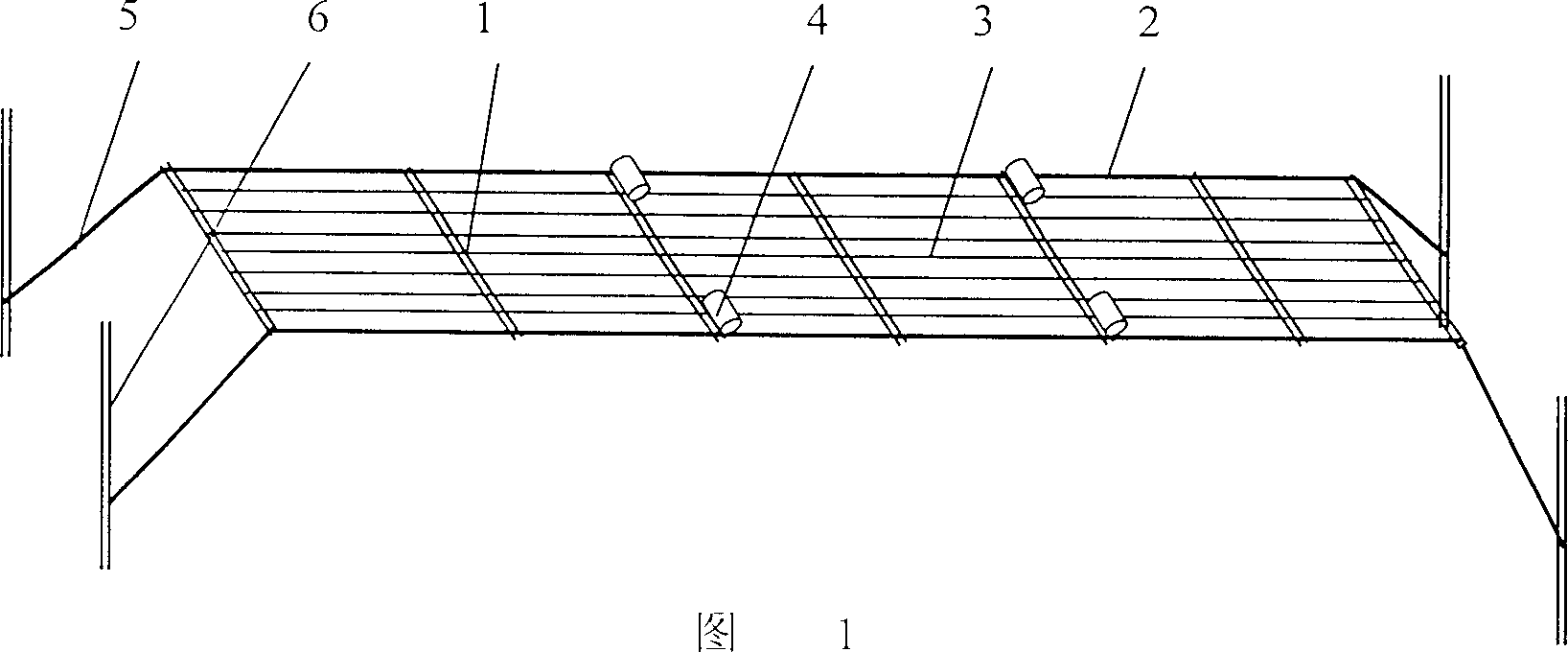

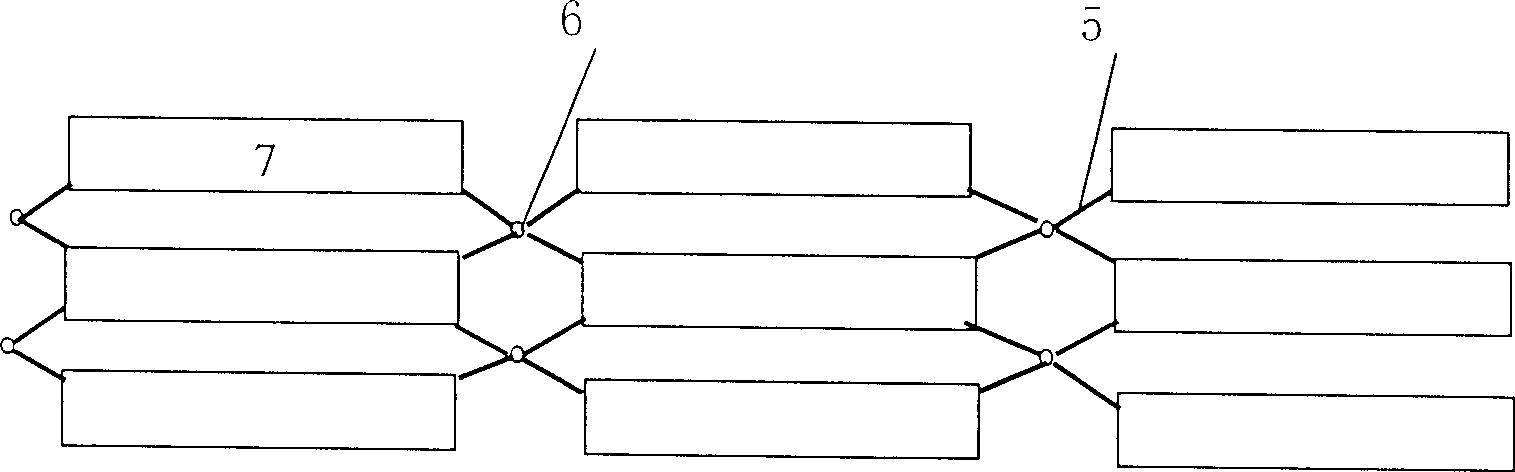

Method for biological repairing eutrophication of subtropical zone sea water fish culture in net cage area

InactiveCN1255335CReduce eutrophicationLow costClimate change adaptationCultivating equipmentsEutrophicationEcological environment

The invention is a bioremediation method of eutrophication in semi-tropical marine fish cage culture region, relating to the cultivation of a kind of edible seaweed, especially the water cultivation nearby or in the fish cage for the bioremediation of the eutrophication. Its steps: selecting algae seeds and breeding them in seawater, where the initially-bred biomass density is less than 800 kg / mu; collecting as the biomass density greater than 1000 kg / mu and then the biomass density is less than 600 kg / mu. The bioremediation hanging culture raft is provided with at least two parallel-arranged poles, the end parts of these poles are connected by ropes or brackets into a frame boby, there are stakeropes between poles, and the frame body are provided with at least 1 supended body and fixed by at least four fixing ropes. It combines algae cultivation with fish cage culture for mixed culture, used for bioremediation of eutrophication of marine culture.

Owner:XIAMEN UNIV +2

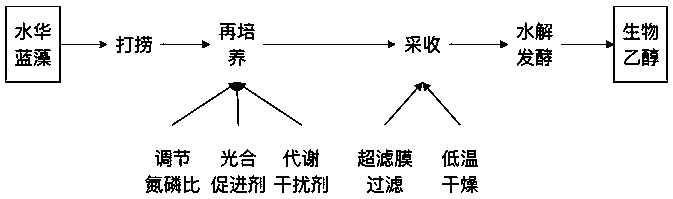

Method for preparing bioethanol from bloom-forming cyanobacteria

ActiveCN109628502AAvoid secondary pollutionSolve ecological and environmental problemsMicroorganism based processesFermentationUltrafiltrationPhotobioreactor

