Method for preparing biogas from mixed plant straws and tanning sludge by dry-type anaerobic fermentation

A technology for dry anaerobic fermentation and tannery sludge, which is applied in biological sludge treatment, fermentation, sludge treatment, etc. It can solve the problems of random discarding of straw, improve activity, realize clean production, and solve the ecological environment problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

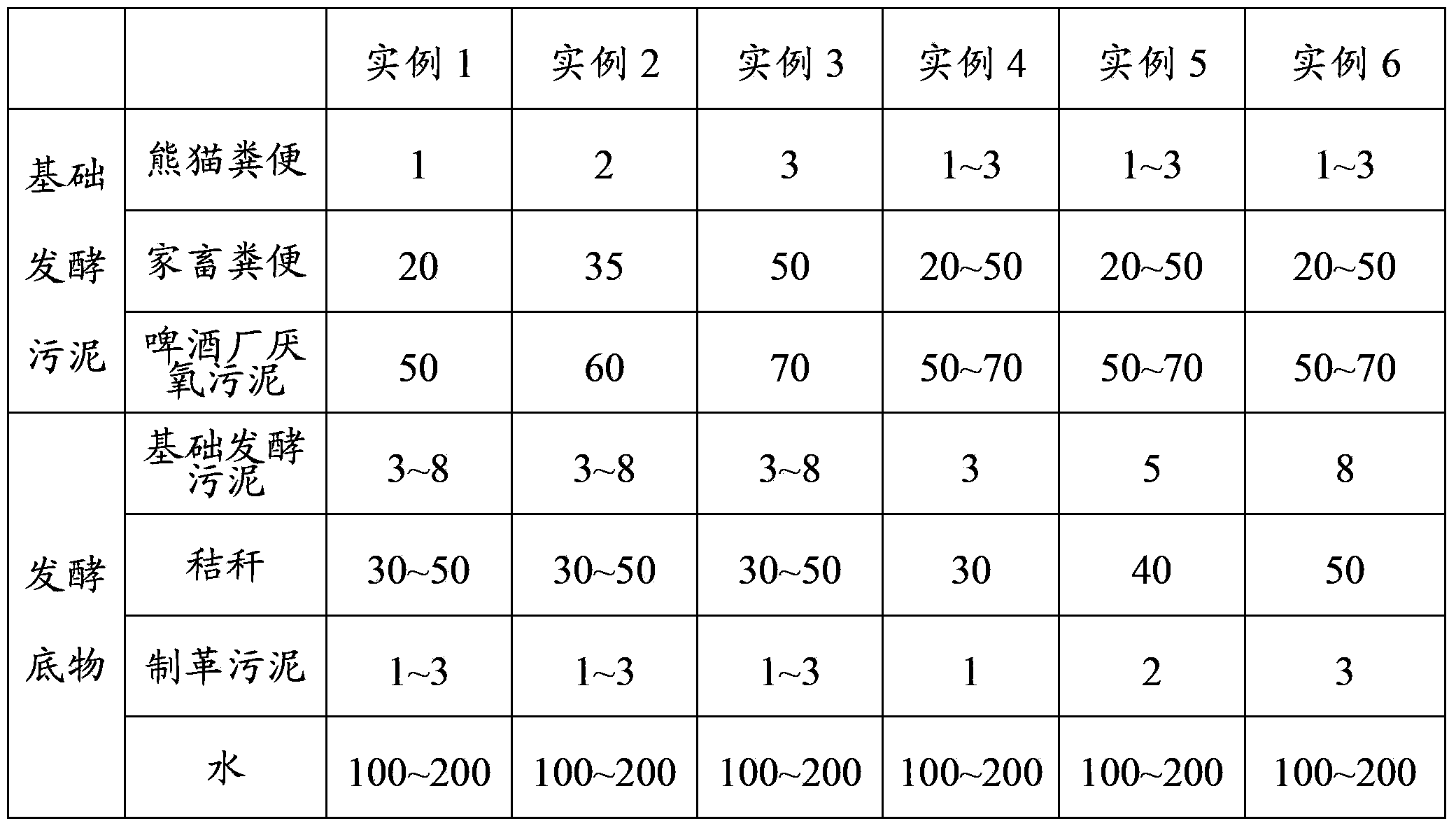

[0017] The present invention adopts a batch-type anaerobic fermentation device. Firstly, white rot bacteria are added to the anaerobic sludge of the brewery for cultivation to form basic fermentation sludge, and then plant straws rich in carbon sources and tannery sludge rich in nitrogen sources are mixed to form The fermentation substrate with a carbon-to-nitrogen ratio of about 30:1 is added to the basic fermentation sludge for dry anaerobic fermentation.

[0018] The technical features of the present invention are concentrated in the following points: First, add white rot bacteria to the anaerobic sludge of the brewery to configure the basic fermentation sludge, and use white rot bacteria to degrade cellulose strains to treat biomass straw and improve straw cellulose The degradation rate solves the problem of incomplete degradation of straw cellulose in traditional anaerobic fermentation. The anaerobic microbial flora in brewery anaerobic sludge can improve the activity of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com