The invention discloses a method for preparing bioethanol from bloom-forming cyanobacteria. The method includes the following steps that 1, bloom-forming cyanobacteria is salvaged and collected; 2, the collected bloom-forming cyanobacteria is inoculated into a photobioreactor, the ratio of nitrogen to phosphorus is regulated, a photosynthesis promoter and a metabolic interfering agent are added, air is introduced, an inorganic carbon source is supplied, and re-culture is performed; 3, after re-culture, a tubular ultrafiltration film is used for filtering and concentration to form high-concentration cyanobacteria liquid, and cyanobacteria powder is obtained after drying; 4, the cyanobacteria powder is hydrolyzed under acidic conditions, and hydrolysate containing reducing sugar is obtained;5, the hydrolysate is adjusted to weak acidity, and yeast is added for fermentation to obtain bioethanol. According to the method, the sugar content in the bloom-forming cyanobacteria and the bio-availability are significantly improved, and the yield of the bioethanol is greatly improved. The method is simple and easy to operate, the cost is low, the problem is solved that algae needs large-scalecultivation in the existing bioethanol preparation process, and meanwhile an effective way of resource utilization is provided for bloom-forming cyanobacteria.

Owner:EAST CHINA NORMAL UNIVERSITY

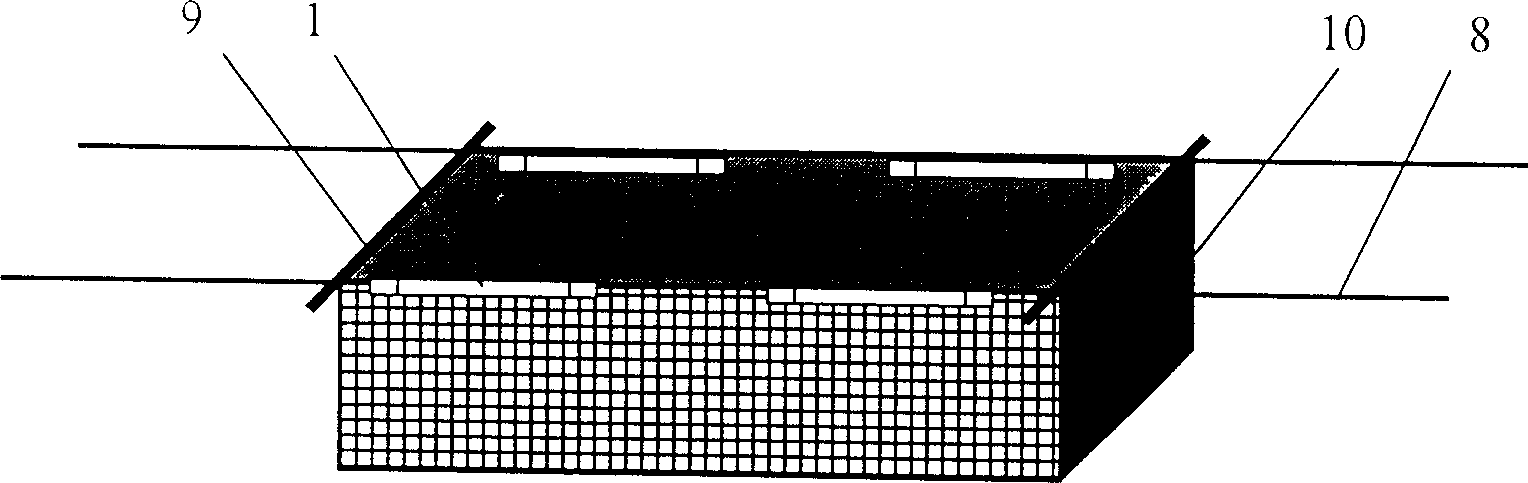

Method for controlling eutrophication of fish farming area in freshwater cage by floating plants

InactiveCN102531183BReduce eutrophicationImprove viewing valueHorticultureBiological water/sewage treatmentHelophyteEcological environment

The invention relates to the field of control to eutrophication of fish farming areas in freshwater cages, in particular to an ecological restoration method for controlling the eutrophication of a fish farming area in a freshwater cage by floating plants. The method comprises the following steps: 1) floating aquatic plants are put into the freshwater cage, and the density of the floating aquatic plants put initially is smaller than 2.3 kg / m2; and 2) after the density of the floating aquatic plants is larger than 5.6 kg / m2, the floating aquatic plants are recovered so as to cause the density of the recovered floating aquatic plants to be smaller than 2.3 kg / m2. In the invention, floating plant cultivation and cage culture are combined, repaired living beings can decorate the water lever to have an ornamental value, above all, the eutrophication of the fish farming area in the freshwater cage is relieved by a simple method at very low cost remarkably, and the ecological environment problem unsolved for a long time is effectively solved. Therefore, the method provided by the invention has prominent ecological benefits, social benefits and economic benefits.

Owner:SHANGHAI OCEAN UNIV

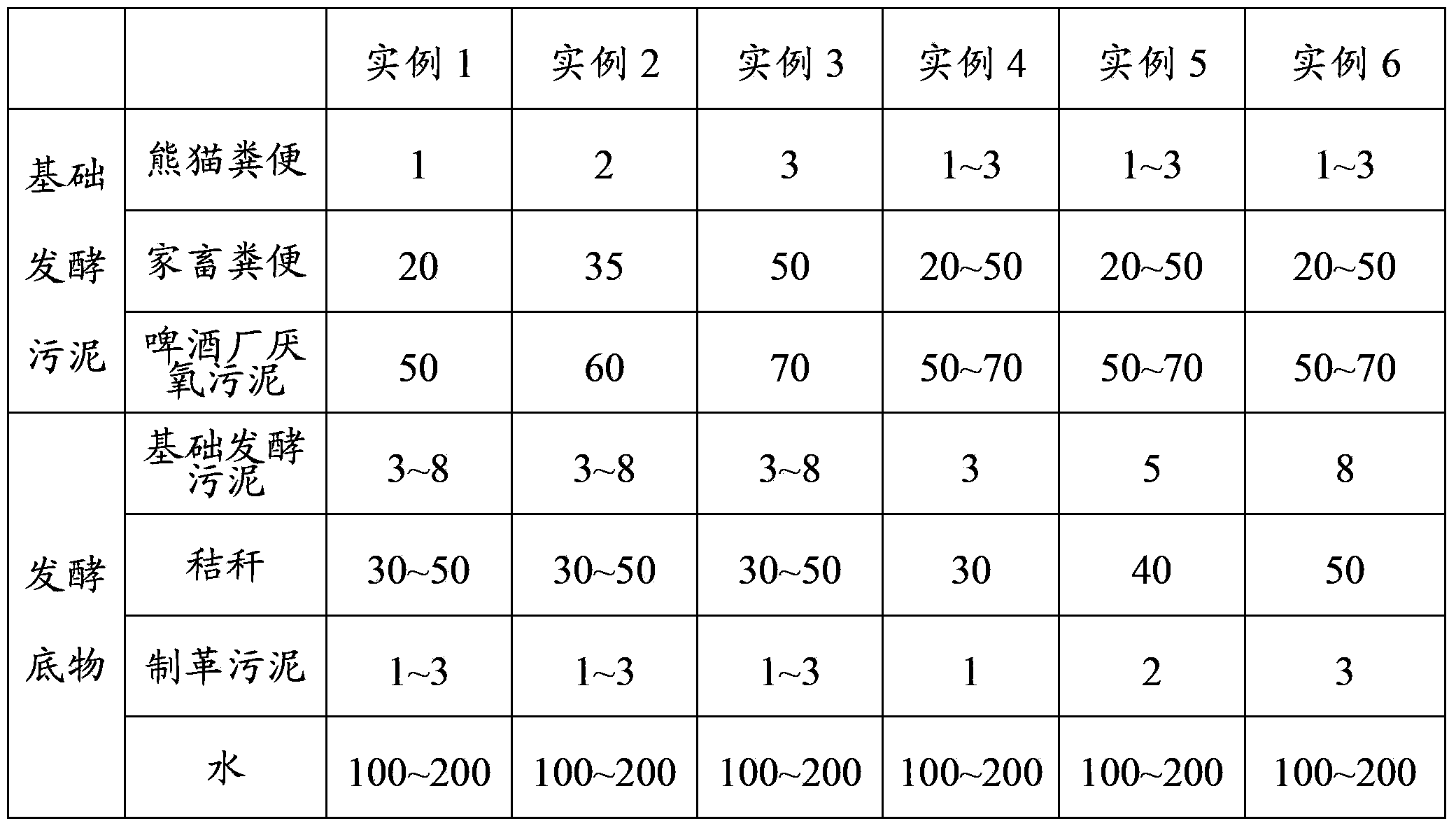

Method for preparing biogas from mixed plant straws and tanning sludge by dry-type anaerobic fermentation

InactiveCN102296091BHigh activityImprove degradation rateWaste based fuelSludge processingCollection methodsFermentation

The invention provides a method for preparing biogas from mixed plant straws and tanning sludge by dry-type anaerobic fermentation, which comprises the following steps: adding white-rot fungus into anaerobic sludge of a brewery to prepare basic fermentation sludge, and fermenting at ordinary temperature for 8 hours; and mixing the basic fermentation sludge, straws, tanning sludge and water to form a fermentation substrate; and evenly mixing the fermentation substrate, putting the fermentation substrate into an intermittent anaerobic fermentation device, carrying out anaerobic dry-type fermentation at ordinary temperature, and finally, collecting the biogas by a draining gas-collection method.

Owner:SHAANXI UNIV OF SCI & TECH

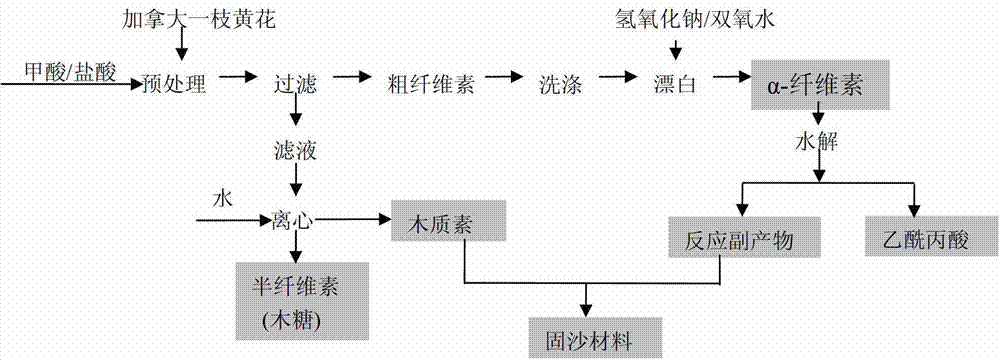

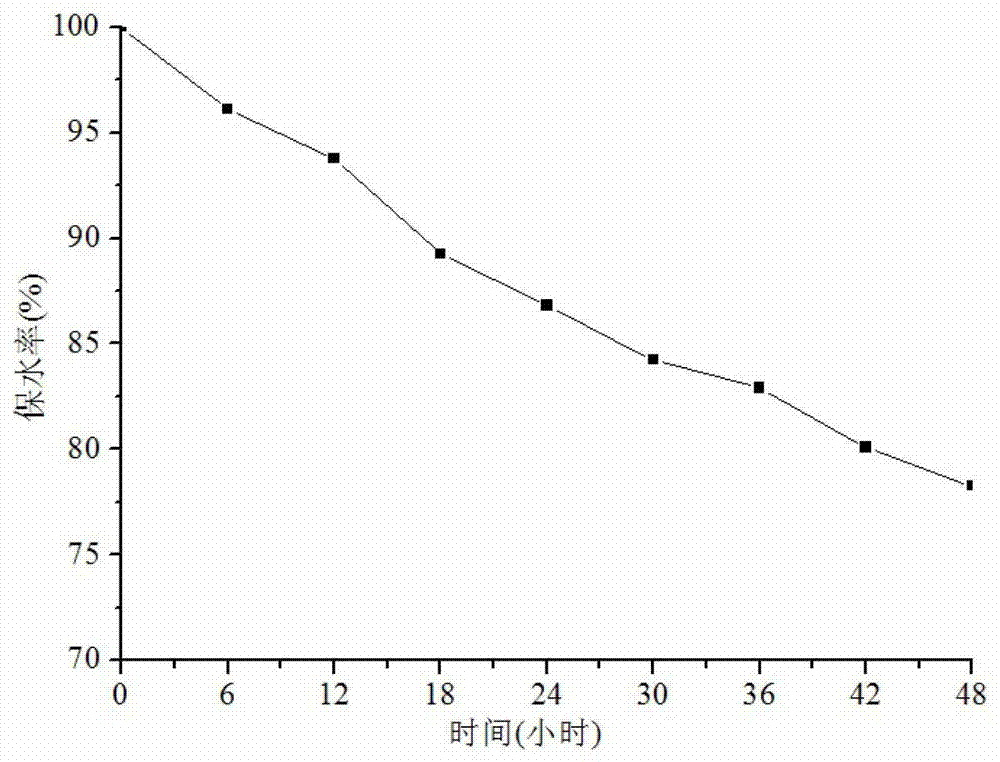

Preparation method of Canada-goldenrod-based sand stabilization material

InactiveCN102936320BIncrease profitLow costOther chemical processesOrganic fertilisersPotassium persulfateLevulinic acid

The invention relates to a preparation method of a Canada-goldenrod-based sand stabilization material. The preparation method includes reacting stalks of Canada goldenrod with formic acid and hydrochloric acid; preparing to obtain lignin, alpha-cellulose and hemicellulose; mixing the alpha-cellulose with dilute sulphuric acid to obtain levulinic acid and reaction by-products; mixing the cellulose, acrylamide, the reaction by-products with water, adding N,N'-dimethylacrylamide and potassium persulfate to obtain the sand stabilization material. According to the method, the method is simple, the resource recycling utilization rate is high, pollution is small, and the method is environment-friendly; and the wood fiber component alpha-cellulose, the lignin and the hemicellulose in the Canada goldenrod are effectively extracted.

Owner:DONGHUA UNIV

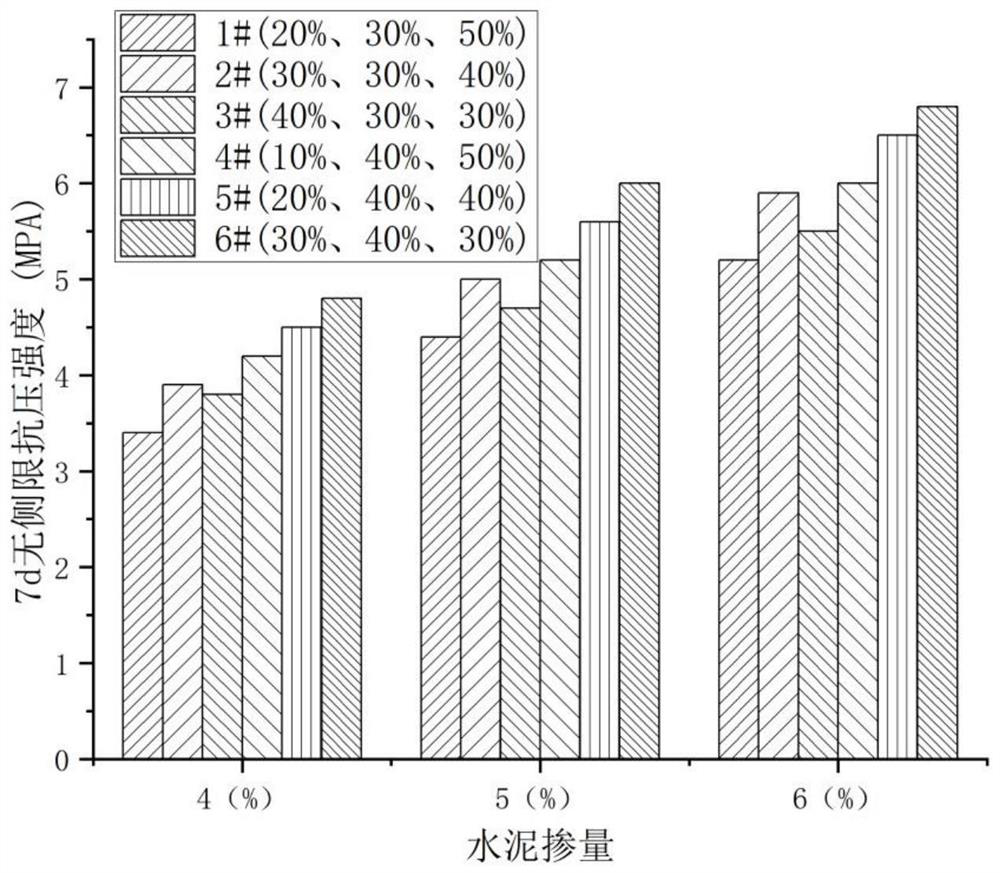

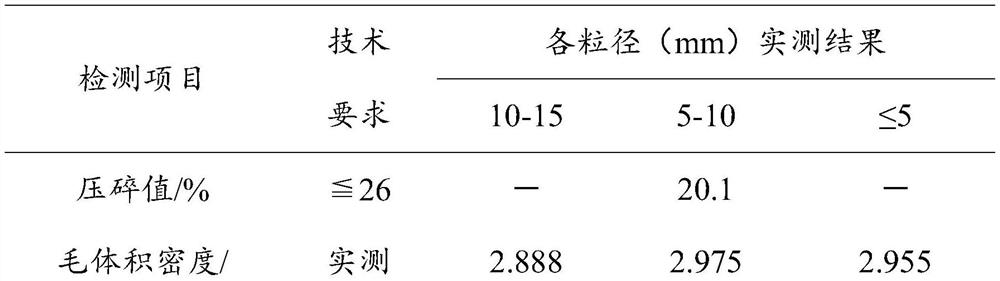

Raw material ratio design method for semi-rigid base layer of cement stabilized steel slag

PendingCN114790087ASolve ecological and environmental problemsSolve the shortageRatio controlRoad engineeringSlag

The invention discloses a raw material ratio design method for a semi-rigid base of cement stabilized steel slag, and belongs to the field of road engineering materials. According to the design method, the steel slag aggregate is graded according to the particle size, the blending proportion of each grade of material is determined according to the principle of maximum density, then the maximum dry density and the optimal moisture content of the mixture with different cement mixing amounts are determined through design of the cement mixing amount and the water using amount and a compaction test, and finally the maximum dry density and the optimal moisture content of the mixture with different cement mixing amounts are determined through a 7d unconfined compressive strength test according to the test result. And obtaining the optimal raw material ratio of the cement-stabilized steel slag semi-rigid base by integrating the unconfined compressive strength requirement and the cement dosage ratio. According to the design method, the compressive strength of the road base can be met at the lowest cost, the problems of shortage of natural gravel road building materials and environmental pollution caused by the shortage of the natural gravel road building materials are solved, the utilization rate and applicability of steel slag waste are improved, and the ecological environment problem caused by accumulation of a large amount of steel slag is solved; and the pavement performance is unstable when the existing steel slag is directly used as a semi-rigid base material.

Owner:中路高科交通检测检验认证有限公司

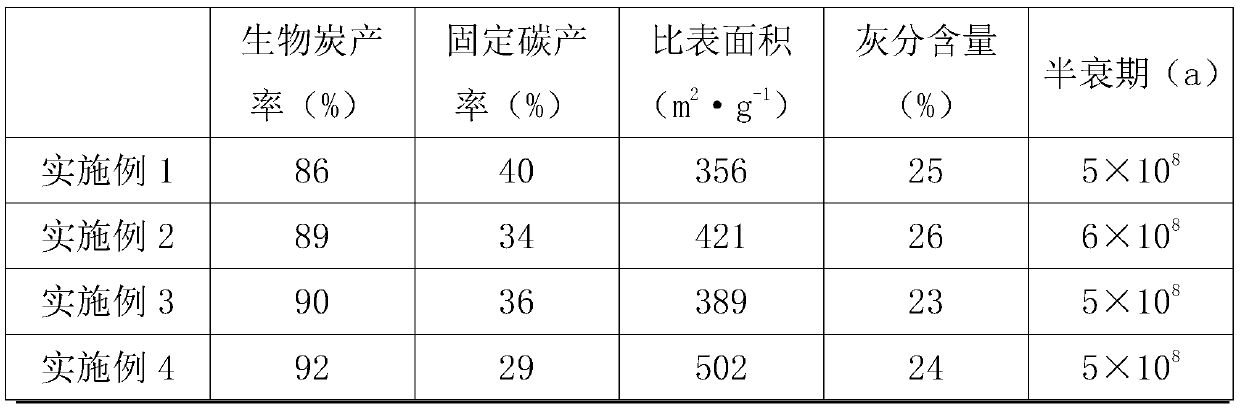

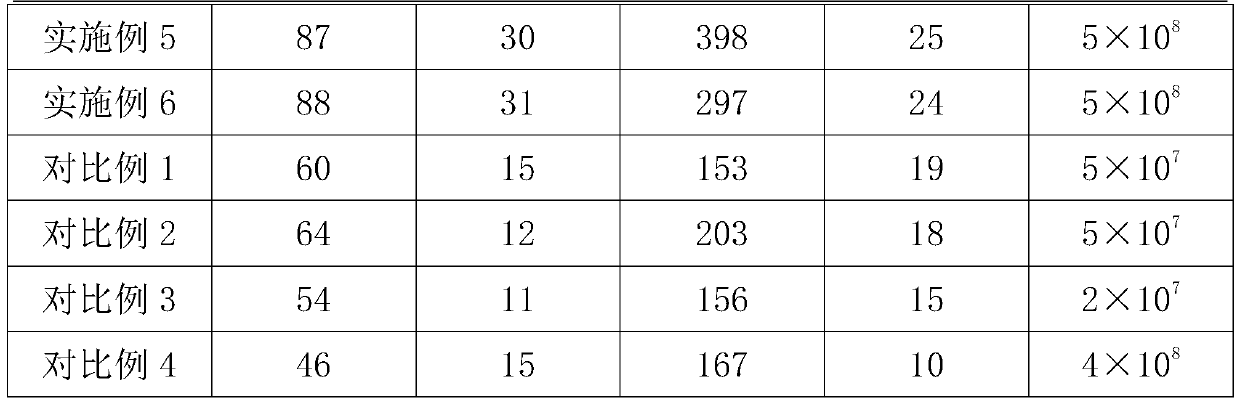

Preparation method of biochar

InactiveCN110422833AWide range of usesGood yieldOther chemical processesCarbon preparation/purificationSodium BentoniteMicrowave

The invention discloses a preparation method of biochar. The preparation method includes the steps that greening garbage is dried and crushed, then the greening garbage is put into a container, a hydrochloric acid solution is added, soaking and stirring are conducted, filtration under reduced pressure is conducted in a microwave reaction kettle, amylase, deionized water, the hydrochloric acid solution and animal dung are added to be evenly stirred, inert gas is introduced into the container, the container is sealed and heated, after the reaction is completed, a product is collected and filtered, filter is dried, bentonite is added into the filter, the filter is added into a reaction container, the inert gas is introduced into the reaction container, the container is sealed, and the reaction container is baked; and a baked product is taken out and placed in a crucible and placed in a muffle furnace to be carbonized, and the biochar is obtained. The biochar is wide in raw material source, low in cost, easy to obtain, abundant in pore structure and higher in stability, the pore structure of the biochar is relatively dense, and various metal ions can be adsorbed.

Owner:JILIN JIANZHU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com